Ko CNC machining inochipa kune yakaoma maumbirwo Ultimate gwara 2022

Muchinyorwa chino, zvichibva pane izvo zvekutanga zvemachining, isu tichasuma mapoinzi ezvinodhura-anoshanda makina zvikamu izvo zvinotanga magadzirirwo emagetsi anowanzo kuwira mazviri.

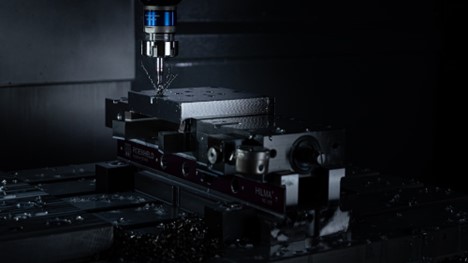

CNC kugaya Punching

Rega ndikuudze nezve chikamu chaunogona kuita zvinhu zvakachipa nekucheka.Paunofunga nezvekugadzira, unogona kunge uine mufananidzo wezvese zvakakasharara, inorganic zvikamu zvezvigadzirwa zvemaindasitiri, asi kutaura zvazviri, unogona kugadzira akasiyana maumbirwo, sekumonyorora nzvimbo dzakakombama.

CNC Machining zvikamu

Panguva ino, isu tichaunza akasiyana "anoshamisa maumbirwo" tichiunza maitiro ekuona maumbirwo akaomarara nekucheka neazvino kudzora komputa.

Chii chinonzi NC processing?

Kunyangwe zvave zvichitaurwa kakawanda, kucheka inzira iyo blade inotenderera inotsikirirwa pane chinhu chiri munzira yakatarwa kuti ichikwekwe uye kubvisa zvisingakoshi.

Saka zvinorevei "pamwe negwara rakaiswa"?

Ndasiya kutaura kusinganzwisisike kusvika pari zvino, asi chikamu chakakosha chekucheka, saka ini ndichatsanangura mune zvishoma zvakadzama.

Ngatiise parutivi maturusi emuchina wechinangwa “anoshandirwa nemaoko” semacheki ezvina-chinangwa panguva ino, totaura nezvezvinonzi “zvinoitwa otomatiki” NC muchina maturusi akadai seNC milling cutter nenzvimbo dzemachining.

Mumichina yakadai, mablades anocheka zvinhu anofambiswa nemutauro wekuraira kumuchina.Paunoisa murairo wekuti "Fambisa chigayo kunzvimbo iyi" mumushini, muchina unongofamba zvinoenderana nekuraira.Nzvimbo yechigayo chekupedzisira inoratidzwa nehuwandu hwehuwandu hwe X, Y uye Z. Machining anoenderera mberi nekufambisa izvi zvakakosha..maererano nepurogiramu.

Chii chinonzi NC milling cutter?

Yakasiyana mhando yeNC milling cutter

Iyo "NC" muNC milling cutter inomiririra "Numerical Control".”X” i“gwara rakachinjika”, “Y” ndiyo “nzira yekumashure neshure”, uye “Z” ndiyo “yakatwasuka”.Nekuenderera mberi nekuisa "inotevera chinzvimbo chekufamba", zvinokwanisika kufambisa chigayo nekudhirowa akatsetseka macurves uye yakaoma trajectories.

Sezvineiwo, muchina unoshanda chete zvinoenderana nemirairo yekupinza.Chimiro chekupedzisira chinoenderana neiyo NC chirongwa.Pamberi pekugadzirwa kwemakomputa, zvinoita sekunge zvirongwa zveNC zvakadhindwa pamatepi epepa akakosha uye akapfuura nemuchina kuti averenge.Izvi zvinoita kunge ndicho chikonzero nei veteran veteran vachidaidza zvirongwa zveNC se "matepi."

NC zvirongwa pamapepa akakosha matepi

Parizvino, isu tinobata zvirongwa zveNC sedata rekombuta.Iyo NC chirongwa chinochengetwa se data mundangariro yemuchina, uye uchiiverenga mutsara nemutsetse semirayiridzo, inoshanda zvinoenderana nezviri mukati memirairo.

Iyo Configuration yeNC Chirongwa

Chirongwa cheNC chine chimiro chakajairwa kune chero chishandiso chemuchina."Chikamu chinodzora kufamba kwemuchina" senge "G kodhi" kana "M kodhi" inotenderedza spindle kana kushandura kumhanya kwekufamba, uye "yekupedzisira mill tip chinzvimbo" seiyo X, Y, Z inoronga kukosha kwayo. ine musanganiswa wechikamu chinopa kukosha kwekuraira.

Kucheka kwemazuva ano uchishandisa makomputa: CAD/CAM

Zvirongwa zveNC zvakapfava senge "kungoboora gomba" kana "kungofambisa blade mumutsara wakatwasuka" zvinogona kugadzirwa zviri nyore, asi zvirongwa zvakaoma zveNC zvakaita se "kucheka nzvimbo yakakombama" inoda huropi hweinjiniya.Zvinopfuura mwero wekufunga uye kutaipa nemaoko.

Iyo inodaidzwa kuti CAD/CAM system inouya mukutamba mumamiriro ezvinhu akadaro.”CAD/CAM” ndiyo “Computer Aided Design” uye “Computer Aided Manufacturing”, saka chaizvo ishoko rekuti “kugadzira nekugadzira uchishandisa makomputa”.

Parizvino, mupfungwa yakamanikana, CAD inoreva software inogadzira mifananidzo uye 3D modhi pakombuta, uye CAM inoreva software inogadzira.NC zvirongwauchishandisa CAD data.Kunyangwe kugadzira zvirongwa zveNC zvakaoma zvinoda rubatsiro rwekombuta.Imwe software ine zvese CAD uye CAM mabasa, uye kune zvakare software ine yakazvimirira mabasa.

Sarudza Iyo Yakakodzera Maitiro eMachining

CAD yakafukidzwa zvakadzama panzvimbo dzakasiyana-siyana, saka pano ini ndichatsanangura mune zvishoma zvakadzama nezveCAM, izvo vagadziri vasingawanzo kuziva.Mune iyo NC chirongwa chekugadzira chirongwa uchishandisa CAM, zvinodikanwa kuti uone maitiro akakodzera, rudzi rwechigayo chekupedzisira, uye machining mamiriro anoenderana nezvinhu uye chimiro cheiyo workpiece, uye kuipinza seruzivo.

Pane zvisingaverengeki zvingasarudzwa zvinogona kutorwa zvichienderana nezvinhu uye chimiro chezvinyorwa, kurongeka kwekugadzirisa, nezvimwewo. Ndeupi rudzi rwezvigadziriso zvekugadzira zvinoenderana zvakanyanya neruzivo uye pfungwa yeinjiniya.

Semuenzaniso, kune nzira dzakawanda dzekugadzirisa zvinhu.Inogona kusungirirwa ne-precision mechanical vise, yakanyatsogadziriswa nejig, yakagadziriswa ne screw, etc. Pane zvingasarudzwa zvakasiyana-siyana zvichienderana nechimiro uye maitiro.Inofanirwa kusetwa zvinoenderana nesetups uye marudzi ekupedzisira mill uye kuchinjirwa kune NC zvirongwa.

Kushandiswa kweEnd Mills mukucheka Curved Surfaces

Kune marudzi akasiyana-siyana emaguyo ekupedzisira, akadai semabhora ekupedzisira akakodzera kucheka nzvimbo dzakakomberedzwa dzine migumo yakatenderedzwa, flat end mill inokodzera kucheka yakatwasuka nzvimbo dzakati sandarara, uye madhiri ekuchera makomba.

marudzi akasiyana-siyana ekupedzisira zvigayo

Rudzi rwega rwega rwakakamurwa kuita maumbirwo akasiyana senge dhayamita, nhamba yemashizha, uye kureba kunoshanda kwebanga.Isa rudzi rwemachining nzira uye rudzii rweMachiningmamiriro ekushandisa kune imwe neimwe yekupedzisira mill.

Kunyangwe zvigayo zvekupedzisira hazvina kuganhurirwa kune imwe mhando yekuseta imwe.Asi, hazvina kujairika kushandisa akawanda emhando.Zvadaro parameters kugadzika kuva hombe.

Ndeapi mamichina mamiriro ekugadzira zvikamu zvakachipa zvakaoma?

Machining mamiriro anosanganisira kuwanda kwekutenderera kweiyo spindle, kumhanya kwekufamba, uye huwandu hwezvinhu zvinobviswa.Iko kune yakaringana musanganiswa zvichienderana nemagumo egayo chimiro, zvinhu, uye zvinhu zvezvinhu.Mubvunzo ndewokuti ungawana sei musanganiswa wakanyanya, kudzivirira kupera kweguyo rekupedzisira, uye kupfupisa nguva yekugadzira.

Yakanakisa NC yekugadzirisa mainjiniya inogadzira chirongwa cheNC munguva ipfupi inokwanisika pasi pemamiriro ekucheka anokonzera kutaura.Ndichiri kufunga mamiriro akakurudzirwa emugadziri weblade uye ruzivo rwangu rwekare, ndinoisa mufananidzo wemamiriro ekugadzirisa mumusoro mangu.

Ndichifungidzira manzwi uye kudedera kwekuveza mumusoro mangu, ndinofungidzira zvinhu zvakaita sekuti, “Chimiro ichi chakanyanya kukurumidza,” kana kuti “Ndinoshamisika kana ndichigona kucheka zvakadzika zvishoma.”Icho chikamu chaicho chehunyanzvi.Uku kusanganiswa kwemaitiro uye NC zvirongwa zvinogona kucheka machining nguva muhafu kana kunyange kota.

Unogona kuzviita!"Matatu-dimensional chimiro nekucheka"

Zvino, ngatitarisei mimwe mienzaniso yekuti CAD/CAM ingashandiswa sei kugadzira zvirongwa zveNC zvaisazogoneka uye kugadzira zvimiro zvakaoma kupfuura zvaungafungidzira.

Mumiriri we5-axis machining: impeller

Muenzaniso wakajairika wechikamu chinogona kuwanikwa chete neinonzi panguva imwe chete 5-axis machining ndiyo "impeller" inoshandiswa mumotokari turbocharger.

Pasina CAD/CAM, chirongwa cheNC chekucheka zvikamu zvakaoma zveiyi impeller hazvigoneke.Imhaka yekuti yakaumbwa sebundu rezasi.

Panguva imwe chete 5-axis machining inogona kuwanikwa chete nekufamba kwakaoma kwetafura yepamusoro (A-axis, B-axis) iyo inoiswa zvinhu uye zvigayo zvekupedzisira (X, Y, Z) zvakabatanidzwa pamwe chete.

Contemporary Sculpture: 3D Modelling

Chero bedzi iwe uine 3D modhi, unogona semi-otomatiki kugadzira NC data yekucheka chimiro neCAM.Naizvozvo, zvinokwanisika kuona ese matatu-dimensional maumbirwo, kusanganisira zvivezwa zvakaita sezviumbwa nenhamba.Ehe, zvinodikanwa kuti utarise kona R uye undercut yandaunza kusvika zvino.

Chimiro chinogona kudzokororwa zvakatendeka kune iyo 3D modhi.Vamwe vevatengi vedu vari kufunga kucheka mavara ane mukurumbira nekugadzira uye kuvatengesa sezvinhu zvemhando yepamusoro.

Ita kuti basa rekucheka rizivikanwe!

Zvikamu zvemuchina zvinouya mumhando dzakasiyana zvichienderana nekushandiswa, asi zvisinei kuti chimiro chingave chakaoma sei, chinogona kugadzirwa chero kona R uye undercut ichitarisirwa.

Iwe unogona kufunga kuti kukanda ndiyo nzira yakanakisa yekumisa-kuburitsa chimiro chakaomarara, asi kune akawanda mabhenefiti ekugadzira.Porosity, iyo inowanzova dambudziko mukukanda, inogona kudziviswa, uye sezvo pasina chikonzero chekugadzira molds, mari yekutanga inogona kuderedzwa, uye kutumira kunogona kupfupiswa.

Summary

Ndingafara kana iwe ukagona kuchengeta kushandiswa kwekucheka mupfungwa kunyangwe kune akawanda-akagadzirwa zvikamu zvakagadziriswa.Mari yose inoshamisa yakaderera, uye kunewo mukana wekukwanisa kupindura nekugadzirisa kuchinja kwekugadzira.

Tinovimba kuti chinyorwa ichi chichakubatsira iwe kuti unzwe kujairana nemachining uye kuwedzera dhizaini yako horizons.

Nguva yekutumira: Zvita-06-2022