Ongororo pfupi pamusoro peKupisa Sink Dhizaini uye Kugadzira

Last update:09/01;Nguva yekuverenga: 6 min

Heat sink

A heat sink is thermodynamic device inobvisa kupisa kubva kumakanika, magetsi, uye zvemagetsi masisitimu.Mumidziyo nemichina yakasiyana-siyana, zvakakosha kuti uchengetedze tembiricha iri mukati menguva yakatarwa kuchengetedza kushanda kwemudziyo iwoyo kana muchina.Pano basa rekupisa-kupisa rinouya.Semuyenzaniso, yako Laptop yakakura kwazvo muchina mumaindasitiri akasiyana inoda kubvisa kupisa kwayo.Saka funga kuti rinoshandiswa zvakadii munyika yanhasi yeruzivo rwemichina.Kupisa kunyura kunobvisa kupisa nekuiendesa kune yakagadziriswa svikiro, senge mhepo kana mvura, yobva yadzingwa kubva mumudziyo uye wekufambisa.

Ichi chinyorwa chichapfuura muchidimbukushanda kwekupisa kunyura, matanho ekugadzira, uye nzira dzekugadzira.

Kushanda kweKupisa Sink

Mutemo weFourier wekupisa kupisa, unotaura kuti kupisa nguva dzose kunoyerera kubva pakupisa kwepamusoro kusvika kune yakaderera-kupisa kwepakati, unopa hwaro hwekuti singi yekupisa inoshanda sei.Nepo midziyo ichiburitsa kupisa, kunopisa kupfuura mhepo yakatenderedza kana mvura, inotamisa kupisa ikoko kuburikidza ne conduction, convection, kana dzimwe nguva mwaranzi kune inotonhorera kubata.

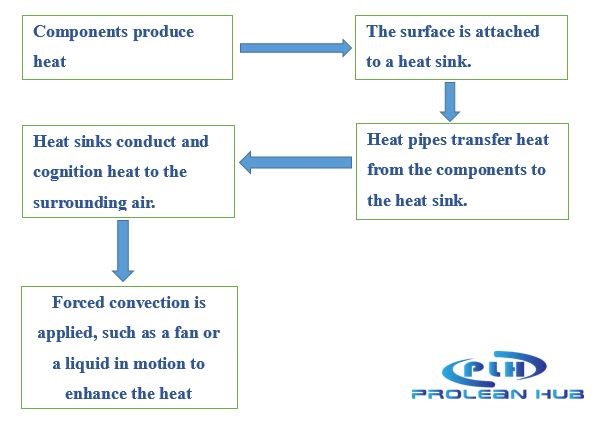

Ngatitarisei kune inoyerera-chati pazasi mufananidzo wakajeka wekupisa-kunyura kushanda;

Kuyerera-chati yekushanda kwekupisa-kunyura

· Passive kupisa kunonyura

Kupisa kwepasi kunonyura kunowanzoendesa kupisa kwakanyura kumhepo iri mumhepo pasina simba rekufambisa, senge feni kana kutenderera kwemvura pavari.Aya anowanzo kuve akakura muchimiro uye ane fin array akaoneswa kune ekunze nharaunda.

· Active heat sink

Iyo inoshanda yekupisa sink ine yekuwedzera fan kana blower uye mvura yakamiswa kuti ibvise kupisa kunze kwemaitiro echisikigo.Iyi yekuwedzera setup inowedzera nzira yekupisa yekupisa neiyo yekumanikidza convection process.Semuyenzaniso, kana feni ichishanda, inowedzera kumhanyisa kwemhepo uye nekukasira kutamisa kupisa kubva kune singi yekupisa kuenda kune yakatenderedza.

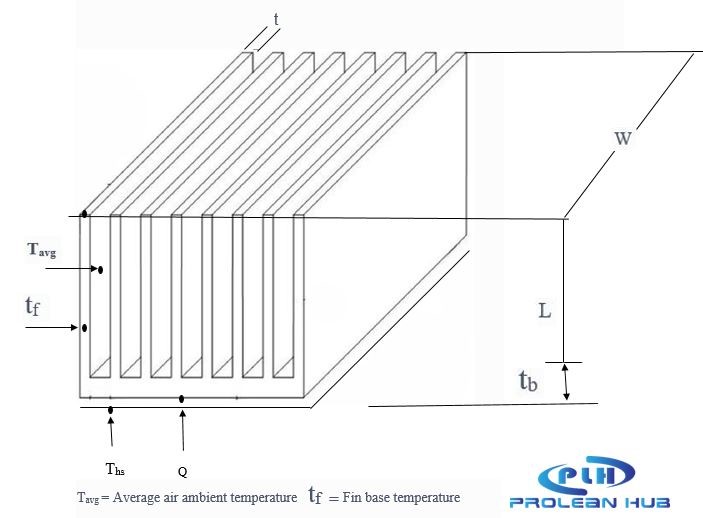

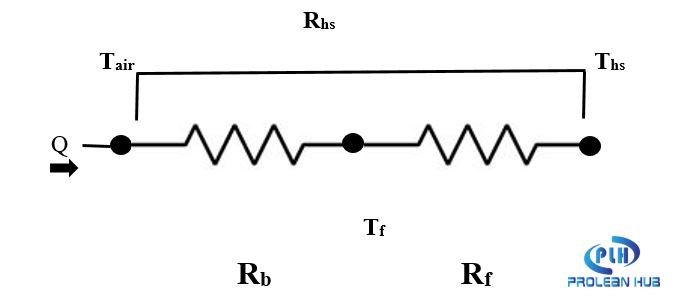

Kuverenga kwekupisa kwekupisa

Munguva yeKugadzira singi yekupisa, kuverenga kweiyo yakazara kupisa kupisa (Rhs) inoita basa rakakosha mukunzwisisa kugona kuita uye kugona, saka ngationei kuti ingaverengerwa sei;

Rhs= (Tj-Ta/P) - (Rth-jc) - RI

P= Total dissipated kupisa

TI= Kunyanya kupisa kwekusangana kwechishandiso pa0C.

Rth-jc= Junction to case thermal resistance

Ta= Ambient tembiricha yemhepo pa0C.

RI= Kupokana kwezvinhu interface

RI= (t/L x W x KI)

t = ukobvu hwekushandisa interface

KI= Thermal conductivity ye interface zvinhu

L = Hurefu hwekupisa sosi

W =Kupamhama kwekupisa

Dhizaini Yekupisa Sink

Pane matanho akawanda ekugadzira.Ngatitarisei mumwe nomumwe wavo muchidimbu.

1. Kusarudzwa kwezvinhu

Thermal conductivity ndiyo imwe yeakakosha maitiro echinhu chinopisa chinopisa nekuti inobvumira kukurumidza kutapurirana kwekupisa kubva kune inopisa mudziyo wechikamu kune sink uye zvakatipoteredza.

Zvinhu zviviri zvekutanga zvinoshandiswa kugadzira masingi ekupisa imhangura nealuminium alloys.Izvi zvinodaro nekuti ivo vane yakanakisa mechaniki hunhu senge simba, corrosion resistance, durability, uye high heat conductivity.Nekudaro, kunyangwe iri mutengo wakanaka, dhaimondi (2,000 W/m/k) rinogona kunge riri rakakodzera zvinhu zvemadhishi ekupisa mune yakakwirira-kuita uye nemazvo emagetsi zvishandiso.

Pamusoro pezvikamu zvemagetsi, mabhatiri e-lithium-ion anogadzira kupisa kupisa kunodiwa.Mumamiriro ezvinhu akadaro, mhangura kana aluminium inogona kunge isiri iyo yakanyanya kunaka zvinhu zvekupisa sink.

Iyo indasitiri yemotokari mhinduro yekudziya manejimendi ndeye inoshamisa conductivity kabhoni fiber zvinhu.

2. Fins kurongeka & kuyerera kwemhepo

Chimwe chinhu chinokanganisa kunyura kwekupisa ndeye inotonhorera svikiro, iyo inokanganisa zvakanyanya mwero wekupisa kupisa.Naizvozvo, kana uchivaka singi yekupisa, chimiro, saizi, uye fini kuronga zvinhu zvakakosha zvekufunga nezvazvo.Kushandisa iyo parametric optimization tekinoroji ndiyo yakanakisa sarudzo yekuwana yakanakira parameter kukosha kuti ienderane nezvinorambidzwa uye kuzadzisa zvibodzwa zvekugadzira.

- Kuvandudza nzvimbo pakati pezvimbi kuti uvandudze kuyerera kwemhepo uye kuderedza kupisa kwekupisa.

- Nekuti nzvimbo yakakura yepamusoro inowedzera conduction uye convection kupisa kwekufambisa, kubatsira mukupisa kupisa, funga kuwedzera ukobvu uye urefu.

- Gadzira diki diki remuganho wekupisa, uye mafambiro emhepo akagadzirwa pakona yakakodzera ine sink yekupisa kuti iwedzere kushanda kwefin.

- Mushure mekugadzirira dhizaini yezvimbi neCAD, unogona kutevedzera mamiriro ekutamisa kupisa kuti uwedzere kushanda kwayo.

3. Kusungirirwa kwekupisa-kunyura

Nzira iyo sink yakabatana nayo kune yekudziya yemudziyo inokanganisawo kuti inoshanda sei.Sarudza yakanakisa yekubatanidza nzira inokwirisa mwero wekupisa kupisa kubva kune standoff spacers, flat spring clips, epoxy, uye thermal tepi sarudzo.

4. Thermal interface

Kukanganisa uye hutsinye hwepamusoro hwekupisa kunyura kunoita basa mukuwedzera kupisa kwekudzivirira nekuda kwekuderera kwenzvimbo yekudziya yekubata uye kudzvanywa kwechimiro.Kuti ukunde nyaya iyi, thermal interface zvinhu ndiyo yakanakisa sarudzo.Kushandisa mapolymers emvura, wakisi, aluminium, graphite, uye matepi pamusoro pekupisa singi uye chinhu chekudziya chemidziyo inodzikisira kupisa kwekupisa.

5. Simulation

Simulation yeDhizaini yakakosha kuona kuita kweiyo kupisa-kunyura chaiko.Computer Simulation inopa pfungwa yekuvandudza uye inosimbisa Dhizaini kana yakakodzera kune zvinodiwa maapplication kana kwete.

Manufacturing Process ye Heat Sink

Mushure mekuita thermally simulating Dhizaini yekupisa inonyura, ikozvino yashandurwa kugadzirwa.Ngationei maitiro akasiyana-siyana ekugadzira zvakadzama;

1. CNC-Machining

Heat sink yakagadzirwa neCNC machining

CNC machiningndiyo yakanakisa nzira yekugadzira kupisa-kunyura kune yakaoma maumbirwo.Iyi nzira inopa zvakawanda kushanduka kune vanogadzira.Chivharo chesimbi chese chinoshandiswa kugadzira sink uko kunodiwa zvimbi zvinochekwa nemichina yeCNC uye yakabhenda kubva pasi pechivharo.Zvisinei, inzira inopedza nguva uye inodhura zvikuru.

2. Extrusion

Imwe yeakajairika maitiro ekugadzira kupisa sinks ndeyeextrusion, izvo zvinosanganisira kudzvanya mabheti anopisa e ductile zvinhu mu-high-simba simbi inofa kugadzira ndiro zvimbi.Iwo anoshandiswa kune akawanda ekutonhodza maapplication anosanganisira aluminium kupisa sinks.Ehe, aruminiyamu ndiyo inonyanya kushandiswa zvinhu pakugadzira kupisa sink.

Heat sink yakagadzirwa neExtrusion

Iyo nzira isingadhuri uye yakatwasuka.Izvo zvinopisa zvinopisa zvinogona kushandiswa munzvimbo dzakasiyana-siyana dzekushanda.Nekudaro, nekuda kwehupamhi hwekuwedzera extrusion kurambidzwa, haigone kushandiswa nemasinji ekupisa ane mafins akafara.

3. Casting

Heat sink yakagadzirwa neCasting

Mucastingyeheat-sink,aluminium, mhangura, kana zingi ndizvo zvinhu zvakajairika.Muchiitiko ichi, ingots yezvinhu zvakasarudzwa zvinotanga kunyungudutswa uye kuiswa mukufa kwekupisa-kunyura pamwe nekumanikidzwa.Mushure mekunge iyo jekiseni yemvura yasimbiswa mufa, inoburitswa, uyezve kushoma machining kunoitwa kubvisa chero kusakwana kwepasi.Zvakanakisa kuwana zvimiro zvakaoma nehupamhi hwechokwadi.

4. Kutonhora-kuvhuvhuta

Heat sink yakagadzirwa nechando forging

Ndiyo imwe yakakwirira-chaiyo yekugadzira nzira yekupisa inonyura yakakodzera aluminium uye alloys ayo.Kunyangwe, inoshandawo kune mhangura nebronze.Cold forging inoshandisa kudzvanyirira kwakanyanya uye inokanganisa chimiro chesimbi patembiricha yekamuri kugadzira mapini akatenderera uye ane elliptical ekunyura kwekupisa.Pamusoro pezvo, inoshandiswa kugadzira zvimbi zvine hupamhi hwepamusoro, izvo zvinosimudzira kutamisa kupisa mumamiriro ekumhanya kwemhepo.

5. 3D kudhinda

3D yakadhindwa Heat Sink

Kuvandudzwa kwekudhinda kwe3D senzira yekugadzira masingi ekupisa kwakakonzerwa nekufambira mberi kwehunyanzvi.Powder bed fusion uye inotungamirwa simba deposition tekinoroji ndidzo nzira mbiri dzinonyanya kufarirwa mukudhinda masingi ekupisa.

6. Stamping

Heat sink yakagadzirwa neinotonhora Stamping

Thestampingnzira inoshandiswa painoda kuvaka mapaipi ekupisa mukati mezvimbi.Zvadaro, nekutsikirira simbi dzesimbi, zvimbi zvinogadzirwa.Muzviitiko apo tekinoroji yekumhanyisa yakanyanya kushandiswa, inonyanya kushanda pakugadzirwa kwehuwandu.Zvakadaro, mutengo wakakwira.

Mhedziso

Masingi ekupisa akakosha mumakanika, magetsi, uye midziyo yemagetsi.Muchinyorwa chino, ndatarisa zvakadzama maitiro ekugadzira uye kugadzira kwakanangana nemidziyo yemagetsi.Iyo Dhizaini yekupisa inonyura inopesvedzera zvakanyanya kuwanda kwekupisa, saka yega yega nhanho yekugadzira yakakosha kutevedzera kuitira optimize mashandiro.Uyezve, yekupisa Simulation mushure mekugadzira inobatsira kunzwisisa iyo inoshanda yekushanda mamiriro uye kugadzirisa Dhizaini.

Pano paProleanHub, tine vagadziri vane anopfuura makore gumi eruzivo uye epamusoro mayuniti ekugadzira.Isu tinopa epamusoro-notch kupisa sink kugadzira uye kugadzira masevhisi.Pamusoro pezvo, mainjiniya edu anotevedzera Dhizaini kuti avandudze mashandiro nekuita.Chekupedzisira, dhipatimendi redu rekudzora mhando rinotarisa nhanho yega yega yekugadzira, saka haufanirwe kukanganisa nemhando yedu yebasa, kana iwe uchida kupisa sink kugadzira, chete.taura nesu.

FAQ's

Ndingavandudza sei kushanda kwemasikisi ekupisa?

Kushanda zvakanaka kunogona kuwedzerwa nenzira dzakati wandei, kusanganisira kudzikira kupisa kwekupisa, kukwenenzvera saizi yefin, chimiro, uye kuronga, nekuvandudza iyo fin interface.

Ndechipi chinhu chakanakisa chemazino ekupisa?

Zvinhu zvakanakisisa zvekupisa sinks ndeyemhangura nealuminium alloys.Zvakare, kunyange zvakadaro, chiyero chekupisa chinotsamira pane Dhizaini yekupisa sink.

Ko sink yekupisa inoshanda sei?

Masingi ekupisa anogadzirwa kubva kune yakakwira yekupisa conductivity zvinhu zvakaita semhangura nealuminium ine zvimbi.Inobatanidzwa kune zvinopisa zvikamu uye inotora kupisa.Ipapo kupisa kwakamisikidzwa kunopera munzvimbo yakatenderedza kuburikidza ne conduction, convection, kana mwaranzi.

Ndeapi matanho ekugadzira emagetsi ekupisa?

Heano matanho;

- Kusarudzwa kwezvinhu

- kugadzirisa chimiro, saizi, uye kuronga kwezvimbi

- Kugadziriswa kwekunamatira (Kupisa sink & chinhu chemudziyo)

- Thermal Interfacing of fins

- Thermal Simulation yeCAD dhizaini

Ndedzipi nzira dzinowanzogadzirwa dzekugadzira singi yekupisa?

CNC machining, casting, forging, Stamping, uye 3D kudhinda inzira dzakajairika.

Nguva yekutumira: Jul-15-2022