Taƙaitaccen Bita akan Ƙirƙirar Ƙira da Ƙirƙirar Zafi

Ƙarshe na ƙarshe: 09/01;Lokacin karantawa: Minti 6

Tushen zafi

Tushen zafi shine na'urar thermodynamic da ke cire zafi daga na'urorin inji, lantarki, da na lantarki.A cikin na'urori da injuna daban-daban, yana da mahimmanci a kiyaye kewayon zafin jiki a cikin ƙayyadaddun iyaka don kula da aikin na'urar ko injin.Anan rawar zafin zafi ya shiga cikin wasa.Misali, injunan kwamfutar tafi-da-gidanka masu nauyi a masana'antu daban-daban na buƙatar kawar da zafinsa.Don haka ka yi tunanin yadda ake amfani da shi sosai a duniyar fasaha ta yau.Ruwan zafi yana zubar da zafi ta hanyar tura shi zuwa matsakaicin tsari, kamar iska ko ruwa, sannan a fitar da shi daga na'urar da matsakaicin canja wuri.

Wannan labarin zai taƙaice shiga cikinyin aiki na dumama zafi, matakan ƙira, da hanyoyin masana'antu.

Aiki na Heat Sink

Dokar Fourier na canja wurin zafi, wadda ta bayyana cewa zafi koyaushe yana gudana daga babban zafin jiki zuwa matsakaicin matsakaici, yana ba da tushe ga yadda zafin rana ke aiki.Yayin da na'urori ke samar da zafi, wanda ya fi zafi da ke kewaye da iska ko ruwa, suna canja wurin zafin ta hanyar gudanarwa, convection, ko radiation lokaci-lokaci zuwa lamba mai sanyaya.

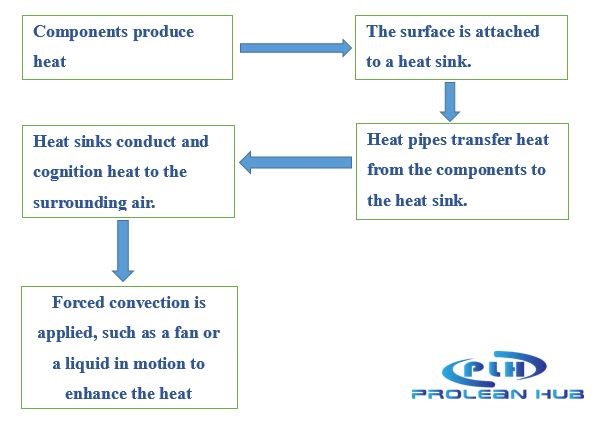

Bari mu dubi jadawalin-ruwa da ke ƙasa don bayyananniyar hoto mai aiki da zafin rana;

Jadawalin yawo don aiki na dumama zafi

· Ƙunƙarar zafi mai wucewa

Zafin da ke nutsewa ta dabi'a yana jujjuya zafin da aka ɗauka zuwa iskar yanayi ba tare da jujjuyawar ƙarfi ba, kamar fanko ko kewayawar ruwa a kusa da su.Waɗannan yawanci manyan sifi ne kuma suna ƙunshe da tsarar fin da aka fallasa ga muhallin waje.

· Rage zafi mai aiki

Ƙunƙarar zafi mai aiki ya ƙunshi ƙarin fanko ko busawa da ruwa da aka saita don cire zafi ban da tsarin yanayi.Wannan ƙarin saitin yana ƙãra tsarin zubar da zafi ta hanyar tilasta convection tsari.Misali, lokacin da fanka ke aiki, yana ƙara saurin iskar kuma da sauri yana canja wurin zafi daga ma'aunin zafi zuwa yanayin da ke kewaye.

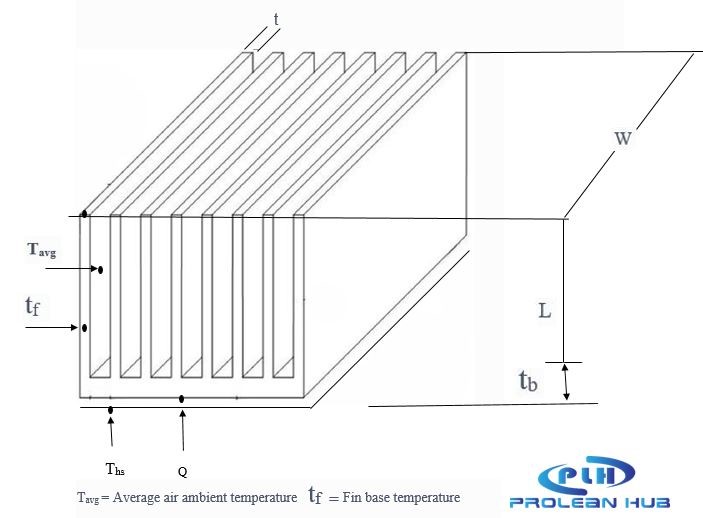

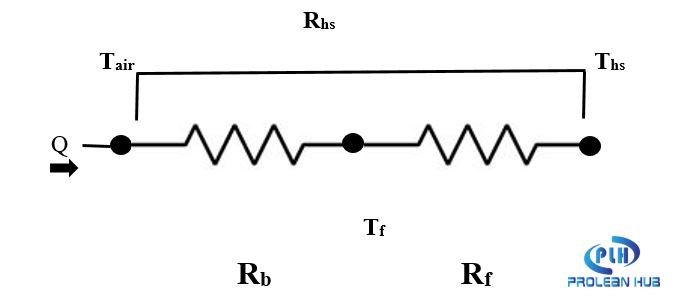

Lissafin juriya na thermal

A lokacin Zane-zanen ramin zafi, lissafin jimlar juriyar thermal (Rhs) yana taka muhimmiyar rawa wajen fahimtar iya aiki da inganci, don haka bari mu ga yadda za a iya ƙididdige shi;

Rhs= (Tj-Ta/P) - (Rda jc) – RI

P= Jimlar zafi da aka watsar

TI= Matsakaicin zafin mahaɗin na'urar a 0C.

Rda jc= Junction zuwa yanayin juriya na thermal

Ta= Yanayin yanayin yanayi a0C.

RI= Juriya na kayan aiki

RI= (t/L x W x KI)

t = kauri na kayan aiki

KI=Thermal conductivity na dubawa abu

L = Tsawon tushen zafi

W = Nisa daga tushen zafi

Zane na Zafin Zurfin

Akwai matakai da yawa wajen tsarawa.Bari mu kalli kowannensu a takaice.

1. Zaɓin kayan aiki

Ƙarƙashin zafi yana ɗaya daga cikin mahimman halaye na kayan aikin zafi saboda yana ba da damar saurin watsa zafi daga na'urar mai zafi zuwa nutsewa da muhalli.

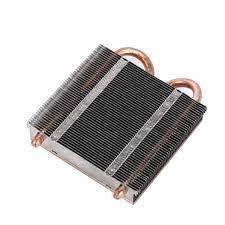

Kayayyakin farko guda biyu da ake amfani da su don yin ɗumbin zafin rana sune tagulla da aluminium.Wannan shi ne saboda suna da kyawawan halaye na inji kamar ƙarfi, juriya na lalata, karko, da haɓakar zafi mai girma.Duk da haka, ko da yake yana da kyawawan farashi, lu'u-lu'u (2,000 W / m / k) na iya zama kayan aiki mai kyau don zubar da zafi a cikin manyan ayyuka da madaidaicin na'urorin lantarki.

Baya ga sassan kayan lantarki, batir lithium-ion suna haifar da zubar da zafi ya zama dole.A irin wannan yanayi, jan ƙarfe ko aluminium bazai zama mafi kyawun kayan da za a iya amfani da su don nutsewar zafi ba.

Maganin masana'antar kera motoci don sarrafa zafi shine mafi kyawun abin da zai iya ɗaukar nauyin fiber carbon.

2. Shirye-shiryen Fins & iska

Wani abin da ke shafar aikin ɗumbin zafin rana shine matsakaicin sanyaya, wanda ke yin tasiri sosai akan ƙimar zafi.Sabili da haka, lokacin da ake gina magudanar zafi, siffar, girman, da tsarin fin sune muhimman abubuwan da za a yi la'akari da su.Yin amfani da dabarar inganta ma'auni shine mafi kyawun zaɓi don nemo madaidaitan ma'auni don dacewa da ƙuntatawa da aka bayyana da cimma burin ƙira.

- Haɓaka sarari tsakanin fins don haɓaka iska da rage juriya na zafi.

- Saboda babban yanki mai girma yana ƙara ƙaddamarwa da canja wurin zafi, yana taimakawa wajen zubar da zafi, la'akari da ƙara kauri da tsayi.

- Ƙirƙirar ƙaramin iyakar zafin jiki, kuma an ƙera hanyar tafiyar iska a madaidaicin kusurwa tare da nutsewar zafi don ƙara ingantaccen aiki.

- Bayan shirya ƙirar fins tare da CAD, zaku iya kwaikwayi yanayin canja wurin zafi don haɓaka ingancinsa.

3. Haɗe-haɗe-haɗe-haɗe

Yadda aka haɗa na'urar ta nutse da na'urar dumama na'urar shima yana shafar yadda yake aiki sosai.Zaɓi mafi kyawun hanyar haɗawa wanda ke haɓaka ƙimar watsa zafi daga masu ba da sarari, shirye-shiryen bazara mai lebur, epoxy, da zaɓuɓɓukan tef ɗin zafi.

4. Thermal dubawa

Rashin lahani da rashin ƙarfi na yanayin zafi suna taka rawa wajen haɓaka juriya na thermal saboda raguwar wurin hulɗar thermal da matsa lamba.Don shawo kan wannan batu, kayan aikin thermal interface shine mafi kyawun zaɓi.Yin amfani da polymers na ruwa, kakin zuma, aluminum, graphite, da kaset a saman ramin zafi da dumama na'urori suna rage juriya na thermal.

5. Kwaikwayo

Kwaikwayo na Zane yana da mahimmanci don ganin aikin dumbin zafin jiki kusan.Kwamfuta Kwamfuta yana ba da ra'ayin don haɓakawa kuma yana tabbatar da Zane ko ya dace da aikace-aikacen da ake buƙata ko a'a.

Tsarin Kera don Ruwan Zafi

Bayan thermally simulating da Zane na zafi nutse, yanzu an juya don samarwa.Bari mu ga tsarin masana'antu daban-daban daki-daki;

1. CNC-Machining

Ruwan zafi da aka yi da injin CNC

Injin CNCita ce hanya mafi kyau don masana'anta-zufi don hadaddun siffofi.Wannan tsarin yana ba da dama ga masu zanen kaya.Ana amfani da duk wani shingen ƙarfe don ƙirƙirar nutsewa inda ake yanke fins ɗin da ake buƙata tare da injinan CNC kuma a lanƙwasa su daga tushe na toshe.Koyaya, hanya ce mai ɗaukar lokaci kuma mai tsada.

2. Extrusion

Ɗaya daga cikin hanyoyin da aka fi sani don samar da wuraren zafi shineextrusion, wanda ya haɗa da latsa zafi mai zafi na kayan ductile a cikin ƙananan ƙarfe mai ƙarfi don ƙirƙirar fins.Ana amfani da su don yawancin aikace-aikacen sanyaya da suka haɗa da dumbin zafi na aluminum.Tabbas, aluminium shine kayan da aka fi amfani dashi don samar da ruwan zafi.

Wutar da aka yi da Extrusion

Hanya ce mai sauƙi kuma mai sauƙi.Ana iya amfani da magudanar zafi a wurare daban-daban na aiki.Duk da haka, saboda matsakaicin iyakancewar nisa na extrusion, ba za a iya amfani da shi tare da magudanar zafi waɗanda ke da filaye masu faɗi ba.

3. Yin wasan kwaikwayo

Wutar da aka yi tare da Casting

A cikinyin simintin gyare-gyarena zafin jiki,aluminum, jan karfe, ko zinc sune kayan gama gari.A cikin wannan tsari, an fara narkar da abubuwan da aka zaɓa na kayan da aka zaɓa kuma a yi musu allura a cikin mutuƙar zafin rana tare da matsa lamba.Bayan an ƙarfafa kayan ruwan da aka yi wa allurar a cikin mutuwa, sai a sake shi, kuma ana yin ƙaramar mashin ɗin don kawar da duk wani lahani na saman.Zai fi dacewa don samun sifofi masu rikitarwa tare da babban matakin daidaito.

4. Sanyi-zurfafa

Wurin da aka yi da ƙirƙira mai sanyi

Yana da wani babban madaidaicin ƙirar ƙirar ƙira don ɗumbin zafin rana wanda ya dace da aluminium da kayan haɗin gwiwa.Ko da yake, yana da amfani ga jan karfe da tagulla.Ƙirƙirar sanyi yana amfani da matsananciyar matsa lamba kuma yana lalata siffar ƙarfe a zafin ɗaki don ƙirƙirar filaye masu zagaye da elliptical don nutsewar zafi.Bugu da ƙari, ana amfani da shi don samar da fins tare da babban yawa, wanda zai inganta yanayin zafi a cikin yanayin iska mai sauri.

5. 3D bugu

3D bugu Heat Sink

Haɓaka bugu na 3D a matsayin hanya don samar da magudanar zafi ya haifar da ci gaban fasaha.Haɗin gadon foda da fasahar saka makamashin da aka ba da umarni su ne hanyoyin da suka fi shahara wajen buga magudanar zafi.

6. Tambari

Wurin da aka yi da sanyi Stamping

Theyin hatimiAna amfani da hanyar inda ya zama dole don gina bututun zafi a cikin fins.Sa'an nan kuma, ta hanyar danna sassan karfe, ana samar da fins.A lokuta lokacin da ake amfani da fasaha mai saurin hatimi, yana da tasiri musamman ga masana'anta.Duk da haka, farashin yana da yawa.

Kammalawa

Tushen zafi suna da mahimmanci a cikin injina, lantarki, da na'urorin lantarki.A cikin wannan labarin, na yi nazarin cikakken tsarin ƙira da masana'anta da aka mayar da hankali kan na'urorin lantarki.Zane-zanen raƙuman zafi yana tasiri sosai akan ƙimar zafi, don haka kowane matakin ƙira yana da mahimmanci don bi don haɓaka aikin.Bugu da ƙari, thermal Simulation bayan ƙira yana taimakawa fahimtar yanayin aiki mai amfani da haɓaka ƙira.

Anan a ProleanHub, muna da masu zanen kaya tare da gogewa fiye da shekaru goma da ɓangarorin masana'antu na ci gaba.Muna ba da sabis na ƙirƙira ƙirar dumama zafi mai daraja.Bugu da kari, injiniyoyin injiniyoyinmu suna kwaikwayi Tsarin don inganta ayyuka da aiki.A ƙarshe, sashin kula da ingancin mu yana lura da kowane matakin masana'anta, don haka ba lallai ne ku yi sulhu da ingancin sabis ɗinmu ba, idan kuna buƙatar masana'antar dumama zafi, kawai.tuntube mu.

FAQ's

Ta yaya zan iya inganta ingancin magudanar zafi?

Ana iya ƙara haɓakawa ta hanyoyi da yawa, gami da rage juriya na zafi, haɓaka girman fin, siffa, da tsari, da haɓaka ƙirar fin.

Menene mafi kyawun abu don nutsewar zafi?

Mafi kyawun kayan don ƙwanƙwasa zafi shine ƙarfe da aluminum gami.Bugu da ƙari, ko da yake, ƙimar canja wurin zafi ya dogara da Zane-zanen zafi.

Ta yaya magudanar zafi ke aiki?

Ana yin ɗumbin zafin jiki daga manyan kayan aikin zafi kamar jan ƙarfe da aluminum tare da fins.Yana samun haɗe zuwa abubuwan da aka zafafa kuma yana ɗaukar zafi.Sa'an nan zafi mai narkewa yana watsawa a cikin yanayin da ke kewaye ta hanyar sarrafawa, convection, ko radiation.

Menene matakan ƙira don magudanar zafi?

Ga matakan;

- Zaɓin kayan aiki

- gyare-gyaren siffa, girman, da tsari na fins

- Gyaran abin da aka makala (Heat nuts & bangaren na'ura)

- Thermal Interfacing na fins

- Thermal Simulation na CAD zane

Menene hanyoyin gama gari na masana'anta don nutsewar zafi?

CNC machining, simintin gyare-gyare, ƙirƙira, Stamping, da 3D bugu sune hanyoyin gama gari.

Lokacin aikawa: Yuli-15-2022