ProLeanHub. Lub sijhawm nyeem ntawv kwv yees: 5 feeb, 17 vib nas this

Sheet hlau dabtsi yog khoov?

Sheet Hlau dabtsi yog khoov khoom

Hom Sheet Hlau dabtsi yog khoov

Sheet Hlau dabtsi yog khoov pub thiab suav cov txheej txheem

1 Sheet hlau dabtsi yog khoov?

Khoov yog ib daim ntawv ntawm deformation thiab yog ib qho ntawm peb cov txheej txheem tseem ceeb hauv kev tsim cov ntawv hlau;lwm ob yog txiav thiab koom.Daim ntawv hlau fabrication dabtsi yog khoov txheej txheem yog cov txheej txheem ntawm shaping sheet hlau rau hauv peb qhov ntev siv cov khoom siv siab thiab tshwj xeeb tuag.Vim yog cov khoom sib txawv, tuab, ntev thiab dav ntawm cov ntawv hlau nrog rau cov duab sib txawv thiab cov kaum sab xis ntawm kev sib sau, cov tons thiab qhov ntau thiab tsawg ntawm cov cuab yeej siv lub siab bending tshuab txawv, nrog rau qhov siab, zoo thiab V- amplitude loj ntawm lub Upper thiab qis tuag, thiab lawv cov duab tshwj xeeb tuag txawv.Feem ntau yog siv los tig cov ntawv tiaj tus hlau rau hauv V-shaped, U-shaped lossis slotted.

2 Sheet hlau dabtsi yog khoov khoom

Cov khoom tseem ceeb tshaj plaws ntawm cov ntawv hlau dabtsi yog khoov yog tus nres, uas tuaj nyob rau hauv ntau yam sib txawv.

- A gable nresyog lub tshuab dabtsi yog khoov yooj yim - thiab qhov siv dav tshaj plaws hauv kev tsim khoom - uas clamps ib daim ntawv ntawm cov hlau mus rau ib qho chaw tiaj tus thiab tom qab ntawd siv lub zog los ntawm kev txav ntawm cov hniav tuaj yeem txav tau los ua kom ncaj khoov lossis yooj yim creases.

- Ib tug dabtsi yog khoov tshuabyog ib hom dabtsi yog khoov tshuab uas siv lub punch txav thiab sib thooj tuag.Hauv cov txheej txheem no, cov ntawv hlau tau muab tso rau ntawm qhov tuag thiab cov punch raug yuam kom txav mus rau hauv cov hlau, yuam nws mus rau hauv qhov tuag.Nyob ntawm cov duab ntawm cov tuag, khoov tshuab tuaj yeem siv los tsim V-khoov, U-khoov thiab lwm yam duab.

- Box brakes(tseem hu ua ntiv tes nres) yog lwm hom kev khoov tshuab uas siv cov kab hlau "ntiv tes" los ua ntau yam kev cai khoov.Raws li lub npe implies, lub thawv brakes feem ntau yog siv los ua cov thawv loj.

- Bar folding tshuabyog ib lub tshuab me me thiab yooj yim khoov nrog ib tus kov uas tuav ib daim ntawv hlau thiab khoov nws hauv ib qho kev taw qhia.

3 Hom Sheet Hlau dabtsi yog khoov

Muaj ntau hom ntawv hlau dabtsi yog khoov siv los ua kom tau raws li qhov sib txawv ntawm qhov sib txawv.Peb txoj kev khoov no (air bending, bottoming and coining) Daim ntawv hlau dabtsi yog khoov txoj kev zoo ib yam li qhov uas lawv lub hom phiaj kawg yog hloov cov ntawv hlau rau hauv daim ntawv xav tau.Txawm li cas los xij, lawv txawv hauv lawv txoj haujlwm.Kev nkag siab yuav ua li cas khoov cov ntawv hlau yuav tsum muaj kev nkag siab txog yam xws li cov khoom thickness, dabtsi yog khoov qhov ntev, daim ntawv hlau dabtsi yog khoov vojvoog thiab npaj siv uas txiav txim siab txoj kev.

1) Cua Bending

Huab cua bending yog ib txoj kev bending bending txoj kev uas cov punch nias cov ntawv hlau rau hauv qhov tuag, tab sis tsis deb li deb uas nws kov cov phab ntsa ntawm cov tuag.

Txoj kev no tsis yog qhov tseeb raws li lwm tus, tab sis nws hloov tau yooj yim: nws tuaj yeem siv los ua V, U thiab lwm cov duab ntawm kev khoov.Qhov no yog ib feem vim tias qhov tuag geometry tsis tas yuav tsum sib haum raws nraim li qhov xav tau ntawm cov ntawv hlau khoov, vim tias tsis muaj kev sib cuag ntawm ob qhov chaw.

2) Hauv qab

Hauv qab yog lwm txoj hauv kev khoov khoov.Thaum lub sij hawm underbending, lub punch presses cov ntawv hlau tag nrho rau hauv qhov tuag, tsim ib tug khoov uas sib haum mus rau lub geometry nyob rau hauv lub tuag.Nws yog siv los ua V-shaped khoov.

3) Nyiaj npib

Coining yog ib qho kim dua ntawm kev khoov khoov nyob rau hauv uas lub punch yog qis dua nrog lub zog ntau dua nyob rau hauv cov ntawv hlau thiab cov tuag, uas ua rau deformation mus tas li nrog me ntsis springback.

4) Folding

Folding tuaj yeem ua tau ntawm cov tshuab xws li gable brakes lossis qws folding tshuab.Cov ntawv hlau yog clamped nyob rau hauv qhov chaw ua ntej lub clamping beam yog tsa los khoov cov hlau nyob ib ncig ntawm qhov profile.Folding ua tiav V-shaped khoov thiab tso cai rau qhov zoo lossis tsis zoo dabtsi yog khoov cov ces kaum.

5) Wiping

Wiping (los yog ntug dabtsi yog khoov lossis so-khoov) yog lwm txoj kev khoov siv rau cov tshuab xws li gable brakes thiab steel folding machines (qee zaum cov tshuab khoov).Nws yog nrawm dua li folding, tab sis tuaj yeem ua rau muaj kev puas tsuaj ntau dua rau cov ntawv hlau nto.

6) Rotary dabtsi yog khoov

Vim lub tshuab siv, yob dabtsi yog khoov yog tej zaum qhov tshwj xeeb tshaj plaws daim ntawv hlau dabtsi yog khoov txheej txheem.Lub yob dabtsi yog khoov tshuab muaj peb lub cylindrical rollers uas khoov cov ntawv hlau rau hauv cov duab nkhaus, yog li nws tuaj yeem siv los ua cov kav dej, cov raj thiab lwm yam puag ncig.

7) Joggle dabtsi yog khoov

Joggle dabtsi yog khoov (qee zaus hu ua dimple dabtsi yog khoov) yog ib txoj kev khoov siv lub tshuab dabtsi yog khoov uas kwv yees du dabtsi yog khoov (xws li uas ua los ntawm yob dabtsi yog khoov).Los ntawm kev ua ob peb qhov me me V-shaped khoov nyob rau hauv succession, Joggle dabtsi yog khoov tuaj yeem tsim khoov uas zoo li nkhaus.

4Sheet Hlau dabtsi yog khoov pub thiab suav cov txheej txheem

1) Sheet Hlau dabtsi yog khoov pub

Thaum ib daim ntawv hlau yog khoov, sab nraud ntawm qhov khoov yog ncab thiab yog li nws qhov ntev hloov.Qhov no txhais tau tias, piv txwv li, tag nrho qhov ntev ntawm ob txhais ceg ntawm V-khoov yuav ntev dua li qhov ntev ntawm daim ntawv.

Yog li, yog tias qhov loj me hloov pauv, peb yuav ua li cas thiaj tsim tau ib feem kom ntseeg tau tias nws haum ua ke nrog lwm cov khoom?Peb yuav txiav txim siab ntev npaum li cas cov ntawv tiaj tus hlau yuav tsum yog?Txhawm rau them nyiaj rau qhov kev hloov pauv, peb yuav tsum xav txog qhov nyiaj khoov: qhov sib txawv ntawm qhov ntev ntawm lub phaj unfolded thiab qhov sib npaug ntawm qhov ntev ntawm txhua ceg ntawm qhov tiav khoov ib feem.

2) Sheet hlau unfolding xam cov mis

Khoov nyiaj pub dawb.Ib daim ntawv hlau khoov muaj peb qhov ntev: ob qhov contour qhov ntev thiab ib lub thickness dimension, thiab ob qhov contour qhov ntev yog txhais li L1 thiab L2, thiab thickness dimension yog T. L1 + L2 yuav tsum ntau tshaj qhov unfolded ntev L. Qhov sib txawv ntawm lawv yog cov nyiaj khoov, txhais raws li K. Tom qab ntawd qhov nthuav dav ntawm qhov khoov L = L1 + L2-K.Tus nqi K ntawm lub dav hlau txias dov steel phaj (qhov xwm txheej: 90 degree khoov, txheem khoov cuab yeej)

T = 1.0 K = 1.8

T = 1.2 K = 2.1

T = 1.5 K = 2.5

T = 2.0 K = 3.5

T = 2.5 K = 4.3

T = 3.0 K = 5.0

T = 3.5 K = 6.05

T = 4.5 K = 7.0

T = 5.0 K = 8.5

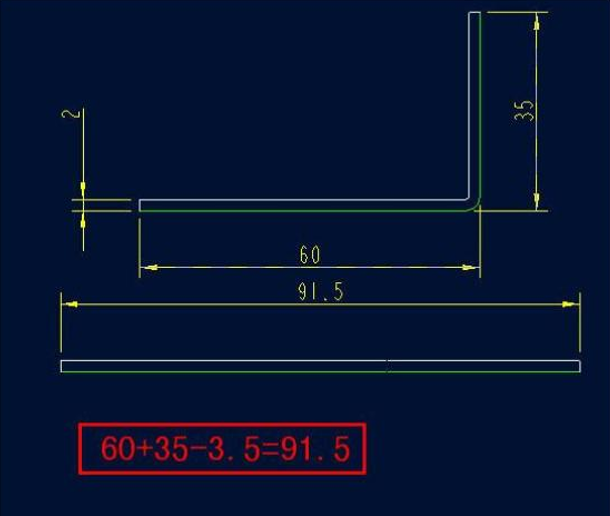

Piv txwv 1

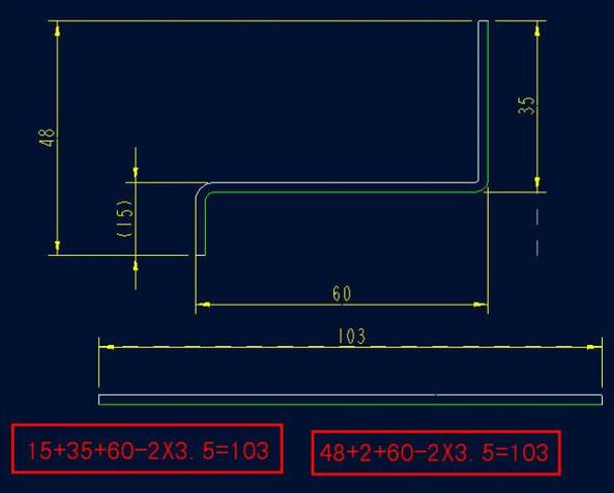

Piv txwv 2

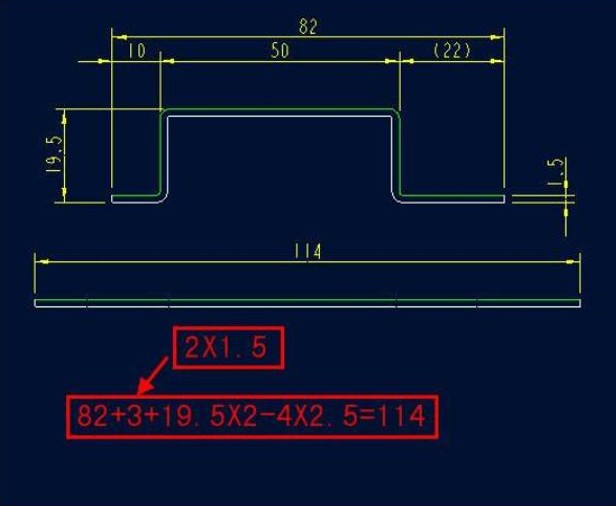

Piv txwv 3

Sheet hlau dabtsi yog khoov los ntawm kev siv PROLEAN'TECHNOLOGY.

Ntawm PROLEAN TECH, peb mob siab rau peb lub tuam txhab thiab cov kev pabcuam uas peb muab rau peb cov neeg siv khoom.Yog li ntawd, peb nqis peev ntau rau hauv kev nce qib tshiab hauv peb cov thev naus laus zis thiab muaj cov kws ua haujlwm siab tshaj plaws ntawm koj qhov pov tseg.Tiv tauj peb dawbnqe lus.

Prolean lub zeem muag yog los ua tus thawj coj kev daws teeb meem ntawm On-Demand Manufacturing.Peb tab tom ua haujlwm hnyav los ua kev tsim khoom yooj yim, nrawm, thiab txuag nqi los ntawm kev tsim qauv mus rau ntau lawm.

Post lub sij hawm: Mar-24-2022