Ndemanga Yachidule Pamapangidwe a Heat Sink ndi Kupanga

Kusintha komaliza: 09/01;Nthawi yowerenga: 6 min

Koziziritsira

Sink ya kutentha ndi chipangizo cha thermodynamic chomwe chimachotsa kutentha kumakina, zamagetsi, ndi zamagetsi.Pazida ndi makina osiyanasiyana, ndikofunikira kusunga kutentha mkati mwa malire ake kuti chipangizocho kapena makinawo azigwira ntchito.Apa ntchito ya kutentha-sink ikubwera.Mwachitsanzo, makina anu a laputopu olemera m'mafakitale osiyanasiyana amayenera kuwononga kutentha kwake.Choncho taganizirani mmene amagwiritsidwira ntchito kwambiri m’dziko lamakono laumisiri.Masinki otentha amataya kutentha powasamutsira ku sing'anga yoyendetsedwa bwino, monga mpweya kapena madzi, kenako amachotsedwa pazida ndi potengerapo.

Nkhaniyi mwachidule kudutsantchito zowukira kutentha, masitepe apangidwe, ndi njira zopangira.

Kugwira ntchito kwa Heat Sink

Lamulo la Fourier la kusamutsa kutentha, lomwe limanena kuti kutentha kumayenda nthawi zonse kuchokera ku kutentha kwakukulu kupita kumalo otsika kwambiri, kumapereka maziko a momwe sink ya kutentha imagwirira ntchito.Ngakhale kuti zipangizo zimatulutsa kutentha, komwe kumakhala kotentha kwambiri kuposa mpweya kapena madzi ozungulira, amasamutsa kutenthako ndi conduction, convection, kapena nthawi zina ma radiation kupita kumalo ozizira.

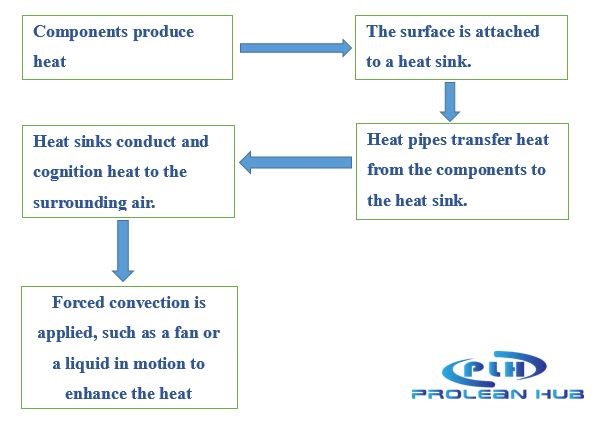

Tiyeni tiyang'ane ku tchati chotsatira m'munsimu kuti muwone bwino momwe kutentha kumagwirira ntchito;

Tchati choyendetsera ntchito ya sinki yotentha

· Pansi kutentha kumamira

Miyendo yotentha yosasunthika imasamutsa kutentha komweko kupita kumpweya wozungulira popanda kukakamiza, monga fani kapena kuzungulira kwamadzi mozungulira.Izi nthawi zambiri zimakhala zazikulu m'mawonekedwe ndipo zimakhala ndi zipsepse zowonekera kunja.

· Sinki yotentha yogwira ntchito

Sinki yotenthetsera yomwe imagwira ntchito imakhala ndi fani yowonjezereka kapena chowuzira ndi madzi okhazikitsidwa kuti achotse kutentha kwina osati njira yachilengedwe.Kukhazikitsa kowonjezeraku kumawonjezera njira yochepetsera kutentha ndi njira yokakamiza.Mwachitsanzo, chotenthetsera chikagwira ntchito, chimawonjezera liwiro la mpweya ndipo chimasamutsa kutentha kuchokera pankhokwe kupita kumalo ozungulira.

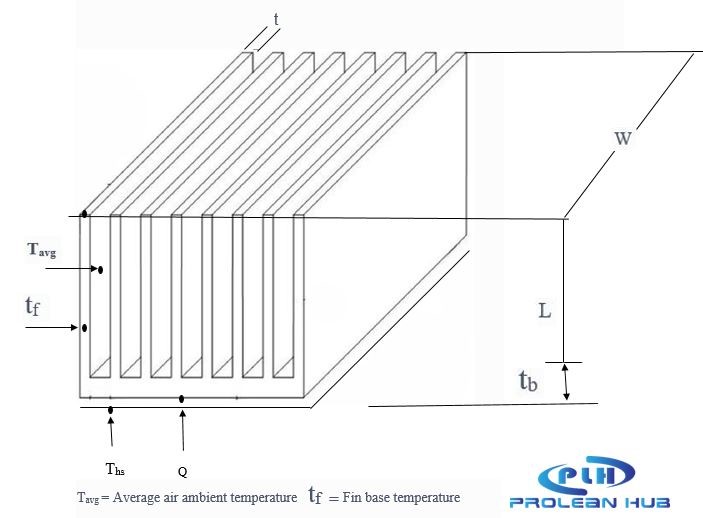

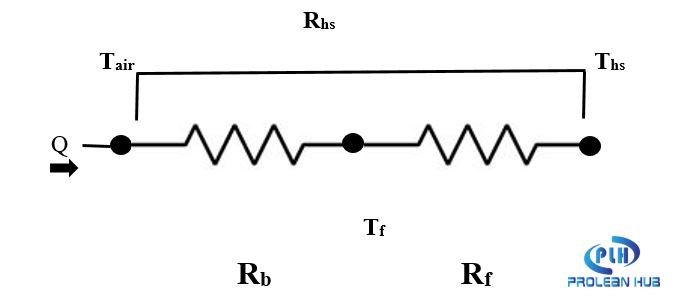

Kuwerengera kukana kwamafuta

Pa Kupanga kwa sinki yotentha, kuwerengera kuchuluka kwa kutentha kwamafuta (Rhs) imakhala ndi gawo lofunikira pakumvetsetsa momwe zingakhalire komanso magwiridwe antchito, kotero tiyeni tiwone momwe angawerengere;

Rhs= (Tj-Ta/P) - (Rndi jc) - RI

P= Kutentha konse kwatha

TI= Kutentha kwakukulu kwa chipangizocho pa 0C.

Rndi jc= Kuphatikizika kwa kukana kwamafuta

Ta= Kutentha kwa mpweya wozungulira0C.

RI= Kukana kwa mawonekedwe a mawonekedwe

RIne= (t/L x W x KI)

t = makulidwe a mawonekedwe

KI= Kutentha kwazinthu zamawonekedwe

L = Kutalika kwa gwero la kutentha

W = Kukula kwa gwero la kutentha

Mapangidwe a Sink ya Kutentha

Pali njira zingapo popanga.Tiyeni tione aliyense wa iwo mwachidule.

1. Kusankha zinthu

Thermal conductivity ndi chimodzi mwazofunikira kwambiri za zinthu zoyatsira kutentha chifukwa zimalola kufalikira kwachangu kutentha kuchokera ku chipangizo chotenthetsera kupita kumadzi ndi chilengedwe.

Zida ziwiri zoyambirira zomwe zimagwiritsidwa ntchito popanga zoyatsira kutentha ndi zitsulo zamkuwa ndi aluminiyamu.Izi ndichifukwa choti ali ndi machitidwe abwino amakina monga mphamvu, kukana dzimbiri, kulimba, komanso kutentha kwambiri.Komabe, ngakhale ndiyokwera mtengo kwambiri, diamondi (2,000 W/m/k) ikhoza kukhala zinthu zabwino kwambiri zoyatsira kutentha pazida zamagetsi zowoneka bwino komanso zolondola.

Kuphatikiza pazigawo zamagetsi, mabatire a lithiamu-ion amatulutsa kutentha kofunikira.Zikatero, mkuwa kapena aluminiyamu sizingakhale zida zabwino kwambiri zoyatsira kutentha.

Yankho lamakampani opanga magalimoto pakuwongolera kutentha ndi chinthu chochititsa chidwi kwambiri cha carbon fiber.

2. Kukonzekera kwa zipsepse & mpweya

Chinanso chomwe chimakhudza magwiridwe antchito a sink ya kutentha ndi sing'anga yozizirira, yomwe imakhudza kwambiri kuchuluka kwa kutentha.Chifukwa chake, pomanga chotengera cha kutentha, mawonekedwe, kukula, ndi makonzedwe a zipsepse ndizofunikira kuziganizira.Kugwiritsa ntchito njira ya parametric kukhathamiritsa ndiye njira yabwino kwambiri yopezera ma parameter oyenera kuti agwirizane ndi zoletsa zomwe zanenedwa ndikukwaniritsa zolinga zamapangidwe.

- Sinthani malo pakati pa zipsepsezo kuti muwongolere mpweya komanso kuchepetsa kukana kwamafuta.

- Chifukwa malo okulirapo amawonjezera ma conduction ndi kusintha kwa kutentha kwa convection, kumathandizira kutulutsa kutentha, lingalirani kukulitsa makulidwe ndi kutalika.

- Pangani malire ang'onoang'ono a kutentha, ndipo njira yolowera mpweya idapangidwa mozungulira bwino ndi sinki yotenthetsera kuti muwonjezeke bwino.

- Mukakonzekera mapangidwe a zipsepse ndi CAD, mutha kutengera momwe zimakhalira kutentha kuti mukwaniritse bwino.

3. Kuphatikizika kwa sink ya kutentha

Momwe sinki imalumikizirana ndi chotenthetsera cha chipangizocho imakhudzanso momwe imagwirira ntchito.Sankhani njira yabwino kwambiri yolumikizira yomwe imakulitsa kuchuluka kwa kutentha kuchokera pazigawo zoyimirira, tatifupi tating'onoting'ono ta masika, epoxy, ndi zosankha za tepi zotentha.

4. Thermal mawonekedwe

Zowonongeka ndi kuuma kwapamwamba kwa sink ya kutentha kumathandizira kuonjezera kukana kwa kutentha chifukwa cha kuchepa kwa malo okhudzana ndi kutentha ndi kupanikizika kwa mawonekedwe.Kuti mugonjetse nkhaniyi, zida zopangira matenthedwe ndizosankha zabwino kwambiri.Kugwiritsira ntchito ma polima amadzimadzi, sera, aluminiyamu, graphite, ndi matepi pamwamba pa sinki ya kutentha ndi kutentha kwa zipangizo kumachepetsa kukana kwa kutentha.

5. Kuyerekezera

Kuyerekeza kwa Design ndikofunikira kuti muwone momwe kutentha kwakuya kumagwirira ntchito pafupifupi.Kuyerekeza kwa Kompyuta kumapereka lingaliro la kuwongolera ndikutsimikizira Mapangidwewo ngati ali oyenera pazofunikira kapena ayi.

Njira Yopangira Kuyikira Kutentha

Pambuyo pofanizira Mapangidwe a masinki otentha, tsopano asinthidwa kuti apange.Tiyeni tiwone njira zosiyanasiyana zopangira mwatsatanetsatane;

1. CNC-Machining

Kutentha kwakuya kopangidwa ndi makina a CNC

CNC makinandiyo njira yabwino kwambiri yopangira kutentha kwa kutentha kwa mawonekedwe ovuta.Njirayi imapereka kusinthasintha kwakukulu kwa opanga.Chitsulo chonse chimagwiritsidwa ntchito popanga sinki pomwe zipsepse zofunikira zimadulidwa ndi makina a CNC ndikupindika kuchokera pansi pa chipikacho.Komabe, ndi njira yowononga nthawi komanso yokwera mtengo.

2. Extrusion

Imodzi mwa njira zodziwika bwino zopangira masinki otentha ndiextrusion, zomwe zimaphatikizapo kukanikiza zitsulo zotentha za ductile muzitsulo zamphamvu kwambiri kuti apange zipsepse za mbale.Amagwiritsidwa ntchito pazinthu zambiri zoziziritsa zomwe zimaphatikizapo masinki otentha a aluminiyamu.Zoonadi, aluminiyamu ndizomwe zimagwiritsidwa ntchito kwambiri popanga zoyatsira kutentha.

Kutentha kwamadzi opangidwa ndi Extrusion

Ndi njira yotsika mtengo komanso yowongoka.Kutentha kwazitsulo kungagwiritsidwe ntchito m'malo osiyanasiyana ogwira ntchito.Komabe, chifukwa cha kuletsa kwakukulu kwa extrusion m'lifupi, singagwiritsidwe ntchito ndi masinki otentha omwe ali ndi zipsepse zazikulu.

3. Kuponya

Sink yotentha yopangidwa ndi Casting

Mukuponyeracha kutentha kwa thupi,aluminiyamu, mkuwa, kapena zinki ndizo zida zofala.Pochita izi, ma ingots a zinthu zosankhidwa amayamba kusungunuka ndikulowetsedwa mu kufa kwa kutentha kwa kutentha ndi kupanikizika kwina.Zinthu zamadzimadzi zomwe zidabayidwazo zitakhazikika mukufa, zimatulutsidwa, ndipo makina ocheperako amachitidwa kuti athetse kusakwanira kulikonse.Ndi bwino kupeza mawonekedwe ovuta ndi kulondola kwakukulu.

4. Kuzizira kozizira

Sink yotentha yopangidwa ndi kuzizira kozizira

Ndi njira ina yopangira molondola kwambiri zoyatsira kutentha zoyenera aluminium ndi ma aloyi ake.Ngakhale, imagwiranso ntchito mkuwa ndi mkuwa.Kuzizira kozizira kumagwiritsa ntchito kuponderezedwa kwambiri ndikusintha mawonekedwe achitsulo kutentha kwachipinda kuti apange mapini ozungulira ndi ozungulira a sinki ya kutentha.Kuphatikiza apo, imagwiritsidwa ntchito popanga zipsepse zokhala ndi kachulukidwe kwambiri, zomwe zimathandizira kutengera kutentha mumayendedwe othamanga kwambiri.

5. 3D kusindikiza

3D yosindikizidwa Heat Sink

Kupanga makina osindikizira a 3D ngati njira yopangira masinki otentha chifukwa cha kupita patsogolo kwaukadaulo.Kuphatikizika kwa bedi la ufa ndi matekinoloje owongolera mphamvu ndi njira ziwiri zodziwika kwambiri posindikiza masinki otentha.

6. Kupondaponda

Kutentha kwakuya kopangidwa ndi Stamping ozizira

ThekupondapondaNjira imagwiritsidwa ntchito pomwe pakufunika kupanga mapaipi otentha mkati mwa zipsepse.Kenako, mwa kukanikiza zitsulo, zipsepsezo zimapangidwa.Pamene teknoloji yothamanga kwambiri imagwiritsidwa ntchito, imakhala yothandiza kwambiri popanga anthu ambiri.Komabe, mtengo wake ndi wokwera.

Mapeto

Masinki otentha ndi ofunikira pamakina, magetsi, ndi zida zamagetsi.M'nkhaniyi, ndafotokozera mwatsatanetsatane ndondomeko ya mapangidwe ndi kupanga zomwe zimayang'ana pa zipangizo zamagetsi.Mapangidwe a masinki otentha amakhudza kwambiri kutentha kwa kutentha, kotero kuti sitepe iliyonse ndiyofunikira kutsatira kuti ntchitoyo ikwaniritsidwe.Kuphatikiza apo, Kutenthetsa Kutentha pambuyo pakupanga kumathandizira kumvetsetsa momwe zimagwirira ntchito ndikuwongolera Mapangidwe.

Pano ku ProleanHub, tili ndi opanga omwe ali ndi zaka zopitilira khumi komanso zida zapamwamba zopangira.Timapereka ntchito zopangira zida zapamwamba komanso zopangira zopangira.Kuphatikiza apo, mainjiniya athu amakina amatengera Mapangidwewo kuti apititse patsogolo magwiridwe antchito ndi magwiridwe antchito.Pomaliza, dipatimenti yathu yoyang'anira khalidwe imayang'anira gawo lililonse lopanga, kotero simuyenera kunyengerera ndi mtundu wathu wautumiki, ngati mukufuna kupanga kutentha kwakuya, basiLumikizanani nafe.

FAQs

Kodi ndingawongolere bwanji magwiridwe antchito a masinki otentha?

Kuchita bwino kumatha kuonjezedwa m'njira zingapo, kuphatikiza kuchepetsa kukana kutentha, kukhathamiritsa kukula kwa zipsepse, mawonekedwe, ndi makonzedwe, komanso kukonza mawonekedwe a zipsepse.

Ndi zinthu ziti zabwino kwambiri zomangira kutentha?

Zida zabwino kwambiri zoyatsira kutentha ndi zitsulo zamkuwa ndi aluminiyamu.Apanso, kutentha kwa kutentha kumadalira Mapangidwe a sinki ya kutentha.

Kodi sinki yotentha imagwira ntchito bwanji?

Masinki otentha amapangidwa kuchokera kuzinthu zopangira matenthedwe apamwamba monga mkuwa ndi aluminiyamu yokhala ndi zipsepse.Imamangirizidwa ku zigawo zotentha ndikuyamwa kutentha.Kenako kutentha kwapang'onopang'ono kumataya malo ozungulira kudzera mu conduction, convection, kapena radiation.

Kodi masitepe opangira zotengera kutentha ndi chiyani?

Nawa masitepe;

- Kusankha zinthu

- kukonza mawonekedwe, kukula, ndi dongosolo la zipsepse

- Kukonza chomata (Kuzama kwa kutentha & chigawo cha chipangizo)

- Kulumikizana kwa kutentha kwa zipsepse

- Thermal Simulation of CAD design

Kodi njira zodziwika bwino zopangira choyikira kutentha ndi ziti?

CNC Machining, kuponyera, forging, Stamping, ndi 3D kusindikiza ndi njira wamba.

Nthawi yotumiza: Jul-15-2022