Akọwara usoro nchacha, mụta otu esi eme ka akụkụ gị na-enwu

Oge ịgụ ihe: 4mins

Nchacha enyo

Nchịkọta nke Polishing

Polishing bụ usoro nhazi nke na-eji igwe, kemịkalụ ma ọ bụ electrochemical iji belata ịdị nro nke ihe arụrụ arụ iji nweta elu na-egbuke egbuke ma dịkwa larịị.N'ozuzu, ọ bụ a finishing usoro n'elu a workpiece na-eji polishing ngwá ọrụ na abrasive ahụ ma ọ bụ ndị ọzọ polishing media, na-emekarị na-esote nke ọma ihicha nke elu tupu usoro.N'elu akụkụ nke a na-egbuke egbuke na-egbuke egbuke ma na-egbuke egbuke.Nsonaazụ ikpeazụ nke polishing bụ mma na-egbuke egbuke na ncha nke elu.A pụkwara inweta elu dị ka enyo na-egbuke egbuke site na nchacha nke ọma.

Kedu ka Polishing si arụ ọrụ?

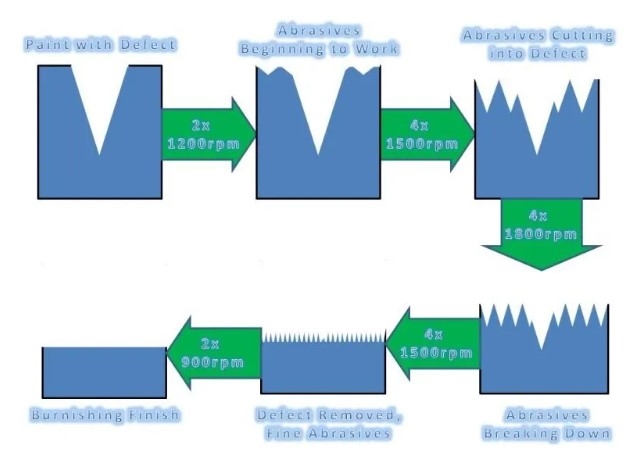

Nchacha bụ omume nke iwepụ oyi akwa dị gịrịgịrị n'elu nke a na-egbucha ya site na iji ngwaahịa na-ekpochapụ ọkụ.Ntucha na-ewepụ oyi akwa dị oke mkpa, nke na-eme ka elu akụkụ ahụ na-egbuke egbuke ma dị larịị.Ọ bụrụ na ntụpọ dị n'elu dị omimi karịa ihe a ga-ewepụ site na polishing, ntụpọ elu ahụ ka ga-ahụ anya, ọ bụ ezie na iwepụ akụkụ nke ntụpọ ahụ ga-eme ka ọ ghara ịhụ ya.Dịka ọmụmaatụ, ọ bụrụ na ntụpọ dị n'elu dị 5 microns na naanị 3 microns nwere ike iwepụ site na polishing, a ka ga-ahapụ 2 microns.Ọ bụ ezie na ntụpọ ahụ dị 3 microns na-adịchaghị omimi ma nwee ike ịhụ ya anya, ọ ka nwere ike ịhụ ya.

Uru nke Polishing

- Ikike iji mechie gas nrụgide na mmiri mmiri

- Iji ịchọ mma

- Ikike iji ngwa ihe atụ flatness anya

- Na-ebelata oke elu na mmebi nke ala

- Na-enye otu ka mma maka elu ụlọ chọrọ usoro epitaxial ma ọ bụ ihe echekwara

- Na-emepụta akụkụ dị nkọ na ngwaọrụ ịkpụ

Ụdị polishing

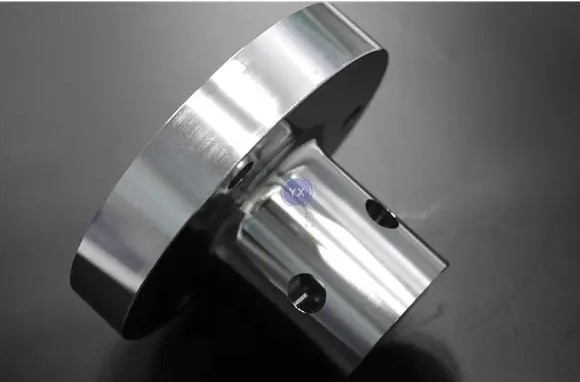

Mechanical polishing

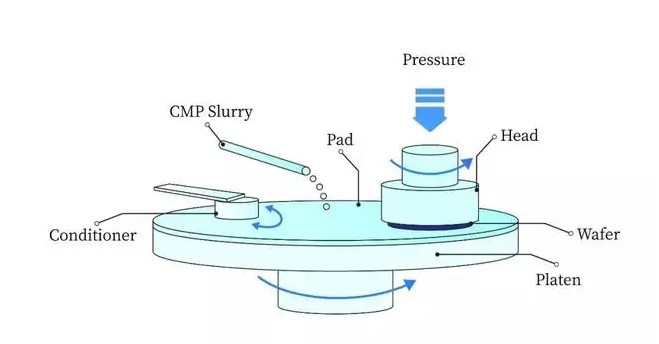

Usoro a na-egbu maramara na-adabere na nrụrụ plastik ma ọ bụ ịkpụ ihe dị n'elu iji nweta ebe dị mma site n'iwepụ elu convex na-egbuke egbuke.Mechanical polishing n'ozuzu na-eji mkpara abrasive, mmetụta wiil, na akwụkwọ aja, na bụ tumadi ntuziaka.Ahụ na-atụgharị na akụkụ ndị ọzọ pụrụ iche nwere ike iji ngwa inyeaka dị ka turntables, na polishing ultra-nkenke nwere ike iji maka ịdị elu elu chọrọ.

Ultra-nkenke polishing bụ iji abrasives pụrụ iche na-atụgharị n'elu edoziri nke workpiece na oke ọsọ site na ịpị ya na ngwọta polishing nwere abrasives.Enwere ike nweta ihe mgbochi elu nke 0.008μm site na iji usoro a, nke kachasị mma n'etiti ụzọ polishing dị iche iche.A na-ejikarị usoro a eme ihe maka oghere oghere anya.

Uru

Nchapụta dị elu

Nchacha elu ka mma

Mmasị ịchọ mma dị elu

Mbelata ngwaahịa adhesion

Imecha elu ka mma

Ọdịmma

Ọnụ ego ọrụ dị elu

Enweghị ike ijikwa akụkụ dị mgbagwoju anya

Ncha nwere ike na-agbanwe agbanwe na ọ gaghị adịte aka

Ọ nwere ike ịdị mfe maka corrosion

Chemical polishing

Chemical n'ibu polishing

Ụdị polishing a na-eji ụkpụrụ bụ na a na-agbaze akụkụ ndị na-apụta n'elu ihe dị na mmiri ọgwụ, si otú a na-eme ka elu nke workpiece dị ire ụtọ mgbe emechara mmeghachi omume kemịkal.Isi ihe na-egbuke egbuke kemịkalụ bụ nkwadebe nke ngwọta na-egbuke egbuke, nke nwere ike nweta nhụsianya elu nke ọtụtụ 10 μm, mana nsonaazụ kpọmkwem nke polishing kemịkalụ bụ ime ka ọ dị nro na ihicha akụkụ nke micro-rough.Ọ na-edugakwa n'otu oge mgbasa nke elu oyi akwa nke akụkụ.

Uru nke chemical polishing

Enwere ike ịchacha ụdị mgbagwoju anya n'ihi na ọ nweghị ntinye aka ozugbo achọrọ

Ịrụ ọrụ dị elu

Enwere ike ịchacha akụkụ dị iche iche n'otu oge

Mbelata ego na akụrụngwa

Ezigbo nguzogide corrosion, na-ekwe ka e guzobe oyi akwa passivation n'elu akụkụ ahụ

Ọdịmma nke kemịkalụ polishing

Ọcha na-enweghị isi

Ọ siri ike ịme ọgwụgwọ okpomọkụ

Gas na-awụfu ngwa ngwa

Ọbụghị omume na gburugburu ebe obibi, nwere ike ịhapụ gas na-emerụ ahụ

Ndozi siri ike na mweghachi nke ngwọta polishing

Electrolytic polishing

Igwe anaghị agba nchara electrolytic polishing

Ụkpụrụ bụ isi nke polishing electrolytic bụ otu ihe ahụ dị ka chemical polishing, ma na-eji ngwọta dissolving na igbari obere protrusions n'elu ma na-eji ire ụtọ elu.Otú ọ dị, e jiri ya tụnyere chemical polishing, mmetụta nke cathodic mmeghachi omume nwere ike ikpochapụ na polishing mmetụta dị mma.Electropolishing na-ewepu ihe na metal workpieces, ibelata elu roughness na mma elu imecha site smoothing obere ọnụ ọnụ ọnụ na ndagwurugwu.Usoro nke electrochemical polishing nwere ike kewaa ụzọ abụọ, nke mbụ, nnukwu polishing, ebe mgbasa ozi na-agbasa n'ime electrolyte, na-eme ka ihe elu roughness ibelata, kama> 1μm, na mgbe ahụ anodic polarization, na-eme ka elu ihie na-amụba.Ra <1μm.

Uru

Ọcha na-adịte aka

Agba na-agbanwe agbanwe n'ime na n'èzí

Enwere ike ịgwọ ọtụtụ ihe dị iche iche

Ọnụ ala na obere oge okirikiri

Na-akwado obere mmetọ

Nnukwu nguzogide corrosion

Ọdịmma

Ntinye ego dị elu

Mgbagwoju anya tupu polishing usoro

Ngwaọrụ na electrodes inyeaka chọrọ maka akụkụ dị mgbagwoju anya

Ogbenye versatility nke electrolyte

Polishing na-abụkarị usoro ikpeazụ n'ichepụta ma bụrụ otu n'ime igodo iji hụ na prototypes ma ọ bụ mmepụta oke ruru ụkpụrụ.Ọ dị oke mkpa nye ndị ahịa anyị na elu nke akụkụ ahụ na-egbuke egbuke ma dị larịị site na polishing ziri ezi na nke dị elu.Ị nwere ike ịlele anyịọrụ ọgwụgwọ elumaka ozi ndị ọzọ.

Ọrụ imecha elu nke Prolean Tech na-enye ọkọlọtọ na nke ewu ewu maka akụkụ.Igwe CNC anyị na teknụzụ imecha elu ndị ọzọ nwere ike nweta nnabata siri ike na ịdị mma dị elu, akwa edo edo maka ụdị akụkụ niile.Naanịbulite faịlụ CAD gịmaka ngwa ngwa, n'efu na ndụmọdụ gbasara ọrụ ndị metụtara ya.

Oge nzipu: Eprel-26-2022