Ukubuyekezwa Kafushane Kokuklama Kokucwila Kokushisa Nokukhiqiza

Isibuyekezo sokugcina: 09/01;Isikhathi sokufunda: 6 imiz

Usinki oshisayo

I-heat sink iyisisetshenziswa se-thermodynamic esisusa ukushisa kumasistimu emishini, kagesi, nawe-elekthronikhi.Emishinini nasemishinini ehlukahlukene, kubalulekile ukugcina izinga lokushisa ngaphakathi komkhawulo othile ukuze kugcinwe ukusebenza kwaleyo divayisi noma umshini.Lapha kudlala indima yama-heat-sink.Isibonelo, imishini emikhulu ye-laptop yakho ezimbonini ezahlukene idinga ukuqeda ukushisa kwayo.Ngakho cabanga ukuthi isetshenziswa kabanzi kangakanani ezweni lanamuhla lobuchwepheshe.Osinki okushisa bachitha ukushisa ngokukudlulisela endaweni elawulwayo, efana nomoya noma uketshezi, bese kukhishwa ku-apparatus nendawo yokudlulisa.

Lesi sihloko sizodlula kafushaneukusebenza komshini wokushisa, izinyathelo zokuklama, nezindlela zokukhiqiza.

Ukusebenza kwe-Heat Sink

Umthetho we-Fourier wokudlulisa ukushisa, othi ukushisa kuhlale kugeleza kusuka kumazinga okushisa aphezulu kuya endaweni enezinga lokushisa eliphansi, unikeza isisekelo sendlela isinki sokushisa esisebenza ngayo.Nakuba izinto ezisetshenziswayo zikhiqiza ukushisa, okushisa kunomoya noma uketshezi oluzungezile, zidlulisela lokho kushisa ngokuhambisa, ukugudluza, noma ngezikhathi ezithile ngemisebe endaweni epholile.

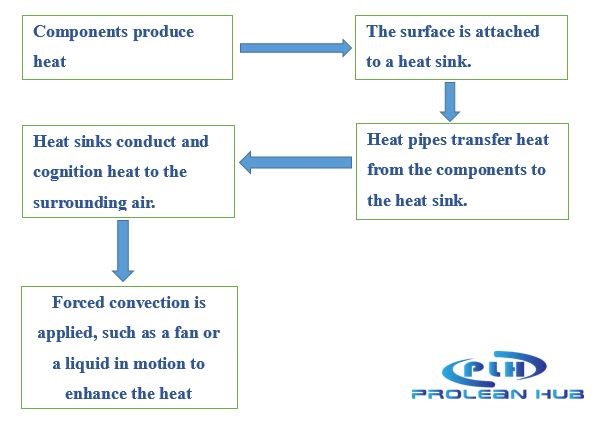

Ake sibheke ku-flow-chart ngezansi ukuze uthole isithombe esicacile sokusebenza kukasinki wokushisa;

Ishadi eligelezayo lokusebenza kosinki wokushisa

· Amasinki okushisa angashintshi

Amasinki okushisa angashintshi ngokwemvelo adlulisela ukushisa okumuncwe emoyeni okuzungezile ngaphandle kokuguqulwa kwamandla, okufana nefeni noma ukuzungeza kwamanzi eduze kwawo.Ngokuvamile lezi zinkulu ngokwakheka futhi ziqukethe i-fin array evezwe endaweni engaphandle.

· Isinki sokushisa esisebenzayo

I-sink yokushisa esebenzayo iqukethe ifeni eyengeziwe noma i-blower kanye noketshezi olusethiwe ukuze kususwe ukushisa ngaphandle kwendlela yemvelo.Lokhu kusetha okungeziwe kukhulisa inqubo yokukhipha ukushisa ngenqubo yokuhambisa ngempoqo.Isibonelo, uma ifeni isebenza, inyusa isivinini somoya futhi idlulise ngokushesha ukushisa ukusuka kusinki wokushisa iye endaweni ezungezile.

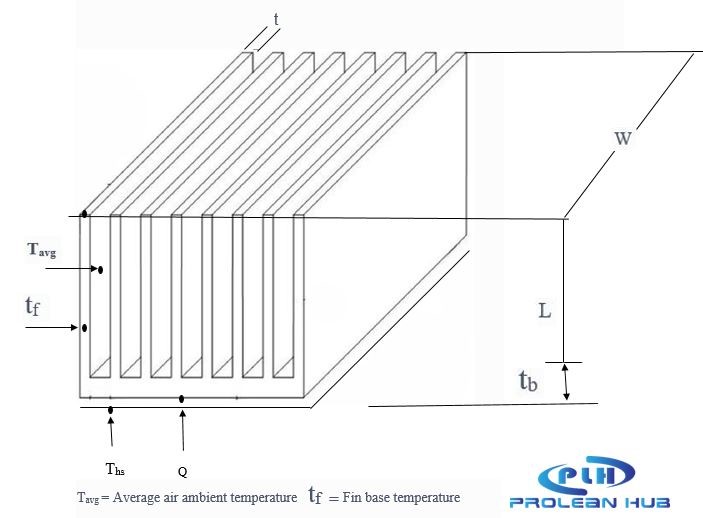

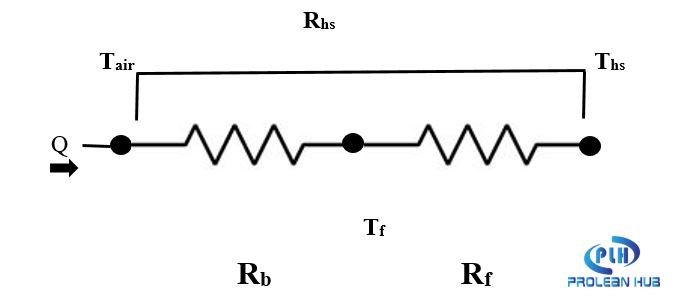

Ukubalwa kokumelana nokushisa

Ngesikhathi sokuklanywa kosinki wokushisa, ukubalwa kokumelana nengqikithi yokushisa (Rhs) idlala indima ebalulekile ekuqondeni ukusebenza okunamandla nokusebenza kahle, ngakho-ke ake sibone ukuthi ingabalwa kanjani;

Rhs= (Tj-Ta/P) - (Rth-jc) - RI

P= Ukushisa okuchithiwe okuphelele

TI= Izinga lokushisa eliphezulu le-junction ledivayisi ku-0C.

Rth-jc= I-Junction to case ukumelana nokushisa

Ta= Izinga lokushisa lomoya elizungezile0C.

RI= Ukumelana ne-interface material

RI= (t/L x W x KI)

t = ukujiya kwezinto ezibonakalayo

KI=I-thermal conductivity ye-interface material

L = Ubude bomthombo wokushisa

W =Ububanzi bomthombo wokushisa

Idizayini yeSinki Yokushisa

Kunezinyathelo ezimbalwa zokuklama.Ake sibheke ngayinye yazo kafushane.

1. Ukukhethwa kwempahla

I-Thermal conductivity ingenye yezici ezibalulekile zezinto zokucwilisa ukushisa ngoba ivumela ukudluliswa kokushisa okuphuthumayo kusuka engxenyeni yedivayisi eshisayo kuya kusinki nendawo ezungezile.

Izinto ezimbili eziyinhloko ezisetshenziselwa ukwenza amasinki okushisa ama-alloys ethusi ne-aluminium.Lokhu kungenxa yokuthi anezimfanelo ezinhle kakhulu zomshini njengamandla, ukumelana nokugqwala, ukuqina, kanye nokushisa okuphezulu.Nokho, nakuba libiza kakhulu, idayimane (2,000 W/m/k) lingaba into efanelekile yamasinki okushisa kumadivayisi kagesi asebenza kahle futhi anembayo.

Ngaphezu kwezingxenye ze-electronics, amabhethri e-lithium-ion akhiqiza ukuchithwa kokushisa kuyadingeka.Esimeni esinjalo, ithusi noma i-aluminiyamu ingase ingabi yizinto ezisetshenziswa kahle zikasinki wokushisa.

Isixazululo semboni yezimoto sokulawula ukushisa siyinto enhle kakhulu ye-carbon fiber conductivity.

2. Ukuhlelwa kwe-Fins & airflow

Esinye isici esithinta ukusebenza kukasinki wokushisa indawo epholile, ethinta kakhulu izinga lokukhipha ukushisa.Ngakho-ke, lapho wakha i-sink yokushisa, ukuma, ubukhulu, nokuhlelwa kwe-fin yizici ezibalulekile okufanele zicatshangelwe.Ukusebenzisa indlela yokwenza kahle ipharamitha kuyinketho engcono kakhulu yokuthola amanani epharamitha afanelekile ukuze afane nemikhawulo eshiwo futhi ufinyelele imigomo yokuklama.

- Thuthukisa isikhala phakathi kwama-fins ukuze uthuthukise ukugeleza komoya futhi unciphise ukumelana nokushisa.

- Ngenxa yokuthi indawo enkulu engaphezulu inyusa ukuhanjiswa kanye nokudlulisa ukushisa kwe-convection, isiza ekulahlekeni kokushisa, cabanga ukwandisa ukujiya nokuphakama.

- Dala isendlalelo somngcele oshisayo omncane, futhi isiqondisindlela sokugeleza komoya saklanywa nge-engeli efanelekile ene-sink yokushisa ukuze kwandiswe ukusebenza kahle kwe-fin.

- Ngemva kokulungisa idizayini yamaphiko nge-CAD, ungakwazi ukulingisa isimo sokudlulisa ukushisa ukuze uthuthukise ukusebenza kahle kwayo.

3. Okunamathiselwe kwe-heat-sink

Indlela usinki oxhunywe ngayo ezintweni zokushisisa zedivayisi iphinde ibe nomthelela ekutheni isebenza kahle kanjani.Khetha indlela engcono kakhulu yokuxhuma ekhuphula izinga lokudlulisa ukushisa kusuka kuma-spacers amile, iziqeshana zentwasahlobo eziyisicaba, i-epoxy, nezinketho zetheyiphu eshisayo.

4. Isixhumi esibonakalayo esishisayo

Amaphutha kanye nokuqina okungaphezulu kwe-sink yokushisa kudlala indima ekwandiseni ukumelana nokushisa ngenxa yokuncipha kwendawo yokuthintana nokushisa kanye nengcindezi yesixhumi esibonakalayo.Ukuze unqobe lolu daba, izinto ezisetshenziswayo ezishisayo ziyisinqumo esingcono kakhulu.Ukusebenzisa ama-polymers awuketshezi, i-wax, i-aluminium, i-graphite, namateyipu ebusweni besinki sokushisa kanye nesici sokushisa samadivayisi kwehlisa ukumelana nokushisa.

5. Ukulingisa

Ukulingisa Kwedizayini kubalulekile ukubona ukusebenza kwe-heat-sink cishe.I-Computer Simulation inikeza umbono wokuthuthukiswa futhi iqinisekisa Idizayini ukuthi ilungele izinhlelo zokusebenza ezidingekayo noma cha.

Inqubo Yokukhiqiza Ye-Heat Sink

Ngemva kokulingisa ngendlela eshisayo Idizayini yamasinki okushisa, manje isiguqulelwe ukukhiqizwa.Ake sibone inqubo yokukhiqiza ehlukahlukene ngokuningiliziwe;

1. I-CNC-Machining

Usinki wokushisa owenziwe ngemishini ye-CNC

CNC imishiniiyindlela engcono kakhulu yokwenziwa kosinki wokushisa kumajamo ayinkimbinkimbi.Le ndlela inikeza ukuguquguquka okuningi kubaklami.Ibhulokhi yonke yensimbi isetshenziselwa ukwakha usinki lapho amaphiko adingekayo asikwa ngemishini ye-CNC futhi agotshwe kusukela phansi kwebhulokhi.Nokho, kuyindlela edla isikhathi futhi ebiza kakhulu.

2. I-Extrusion

Enye yezinqubo ezivame kakhulu zokukhiqiza amasinki okushisa iwukubai-extrusion, okubandakanya ukucindezela amabhilidi ashisayo ento edonsayo ensimbini enamandla amakhulu ukuze kudaleke amaphiko epuleti.Asetshenziselwa izinhlelo eziningi zokupholisa ezibandakanya osinki bokushisa be-aluminium.Vele, i-aluminium iyinto esetshenziswa kakhulu ekukhiqizeni usinki wokushisa.

Usinki wokushisa owenziwe nge-Extrusion

Kuyinqubo engabizi futhi eqondile.Amasinki okushisa angasetshenziswa ezindaweni ezihlukahlukene zokusebenza.Nokho, ngenxa yomkhawulo omkhulu wobubanzi be-extrusion, ayikwazi ukusetshenziswa namasinki okushisa anamaphiko abanzi.

3. Iyasakaza

Usinki wokushisa owenziwe nge-Casting

Kweukuphonsai-heat-sink,i-aluminium, ithusi, noma i-zinc yizinto ezivamile.Kule nqubo, ama-ingots ezinto ezikhethiwe aqale ancibilikiswe futhi ajovwe ku-die of the heat-sink ngokucindezela okuthile.Ngemuva kokuthi uketshezi olujovwe luqiniswe ku-die, luyakhululwa, bese kwenziwa ukucutshungulwa okuncane ukuze kuqedwe noma yikuphi ukungapheleli okungaphezulu.Kungcono kakhulu ukuthola izimo eziyinkimbinkimbi ngezinga eliphezulu lokunemba.

4. Ukuganga okubandayo

Usinki wokushisa owenziwe nge-forging ebandayo

Kungenye indlela yokukhiqiza enembayo ephezulu yamasinki okushisa afanele i-aluminium nama-alloys ayo.Nakuba, iyasebenza nasethusini nasethusini.Ukubumba okubandayo kusebenzisa ukucindezela okukhulu futhi kulimaze ukwakheka kwensimbi kuzinga lokushisa legumbi ukuze kwakhe izikhonkwane eziyindingilizi neziyibhilibhili zosinki wokushisa.Ngaphezu kwalokho, isetshenziselwa ukukhiqiza amaphiko ngobuningi obukhulu, okuzothuthukisa ukudluliswa kokushisa ezimweni zokugeleza komoya ngesivinini esikhulu.

5. Ukuphrinta kwe-3D

I-Heat Sink ephrintiwe ye-3D

Ukuthuthukiswa kokuphrinta kwe-3D njengendlela yokukhiqiza amasinki okushisa kubangelwa ukuqhubeka kwezobuchwepheshe.Ukuhlanganiswa kombhede wempuphu kanye nobuchwepheshe bokufakwa kwamandla okuqondisiwe izindlela ezimbili ezidume kakhulu ekuphrinteni osinki bokushisa.

6. Ukugxiviza

Usinki wokushisa owenziwe nge-Stamping ebandayo

Iukunyathelaindlela isetshenziswa lapho kudingekile ukwakha amapayipi okushisa ngaphakathi kwamaphiko.Khona-ke, ngokucindezela amapheshana ensimbi, amaphiko akhiqizwa.Ezimweni lapho kusetshenziswa ubuchwepheshe bokugxiviza ngesivinini esikhulu, busebenza kahle kakhulu ekukhiqizeni abantu abaningi.Noma kunjalo, intengo iphezulu.

Isiphetho

Osinki bokushisa babalulekile emishinini, kagesi, nekagesi.Kulesi sihloko, ngibukeze inqubo enemininingwane yokuklama kanye nokukhiqiza okugxile kumishini kagesi.Idizayini yamasinki okushisa ithonya kakhulu izinga lokulahla ukushisa, ngakho-ke isinyathelo ngasinye sedizayini sibalulekile ukuthi silandelwe ukuze kuthuthukiswe ukusebenza.Ngaphezu kwalokho, Ukulingisa okushisayo ngemva kokuklama kusiza ukuqonda isimo sokusebenza esisebenzayo futhi kuthuthukise Idizayini.

Lapha e-ProleanHub, sinabaklami abanolwazi olungaphezu kweminyaka eyishumi namayunithi okukhiqiza athuthukile.Sihlinzeka ngezinsizakalo zokuklama nokukhiqiza kosinki wokushisa osezingeni eliphezulu.Ngaphezu kwalokho, onjiniyela bethu bemishini balingisa Idizayini ukuze bathuthukise ukusebenza nokusebenza.Okokugcina, umnyango wethu wokulawula ikhwalithi uqapha isinyathelo ngasinye sokukhiqiza, ukuze ungafaki engozini ikhwalithi yethu yesevisi, uma udinga ukukhiqizwa kukasinki wokushisa, njeXhumana nathi.

Imibuzo Evame Ukubuzwa

Ngingakuthuthukisa kanjani ukusebenza kahle kwamasinki okushisa?

Ukusebenza kahle kunganyuswa ngezindlela ezimbalwa, okuhlanganisa ukwehlisa ukumelana nokushisa, ukwenza kahle usayizi we-fin, umumo, nokuhlelwa, nokuthuthukisa isixhumi esibonakalayo se-fin.

Iyiphi impahla engcono kakhulu yamasinki okushisa?

Izinto ezingcono kakhulu zamasinki okushisa ama-alloys ethusi ne-aluminium.Kodwa-ke, futhi, izinga lokudlulisa ukushisa lincike Kumklamo we-sink yokushisa.

Isebenza kanjani i-heat sink?

Osinki bokushisa benziwa ngezinto ezisezingeni eliphezulu ze-thermal conductivity njengethusi ne-aluminium enamaphiko.Inamathela ezingxenyeni ezishisayo futhi ibambe ukushisa.Bese ukushisa okumuncwe kuyahlakazeka endaweni ezungezile ngokusebenzisa i-conduction, convection, noma imisebe.

Yiziphi izinyathelo zedizayini zamasinki okushisa?

Nazi izinyathelo;

- Ukukhethwa kwempahla

- ukulungiswa komumo, usayizi, nokuhlelwa kwamaphiko

- Ukulungiswa kokunamathiselwe (i-heat sink nengxenye yedivayisi)

- I-Thermal Interfacing of fins

- Ukulingisa okushisayo kwedizayini ye-CAD

Yiziphi izindlela ezijwayelekile zokukhiqiza isinki lokushisa?

I-CNC machining, casting, forging, Stamping, kanye nokuphrinta kwe-3D kuyizindlela ezivamile.

Isikhathi sokuthumela: Jul-15-2022