Uphononongo olufutshane malunga noYilo lweSinki yobushushu kunye noVeliso

Uhlaziyo lokugqibela: 09/01;Ixesha lokufunda: 6 imiz

Isinki yobushushu

I-heat sink sisixhobo se-thermodynamic esisusa ubushushu kwiinkqubo zoomatshini, zombane kunye nezombane.Kwizixhobo ezahlukeneyo kunye noomatshini, kubalulekile ukugcina uluhlu lobushushu ngaphakathi komda othile ukugcina ukusebenza kweso sixhobo okanye umatshini.Apha indima ye-heater-sinks idlala.Umzekelo, oomatshini abakhulu belaptop yakho kumashishini ahlukeneyo kufuneka bachithe ubushushu bawo.Ngoko khawucinge indlela esetyenziswa ngokubanzi ngayo kwihlabathi lanamhlanje lobugcisa.I-Heat sinks ichitha ubushushu ngokuyidlulisela kwindawo elawulwayo, efana nomoya okanye ulwelo, emva koko ikhutshwe kwi-apparatus kunye ne-transfer medium.

Eli nqaku liza kuhamba ngokufutshane kwiukusebenza kwe-heat sink, amanyathelo oyilo, kunye neendlela zokuvelisa.

Ukusebenza kweSinki yoBubushushu

Umthetho weFourier wokudluliselwa kobushushu, othi ubushushu buhlala buhamba ukusuka kwiqondo eliphezulu ukuya kwindawo yobushushu obuphantsi, unika isiseko sendlela yokusebenza kwe-heat sink.Ngelixa izixhobo zivelisa ubushushu, obushushu kunomoya okanye ulwelo olujikelezileyo, zibudlulisa obo bushushu ngokuhambisa, nge-convection, okanye ngamanye amaxesha ngemitha kunxibelelwano olupholileyo.

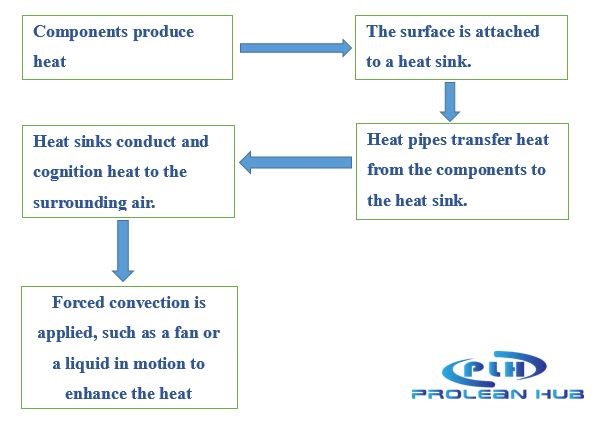

Makhe sijonge kwi-flow-chart engezantsi ngomfanekiso ocacileyo wokusebenza kwe-heat-sink;

Itshati equkuqelayo yokusebenza kwesinki yobushushu

· Ubushushu obungatshintshiyo butshona

Iizinki zobushushu obungatshintshiyo ngokwendalo zidlulisela ubushushu obufunnyiweyo kumoya ojikeleze ngaphandle kokuhanjiswa ngamandla, okufana nefeni okanye ukujikeleza kwamanzi okuwangqongileyo.Ezi zikholisa ukuba zikhulu ngokwemilo kwaye ziqulathe uluhlu olupheleleyo oluvezwe kwindawo engaphandle.

· Isinki yobushushu esebenzayo

Isinki sobushushu esisebenzayo siquka ifeni eyongezelelweyo okanye isivuthelo kunye nolwelo olusekiweyo ukususa ubushushu ngaphandle kwendlela yendalo.Olu cwangciso olongezelelweyo lwandisa inkqubo yokutshatyalaliswa kobushushu ngenkqubo yokuhambisa ngenkani.Umzekelo, xa ifeni isebenza, yongeza isantya somoya kwaye ngokukhawuleza igqithise ubushushu ukusuka kwindawo yokutshisa ubushushu ukuya kwindawo engqongileyo.

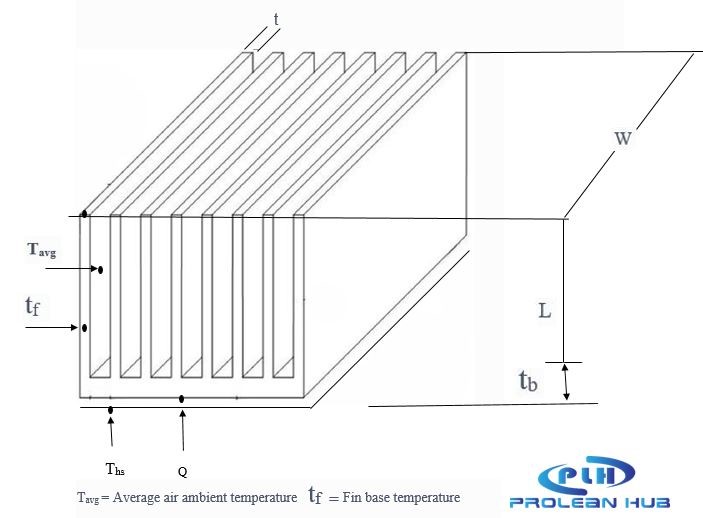

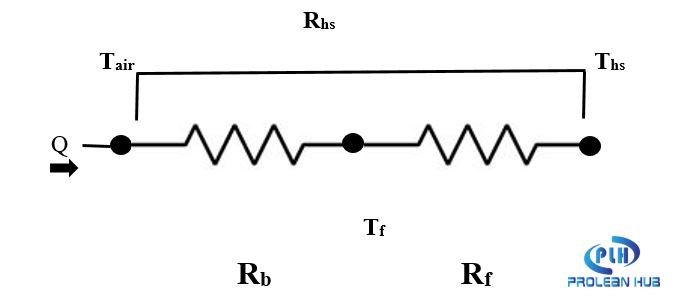

Ukubalwa kokumelana ne-thermal

Ngexesha lokuYilwa kwesitya sobushushu, ukubalwa kokumelana ne-thermal iyonke (Rhs) idlala indima ebalulekileyo ekuqondeni ukusebenza okunokwenzeka kunye nokusebenza kakuhle, ngoko makhe sibone ukuba ingabalwa njani;

Rhs= (Tj-Ta/P) – (Rth-jc) -RI

P= Ubushushu obuchithiweyo bubonke

TI= Ubukhulu bobushushu besiphambuka sesixhobo kwi-0C.

Rth-jc= Ukuhlangana kwimeko yokumelana ne-thermal

Ta= Ubushushu bomoya kwi0C.

RI= Ukuchaswa kwemathiriyeli yojongano

RI= (t/L x W x KI)

t = ubukhulu besixhobo sojongano

KI=I-Thermal conductivity ye-interface yezinto

L = Ubude bomthombo wobushushu

W =Ububanzi bomthombo wobushushu

Uyilo lweSinki yoBubushushu

Kukho amanyathelo amaninzi ekuyileni.Makhe sijonge nganye kuzo ngokufutshane.

1. Ukukhethwa kwezinto

I-Thermal conductivity yenye yeempawu eziyimfuneko zezinto zokutshisa ukushisa kuba ivumela ukuhanjiswa ngokukhawuleza kobushushu ukusuka kwisixhobo esishushu kwi-sink kunye nokusingqongileyo.

Izinto ezimbini eziphambili ezisetyenziselwa ukwenza iisinki zobushushu lubhedu kunye nealloyi zealuminiyam.Oku kungenxa yokuba baneempawu ezibalaseleyo zobuchwephesha njengamandla, ukuxhathisa umhlwa, ukuqina, kunye nobushushu obuphezulu.Nangona kunjalo, nangona inexabiso elihle, idayimane (2,000 W/m/k) inokuba yeyona nto ifanelekileyo kwizitsini zobushushu ekusebenzeni okuphezulu kunye nokuchaneka kwezixhobo zombane.

Ukongeza kwiindawo zombane, iibhetri ze-lithium-ion zivelisa ukutshatyalaliswa kobushushu kuyimfuneko.Kwimeko enjalo, ubhedu okanye i-aluminiyam isenokungabi yeyona nto ifanelekileyo yesixhobo sobushushu.

Isisombululo soshishino lweemoto kulawulo lobushushu sisixhobo esihle kakhulu sokuqhuba icarbon fiber.

2. Ulungiselelo lweeFins & airflow

Enye into echaphazela ukusebenza kwesitya sokupholisa sisiphakathi sokupholisa, esinefuthe elimandla kwisantya sokulahla ubushushu.Ke ngoko, xa kusakha i-heat sink, imilo, ubukhulu, kunye nolungiselelo lwe-fin yimiba ebalulekileyo ekufuneka iqwalaselwe.Ukusebenzisa i-parametric optimization technique lolona khetho lulungileyo lokufumana amaxabiso afanelekileyo eparameter ukuhambelana nezithintelo ezichaziweyo kunye nokufezekisa iinjongo zoyilo.

- Ukuphucula indawo phakathi kwamaphiko ukuphucula ukuhamba komoya kunye nokunciphisa ukuxhathisa kwe-thermal.

- Ngenxa yokuba indawo enkulu yomphezulu inyusa i-convection kunye nokuhanjiswa kobushushu, inceda ekugxothweni kobushushu, cinga ukwandisa ubukhulu kunye nobude.

- Yenza umaleko omncinci womda we-thermal, kwaye umkhombandlela wokuhamba komoya wawuyilwe kwi-engile efanelekileyo kunye nesinki yobushushu ukwandisa ukusebenza kakuhle.

- Emva kokulungiselela uyilo lwee-fins kunye ne-CAD, ungalinganisa imeko yokudlulisa ubushushu ukuze ukhulise ukusebenza kakuhle kwayo.

3. I-attachment of heat-sink

Indlela isinki edityaniswe ngayo kwindawo yokufudumeza isixhobo nayo ichaphazela indlela esebenza ngayo.Khetha eyona ndlela yokudibanisa iphakamisa izinga lokuhambisa ubushushu ukusuka kwizikhewu ezimileyo, iikliphu zentwasahlobo ezicaba, i-epoxy, kunye nokhetho lweteyiphu eshushu.

4. Ujongano lobushushu

Iziphene kunye noburhabaxa bomphezulu we-heat sink idlala indima ekwandiseni ukuxhathisa kwe-thermal ngenxa yokuncipha kwendawo yokunxibelelana ne-thermal kunye noxinzelelo lwe-interface.Ukoyisa lo mbandela, izixhobo zokujonga i-thermal lolona khetho lulungileyo.Ukusebenzisa i-polymers elulwelo, i-wax, i-aluminiyam, i-graphite, kunye neeteyiphu kumphezulu we-heat sink kunye ne-heater element yezixhobo zehlisa ukuxhathisa kwe-thermal.

5. Ukulinganisa

Ukulinganisa koYilo kubalulekile ukubona ukusebenza kwe-heat-sink phantse.Ukulinganisa kwiKhompyutha inika umbono wophuculo kwaye iqinisekisa uYilo nokuba ilungele izicelo ezifunekayo okanye hayi.

Inkqubo yokuVelisa iSinki yoBubushushu

Emva kokulinganisa ngokufudumeleyo uYilo lweentsini zobushushu, ngoku ijikelwe imveliso.Makhe sibone iinkqubo ezahlukeneyo zokwenziwa ngokweenkcukacha;

1. CNC-Machining

Isinki yobushushu eyenziwe nge-CNC machining

CNC machiningyeyona ndlela ilungileyo yokwenza isinki sobushushu kwiimilo ezintsonkothileyo.Le ndlela inika ukuguquguquka okukhulu kubaqulunqi.Ibhloko yonke yentsimbi isetyenziselwa ukwenza i-sink apho iifins ezifunekayo zinqunywe kunye noomatshini be-CNC kwaye zigobe ukusuka kwisiseko sebhloko.Nangona kunjalo, yindlela echitha ixesha kunye neendleko eziphezulu.

2. Extrusion

Enye yeenkqubo eziqhelekileyo zokuvelisa i-heater sinksi-extrusion, Okubandakanya ukucofa iibhilidi ezishushu ze-ductile material kwi-high-high-strey steel die ukudala i-plate fins.Zisetyenziselwa uninzi lwezicelo zokupholisa ezibandakanya iisinki zobushushu ze-aluminiyam.Ngokuqinisekileyo, i-aluminiyam yeyona nto isetyenziswa kakhulu kwimveliso ye-heat sink.

Isinki yobushushu eyenziwe nge-Extrusion

Yinkqubo engabizi kakhulu kwaye ecacileyo.Izixhobo zokushisa zingasetyenziselwa kwiindawo ezahlukeneyo zokusebenza.Nangona kunjalo, ngenxa yothintelo lobubanzi obuphezulu be-extrusion, ayinakusetyenziswa ngeesinki zobushushu ezinamaphiko abanzi.

3. Iyaphosa

Isinki yobushushu eyenziwe ngeCasting

Kwiukuphosakwindawo yokutshisa ubushushu,aluminiyam, ubhedu, okanye i-zinc zizinto eziqhelekileyo.Kule nkqubo, i-ingots yezinto ezikhethiweyo ziyancibilika kuqala kwaye zifakwe kwi-die of the heat-sink kunye noxinzelelo oluthile.Emva kokuba ulwelo olutofelweyo luqinisiwe kwifa, luyakhululwa, kwaye ukwenziwa komatshini okuncinci kwenziwa ukuphelisa nakuphi na ukungafezeki komphezulu.Kungcono ukufumana iimilo ezintsonkothileyo ezinomgangatho ophezulu wokuchaneka.

4. Ukubumba okubandayo

Isinki yobushushu eyenziwe ngefogi ebandayo

Yenye indlela yokuvelisa echanekileyo ephezulu yeesinki zobushushu ezifanelekileyo kwi-aluminium kunye ne-alloys yayo.Nangona, iyasebenza nakubhedu kunye nobhedu.Ukubumba okubandayo kusebenzisa uxinzelelo olugqithisileyo kunye nokuguqula imilo yesinyithi kwiqondo lobushushu begumbi ukwenza izikhonkwane ezingqukuva neziyi-elliptical ze-sink yobushushu.Ukongeza, isetyenziselwa ukuvelisa amaphiko ngoxinaniso oluphezulu, oluya kuphucula ukuhanjiswa kobushushu kwiimeko zokuphuma komoya ngesantya esiphezulu.

5. Ushicilelo lwe-3D

ISinki yoBubushushu eprintiweyo ye-3D

Ukuphuhliswa koshicilelo lwe-3D njengendlela yokuvelisa iisinki zobushushu ngenxa yenkqubela phambili yezobuchwepheshe.Ukudityaniswa kwebhedi yomgubo kunye netekhnoloji yokubekwa kwamandla zezona ndlela zimbini zidumileyo ekushicileleni amasinki obushushu.

6. Isitampu

Isinki yobushushu eyenziwe ngeStamping ebandayo

Iisitampuindlela isetyenziswa apho kuyimfuneko ukuba kwakhiwe imibhobho yobushushu ngaphakathi kwamaphiko.Emva koko, ngokucinezela imicu yentsimbi, iifins ziveliswa.Kwiimeko xa kusetyenziswa itekhnoloji yesantya esiphezulu, iyasebenza kakhulu kwimveliso yobuninzi.Nangona kunjalo, ixabiso liphezulu.

Ukuqukumbela

Iisinki zobushushu zibalulekile kumatshini, umbane, kunye nezixhobo zombane.Kweli nqaku, ndijonge inkqubo yoyilo eneenkcukacha kunye nokuveliswa okugxile kwizixhobo zombane.Uyilo lweesinki zobushushu lunefuthe kakhulu kwisantya sokulahla ubushushu, ngoko ke inyathelo loyilo ngalinye libalulekile ukuba lilandelwe ukuze kuphuculwe ukusebenza kakuhle.Ngaphaya koko, ukulinganisa okushushu emva kokuyila kunceda ukuqonda imeko esebenzayo kunye nokuphucula uYilo.

Apha e-ProleanHub, sinabaqulunqi abanamava angaphezu kweshumi leminyaka kunye neeyunithi zokuvelisa eziphambili.Sinikezela ngeenkonzo zokuyila kunye neenkonzo zokuvelisa.Ukongeza, iinjineli zethu zoomatshini zilinganisa uYilo ukuphucula ukusebenza kunye nokusebenza.Okokugqibela, isebe lethu lolawulo lomgangatho libeka esweni inyathelo ngalinye lokuvelisa, ke akunyanzelekanga ukuba ulalanise nomgangatho wenkonzo yethu, ukuba ufuna ukwenziwa kobushushu,Qhagamshelana nathi.

Ii-FAQ's

Ndingayiphucula njani intsebenzo yeentsini zobushushu?

Ukusebenza kunokongezwa ngeendlela ezininzi, kubandakanya ukunciphisa ukumelana nobushushu, ukukhulisa ubungakanani besiphelo, imilo, kunye nolungiselelo, kunye nokuphucula ujongano lwefin.

Yeyiphi eyona mathiriyeli ilungileyo yokucoca ubushushu?

Izixhobo ezingcono kakhulu zokushisa ukushisa zinobhedu kunye ne-aluminium alloys.Kwakhona, nangona kunjalo, izinga lokufudumeza ubushushu lixhomekeke kuYilo lwesitya sobushushu.

Isebenza njani i-heat sink?

Iisinki zokushisa zenziwe ngezinto eziphezulu ze-thermal conductivity ezifana nobhedu kunye ne-aluminiyam enamaphiko.Idityaniswa kumalungu ashushu kwaye ifunxa ubushushu.Emva koko ubushushu obufunxayo buyaphela kwindawo engqongileyo nge-convection, convection, okanye radiation.

Ngawaphi amanyathelo oyilo lweesinki zobushushu?

Nanga amanyathelo;

- Ukukhethwa kwezinto

- ukulungiswa kwemilo, ubungakanani, kunye nokulungelelaniswa kwamaphiko

- Ukulungiswa koncamathiselo (Isinki yobushushu kunye nesixhobo sesixhobo)

- I-Thermal Interfacing of fins

- Ukulinganisa iThermal yoyilo lweCAD

Zeziphi iindlela eziqhelekileyo zokwenza isinki yobushushu?

CNC machining, casting, forging, Stamping, kunye noshicilelo lwe-3D ziindlela eziqhelekileyo.

Ixesha lokuposa: Jul-15-2022