8 Izicelo Ezinkulu Zenqubo Yokuqhunyiswa Kwesihlabathi, Yenza Indwangu Yakho Yokusebenza Ecebile

Isikhathi sokufunda imizuzu emi-3

Izingxenye eziningi zensimbi ekuphileni kwansuku zonke, ubuso bawo abukho isibuko, kodwa umphumela othi "abrasive" obumaholoholo, lo mphumela "wokuthungwa okucebile" uthandwa abantu abaningi.Lena inqubo evamile kakhulu ekwelapheni kwendawo yensimbi“Ukuqhunyiswa kwesihlabathi”.I-Sandblasting umqondo obanzi kakhulu, futhi umgomo we-sandblasting uwukuba bushelelezi, ukwakheka nokuhlanza indawo eqinile ngokuphoqelela izinhlayiya eziqinile ezinesivinini esikhulu kuleyo ndawo.Kulesi sihloko, sizogxila ekusetshenzisweni okusebenzayo kwe-sandblasting, kanye nawe ongakwenza hlola izinsiza zethu ze-sandblasting ukubona ukuthi ziyahlangabezana yini nezidingo zakho.

I-Sandblasting ithole ukuthandwa ezimbonini eziningi ngenxa yezindawo zayo eziyingqayizivele, ngakho-ke yiziphi izinhlelo zokusebenza eziyinhloko zenqubo yokuqhunyiswa kwesihlabathi?

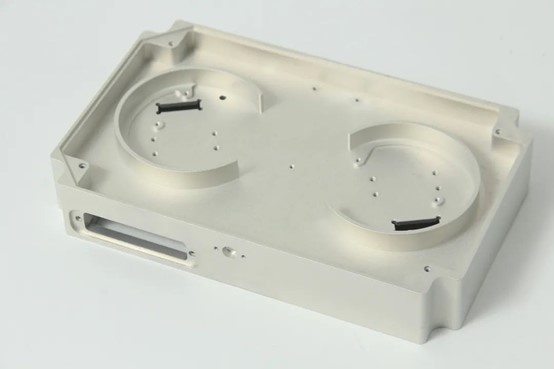

1. Ukwenza ngcono Ukusetshenziswa Kwezingxenye Zemishini

Izingxenye zemishini ngemuva kokuqhunyiswa kwesihlabathi zingathuthukiswa ngokusekelwe ezingeni lokuqala elingu-0.5-1 lokuqeda, indawo efafaziwe inemigodi emincane emifaniswano emincane,ingagcina isitoreji samafutha okugcoba, so ukuthi izimo zayo zokugcoba ziyathuthukiswa, futhi ngaleyo ndlela inganweba impilo yesevisi yezingxenye, ukunciphisa umsindo wokusebenza kwemishini.Isicelo esifana nalokhu: amagiya, i-crankshaft, imishini yendwangu, imishini yokuthunga, njll.

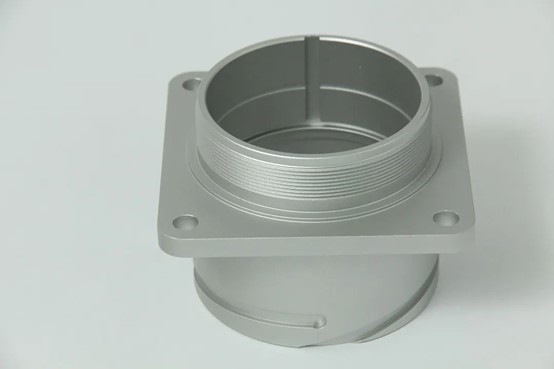

2. Ukuze Ulungiselele Ezinye Izinqubo Zokwelapha Ngaphansi

Ukusetshenziswa kwe-sandblasting inqubo pretreatment Plating izingxenye canthuthukisa amandla okubopha ungqimba lokucwenga, ikakhulukazi ucwecwe oluqinile lwe-chrome.Okufana: indandatho ye-piston ye-chrome plating, i-textile machine wire roller chrome plating, njll. Ngezingxenye ezipendiwe, izingxenye zokufafaza, ukusetshenziswa kwenqubo ye-sandblasting kungathuthukisa amandla okubopha we-coating;ngaphezu kwalokho, izingxenye zokubopha zisebenzisa inqubo ye-sandblasting zingathuthukisa ikhwalithi yokubopha, okwenza ukubopha kuqine kakhulu.

3. Khipha Isikhumba Se-oksijini

Ngemuva kokwelashwa okushisa kwensimbi ehlukahlukene ngokuvamile kuza ne-oxide, izinsalela zikasawoti, amabala nezinye izinto, ukusetshenziswa kwenqubo ye-sandblastinghhayi kuphela ukususa lezi zinto, kodwa futhi ngcono isiphetho ebusweni izingxenye, ikakhulukazi ukuma okuyinkimbinkimbi kwesikhunta kanye nezingxenye zokunemba zomphumela kugqame kakhulu.

4. Ukususwa kweMicro Burr Machining Workpiece

Kwezinye izimo, ama-burrs angabangela izinkinga eziningi.Ezinye izingxenye zemishini zinezidingo eziphakeme kakhulu zokunemba, izimo zokufaka isicelo ziqinile kakhulu futhi zenzaungavumeli i-burr encane, isibonelo: imboni yezokuxhumana ye-3C, izingxenye zemishini yendwangu, izingxenye ze-hydraulic, ukunemba kanye nezingxenye eziyinkimbinkimbi zemboni ye-aerospace, imishini yezokwelapha, ukubuyiselwa kwamazinyo ekubunjweni nokunye.

5. Hlanza Indawo Emaholoholo Yokusakaza Okunembayo

Ukusetshenziswa kwenqubo ye-sandblasting canhlanza ubuso be-castings oxidation enembile nezinsalela, futhi ngesikhathi esifanayo ingadlala indima yokupholisha ukuze kuthuthukiswe ukuqedwa kokusakazwa okungaphezulu, isibonelo: izindwani zenjini yendiza, izinsimbi zokuhlinza, ubucwebe, njll. Ingakwazi futhi ukwenza izingxenye zokulingisa ukuze ziveze umbala woqobo wensimbi ongaguquki, ukuze ukubonakala kwezingxenye ezinhle kakhulu.Okufana njengokuthi: izinhlobonhlobo zamagobolondo wezinsimbi, amafreyimu, njll.

6. Hlanza Ukungcola Nokugqwala

Izibunjwa ezahlukahlukene ezinjengalezi: ukubumba ukufa, ukufaka isitembu, isikhunta senjoloba, isikhunta samasondo, isikhunta sokucindezela ipulasitiki, isikhunta semikhiqizo yengilazi, njll.,lezi zikhunta zizongcoliswa ukungcola okufana ne-ejenti yokukhulula noma ngisho nezimpawu zokusha ngemva kokusetshenziswa isikhathi esithile,usebenzisa inqubo ye-sandblasting yokuhlanza, umphumela ubaluleke kakhulu, futhi ngesikhathi esifanayo ungathuthukisa impilo yesevisi yesikhunta.

7. Okokuhlobisa Ubuso

Ngesidingo sendawo ebushelelezi futhi ayivumeli ukubonakaliswa kwezingxenye, ukusetshenziswa kwenqubo ye-sandblasting kuyindlela yenqubo ephumelelayo, njengezinsimbi zokuhlinza.Okunye okunjengezitsha zengilazi ezifakwe iqhwa namaphethini anephethini, amaphaneli wezinsimbi, umdwebo wepulasitiki we-sandpaper surface processing kanye nendwangu ekhethekile yokucubungula i-plush, njll., inqubo ye-sandblasting inezinhlobonhlobo zezinhlelo zokusebenza.

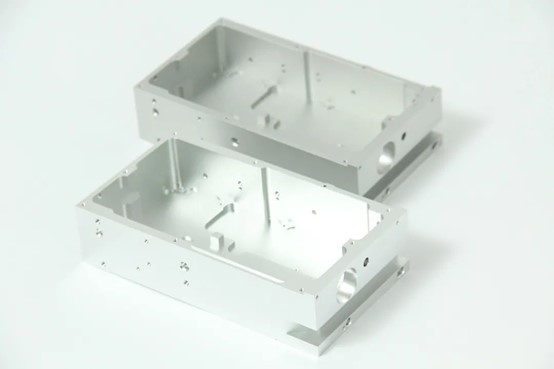

8. ukukhanya Finishing Processing

inqubo ye-sandblasting njengendlela yokucubungula ukukhanya,umphumela muhle kakhulu.Ikakhulukazi izingxenye eziyinkimbinkimbi, njengokuthi: izindwani zenjini ye-impeller, indawo ehlukahlukene emise okwesikhunta (isikhunta semali, izinhlamvu zemali zempepho, isikhunta sezinhlamvu zemali eyisikhumbuzo) ukupholishwa, akunakuqhathaniswa nanoma iyiphi enye indlela.Ukupholisha izitsha zobumba, amadayimane, igolide, nobucwebe besiliva ngokuqhunyiswa kwesihlabathi kuyindlela eyonga kakhulu.

Kungenxa yokuthi inqubo ye-sandblasting inezinzuzo eziningi kangangokuthi isetshenziswa kabanzi emikhakheni ehlukahlukene, futhi njengoba izingxenye kanye nezibungu ziba zikhudlwana futhi zibe zinkulu, inqubo ye-sandblasting iphinde ithuthuke ekuqondeni kobukhulu obukhulu.

Isiphetho

Nakuba i-sandblasting isetshenziswa kabanzi futhi inezakhiwo eziyingqayizivele.Kodwa-ke, imisebenzi yokuhlanza ukuqhuma ibeka engcupheni impilo nokuphepha kwabasebenzi, ikakhulukazi egumbini lokuqhuma lapho uthuli oluningi lukhiqizwa ngama-substrates nama-abrasives ngokuqhuma, okungase kube yingozi kubasebenzisi, kodwa sihlinzeka abasebenzi ngezindawo zokuzivikela. kanye nezinqubo zokuphepha zokuqinisekisa ukuphepha noma nini lapho kunokwenzeka.Siphinde sisebenzisa inqubo yokuqhunyiswa komhwamuko ehlinzeka ngokuqedwa okuyingqayizivele kwendawo kuyilapho sinciphisa ukungcola.Ungakwazi njalocthintana nonjiniyela bethuukuze uthole iseluleko sakamuva.

Isikhathi sokuthumela: Apr-15-2022