Sheet Hlau Fabrication Nqi: Txhua Yam Koj Yuav Tsum Paub

Hloov tshiab kawg: 09/01;Lub sij hawm nyeem: 6 mins

Cov ntawv hlau

Cov khoom tseem ceeb tshaj plaws hauv kev tsim khoom yogdaim hlau.Sheet hlau yog siv los tsim ntau yam khoom siv rau ntau yam kev siv, los ntawm kev siv tsheb, kev kho mob, thiab kev lag luam aerospace mus rau cov khoom uas peb siv txhua hnub.

Sheet hlau fabrication yog ib txoj hauv kev uas tsis tshua muaj nqi, qhov uas cov engineers xaiv cov ntawv tsim nyog thiab tsim cov khoom siv lossis tag nrho cov khoom raws li qhov yuav tsum tau ua.Tom qab ntawd mechanics nqa tawm ntau yam machining txheej txheem los tsim cov khoom raws li kev tsim,

Kab lus no yuav luv luv mus txog ntawmtus nqi ntawm cov ntawv hlau fabrication, cuam tshuam rau yam, thiab txoj hauv kev los txo cov nqi thoob plaws hauv cov txheej txheem.

Kev kwv yees tus nqi

Hauv kev lag luam tsim khoom, muaj kev suav nyiaj ntau heev rau kev tsim cov ntawv hlau: tus nqi tsim khoom yog peb npaug ntawm cov ntawv hlau.Txawm li cas los xij, ntau yam cuam tshuam rau daim ntawv hlau fabrication nqi.Cia peb mus dhau qhov tseem ceeb uas cuam tshuam rau tus nqi ntawm cov ntawv hlau tsim thoob plaws hauv cov txheej txheem.

Ntau lawm voj voog tawg

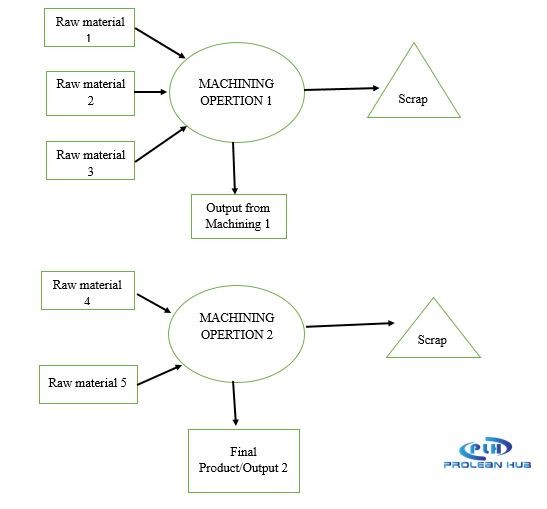

Cov txheej txheem tsim khoom rau ib yam khoom tsis zoo ib yam li lwm yam.Yog li ntawd, kev rhuav tshem lub voj voog ntau lawm ua ntej ntsuas cov nqi tsim khoom yog qhov tseem ceeb.

Rau lub voj voog ntau lawm, txiav txim siab tag nrho cov khoom siv raw khoom tsim nyog thiab kev ua haujlwm machining rau qhov project.Piv txwv li, koj tuaj yeem xav tau cov ntawv hlau hlau, tooj dag, thiab bolts yog tias koj tab tom ua ib lub thawv.Ntxiv nrog rau cov ntawv hlau, lwm yam khoom siv raw xav tau rau cov khoom sib xyaw.

Saib ntawm lub voj voog ntau lawm cov duab hauv qab no kom nkag siab tob dua.

ntau lawm voj voog ntawm Machining kev ua haujlwm

Cov kauj ruam rau Nqi-Xaiv

Tom qab ua lub voj voog ntau lawm, suav cov nqi rau kev tsim, cov khoom siv, kev ua haujlwm machining, kws kho tsheb, tom qab ua tiav, thiab lwm yam nqi kom koj tuaj yeem kwv yees tag nrho cov nqi tsim nyog.

Kauj Ruam 1: Tus nqi raw khoom

Tom qab txiav txim siab txog cov khoom siv raw, xav seb ntau npaum li cas ntawm txhua yam khoom siv los ua ib qho khoom.Thaum kwv yees tus nqi ntawm cov khoom siv, tsis txhob hnov qab suav rau cov khoom seem.Txij li cov ntawv hlau feem ntau yog muag ib kg, tus nqi yuav tsum txiav txim siab siv ib-kg hauv paus.

Tus nqi ntawm cov khoom siv = ntim x ntom ntawm cov ntaub ntawv hlau x nqi ib kg.

Yog tias xav tau cov ntawv sib txawv, rov ua cov kauj ruam no rau txhua tus.

Kauj Ruam 2: Tus nqi tsim khoom

Kev tsim qauv yog tsim cov khoom siv virtual hauv computer software lossis ntawm daim ntawv los nrhiav kev ua haujlwm ntawm tag nrho qhov project.Nws yog ib qho tseem ceeb hauv kev tsim cov ntawv hlau rau kev ua kom cov khoom zoo thiab txo tus nqi.Yog li ntawd, engineers xav txog ntau yam kev txawj thiab nyiaj txiag teeb meem thaum tsim ib yam khoom - qhov complexity ntawm lub geometry, theem ntawm engineers, lub siab ntev, thiab lwm yam.

Kauj Ruam 3: Machining nqi

Ntau yam kev ua haujlwm machining

Machining tus nqi hauv kev tsim khoom yog qhia nyob rau hauv ib teev, suav nrog tus nqi peev, tus nqi ntawm cov neeg ua haujlwm thiab cov neeg ua haujlwm, tus nqi tu, nqi hluav taws xob, tus nqi hauv cheeb tsam, thiab cov nqi ntawm lwm yam khoom siv.Cov khoom siv tau suav nrog cov roj nplua nyeem, tuag, lim, thiab roj av-txhua yam ntawm lub tshuab siv dua li hluav taws xob.

| SN | Ntau tus nqi | Kev suav |

| 1 | Tshuab-kev nqis peev nqi | |

| 2 | Tus nqi hluav taws xob | Rated zog ntawm cov tshuab ua haujlwm (KW) x Tus nqi hluav taws xob ib chav tsev |

| 3 | Tus Nqi Ua Haujlwm | · Tus nqi ntawm tus neeg ua haujlwm (/ teev) · Tus nqi ntawm cov neeg ua haujlwm pab (/ teev) · Tus Thawj Saib Xyuas Haujlwm (/ teev) |

| 4 | Tus nqi kho mob | |

| 5 | Nyob Yog Tus Nqi | |

|

6 | Tus nqi ntawm cov khoom siv | Tag nrho cov khoom siv tau raug nqi ib teev |

Tag nrho cov nqi machining thiab xam mus kom ze

Tag nrho cov nqi machining ib teev yog cov lej ntawm tag nrho cov nqi teev saum toj no, thiab ntxiv rau cov nqi no, cov tuam txhab ntxiv cov nyiaj tau los ntawm kev ua haujlwm txhua teev.

Yuav luag txhua daim ntawv hlau fabrication muaj ib tug sib txawv machining voj voog, raws li tau tham yav dhau los nyob rau hauv lub ntau lawm breakdown voj voog.Yog li tus nqi machining yuav tsum raug xam rau txhua lub voj voog vim tias cov khoom ntawm machining 1 dhau los ua cov khoom siv rau cov txheej txheem machining tom ntej kom txog rau thaum cov khoom npaj siv.

Kauj Ruam 4: Tus Nqi Tshaj Tawm

Tus nqi ntawm cov qauv, kev sib tham, nqi kev pabcuam, thiab cov nqi ntawm lwm cov kev tswj xyuas ua haujlwm hauv lub tuam txhab tsim khoom.

Tus nqi tsim khoom tag nrho

Tag nrho cov nqi yog qhov suav ntawm tag nrho cov nqi suav hauv cov kauj ruam saum toj no, los ntawm kev tsim cov khoom mus rau cov nqi siv nyiaj.

Tag nrho cov nqi = (Cov nqi ntawm cov ntawv hlau) + (Tag nrho Machining nqi / hr.) x cov sij hawm ua haujlwm + Tus nqi tsim khoom + Cov nqi siv nyiaj

Tej yam uas yuav tsum tau xav txog rau kev kwv yees

Ua ntej sib tham txog cov kev xaiv rau kev txiav nqi, cia peb tham txog cov yam uas cuam tshuam rau tus nqi ntawm cov ntawv hlau fabrication.Kev nkag siab txhua tus hauv kev nthuav dav tuaj yeem pab koj txhim kho koj cov peev nyiaj.

1. Sheet hlau & Gauge tooj

Thawj thiab qhov tseem ceeb tshaj plaws kev txiav txim siab yog hom khoom koj xav tau rau koj cov khoom, uas yog txiav txim siab los ntawm kev npaj siv cov khoom kawg.Piv txwv li, txhuas, hlau, tooj dag, thiab titanium yog cov nplooj ntawv nrov siv hauv cov ntawv hlau fabrication.Thaum tooj dag thiab titanium kim dua, steel yog pheej yig dua.Tsis tas li ntawd, kev xaiv ntawm lub ntsuas zoo meej txo qis cov nqi ntawm cov ntawv hlau vim tias thaum koj xaiv cov tuab tsim nyog, nws txuag tau ntau qhov hnyav ntxiv.

2. Siv technology

Tus nqi machining feem ntau cuam tshuam cov nqi ntawm cov ntawv hlau vim nws nce ntxiv thaum siv cov tshuab siv ntau dua thiab cov txheej txheem siv zog siv zog.Piv txwv li, yog tias koj xaiv laser beam welding thaum MIG tuaj yeem tsim qhov kev sib koom ua ke rau cov khoom, Nws yuav kim dua.

3. Ua siab ntev

Tus nqi yuav nce ntxiv yog tias koj xav tau cov khoom siv rov ua dua, nruj-siab ntev vim tias kev tswj hwm lawv yuav tsum tau siv zog ntxiv thiab teeb tsa.Cov kws tswj xyuas kev tswj hwm sib txawv kuj tseem yuav xav tau los saib xyuas thiab ntsuas cov txheej txheem yog tias cov khoom siv yuav tsum tau ua siab ntev.

Yuav ua li cas txiav cov ntawv hlau fabrication nqi?

Cov neeg siv khoom nquag pom tias cov nqi ntawm cov ntawv hlau tsim khoom yog me ntsis siab dua qhov xav tau.Txawm li cas los xij, muaj ntau txoj hauv kev los txo cov nqi los ntawm kev xav txog cov ntsiab lus sib txawv thiab ua kom muaj kev xaiv zoo.

1. Siv cov ntsuas kom raug

Cov qauv tsim tsis raug thiab cov kev xav tau yog xav tau rau kev kwv yees kom raug.Yog li nco ntsoov suav nrog tag nrho cov kev qhia tshwj xeeb thiab cov yam ntxwv koj xav tau hauv cov khoom;ua li ntawd yuav pab tau qhov tseeb kwv yees thiab txuag cov nqi los ntawm kev txhim kho kev ua haujlwm.

2. Yooj yim tsim

Cov ntsiab lus tshwj xeeb thiab qib siab ntawm cov ntawv hlau tsim yuav zoo dua, tab sis nws raug nqi ntau thaum fabricating vim tias yuav siv sij hawm ntau thiab cov kws tshaj lij engineers thiab cov neeg ua haujlwm.Yog li simplicity nyob rau hauv kev tsim nrog kev tswj cov functionality ntawm aiming tivthaiv los yog cov khoom uas txo tus nqi.Piv txwv li, thaum tsis muaj kev pheej hmoo ntawm kev raug mob raws li qhov chaw teeb tsa thiab cov khoom sib cuam tshuam nrog cov neeg siv, zoo kawg nkauschamfered npoo tej zaum yuav tsis siv thiab tsav tus nqi.

3. Cov ntaub ntawv zoo meej thiab thickness

Ua ntej xaiv cov ntaub ntawv hlau, xav txog cov khoom siv xws li lub zog, hardness, toughness, thiab durability.Tom qab ntawd, ua ib daim ntawv teev cov ntaub ntawv sib txawv cov nqi uas haum rau qhov yuav tsum tau muaj ntawm cov yam ntxwv no.Tom qab ntawd, txheeb xyuas qhov zoo meej thickness uas muab cov kev xav tau.

4. Siv cov tshuab zoo meej thiab cov txheej txheem.

Tshuab thiab cov txheej txheem machining tsim nyog pab kom txo tau lub sij hawm thiab txo cov seem hlau, txo cov ntawv hlau fabrication nqi.Tom qab tsim qauv, npaj cov haujlwm ua haujlwm thiab siv lub tshuab tsim nyog thiab thev naus laus zis.Piv txwv li, lub tshuab CNC tuaj yeem siv sijhawm tsawg dua thiab tus nqi ntau dua li cov tshuab dhos ua ke thaum koj npaj cov khoom nres rau tsheb.

5. Loj loj ntau lawm

Fabricating tib yam khoom rau qhov loj quantizes txiav tus nqi ib yam khoom.Tsim ntau yam nyiaj siv ua haujlwm xws li kev sab laj & kev tswj hwm cov nuj nqis, thiab tus nqi tsim nyog yuav tsis rov ua dua.

Xaus

Rau kev tsim khoom lag luam, cov ntawv hlau yog tshwj xeeb tshaj yog raug nqi thiab ntau yam.Cov lej ntawm cov nqi cuam tshuam nrog kev tsim cov ntawv hlau suav nrog tus nqi ntawm cov hlau nws tus kheej, tus nqi ntawm kev tsim thiab machining nws, qee cov nqi nyiaj siv ua haujlwm, thiab cov chaw tsim khoom tau txais txiaj ntsig.Kab lus no muab ib txoj hauv kev yooj yim los txiav txim siab tag nrho cov nqi tsim khoom.

Kab lus tham txog ntau yam uas muaj feem cuam tshuam rau tus nqi.Txawm hais tias qhov nyuaj npaum li cas ntawm tus nqi-tsawg kawg yog qhov tseem ceeb, nws tseem ceeb heev.Lub tswv yim ntawm kev txo tus nqi yam tsis muaj kev cuam tshuam qhov kev ua tau zoo thiab cov yam ntxwv ntawm lub hom phiaj tiv thaiv lossis cov khoom lag luam los ntawm kev paub txog cov khoom muaj feem cuam tshuam thiab cov txheej txheem kwv yees meej.

Kev kwv yees ntawm cov ntawv hlau fabrication Thaum ua haujlwmnrog peb, kwv yees daim ntawv hlau fabrication nqi tsis yog complex lawm.Peb muaj cov kws tshaj lij engineers ua haujlwm rausheet hlau fabricationrau ntau tshaj kaum xyoo.Tsis tas li ntawd, peb muab cov kev pabcuam hlau ua haujlwm xws li CNC machining, Aluminium Extrusion, thiab nto tiav.Yog li, yog tias koj xav tau ib qho chaw cuam tshuam, tsis txhob yigtiv tauj peb.

FAQ's

Cov ntaub ntawv twg yog qhov zoo tshaj plaws rau kuv qhov project?

Nws nyob ntawm qhov specification thiab xav tau txhua yam khoom rau koj qhov project.Piv txwv li, ib daim ntawv tuab stainless hlau yuav yog qhov zoo tshaj plaws haum yog tias koj xav tau cov khoom rau qhov chaw ntub dej.

Puas yog sheet hlau fabrication yog tus nqi tsim nyog?

Yog, nws yog ib qho kev siv nyiaj txiag zoo, tshwj xeeb tshaj yog rau cov khoom ntim loj.

Dab tsi yog qhov cuam tshuam rau tus nqi ntawm cov ntawv hlau fabrication?

Ob peb yam muaj xws li tsim complexity, lub thickness ntawm daim ntawv, siv technology, yuav tsum kam rau ua, thiab lwm yam.

Dab tsi yog cov nqi tseem ceeb suav nrog hauv kev tsim cov ntawv hlau?

Daim ntawv tus nqi, tus nqi machining, tus nqi tsim, thiab nyiaj siv ua haujlwm yog tus nqi cuam tshuam nrog tus nqi tsim khoom.

Post lub sij hawm: Lub Xya hli ntuj-12-2022