Shin CNC machining yana da rahusa don hadaddun siffofi Ultimate jagora 2022

A cikin wannan labarin, bisa tushen kayan aikin injiniya, za mu gabatar da abubuwan da ake amfani da su na kayan aiki masu tsada waɗanda masu kera injinan mafari sukan faɗo a ciki.

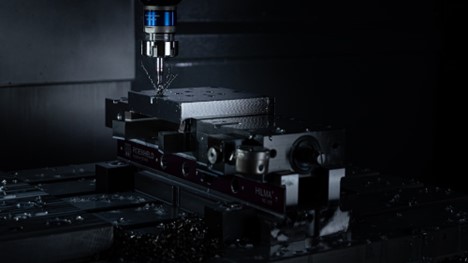

CNC milling Punching

Bari in gaya muku game da bangaren da za ku iya yin abubuwa da rahusa tare da yanke.Lokacin da kake tunanin yin inji, ƙila za ka sami hoton duk ƙaƙƙarfan ɓangarorin inorganic don samfuran masana'antu, amma a zahiri, zaku iya ƙirƙirar siffofi iri-iri, kamar murɗaɗɗen saman.

CNC Machining sassa

A wannan lokacin, za mu gabatar da "siffa masu ban mamaki" daban-daban yayin gabatar da tsarin gane hadaddun siffofi ta hanyar yanke tare da sarrafa kwamfuta na yanzu.

Menene sarrafa NC?

Ko da yake an ambaci shi sau da yawa, yankan wani tsari ne wanda ake danna ruwan wukake mai jujjuya akan abu tare da saiti don goge shi da cire sassan da ba dole ba.

To menene ma'anar "tare da saiti"?

Na bar maganar a bayyane ya zuwa yanzu, amma yana da matukar muhimmanci a yanke, don haka zan yi bayani dalla-dalla.

Bari mu ajiye kayan aikin injin gabaɗaya waɗanda “aka sarrafa su da hannu” kamar masu yankan niƙa na gama-gari na yanzu, kuma muyi magana game da abin da ake kira “aiki ta atomatik” kayan aikin injin NC kamar NC milling cutters da machining.

A cikin irin waɗannan injuna, igiyoyin da suka yanke kayan ana motsa su ta hanyar harshen umarni zuwa na'ura.Lokacin da kuka shigar da umarnin "Matsar da injin ƙarshen zuwa wannan matsayi" cikin injin, injin yana motsawa ta atomatik bisa ga umarnin.Matsayin ƙarshen niƙa yana bayyana ta kowane ƙimar lambobi na X, Y da Z. Machining yana ci gaba ta hanyar motsa waɗannan ƙimar.;a cewar shirin.

Menene NC milling cutter?

Daban-daban nau'in NC milling abun yanka

The "NC" a NC milling abun yanka na tsaye ga "Lambobin Control".“X” ita ce “a kwance alkibla”, “Y” ita ce “alkiblar baya da gaba”, kuma “Z” ita ce “alkiblar tsaye”.Ta ci gaba da shigar da "matsayi na gaba don motsawa", yana yiwuwa a matsar da niƙa ta ƙarshe ta zana santsi mai santsi da hadaddun hanyoyi.

Akasin haka, injin yana aiki ne kawai bisa ga umarnin shigarwa.Siffar ƙarshe ta dogara da shigar da shirin NC.Kafin haɓakar kwamfutoci, da alama an buga shirye-shiryen NC akan kaset na musamman na takarda kuma an wuce ta na'ura don karanta su.Wannan ya zama dalilin da yasa Veteran masu sana'a suna nufin shirye-shiryen NC a matsayin "kasawa."

Shirye-shiryen NC akan kaset na musamman na takarda

A halin yanzu, muna sarrafa shirye-shiryen NC azaman bayanan kwamfuta.Ana adana shirin NC a matsayin bayanai a cikin ƙwaƙwalwar na'ura, kuma yayin karanta shi layi-layi a matsayin umarni, yana aiki bisa ga abubuwan da ke cikin umarnin.

Kanfigareshan Shirin NC

Shirin NC yana da tsari na gama gari don kowane kayan aikin injin."Bangaren da ke sarrafa motsi na na'ura" kamar "G code" ko "M code" wanda ke juya spindle ko canza saurin motsi, da "matsayin niƙa na ƙarshe" kamar yadda haɗin X, Y, Z ke kimanta shi. ya ƙunshi haɗin ɓangaren da ke ba da ƙimar umarni.

Yanke na zamani ta amfani da kwamfutoci: CAD/CAM

Sauƙaƙan shirye-shiryen NC irin su “hana rami kawai” ko “kawai matsar da ruwa a madaidaiciyar layi” ana iya ƙirƙira cikin sauƙi, amma hadaddun shirye-shiryen NC kamar “yanke ƙasa mai lankwasa” na buƙatar kwakwalwar injiniyan.Ya wuce matakin tunani da bugawa da hannu.

Tsarin da ake kira CAD/CAM yana shiga cikin irin wannan yanayi.”CAD/CAM"Shi ne "Kwarewar Taimakon Kwamfuta" da "Kwamfuta Taimakawa Manufacturing", don haka ainihin kalma ce ta "tsara da ƙira ta amfani da kwamfuta".

A halin yanzu, a cikin kunkuntar hankali, CAD yana nufin software da ke ƙirƙirar zane da ƙirar 3D akan kwamfuta, CAM kuma yana nufin software da ke ƙirƙira.NC shirye-shiryeamfani da CAD data.Hatta ƙirƙirar hadaddun shirye-shiryen NC yana buƙatar taimakon kwamfuta.Wasu software suna da duka ayyukan CAD da CAM, kuma akwai kuma software tare da ayyuka masu zaman kansu.

Ƙayyade Dace Tsari don Machining

An rufe CAD daki-daki a kan shafuka daban-daban, don haka a nan zan yi bayani dalla-dalla game da CAM, wanda masu zanen kaya ba su sani ba.A cikin tsarin ƙirƙirar shirin NC ta yin amfani da CAM, ya zama dole don ƙayyade tsarin da ya dace, nau'in niƙa na ƙarshe, da yanayin machining dangane da kayan aiki da siffar kayan aiki, da shigar da su azaman bayanai.

Akwai zaɓuɓɓuka marasa ƙima waɗanda za a iya ɗauka dangane da kaya da siffar kayan, tsarin saiti, da dai sauransu. Wane irin saitunan da za a yi ya dogara ne akan ƙwarewa da ma'anar injiniya.

Misali, akwai hanyoyi da yawa don gyara kayan.Ana iya ƙulla shi tare da madaidaicin vise na inji, kai tsaye gyarawa tare da jig, gyarawa tare da dunƙule, da dai sauransu Akwai zaɓuɓɓuka daban-daban dangane da siffar da tsari.Dole ne a saita shi bisa ga kowane saiti da nau'ikan masana'anta na ƙarshe kuma a canza shi zuwa shirye-shiryen NC.

Aikace-aikacen Ƙarshen Mills a cikin Yanke Filaye masu lanƙwasa

Akwai nau'ikan ƙananan miliyoyin, kamar ƙwallan ƙwallon ƙafa waɗanda suka dace da yankan shimfidar wurare tare da ƙarshen harbin da suka dace da yankan madaidaiciya.

daban-daban na karshen Mills

Kowane nau'i ya kasu kashi daban-daban kamar diamita, adadin ruwan wukake, da tsayin daka mai tasiri.Saita irin hanyar mashin ɗin kuma wane irininjiyanayin da za a yi amfani da shi don kowane injin niƙa.

Ko da masana'antun ƙare ba'a iyakance ga nau'i ɗaya don saiti ɗaya ba.Maimakon haka, ba sabon abu ba ne don amfani da nau'i-nau'i iri-iri.Sannan sigogin da za a saita su zama babba.

Menene yanayin injina don yin sassa masu rikitarwa masu rahusa?

Yanayin injina sun haɗa da adadin jujjuyawar igiya, saurin motsi, da adadin kayan da za a cire.Akwai ingantacciyar haɗuwa dangane da ƙarshen niƙa siffar, abu, da kayan abu.Tambayar ita ce yadda za a sami mafi kyawun haɗin gwiwa, hana lalacewa na ƙarshen niƙa, da rage lokacin mashin ɗin.

Kyakkyawan injiniyan sarrafawa na NC yana ƙirƙirar shirin NC a cikin mafi ƙarancin lokaci mai yuwuwa a ƙarƙashin yanayin yanke da ke haifar da zance.Yayin yin la'akari da yanayin shawarar masana'anta da gogewar da na yi a baya, na saita hoton yanayin sarrafawa a cikin kaina.

Ina tunanin sauti da rawar jiki na sassaƙa a kaina, ina tunanin abubuwa kamar, "Wannan yanayin yana da sauri sosai," ko "Ina mamakin ko zan iya ɗan ƙara zurfi."Daidai ɓangaren ƙwarewa ne.Wannan hadewar matakai da shirye-shiryen NC na iya yanke lokacin injina cikin rabin ko ma kwata.

Kuna iya yin shi!“Siffa mai girma uku ta yankan”

Yanzu, bari mu dubi wasu misalan yadda za a iya amfani da CAD/CAM don ƙirƙirar shirye-shiryen NC wanda ba zai yiwu ba kuma don ƙirƙirar siffofi masu rikitarwa fiye da yadda kuke tsammani.

Wakilin 5-axis machining: impeller

Misali na al'ada na ɓangaren da kawai za a iya samu ta hanyar abin da ake kira na'ura na lokaci guda 5-axis machining shine "impeller" da aka yi amfani da shi a cikin turbochargers.

Ba tare da CAD/CAM ba, shirin NC don yanke sassa masu rikitarwa na wannan impeller ba zai yiwu ba.Domin an siffata shi kamar dunƙulewar da aka yanke.

Za'a iya samun mashin ɗin 5-axis na lokaci ɗaya kawai ta hanyar hadaddun motsi na saman tebur (A-axis, B-axis) wanda aka sanya kayan da ƙarshen niƙa (X, Y, Z) haɗa tare.

Hoton Zamani: 3D Modeling

Muddin kuna da samfurin 3D, zaku iya samar da bayanan NC ta atomatik ta atomatik don yanke siffar tare da CAM.Sabili da haka, yana yiwuwa a gane dukkanin siffofi masu girma uku, ciki har da sassaka kamar mutum-mutumi da siffofi.Tabbas, wajibi ne a yi la'akari da kusurwar R da ƙananan da na gabatar da shi zuwa yanzu.

Ana iya sake fasalin siffar da aminci zuwa ƙirar 3D.Wasu abokan cinikinmu suna tunanin yanke shahararrun haruffa ta hanyar sarrafa su da sayar da su azaman kayan alatu.

Sanya aikin yankan ya zama sananne!

Abubuwan da aka yi amfani da su sun zo da nau'i-nau'i iri-iri dangane da aikace-aikacen, amma ko ta yaya siffar za ta kasance mai rikitarwa, ana iya sarrafa ta idan dai an kula da kusurwar R da ƙasa.

Kuna iya tunanin cewa simintin gyare-gyare ita ce hanya mafi kyau don samar da tsari mai rikitarwa, amma akwai fa'idodi da yawa ga injina.Porosity, wanda ya zama matsala a cikin simintin gyare-gyare, ana iya kauce masa, kuma tun da ba a buƙatar yin gyare-gyare, za a iya rage farashin farko, kuma za a iya taƙaita bayarwa.

Takaitawa

Zan yi farin ciki idan za ku iya ci gaba da yin amfani da yankan a hankali har ma da sassan da aka sarrafa da yawa.Jimlar farashin yana da ƙarancin mamaki, kuma akwai kuma fa'idar samun damar amsawa a sassauƙa don ƙira canje-canje.

Muna fatan wannan labarin zai taimaka muku don ƙarin masaniya game da mashin ɗin kuma don faɗaɗa hangen nesa na ƙirar ku.

Lokacin aikawa: Dec-06-2022