Likopo tse 8 tse kholo tsa ts'ebetso ea Sandblasting, Etsa hore Workpiece ea Hao e be Rich Texture

Nako ea ho bala metsotso e 3

Likarolo tse ngata tsa tšepe bophelong ba letsatsi le leng le le leng, bokaholimo ba eona ha se seipone, empa ke phello e thata ea "abrasive", phello ena "e ruileng" e ratoa ke batho ba bangata.Ena ke mokhoa o tloaelehileng haholo oa phekolo ea holim'a tšepe“Ho qhomisa lehlabathe”.Ho qhomisa lehlabathe ke khopolo e pharaletseng haholo, 'me molao-motheo oa ho qhomisa lehlabathe ke ho boreleli, ho bōpa le ho hloekisa sebaka se thata ka ho qobella likaroloana tse tiileng tsa lebelo le phahameng ho pholletsa le sebaka seo.Sehloohong sena, re tla shebana le lits'ebetso tse 'maloa tse sebetsang tsa sandblasting, hammoho le uena u ka li etsang sheba litšebeletso tsa rona tsa sandblasting ho bona hore na li finyella litlhoko tsa hau.

Sandblasting e fumane botumo liindastering tse ngata ka lebaka la thepa ea eona e ikhethang, joale lisebelisoa tse ka sehloohong tsa ts'ebetso ea lehlabathe ke life?

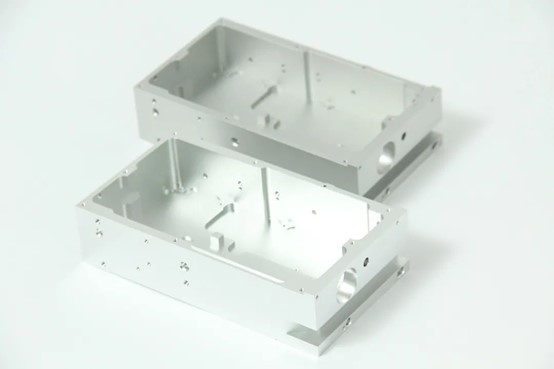

1. Ntlafatsa Tšebeliso ea Likarolo tsa Mechini

Likarolo tsa mochini ka mor'a ho phatloha ha lehlabathe li ka ntlafatsoa ho ipapisitsoe le boemo ba pele ba 0.5-1, sebaka se fafalitsoeng se na le li-crater tsa junifomo tse nyane,e ka boloka polokelo ea oli e tlotsang, so hore maemo a eona a lubrication a ntlafatsoe, 'me kahoo e ka lelefatsa bophelo ba tšebeletso ea likarolo, ho fokotsa lerata la ts'ebetso ea mechine.Lisebelisoa tse kang: likere, crankshaft, mochini oa masela, mochini oa ho roka, jj.

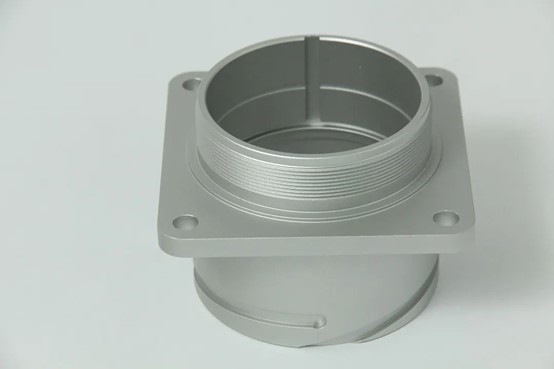

2. Bakeng sa Mekhoa e Meng ea Kalafo ea Bokaholimo ho Lokisetsa

Tšebeliso ea li-sandblasting process pretreatment plating likarolo li kantlafatsa matla a ho kopanya plating, haholo-holo bakeng sa plating e thata ea chrome.Tse kang: enjene piston ring chrome plating, textile machine wire roller chrome plating, joalo-joalo Bakeng sa likarolo tse pentiloeng, likarolo tsa ho fafatsa, tšebeliso ea ts'ebetso ea sandblasting e ka ntlafatsa matla a ho kopanya a ho roala;ho phaella moo, likarolo tse kopanyang tse sebelisang mokhoa oa sandblasting li ka ntlafatsa boleng ba ho tlamahane, ho etsa hore ho tlamahane ho be thata haholoanyane.

3. Tlosa Letlalo la Oxide

Kamora kalafo ea mocheso ea lisebelisoa tse fapaneng tsa tšepe hangata li tla le oxide, masala a letsoai, matheba le lintho tse ling, ts'ebeliso ea sandblasting e ka sebelisoa.u se ke ua tlosa lintho tsena feela, empa hape u ntlafatse qetellong ea likarolo, haholo-holo bakeng sa sebōpeho se rarahaneng sa hlobo le likarolo tse nepahetseng tsa phello li hlahella ka ho khetheha.

4. Ho Tlosoa ha Micro Burr Machining Workpiece

Maemong a mang, li-burrs li ka baka mathata a mangata.Likarolo tse ling tsa mochini li na le litlhoko tse phahameng haholo tsa ho nepahala, maemo a kopo a thata haholo mme a etsa joaloho se lumelle burr e nyane, mohlala: indasteri ea puisano ea 3C, likarolo tsa mechine ea masela, likarolo tsa hydraulic, ho nepahala le likarolo tse rarahaneng tsa indasteri ea lifofane, lisebelisoa tsa bongaka, ho tsosolosoa ha meno ho li-castings joalo-joalo.

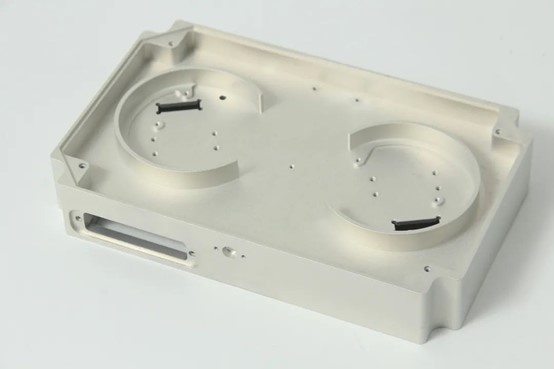

5. Hloekisa Sebaka se Rough Of Precision Castings

Tšebeliso ea mokhoa oa sandblasting e kahloekisa bokaholimo ba ho nepahala castings oxidation le mesaletsa, 'me ka nako e ts'oanang e ka phetha karolo ea ho bentša ho ntlafatsa ho qeta holimo ha li-castings, mohlala: li-blades tsa turbine tsa lifofane, lisebelisoa tsa ho buoa, mabenyane, joalo-joalo. ponahalo ya ditho tse ntle haholo.Joalo ka: mefuta e fapaneng ea likhetla tsa lisebelisoa, liforeimi, joalo-joalo.

6. Hloekisa Litšila le Mafome

Mefuta e fapaneng e kang: forging die, stamping die, rabara hlobo, thaere hlobo, polasetiki e hatella hlobo, lihlahisoa tsa khalase hlobo, joalo-joalo,hlobo tsena li tla silafatsoa ke litšila joalo ka ntho e lokollang kapa esita le matšoao a cheleng kamora ho sebelisoa nako e telele,ho sebelisa mokhoa oa sandblasting ho hloekisa, phello e bohlokoa haholo, 'me ka nako e ts'oanang e ka ntlafatsa bophelo ba tšebeletso ea hlobo.

7. Bakeng sa Mokhabiso oa Bokaholimo

Bakeng sa tlhokahalo ea sebaka se boreleli 'me ha se lumelle ho bonahatsa likarolo, tšebeliso ea mokhoa oa ho senya lehlabathe ke mokhoa o atlehang oa ts'ebetso, joalo ka lisebelisoa tsa ho buoa.Tse ling tse kang li-glassware tse nang le serame le lipaterone tsa mohlala, lisebelisoa tsa lisebelisoa, lisebelisoa tsa polasetiki tsa ho taka sandpaper le lisebelisoa tse khethehileng tsa lesela, joalo-joalo, mokhoa oa sandblasting o na le mefuta e mengata ea likopo.

8. leseli Finishing Processing

mokhoa oa sandblasting e le mokhoa o bobebe oa ho qeta ho sebetsa,phello e ntle haholo.Haholo-holo bakeng sa likarolo tse rarahaneng tse nang le sebōpeho, joalo ka: li-blades tsa enjene ea impeller, mefuta e sa tšoaneng ea sebopeho sa hlobo (mofuta oa lichelete, lichelete tsa tšepe tsa libano, li-molds tsa sehopotso) ho belisoa, ho ke ke ha bapisoa le mokhoa leha e le ofe o mong.Ho bentša lirafshoa, litaemane, mabenyane a khauta le silevera ka ho qhomisa lehlabathe ke mokhoa o baballang chelete ka ho fetisisa.

Ke hobane ts'ebetso ea sandblasting e na le melemo e mengata hoo e sebelisoang haholo libakeng tse fapa-fapaneng, 'me ha likarolo le hlobo li ntse li eketseha le ho feta, ts'ebetso ea sandblasting e boetse e atisa ho ntshetsa pele ka tsela ea boholo bo boholo.

Qetello

Le hoja sandblasting e sebelisoa haholo ebile e na le thepa e ikhethang.Leha ho le joalo, ts'ebetso ea ho hloekisa ho phatloha ho beha kotsi ho bophelo bo botle le polokeho ea basebetsi, haholo-holo ka kamoreng ea ho phatloha moo lerōle le leholo le hlahisoang ho tloha ho substrates le abrasives ka ho phatloha, e ka bang kotsi ho basebetsi, empa re fa basebetsi lisebelisoa tsa tšireletso. le mekhoa ea polokeho ho netefatsa polokeho neng kapa neng ha ho khoneha.Re boetse re sebelisa mokhoa oa ho phatloha ha mouoane o fanang ka sebaka se ikhethang sa bokaholimo ha o ntse o fokotsa tšilafalo.U ka khona kamehlackopana le baenjiniere ba ronabakeng sa keletso ea morao-rao.

Nako ea poso: Apr-15-2022