Ingabe i-CNC yenza imishini ishibhile kumajamo ayinkimbinkimbi Ultimate guide 2022

Kulesi sihloko, ngokusekelwe ezisekelweni zemishini, sizokwethula amaphuzu ezingxenye zomshini ezibiza izindleko abaklami bemishini abasaqalayo abavame ukuwela kuzo.

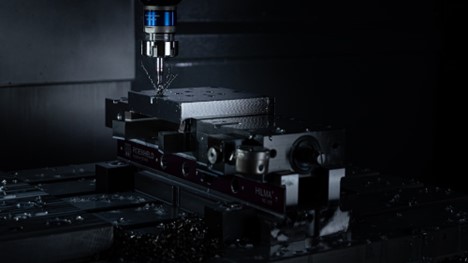

CNC Milling Punching

Ake ngikutshele ngengxenye lapho ungenza khona izinto ezishibhile ngokusika.Uma ucabanga ukwenza imishini, ungase ube nesithombe sazo zonke izingxenye ezimaholoholo, ezingaphili zemikhiqizo yezimboni, kodwa empeleni, ungakwazi ukudala izimo ezihlukahlukene, ezifana nokusonteka kwezindawo ezigobile.

CNC Machining izingxenye

Kulokhu, sizokwethula "izimo ezimangalisayo" ezihlukahlukene ngenkathi sethula inqubo yokubona izimo eziyinkimbinkimbi ngokusika ngesilawuli samanje sekhompyutha.

Iyini i-NC processing?

Nakuba sekushiwo izikhathi eziningi, ukusika kuyinqubo lapho i-blade ejikelezayo icindezelwa okuthile eduze kwe-trajectory emisiwe ukuze ikhulwe futhi isuse izingxenye ezingadingekile.

Ngakho-ke kusho ukuthini "ukuhambisana ne-set trajectory"?

Ngishiye inkulumo ingacacile kuze kube manje, kodwa iyingxenye ebaluleke kakhulu yokusika, ngakho-ke ngizoyichaza ngemininingwane eminingi.

Ake sibeke eceleni amathuluzi omshini enhloso evamile “asebenza mathupha” njengabasiki benjongo evamile okwamanje, futhi sikhulume ngalawa mathuluzi omshini we-NC “asebenza ngokuzenzakalelayo” njengabasiki be-NC kanye nezikhungo zomshini.

Emishinini enjalo, izindwani ezisika izinto zihanjiswa ulimi lomyalo emshinini.Uma ufaka umyalo othi “Hambisa isigayo kule ndawo” emshinini, umshini uzihambela ngokuzenzakalelayo ngokomyalelo.Indawo yesigayo sokuphela ivezwa ivelu lenombolo ngayinye engu-X, Y kanye no-Z. Umshini uqhubeka ngokuhambisa lawa manani..ngokohlelo.

Iyini i-NC milling cutter?

Uhlobo oluhlukile lwe-NC milling cutter

I-“NC” ku-NC milling cutter imele “Ukulawulwa Kwezinombolo”.”X” “indlela evundlile”, “Y” “indlela eya emuva naphambili”, futhi “Z” “indlela eqondile”.Ngokufaka ngokuqhubekayo "indawo elandelayo yokuhamba", kungenzeka ukuhambisa isigayo sokuphela ngokudweba amajika abushelelezi nama-trajectories ayinkimbinkimbi.

Ngokuphambene, umshini usebenza kuphela ngokuya ngemiyalelo yokufaka.Umumo wokugcina uncike ohlelweni lokufakwayo lwe-NC.Ngaphambi kokuthuthukiswa kwamakhompiyutha, kubonakala sengathi izinhlelo ze-NC zazigxivizwa kumakhasethi ephepha akhethekile futhi zidluliselwe emshinini ukuze zifundwe.Lokhu kubonakala kuyisizathu esenza ukuthi omakadebona bezandla babize izinhlelo ze-NC ngokuthi “amateyipu.”

Izinhlelo ze-NC kumateyipu ephepha akhethekile

Okwamanje, siphatha izinhlelo ze-NC njengedatha yekhompyutha.Uhlelo lwe-NC lugcinwa njengedatha enkumbulweni yomshini, futhi ngenkathi lufunda umugqa ngomugqa njengemiyalelo, lusebenza ngokuvumelana nokuqukethwe yiziyalezo.

Ukumiswa kohlelo lwe-NC

Uhlelo lwe-NC ngokuyisisekelo lunokucushwa okuvamile kwanoma yiliphi ithuluzi lomshini.”Ingxenye elawula ukunyakaza komshini” njengokuthi “G code” noma “M code” ezungezisa ukuphotha noma eshintsha isivinini sokunyakaza, kanye “nendawo yethiphu yokugaya” njengoba i-X, Y, Z ilinganisa iqukethe inhlanganisela yengxenye enikeza inani lomyalo.

Ukusika kwesimanje kusetshenziswa amakhompyutha: CAD/CAM

Izinhlelo ze-NC ezilula njengokuthi “vele ubhoboze imbobo” noma “vele uhambise i-blade ngendlela eqondile” zingadalwa kalula, kodwa izinhlelo eziyinkimbinkimbi ze-NC ezifana “nokusika indawo egobile” zidinga ubuchopho bukanjiniyela.Idlula izinga lokucabanga nokuthayipha ngesandla.

Uhlelo olubizwa nge-CAD/CAM lusebenza ezimeni ezinjalo.”I-CAD/CAM” ithi “I-Computer Aided Design” kanye “Ne-Computer Aided Manufacturing”, ngakho-ke igama elivamile elithi “ukuklama nokukhiqiza kusetshenziswa amakhompyutha”.

Njengamanje, ngomqondo omncane, i-CAD isho isofthiwe eyenza imidwebo namamodeli e-3D kukhompuyutha, futhi i-CAM ibhekisela kusofthiwe edala.Izinhlelo ze-NCusebenzisa idatha ye-CAD.Ngisho nokudala izinhlelo ze-NC eziyinkimbinkimbi kudinga usizo lwekhompyutha.Enye isofthiwe inemisebenzi yomibili ye-CAD ne-CAM, futhi kukhona nesofthiwe enemisebenzi ezimele.

Nquma Inqubo Efanelekile Yomshini

I-CAD ihlanganiswe ngokuningiliziwe kumasayithi ahlukahlukene, ngakho-ke lapha ngizochaza ngemininingwane emincane mayelana ne-CAM, abaklami abangajwayele ukuyiqonda.Enqubweni yokudala uhlelo lwe-NC kusetshenziswa i-CAM, kuyadingeka ukunquma inqubo efanelekile, uhlobo lwesigayo sokugcina, nezimo zomshini ezisekelwe ezintweni kanye nokuma kwendawo yokusebenza, bese uzifaka njengolwazi.

Kunezinketho ezingenakubalwa ezingathathwa kuye ngezinto kanye nokuma kwempahla, ukuhleleka kokusetha, njll. Hlobo luni lwezilungiselelo okumelwe zenziwe luncike kakhulu ekuhlangenwe nakho kanye nomuzwa kanjiniyela.

Isibonelo, kunezindlela eziningi zokulungisa izinto zokwakha.Ingaboshelwa nge-vise yemishini enembile, elungiswe ngokuqondile nge-jig, ehlanganiswe nesikulufu, njll. Kunezinketho ezihlukahlukene kuye ngokuthi umumo kanye nenqubo.Kufanele isethwe ngokuvumelana nakho konke ukusetha nezinhlobo zezigayo zokugcina futhi iguqulelwe ezinhlelweni ze-NC.

Ukusetshenziswa Kwemishini Yokugcina Ekusikeni Indawo Eyigobile

Kunezinhlobo ezahlukene zezigayo zokugcina, ezifana nezigayo zokuphela kwebhola ezifanele ukusika izindawo ezigobile ezineziphetho eziyindilinga, izigayo zokugcina eziyisicaba ezifanele ukusika izindawo eziqondile eziyisicaba, kanye nezimbobo zokubhoboza izimbobo.

izinhlobo ezahlukene zokugaya

Uhlobo ngalunye luhlukaniswe lwaba izimo ezihlukahlukene ezifana nobubanzi, inombolo yezindwani, nobude obusebenzayo be-blade.Setha ukuthi hlobo luni lwendlela yokwenza imishini nokuthi hlobo luni lweimishiniizimo zokusebenzisa isigayo ngasinye sokuphela.

Ngisho nezigayo azikhawulelwe ohlotsheni olulodwa ekusetheni okukodwa.Kunalokho, akuvamile ukusebenzisa inqwaba yezinhlobo.Khona-ke amapharamitha azosethwa abe mkhulu.

Yiziphi izimo zemishini yokwenza izingxenye eziyinkimbinkimbi ezishibhile?

Izimo zomshini zihlanganisa inani lokujikeleza kwe-spindle, isivinini sokunyakaza, kanye nenani lezinto ezizosuswa.Kukhona inhlanganisela elilungile kuye ngokuthi isigayo shape, impahla, kanye impahla impahla.Umbuzo uwukuthi ungayithola kanjani inhlanganisela engcono kakhulu, uvimbele ukuguga kwesigayo sokuphela, futhi unciphise isikhathi somshini.

Unjiniyela osebenza kahle kakhulu we-NC udala uhlelo lwe-NC ngesikhathi esifushane kakhulu ngaphansi kwezimo zokusika ezibangela ukuxoxa.Ngenkathi ngicabangela izimo ezinconyiwe zomkhiqizi we-blade kanye nesipiliyoni sami esidlule, ngibeka isithombe sesimo sokucubungula ekhanda lami.

Uma ngicabanga ngemisindo nokudlidliza kokuqoshwa ekhanda lami, ngicabanga izinto ezinjengokuthi, “Lesi simo siyashesha kakhulu,” noma “Ngiyazibuza ukuthi ngingakwazi yini ukujula kancane.”Iyingxenye ncamashi yobungcweti.Le nhlanganisela yezinqubo kanye nezinhlelo ze-NC zingasika isikhathi somshini ngesigamu noma ikota.

Ungakwena lokhu!"Umumo we-Three-dimensional ngokusika"

Manje, ake sibheke ezinye izibonelo zokuthi i-CAD/CAM ingasetshenziswa kanjani ukwakha izinhlelo ze-NC ebezingeke zingenzeki futhi nokudala izimo eziyinkimbinkimbi kakhulu kunalokho ongase ukucabange.

Omele imishini ye-5-axis: impeller

Isibonelo esijwayelekile sengxenye engazuzwa kuphela ngalokho okubizwa ngokuthi kanyekanye i-5-axis machining “i-impeller” esetshenziswa kuma-turbocharger ezimoto.

Ngaphandle kwe-CAD/CAM, uhlelo lwe-NC lokusika izingxenye eziyinkimbinkimbi zale impeller ngeke kwenzeke.Kungenxa yokuthi imise okwesigaxa se-undercut.

Ukwenziwa ngesikhathi esisodwa kwe-axis engu-5 kungafinyelelwa kuphela ngokunyakaza okuyinkimbinkimbi kwendawo yetafula (i-A-eksisi, i-axis ye-B) lapho impahla ibekwe khona kanye nezigayo zokugcina (X, Y, Z) zixhunywe ndawonye.

Isithombe sesimanjemanje: Ukumodela kwe-3D

Uma nje unemodeli ye-3D, ungakwazi ukukhiqiza idatha ye-NC ngokuzenzakalelayo ukuze usike umumo nge-CAM.Ngakho-ke, kungenzeka ukuqaphela zonke izimo ezintathu-ntathu, kuhlanganise eziqoshiwe ezifana eziqoshiwe kanye nezibalo.Yiqiniso, kuyadingeka ukucabangela ikona R kanye ne-undercut engiyethule kuze kube manje.

Umumo ungaphinda ukhiqizwe ngokwethembeka kumodeli ye-3D.Amanye amakhasimende ethu acabanga ukusika abalingiswa abadumile ngokwenza futhi abadayise njengezinto eziphambili kakhulu.

Yenza umsebenzi wokusika ujwayeleke kakhudlwana!

Izingxenye eziwumshini ziza ngezinhlobonhlobo zomumo kuye ngohlelo lokusebenza, kodwa kungakhathaliseki ukuthi ukwakheka kungase kube nzima kangakanani, kungenziwa ngomshini inqobo nje uma kukhona u-R kanye ne-undercut inakekelwa.

Ungase ucabange ukuthi ukusakaza kuyindlela engcono kakhulu yokukhiqiza ngobuningi umumo oyinkimbinkimbi, kodwa kunezinzuzo eziningi ekwenzeni imishini.I-porosity, evame ukuba yinkinga ekubunjweni, ingagwenywa, futhi njengoba singekho isidingo sokukhiqiza isikhunta, izindleko zokuqala zingancishiswa, futhi ukulethwa kungafinyezwa.

Isifinyezo

Ngingajabula uma ungagcina ukusetshenziswa kokusika engqondweni ngisho nezingxenye ezicutshungulwe ngobuningi.Izindleko eziphelele ziphansi ngokumangalisayo, futhi kukhona futhi inzuzo yokukwazi ukuphendula ngokuguquguqukayo ekushintsheni kokuklama.

Sithemba ukuthi lesi sihloko sizokusiza ukuthi uzizwe ujwayelene kakhulu nemishini futhi wandise ama-horizons akho omklamo.

Isikhathi sokuthumela: Dec-06-2022