Kudin Kera Sheet Metal: Duk abin da kuke Bukatar Sanin

Ƙarshe na ƙarshe: 09/01;Lokacin karantawa: mins 6

Karafa na takarda

Abu mafi mahimmanci a cikin masana'anta shinekarfen takarda.Ana amfani da ƙarfe na takarda don ƙirƙirar sassa daban-daban na inji don aikace-aikace da yawa, daga masana'antar kera motoci, likitanci, da masana'antar sararin samaniya zuwa samfuran da muke amfani da su yau da kullun.

Ƙirƙirar ƙarfe na takarda yana ɗaya daga cikin ƙananan hanyoyi, inda injiniyoyi ke zaɓar takarda mai dacewa kuma su tsara abubuwan da aka haɗa ko duka samfurin zuwa ƙayyadaddun da ake buƙata.Sa'an nan makanikai suna aiwatar da ayyukan injiniyoyi daban-daban don ƙirƙirar abun bisa ga ƙira,

Wannan labarin zai taƙaice shiga cikinfarashin ƙirƙira ƙarfe na takarda, abubuwan da ke tasiri, da kuma hanyoyin da za a rage farashi a duk lokacin aiwatarwa.

Hanyar Ƙimar Kuɗi

A cikin masana'antun masana'antu, akwai ƙididdige ƙididdiga na ƙididdiga na ƙididdiga don masana'anta: farashin ƙirƙira ya ninka sau uku na ƙarfe.Koyaya, abubuwa daban-daban suna shafar farashin ƙirƙira takardar takarda.Bari mu je a kan muhimman al'amurran da tasiri farashin sheet karfe masana'antu a ko'ina cikin tsari.

Rushewar zagayowar samarwa

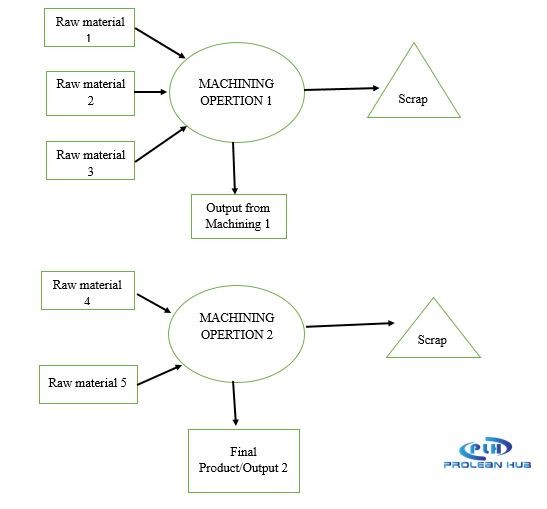

Tsarin kera na samfur ɗaya ba ɗaya bane da wani.Don haka, rushe tsarin samarwa kafin kimanta farashin ƙirƙira yana da mahimmanci.

Don rushewar sake zagayowar samarwa, ƙayyade duk albarkatun da ake buƙata da ayyukan injina don aikin.Misali, zaku iya buƙatar karfen ƙarfe, ƙwayayen tagulla, da kusoshi idan kuna yin akwatin kayan aiki.Bugu da ƙari ga ƙarfe na takarda, ana buƙatar sauran kayan albarkatun kasa don hadaddun sassa.

Dubi faifan rarrabuwar yanayin samarwa da ke ƙasa don ƙarin fahimta.

samar da sake zagayowar na Machining aiki

Matakai don Lissafin Kuɗi

Bayan yin rushewar sake zagayowar samarwa, ƙididdige farashi don ƙira, kayan aiki, aikin injina, injiniyoyi, sarrafa kayan aiki, da sauran cajin don ku iya ƙididdige ƙimar aikin gaba ɗaya daidai.

Mataki 1: Farashin kayan danye

Bayan yin yanke shawara na ɗanyen abu, gano adadin kowane abu da ake buƙata don yin samfuri ɗaya.Lokacin ƙididdige adadin kayan, kar a manta da yin lissafin tarkace.Tunda ana siyar da ƙarfen takarda akan kowace kilogiram ɗaya, yakamata a ƙayyade farashin ta amfani da tushen-kg.

Kudin kayan aiki = ƙarar x yawan kayan ƙarfe x farashin kilogiram.

Idan akwai zanen gado na kayan daban-daban, maimaita wannan matakin ga kowane ɗayan.

Mataki na 2: Ƙirar ƙira

Zane-zane shine ƙirƙirar samfuri mai kama-da-wane a cikin software na kwamfuta ko kan takarda don nemo aikin gabaɗayan aikin.Mataki ne mai mahimmanci a cikin masana'antar takarda don inganta ingancin samfur da rage farashi.Sabili da haka, injiniyoyi suna la'akari da batutuwan fasaha da kuɗi daban-daban lokacin zayyana samfur - sarƙar da ke tattare da geometries, matakin ƙwarewar injiniya, haƙurin da ake buƙata, da ƙari.

Mataki na 3: Farashin injina

Daban-daban machining ayyuka

Ana bayyana farashin injuna a masana'antu a cikin sa'a guda, gami da farashin saka hannun jari, cajin masu aiki da ma'aikata, farashin kulawa, farashin wutar lantarki, farashin yankin da aka mamaye, da farashin sauran abubuwan da ake amfani da su.Abubuwan da ake amfani da su sun haɗa da man shafawa, mutu, tacewa, da gas—duk abin da injin ke cinye bayan wutar lantarki.

| SN | Farashin iri-iri | Lissafi |

| 1 | Kudin zuba jari na inji | |

| 2 | Kudin wutar lantarki | Ƙarfin wutar lantarki na injina (KW) x Farashin wutar lantarki kowace raka'a |

| 3 | Kudin Aiki | · Cajin Mai Aiki (/hrs.) · Cajin ma'aikatan taimako (/hrs.) · Cajin mai kulawa (/hrs.) |

| 4 | Kudin Kulawa | |

| 5 | Matsakaicin Kudin | |

|

6 | Farashin Abubuwan da ake amfani da su | Duk abubuwan da ake amfani da su suna tsada a kowace awa |

Duk farashin injina da tsarin lissafi

Jimlar farashin inji na sa'a shine jimlar duk farashin da aka jera a sama, kuma baya ga waɗannan farashin, masana'antun suna ƙara ribar ribar akan injinan sa'o'i.

Kusan kowane ƙera ƙarfen takarda ya ƙunshi wani tsarin mashin ɗin daban, kamar yadda aka tattauna a baya cikin zagayowar rushewar samarwa.Don haka ana buƙatar ƙididdige farashin mashin ɗin don kowane zagayowar saboda samfurin machining 1 ya zama ɗanyen abu don aikin injin ɗin na gaba har sai samfurin ya shirya don amfani.

Mataki na 4: Kuɗin Sama

Farashin tsarin, shawarwari, farashin sabis, da farashin wasu gwamnatoci suna aiki a cikin kamfanin kera.

Jimlar farashin ƙirƙira

Jimlar farashi shine jimilar duk farashin da aka ƙididdigewa a cikin matakan da ke sama, daga ƙirƙira samfurin zuwa farashin sama da ƙasa.

Jimlar farashi = (Farashin Sheet) + (Jimlar farashin injinin / hr.) x hours aiki + Farashin ƙira + farashi mai ƙima

Abubuwan da za a yi la'akari don Ƙimar

Kafin mu tattauna zaɓuka don yanke farashi, bari mu fara tattauna abubuwan da suka shafi farashin ƙirƙira ƙirar takarda.Fahimtar kowane ɗayan daki-daki zai iya taimaka muku haɓaka kasafin kuɗin ku.

1. Sheet karfe & lambar ma'auni

La'akari na farko kuma mafi mahimmanci shine nau'in kayan da kuke buƙata don ɓangaren ku, wanda aka ƙaddara ta hanyar amfani da samfurin ƙarshe.Misali, aluminium, karfe, tagulla, da titanium sune shahararrun zanen gadon da ake amfani da su wajen kera karafa.Yayin da tagulla da titanium sun fi tsada, karfe shine mafi arha.Har ila yau, zaɓin ma'auni mai mahimmanci yana rage yawan farashin takarda saboda yayin da kuka zaɓi kauri mai dacewa, yana adana ƙarin nauyi mai yawa.

2. Fasahar da aka yi amfani da ita

Farashin mashin ɗin yana tasiri da ƙimar ƙirƙira da ƙarfe tunda yana ƙaruwa lokacin da ake amfani da injunan ƙwararru da injunan aiki.Misali, idan kun zaɓi waldawar katako na Laser lokacin da MIG kuma zai iya ƙirƙirar haɗin gwiwa da ake buƙata don samfurin, Zai fi tsada.

3. Hakuri

Farashin zai karu idan kuna buƙatar sassauƙa masu jujjuyawar juriya saboda kiyaye su yana buƙatar ƙarin ƙoƙari da saitin kayan aiki.Hakanan za'a buƙaci injiniyoyi masu sarrafa inganci daban-daban don saka idanu da tantance tsarin idan kayan aikin suna buƙatar juriya mai ƙarfi.

Yadda za a yanke farashin ƙirƙira takardar takarda?

Abokan ciniki akai-akai suna gano cewa farashin masana'anta na masana'anta sun ɗan fi girma fiye da yadda ake tsammani.Duk da haka, akwai hanyoyin da za a rage farashi ta hanyar yin la'akari da abubuwa daban-daban da yin zaɓe masu kyau.

1. Amfani da ingantattun sigogi

Ana buƙatar ingantattun sigogin ƙira da buƙatu don ƙima mai kyau.Don haka tabbatar da haɗa duk ƙayyadaddun bayanai da fasalulluka da kuke buƙata a cikin samfurin;yin haka zai taimaka a cikin madaidaicin ƙiyasin kuma yana adana farashi ta hanyar ingantaccen tsarin aiki.

2. Zane mai sassauƙa

Abubuwa na musamman da ci-gaba akan ƙirar ƙirar takarda na iya zama mafi kyau, amma yana da tsada sosai yayin ƙirƙira saboda hakan na iya ɗaukar lokaci mai yawa da ƙwararrun injiniyoyi da masu aiki.Don haka sauƙi a cikin ƙira tare da kiyaye ayyukan abubuwan da aka sa a gaba ko samfurin rage farashin.Misali, yayin da babu haɗarin raunin da ya faru bisa ga wurin shigarwa da hulɗar samfur tare da masu amfani, daidaiZa a iya yin amfani da gefuna da aka zazzage kuma suna haɓaka farashi.

3. Cikakken kayan takarda da kauri

Kafin zaɓar kayan ƙarfe na takarda, la'akari da kaddarorin inji kamar ƙarfi, taurin, tauri, da karko.Sa'an nan, yi lissafin daban-daban na takardar farashin takardar da ya dace da kewayon da ake buƙata na waɗannan abubuwan.Sannan, bincika cikakken kauri wanda ke ba da buƙatu.

4. Yi amfani da ingantattun injuna da tsari.

Fasaha da tsarin aikin injin da ya dace suna taimakawa wajen rage lokaci da rage tarkacen karfe, rage farashin ƙirƙirar takarda.Bayan zane, shirya aikin aiki kuma yi amfani da na'ura da fasaha masu dacewa.Misali, injin CNC na iya ɗaukar ɗan lokaci kaɗan da tsada fiye da lathe na al'ada yayin da kuke shirya abubuwan haɗin birki don mota.

5. Babban sikelin samarwa

Ƙirƙirar abu ɗaya don manyan ƙididdiga yana yanke farashin kowane abu.Zana farashi daban-daban na sama kamar shawarwari & kuɗaɗen gudanarwa, kuma ba za a maimaita cajin tsarin ba.

Kammalawa

Ga masana'antun masana'antu, ƙarfe na takarda yana da tsada musamman kuma mai dacewa.Jimlar farashin da ke da alaƙa da ƙirƙira ƙarfen takarda ya ƙunshi farashin ƙarfen da kansa, farashin ƙira da sarrafa shi, wasu farashin sama da ƙasa, da ribar masana'anta.Wannan labarin yana ba da hanya madaidaiciya don ƙayyade duk farashin ƙirƙira.

Labarin ya tattauna abubuwa da yawa waɗanda ke da tasiri akan farashi.Komai rikitarwa tsarin rage farashin, har yanzu yana da mahimmanci.Tunanin rage farashi ba tare da ɓata aiki da halayen abin da ake nufi ba ko samfurin ya fito ne daga sanin abubuwan da ke da tasiri da madaidaitan matakan ƙididdiga.

Ƙimar ƙirƙira ƙirar takarda Lokacin aikitare da mu, Ƙimar farashin ƙirƙira takarda ba ta da wahala kuma.Muna da ƙwararrun injiniyoyi da ke aiki a kaizane karfe ƙirƙirasama da shekaru goma.Bugu da kari, muna samar da ƙwararrun ƙwararrun masana'antar ƙirƙira kamar CNC machining, Aluminum Extrusion, da kammala saman.Don haka, idan kuna buƙatar kowane wuri mai alaƙa, kada ku yi shakkatuntube mu.

FAQ's

Wanne takardar abu ne ya fi dacewa don aikina?

Ya dogara da ƙayyadaddun ƙayyadaddun kayan aikin injiniya da ake buƙata don aikin ku.Misali, takardar bakin karfe mai kauri zai zama mafi dacewa idan kuna buƙatar samfurin don yanayi mai ɗanɗano.

Shin ƙirƙira ƙirar ƙarfe tsari ne mai tsada?

Ee, hanya ce mai tsada, musamman don samar da ƙarar girma.

Menene abubuwan da ke tasiri akan farashin ƙirƙira ƙirar takarda?

Abubuwa da yawa sun haɗa da rikitaccen ƙira, kauri na takardar, fasahar da aka yi amfani da su, haƙuri da ake buƙata, da sauransu.

Menene mahimmin farashin da aka haɗa a cikin ƙirƙira ƙarfe?

Farashin takarda, farashin injina, farashin ƙira, da ƙari sune farashin da ke da alaƙa da farashin ƙirƙira.

Lokacin aikawa: Jul-12-2022