I-ProLeanHub.Isikhathi esilinganisiwe sokufunda: imizuzu emi-3, imizuzwana engama-45

CNC imishiniisetshenziswa kakhulu ezimbonini ezihlukahlukene ngenxa yokunemba kwayo okuphezulu, ukunemba, isivinini kanye nokusebenza kahle.Izindleko zezingxenye zomshini we-CNC azikho izindleko ezingaguquki ezingasetshenziswa emhlabeni wonke kumaphrojekthi wemishini ehlukene.Izindleko zephrojekthi yemishini ye-CNC inqunywa inhlanganisela zezici eziningana.

Njengoba izindleko ziwukucatshangelwa okubalulekile kwamaphrojekthi amaningi, kuyatuseka ukuqonda lezi zici kanye nezinga ezithinta izindleko.

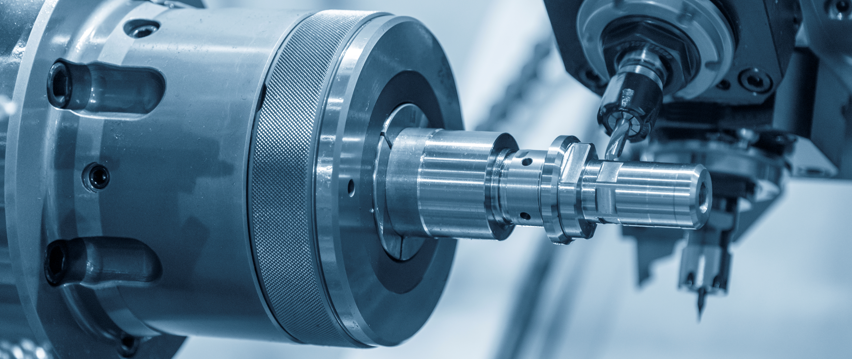

Eqinisweni, abakhiqizi bacabangela izici eziningi lapho bebeka amanani ezingxenyeni ze-CNC.Lokhu kubandakanya, kodwa akupheleli lapho,isikhathi sabo sokukhiqiza, izinto zokwakha, indawo ezungezile, nobunkimbinkimbi.Lesi sihloko sizokusiza ukuthi uqonde izici ezinkulu zezindleko zokwenza imishini ye-CNC futhi wandise iphrojekthi yakho ukuze usizakale ngayo.

1Izinto zezingxenye

2 Inani lezingxenye ezikhiqiziwe

3 Imishini nemishini

4Imishini nemishini

5 Ingxenye yobunkimbinkimbi nobukhulu

6 Ukwelashwa okwengeziwe kanye nezinqubo zokuqeda

1 Izinto zezingxenye

Ukukhethwa kwezinto ezisetshenziselwa izingxenye zomshini kuthinta izindleko ngezindlela ezimbili: izindleko zeAma-Raw materialkanye neizindleko zokusebenzisa imishini.Ezinye izinto zibiza kakhulu kunezinye njengezisetshenziswa zokusetshenziswa, kanti ezinye zinzima kakhulu ukuzenza kunezinye.Impahla ephansiumshini, intengo iphakeme.Uma into ezosetshenziswa ingase ibe yingozi, kuzodingeka izinyathelo zokuphepha ezengeziwe, ngakho izindleko zokukhiqiza zizokhuphuka.Izinto ezisetshenziselwa umshini ingxenye zingathinta kakhulu inani lentengo yomshini.

Ngokwesibonelo,insimbi nama-alloys ayo kungase kuthathe isikhathi eside ukucutshungulwa kunethusi.Lokhu kusho ukuthi abakhiqizi basebenzisa izinsiza eziningi ukucubungula insimbi kunethusi.Ngenxa yalokho, izingxenye zensimbi zizobiza kakhulu uma kuqhathaniswa nethusi.Ngokufanelekile, uma impahla ilukhuni, izobiza kakhulu.Ngaphezu kwalokho, ukutholakala kwempahla nakho kuzothinta izindleko.Okunzima ukuthola izinto ezisetshenziswayo kuvame ukubiza kakhulu futhi kudinga izikhathi ezinde zokucubungula, ngaleyo ndlela andise izindleko.

2Inani lezingxenye ezikhiqiziwe

Enye yezindlela ezilula zokuthola izingxenye zemishini ye-CNC ngentengo ephansi uku-oda izingxenye zokukhiqiza ngobuningi.Lokhu kungenxa yokuthi ukukhiqizwa ngobuningi ishibhile kunokuphatha izingxenye ngazinye.Njengoba inani lezingxenye likhula, izindleko zeyunithi zeqembu lezingxenye ezifanayo zehla kakhulu.

Njengoba kunezingxenye ezengeziwe, imishini ingasethwa ngokuzenzakalelayo futhi izindleko zabasebenzi zizokwehla kakhulu.Nokho, ama-oda amancane angase adinge ukukhiqizwa ngesandla, okungase kwenyuse izindleko ezihambisanayo.

3 Imishini nemishini

Izindleko zezisetshenziswa zitholwa ngaphambi kokuthi ukucubungula kuqale.Nokho, ziyizindleko zokusetha futhi zingathinta izindleko zephrojekthi yomshini.Lapho kubiza kakhulu ukuthenga, ukusebenzisa nokunakekela umshini, kulapho izingxenye ezenziwe ngalowo mshini zizomba eqolo.Futhi uma umkhiqizi engenayo yonke imishini edingekayo, uzofaka enanini izindleko zokukhipha omunye umsebenzi.Ngaphezu kwalokho, uma inqubo yehlisa inani lomshini, lezo zindleko zizofakwa enanini lokugcina.Yingakho ezinye izingxenye ezincane ngokuvamile zibiza kakhulu.

4 Izidingo zokubekezelelana

Ukunemba kuwumgomo wayo yonke inqubo yemishini ye-CNC.Nokho, le nqubo iza ngezindleko.Abakhiqizi bazovame ukukhuphula intengo ngokusekelwe ezingeni lokubekezelela okudingayo.Uma udinga ukunemba okuphezulu, okufana nokuthi +/- 0.001 mm, umkhiqizi angase adinge ukusebenzisa okokusebenza okuhlukile kanye namathuluzi.Angase futhi adinge isikhathi esengeziwe ukuze afike ekunembeni okudingekayo.Ukunemba kwethu okujwayelekile kokubekezelela kusuka ku-+/-0.02mm kuya ku-0.1mm, kuye ngezidingo zekhasimende.

5 Ingxenye eyinkimbinkimbi nosayizi

Izingxenye ezixubile nezinhle kakhulu zinganyusa kakhulu izindleko.Lokhu kungenxa yezinqubo eziningi ezidinga ukuqashwa uma kuqhathaniswa nezingxenye ezilula.Kulula kakhulu ukuklama izingxenye ezingadingekile futhi ezibizayo ngesikhathi sesigaba sokuklama somshini, ngakho-ke kunconywa ukubabuza nonjiniyela bethungaleso sikhathi ukuze ukhiqize izingxenye ozidingayo ngokuphumelelayo.

6 Ukwelashwa okwengeziwe kanye nezinqubo zokuqeda

Ezinye izinhlelo zokusebenza zidinga izingxenye zokwenza imisebenzi yangemva kokwelashwa njengokwelashwa kokushisa, ukulungiswa kwendawo kanye nokunameka ukuze kuthuthukiswe ukusebenza kwazo, ukusebenza kanye nobuhle.Izindleko zamasheya ProLean TECHingxenye eqedwayo ihlanganisa: ukudweba, i-anodizing, i-chrome plating, i-metallizing kanye ne-chrome sputtering, ukumnyama, ukuphrinta isikrini, ukuphrinta ukudluliswa kwamanzi, nokuningi.

CNC machining ngokusebenzisaI-PROLEAN'TECHNOLOGY.

Kwa PROLEAN TECH, sinentshisekelo ngenkampani yethu namasevisi esiwanikeza amakhasimende ethu.Kanjalo, sitshala imali eningi ekuthuthukisweni kwakamuva kwemishini ye-CNC futhi sinonjiniyela abazinikele onakho.Xhumana nathi mahhalacaphuna.

Umbono ka-Prolean uwukuba umhlinzeki wesixazululo oholayo we-On-Demand Manufacturing.Sisebenza kanzima ukwenza ukukhiqiza kube lula, kusheshe, futhi kongiwe kusuka ku-prototyping kuye ekukhiqizeni.

Isikhathi sokuthumela: Mar-24-2022