“The most crucial component in manufacturing is sheet metal. Sheet metal is used to create various mechanical parts for several applications, from the automotive, medical, and aerospace industries to the products we use daily.”

Sheet metal fabrication is one of the low-cost methods, where engineers choose the suitable sheet and design the components or entire product to the required specifications. Then mechanics carry out various machining processes to create the item according to design,

This article will briefly go through the cost of sheet metal fabrication, affecting factors, and ways to minimize costs throughout the process.

Cost Estimation Approach

In the manufacturing industry, there is a very generic cost calculation for sheet metal manufacturing: the fabrication cost is three times that of sheet metal. However, various factors affect the sheet metal fabrication cost. Let’s go over the significant aspects that influence the cost of sheet metal manufacturing throughout the process.

Production cycle breakdown

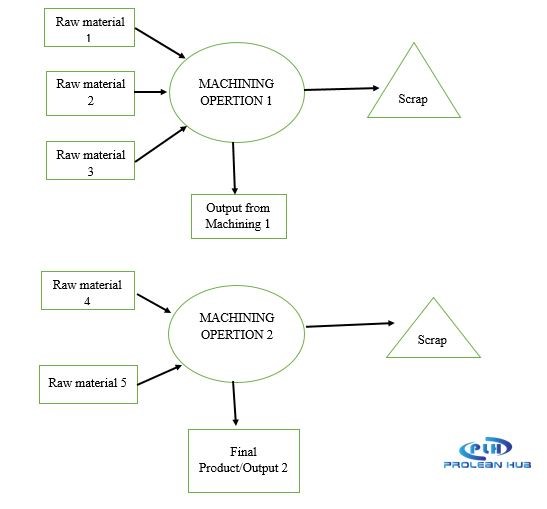

The manufacturing process for one product is not the same as another. Therefore, breaking down the production cycle before evaluating fabrication costs is crucial.

For the production cycle breakdown, determine all the necessary raw materials and machining operations for the project. For instance, you could require steel sheet metal, brass nuts, and bolts if you’re making a toolbox. In addition to sheet metal, other raw materials are needed for the complex components.

Look at the production cycle breakdown graphic below for a deeper understanding.

Production cycle of machining operation

Try Prolean Now!

Steps for Cost-Calculation

After making the production cycle breakdown, calculate the cost for the design, materials, machining operation, mechanist, post-processing, and other charges so that you can estimate the entire project cost very accurately.

Step 1: Raw material cost

After making a raw material decision, determine how much of each material is needed to make a single product. When estimating the amount of material, don’t forget to account for scraps. Since sheet metal is typically sold per kg, cost should be determined using a per-kg basis.

Material cost = volume x density of sheet metal material x cost per kg.

If there are sheets of different materials, repeat this step for each one.

Step 2: Designing cost

Designing is the creating a virtual product in computer software or on paper to find the workflow of the whole project. It is an essential step in sheet metal manufacturing for optimizing product quality and reducing cost. Therefore, engineers consider various technical and financial issues when designing a product—the geometries’ complexity, the engineer’s experience level, the required tolerance, and more.

Step 3: Machining cost

Various machining operations

Machining cost in manufacturing is expressed hourly, including the investment cost, the charge of operators and laborers, Maintenance cost, electricity cost, occupied area cost, and other consumable items. Consumable items include lubricants, dies, filters, and gaseous—everything the machine consumes besides electricity.

Table: All machining costs and calculation approach

|

SN |

Various costs |

Calculation |

|

1 |

Machines-investment Cost |

|

|

2 |

Electricity cost |

Rated power of operating machines( KW) x Electricity cost per unit |

|

3 |

Operating Cost |

· Charge of Operator (/hrs.) · Charge of assistance workers (/hrs.) · Charge of supervisor (/hrs.) |

|

4 |

Maintenance Cost |

|

|

5 |

Occupied Are Cost |

|

|

6 |

Cost of Consumable Items |

All consumable items cost per hour |

Total hourly machining cost is the sum of all the costs listed above, and besides these costs, manufacturers add the profit margin on the hourly machining.

Almost every sheet metal fabrication involves a different machining cycle, as discussed previously in the production breakdown cycle. So the machining cost needs to be calculated for each cycle because the product of machining 1 becomes raw material for the subsequent machining process until the product is ready for use.

Step 4: Overhead Cost

Cost of structures, consultation, service costs, and cost of other administrations work in a manufacturing company.

Step 5: The Total fabrication Cost

Total cost is the sum of all costs calculated in the above steps, from the design of the product to overhead costs.

Total cost= (Sheet metal cost) + (Total Machining cost / hr.) x operating hours + Designing cost + Overhead costs

Factors to Consider for the Estimation

Before discussing options for cost-cutting, let’s first discuss the aspects that affect the cost of sheet metal fabrication. Understanding each one in detail can help you optimize your budget.

Sheet metal & Gauge number

The first and most crucial consideration is the type of material you require for your component, which is determined by the intended use of the final product. For example, aluminum, steel, brass, and titanium are the popular sheets used in sheet metal fabrication. While brass and titanium are more expensive, steel is the cheaper one. Also, the selection of a perfect gauge lowers the sheet metal cost because while you select the appropriate thickness, it saves a lot of extra weight.

Used technology

The machining cost primarily influences sheet metal fabrication costs since it increases when more sophisticated machinery and labor-intensive processes are used. For instance, if you choose laser beam welding when MIG can also create the required joint for the product, It will be more expensive.

Tolerance

The cost will increase if you need repeatable, tight-tolerance parts because maintaining them requires additional effort and tool setup. Different quality control engineers will also be needed to monitor and assess the process if the components require tight tolerance.

Try Prolean Now!

How to Cut Down the Sheet Metal Fabrication Cost?

Customers frequently find out that the prices of sheet metal manufacturing are slightly higher than expected. Nevertheless, there are ways to reduce costs by considering different elements and making wise selections.

- Using accurate parameters: Accurate design parameters and requirements are required for proper estimation. So make sure to include all the specifications and features you need in the product; doing so will aid in the accurate estimate and save costs through the improved workflow.

- Flexible design: Specialized and advanced elements on the sheet metal design might look better, but it costs a lot while fabricating because that can take much time and expert engineers and operators. So simplicity in design while maintaining the functionality of aiming component or product lowers the Cost. For example, while there is no risk of injuries according to the installation site and product interaction with users, perfectly chamfered edges might be unused and drive up the cost.

- Perfect sheet material and thickness: Before selecting the sheet metal material, consider the mechanical properties such as strength, hardness, toughness, and durability. Then, make a list of different materials sheet costs that fit the required range of these factors. Then, analyze the perfect thickness that provides the requirement.

- Use the perfect machine and process: Technology and appropriate machining processes help to reduce the time and minimize the scrap metal, lowering the sheet metal fabrication cost. After the design, prepare the workflow and use the suitable machine and technology. For example, a CNC machine could take much less time and cost than the conventional lathe while you prepare the brake components for automotive.

- Large-scale production: Fabricating the same item for large quantizes cuts a per-item cost. Design various overhead costs such as consultation & administrative expenses, and the structural charge will not be repeated.

Conclusion

For the manufacturing sector, sheet metal is particularly cost-effective and versatile. The sum of the costs associated with fabricating sheet metal comprises the price of the metal itself, the cost of designing and machining it, some overhead costs, and manufacturer profit margins. This article provides a straightforward method to determine the entire fabrication cost.

The article discusses many elements that have an impact on pricing. No matter how complicated the cost-minimization process is, it is still crucial. The idea of reducing the cost without compromising the performance and characteristics of the target component or product comes from knowing the influencing element and precise estimating processes.

Estimation of sheet metal fabrication When working with us, estimating sheet metal fabrication costs is not complex anymore. We have expert engineers working on sheet metal fabrication services for over a decade. In addition, we provide professional sheet metal fabrication services such as CNC machining, Aluminum Extrusion, and surface finishing. So, if you need any related surfaces, do not hesitate to contact us.

FAQ’s

Which material sheet is the best for my project?

It depends on the specifications and required mechanical properties for your project. For example, a thick stainless steel sheet would be the best fit if you need the product for a moist environment.

Is sheet metal fabrication a cost-effective process?

Yes, it is a cost-effective approach, especially for large-volume production.

What are the factors that influence the cost of sheet metal fabrication?

Several factors include design complexity, the thickness of the sheet, used technology, required tolerance, and others.

What are the significant costs included in sheet metal fabrication?

Sheet cost, machining cost, design cost, and overhead are the costs associated with the fabrication cost.

0 Comments