Electro-less nickel plating: Txhua yam koj yuav tsum paub

Hloov tshiab kawg 08/31, kwv yees lub sij hawm nyeem ntawv: 6 mins

Parts nrog Electroless nickel plating

Nickel yog qhov thib tsib feem ntau pom hlau hauv ntiaj teb, nrog lub ntsej muag ci, zoo heev hardness, thiab corrosion-resistive zog, ua rau nws zoo tagnrho rau kev tiv thaiv txheej ntawm lwm yam ntaub ntawv.Yog li ntawd, Nickel yog qhov zoo tshaj plaws plating xaiv rau ntau yam hlau xws lialuminium, hlau, tooj liab, tungsten, polymer, thiab ntau ntxiv.Electroless Nickel platingyog txheej txheem tshuaj plating nrov los ntawm cov tshuaj uas muaj Nickel, sulfate, phosphate, thiab carbolic acid.Cov kev daws teeb meem no yog sib xyaw thiab ua kom sov ua ntej pib nrog cov plating.Cov txheej txheem no tau siv nyob rau hauv kev tsim khoom lag luam rau ntau tshaj 50 xyoo, yog li koj tuaj yeem xav txog tias nws nrov npaum li casdaim ntawv thov nto finishing.

Cov kev daws teeb meem siv hauv Electroless Nickel Plating

Muaj ntau yam tshuaj siv rau electroless nickel plating.Cia peb nkag siab txhua tus ntawm lawv los ntawm cov lus sib piv hauv qab no;

| SN | Tshuaj

| Lub luag haujlwm | Piv txwv

|

| 1 | Soluble ntsev ntawm Nickel

| Nws tau txo thiab tso rau ntawm qhov chaw ntawm cov khoom yuav tsum tau coated (substrate)

| Nickel chloride (NiCl₂), Nickel Sulfate (NiSO₄) |

| 2 | Tus neeg sawv cev txo qis

| Nws tau oxidized los ntawm kev txo cov hlau ion.

| Formaldehyde (CH 2 O), Hypophosphite

|

| 3 | Tus neeg saib xyuas lub ntsej muag

| Txhim kho qhov zoo ntawm nickel deposition

| Fluoride, glycinates, succinates

|

| 4 | Stabilizer

| Tiv thaiv kom tsis txhob decomposition ntawm plating da dej

| Thallium, Calcium

|

| 5 | Tsis pub

| Tswj tus PH ntawm lub plating da dej kom tau ib tug nyias thiab uniform deposition ntawm Nickel

| Sodium acetate, sodium hydroxide

|

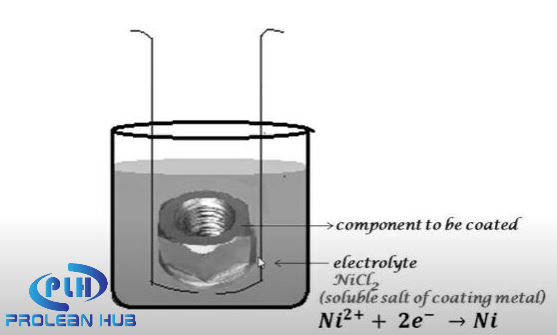

Nws Ua Haujlwm li cas?

Txoj cai ua haujlwm

Ntawm no, electro-tsawg txhais tau hais tias tsis muaj tam sim no siv rau hauv cov txheej txheem plating.Hloov chaw, tus neeg sawv cev txo qis muab cov khoom siv hluav taws xob rau hlau ion txo, ua rau muaj kev cuam tshuam loj heev.Cov nickel ion (2e +) nyob rau hauv cov tshuaj, thaum reacting nrog tus neeg sawv cev txo (2e-), tso cov Nickel rau ntawm qhov chaw ntawm cov khoom siv substrate.

Ni2+(los ntawm nickel ntsev tov) + 2e- (los ntawm tus neeg sawv cev Txo) = Ni (ntawm substrate nto)

Cov kauj ruam ntawm Electroless Nickel Plating

Kauj Ruam 1: Npaj rau lub plating

Thawj kauj ruam yog los ntxuav cov khoom uas yuav tsum tau coated kom txhua yam kab mob, xws li plua plav, roj, slags, roj, thiab tej yam tshuaj nyob rau saum npoo, yog ntxuav tawm, npaj nws rau qhov zoo tshaj plaws nickel txheej adhesion.Qhov twg siv cov tshuaj ntxuav tes xws li sulfuric acid thiab hydrochloric acid, nws yuav tsum tau ntxuav nrog dej distilled hauv da dej kub kom tsis txhob muaj cov kua qaub thiab tiv thaiv nws los ntawm degrading nto.

Kauj Ruam 2: Kev kho ntawm lub plating da dej

Kev kho-cog rau electroless nickel plating

Tom qab ntxuav cov khoom thiab npaj cov tshuaj da dej, cov txheej txheem plating tuaj yeem pib.Cov khoom tam sim no tau muab tso rau hauv lub nickel plating da dej uas muaj cov nqi zoo.Cov khoom yuav tsum tau coated attracts zoo nqi npib tsib xee ions rau lawv qhov chaw, ua rau ib tug zoo txheej ntawm txheej.Vim tias electroless npib tsib xee plating tsis xav tau qhov hluav taws xob, qhov kub ntawm lub plating da dej yog qhov tseem ceeb ntawm kev tswj qhov sib txawv ntawm cov txheej txheem (70 txog 90).0C yog nyiam).

Lub thickness ntawm lub deposited npib tsib xee txheej txawv ntawm 5 thiab 25 microns ib teev.Txawm li cas los xij, vim tias tsis muaj tam sim no thiab nws yog txheej txheem autocatalytic plating, tsis muaj qhov txwv ntawm thickness;raws li lub sij hawm kho mob nce, thiaj li yuav cov deposition thickness.

Kauj Ruam 3: Tom qab ua tiav

Thaum lub sij hawm tom qab ua tiav, cov khoom txuas thiab cov seem raug tshem tawm los ntawm kev yaug nrog cov kua qaub, alkali, thiab surfactant tov.Tom qab ntawd, kev ua tiav ntxiv, xws li polishing, waxing, thiab lwm yam, yog siv raws li qhov yuav tsum tau ua.

Muaj feem cuam tshuam rau hauv Electroless Nickel Plating

Ntau yam cuam tshuam rau cov txiaj ntsig ntawm nickel electroless plating, uas yuav tsum tau tswj kom ua tiav qhov yuav tsum tau ua kom tiav qhov zoo.

1. Kev tsis zoo ntawm qhov chaw

Cov npib tsib xee plating yog cuam tshuam los ntawm qhov chaw tsis zoo xws li burrs, slags, thiab preformed xeb.Yog li lub tswv yim zoo tshaj plaws yog khaws cov khoom no hauv siab thaum machining thiab tom qab ntawd tshem tawm qhov tsis xws luag nrog cov txheej txheem deburring.

2. Kev huv ntawm qhov chaw

Ua ntej pib nrog cov npib tsib xee plating, cov plua plav, roj, lossis xab npum tsim los ntawm cov roj saponification los ntawm alkaline ntxuav yuav tsum tau muab tshem tawm.Yog tias qhov kev tu saum npoo tsis ua kom raug, txheej ntawm Nickel tuaj yeem tev lossis puas tom qab qee lub sijhawm.

3. Tus nqi PH

Kev tuav tus nqi PH yog ib qho tseem ceeb rau kev siv cov npib tsib xee plating uas siv electroless mus kom ze.Qhov ntsuas PH yuav tsum nyob nruab nrab ntawm 3.8 thiab 5. Hauv kev daws, nws xav tias pH yuav nce siab thaum lub sij hawm dhau mus, yog li cov stabilizer thiab cov kev daws teeb meem yuav tsum tau siv los ua kom PH ruaj khov nyob rau hauv cov txheej txheem kho.

Raws li PH nce, ntau hydroxide ions raug tsim, uas khi nrog npib tsib xee ions thiab tsim nickel hydroxide, uas muaj lub teeb ntsuab.

4. Qhov concentration ntawm Nickel ion

Cov tshuaj ntsev siv nyob rau hauv qhov chaw kho mob yog cov nickel ion qhov chaw tso rau ntawm qhov chaw substrate.Yog li ntawd, yog tias cov nickel ion concentration tsawg, cov txheej txheem plating yuav qeeb dua.Txawm li cas los xij, cov concentration ntau dhau yog tso sai dua, tab sis cov deposition yuav tsis sib xws.Tus txheej txheem ntau ntawm nickel concentration yog nruab nrab20 thiab 45 g / l.

5. Kub

Kev kho da dej kub yuav tsum nyob nruab nrab ntawm70i90 ua0C.Raws li qhov kub thiab txias, qee cov khoom muaj ntxhiab ntawm cov additives yuav evaporate, yuav tsum tau siv sij hawm ntau rau kev tso tawm.

Qhov zoo

Zoo li lwm cov txheej txheem plating thiab nto tiav, lub ntsiab kom zoo dua yog cov coated qhov chaw thiab cov khoom ua corrosion heev resistive thiab tiv taus qhov tseem ceeb ntawm ib puag ncig.Tab sis, dhau li ntawd, electroless nickel plating muaj ntau yam txiaj ntsig.Cia peb saib qee qhov txiaj ntsig tseem ceeb hauv kev nthuav dav.

Tus nqi qis

Ib qho ntawm cov nqi ntawm cov txheej txheem plating tiav yog cov nqi hluav taws xob.Txawm li cas los xij, vim electroless npib tsib xee plating tsis xav tau qhov hluav taws xob, nws yog tus nqi ntau dua li lwm txoj hauv kev, xws li zinc plating.

Uniform txheej

Electroless npib tsib xee plating ua rau ib txheej txheej ntawm lub substrate nto.Kub, PH nqi ntawm plating da dej, qhov concentration ntawm npib tsib xee ion, lub sij hawm kho, thiab ntau lwm yam yuav tsum tau tag nrho cov tswj kom ua tau raws li qhov xav tau thickness ntawm nickel plating.

Dimensional sib xws

Vim tias mus txog 5-micron plating thickness yog ua tiav, nws tsis cuam tshuam rau qhov yuav tsum tau ua siab ntev ntawm cov khoom.

Hardness

Lub plating da dej cov ntsiab lus phosphorous cuam tshuam cov plated qhov chaw 'hardness.Tsawg phosphorus qib nce hardness thaum txo cov corrosion kuj ntawm plating txheej.

Kev kho me me

Electroless npib tsib xee plating kuj pab kho cov kab nrib pleb me me ntawm lub substrate nto.Yog li ntawd, nws tuaj yeem ua tau zoo heev rau cov phaj nooks, crannies, thiab qhov muag tsis pom qhov khoob nrog cov tuab tuab.

Aesthetic thiab lwm yam txiaj ntsig

Cov xim daj-dawb ntawm npib tsib xee plating muab kev zoo nkauj zoo nkauj rau cov pats thiab cov khoom.Tsis tas li ntawd, nws tsis tshua muaj complex.Nws tsis tas yuav muaj cov txheej txheem filtration nyuaj.Hauv qhov xwm txheej niaj hnub no, cov cuab yeej siv hluav taws xob muaj nyob hauv kev tsim khoom, ua kom yooj yim rau kev tswj cov txheej txheem.

Daim ntawv thov

Cov txheej txheem electroless npib tsib xee plating pab txhawb rau ntau yam kev lag luam kom lawv cov khoom tiv thaiv corrosion thiab ruaj khov.Hauv qab no yog cov lag luam tseem ceeb uas siv nickel plating;

| SN | Kev lag luam | Cov khoom siv tau | Nws ua dab tsi? |

| 1 | Aerospace | valves, pistons, cav shafts npog qhov chaw, cav mounts, compressor hniav, thiab lwm yam davhlau-tseem ceeb Cheebtsam | Nws muaj kev hnav zoo heev, kev tiv thaiv corrosion, tshuaj tiv thaiv, thiab lubricity, uas yog ib qho tseem ceeb rau qhov chaw aerospace uas yuav tsum tau muaj qhov tseeb ntawm lub sijhawm ntev. |

| 2 | Automotive | Pistons, lub tog raj kheej, lub zog, ncej, roj txhaj tshuaj, rivets, thrust transmitters, knuckle pins, vaj tse, thiab ntau yam ntxiv | Muab kev tiv thaiv hnav thiab corrosion kuj |

| 3 | Kho vajtse | Cov khoom siv hauv chav dej, qhov rooj, tuav Piping, thiab lwm yam. | Corrosion kuj |

| 4 | Hluav taws xob & Electronics | Npog ntau yam khoom siv, Kub dab dej, hard drive disks, Printed circuit boards | Kev tiv thaiv los ntawm corrosion thiab ib puag ncig exposer |

| 5 | Roj & roj | Valves, twj tso kua mis, yeeb nkab fittings, cia tank, thiab lwm yam | Kev tiv thaiv corrosion thiab ib puag ncig & tshuaj raug. |

Xaus

Electroless npib tsib xee plating yog ib qho tshwj xeeb nto xov rau ntau yam ntaub ntawv, xws li hlau, tooj liab, tooj liab, txhuas, yas, thiab lwm yam.Nickel plating txhim kho cov kav ntev los ntawm kev muab kev tiv thaiv corrosion zoo heev ntawm lub substrate nto.Tsis tas li ntawd, vim tias Nickel muaj lub ntsej muag daj daj xim dawb, nws muaj kev zoo nkauj zoo nkauj.Tsis tas li ntawd, cov plating tuaj yeem ua nrog lossis tsis muaj electrolysis, xyuas qhov sib txawv ntawmElectroplating thiab Electro-tsawg plating.

Vim tias muaj ntau cov tshuaj thiab cov tshuaj tiv thaiv catalytic hauv cov txheej txheem, electroless npib tsib xee plating tej zaum yuav tsis meej pem rau ntau tus neeg, tshwj xeeb tshaj yog cov uas tsis muaj ib qhokev paub txog engineering chemistry.Txawm li cas los xij, ntawm noProleanHub, peb cov engineers thiab cov kws tshaj lij tau ua haujlwm rau saum npoo txheej tshuab, suav nrog electroless nickel plating, rau ntau tshaj kaum xyoo.Yog li ntawd, lawv yuav nkag siab txog cov tshuaj muaj pes tsawg leeg thiab mus kom ze thaum koj piav qhia koj cov kev xav tau thiab kev siv.

FAQ's

Dab tsi yog electroless nickel plating?

Nws yog ib qho ntawm cov txheej txheem txheej txheej txheej ntawm Nickel tso rau ntawm lub substrate los ntawm kev siv tshuaj tiv thaiv catalytic & tsis siv hluav taws xob.

Dab tsi yog ob txoj kev daws teeb meem siv hauv electroless nickel plating?

Cov tshuaj ntsev uas muaj cov nickel ions & Tus neeg sawv cev txo qis yog ob lub ntsiab lus tshuaj siv hauv cov txheej txheem.

Dab tsi yog cov khoom siv feem ntau coated nrog electroless nickel plating?

Txoj kev no feem ntau yog siv los pleev xim hlau, stainless hlau, txhuas tooj liab, tooj dag, tooj dag, thiab yas.

Dab tsi yog yam uas cuam tshuam rau qhov zoo ntawm nickel plating?

Kub & PH ntawm lub plating da dej, lub sij hawm kho, huv si ntawm substrate nto, thiab concentration ntawm Nickel ion nyob rau hauv cov tshuaj yog thawj yam cuam tshuam rau lub plating tshwm sim.

Post lub sij hawm: Aug-05-2022