ProLeanHub.Kiyasta lokacin karantawa: Minti 3, daƙiƙa 45

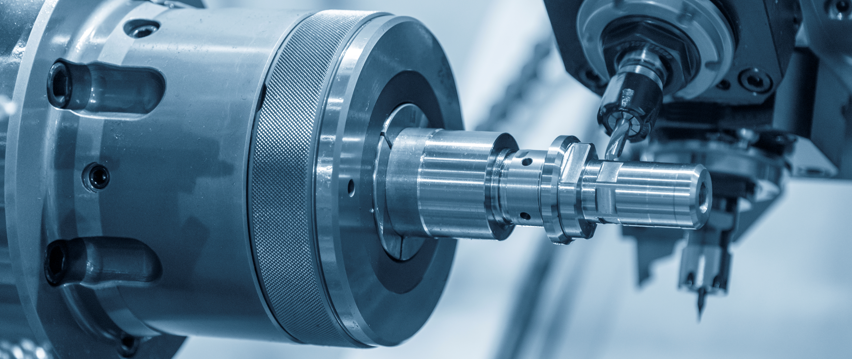

Injin CNCana amfani da shi sosai a masana'antu daban-daban saboda daidaitattun daidaito, daidaito, saurin sauri da inganci.Kuɗin da aka yi amfani da kayan aikin CNC ba shi da ƙayyadaddun farashi wanda za a iya amfani da shi a duk faɗin duniya don ayyukan mashin ɗin daban-daban. na abubuwa da dama.

Tun da farashi yana da mahimmancin la'akari ga yawancin ayyukan, yana da kyau a fahimci waɗannan abubuwan da kuma girman abin da suka shafi farashi.

A gaskiya ma, masana'antun sunyi la'akari da dalilai da yawa lokacin farashin sassan CNC.Wannan ya haɗa da, amma ba'a iyakance ga,lokacin samar da su, kayan aiki, muhalli, da rikitarwa.Wannan labarin zai taimake ka ka fahimci manyan dalilai a cikin CNC machining halin kaka da kuma inganta aikin ku yi amfani da shi.

1Kayan aiki don sassa

2 Yawan sassan da aka samar

3 Kayan aiki da injuna

4Kayan aiki da injuna

5 Sashe mai rikitarwa da girma

6 Ƙarin jiyya da matakan ƙarewa

1 Kayayyaki don sassa

Zaɓin kayan da ake amfani da su don kayan aikin injin yana rinjayar farashi ta hanyoyi biyu: farashinalbarkatun kasada kumafarashin kayan inji.Wasu kayan sun fi wasu tsada a matsayin albarkatun ƙasa, yayin da wasu sun fi sauran wuyar ƙira.Ƙananan kayaninjina, mafi girma farashin.Idan kayan da za a yi amfani da su na da haɗari, za a buƙaci ƙarin matakan tsaro, don haka farashin samarwa zai tashi.Abubuwan da ake amfani da su don injin sashin na iya tasiri sosai ga farashin injin gabaɗaya.

Misali,Karfe da kayan aikin sa na iya ɗaukar tsawon lokaci don sarrafawa fiye da jan ƙarfe.Wannan yana nufin cewa masana'antun suna kashe ƙarin albarkatu don sarrafa ƙarfe maimakon jan karfe.A sakamakon haka, sassan karfe za su fi tsada idan aka kwatanta da tagulla.Da kyau, da wuya kayan, mafi tsada zai zama.Bugu da ƙari, samun kayan aiki kuma zai shafi farashi.Wahalar samun kayan yawanci sun fi tsada kuma suna buƙatar tsawon lokacin sarrafawa, don haka ƙara farashi.

2Yawan sassan da aka samar

Ɗaya daga cikin mafi sauƙi hanyoyin da za a samu sassa na CNC inji a wani m farashin shi ne yin oda sassa domin taro samar.Wannan saboda yawan samarwa yana da arha fiye da sarrafa sassa ɗaya.Yayin da adadin sassan ke ƙaruwa, farashin naúrar rukuni na sassa iri ɗaya yana raguwa sosai.

Tare da ƙarin sassa, ana iya saita injuna ta atomatik kuma farashin aiki zai ragu sosai.Koyaya, ƙananan umarni na iya buƙatar samarwa da hannu, wanda zai iya haɓaka farashin haɗin gwiwa.

3 Kayan aiki da injuna

Ana samun farashin kayan aiki kafin fara sarrafawa.Koyaya, farashin saiti ne kuma suna iya shafar farashin aikin injin.Yayin da ake kashe kuɗi don siya, sarrafa da kula da na'ura, ƙarin tsadar sassan da aka yi da injin ɗin za su yi tsada.Har ila yau, idan masana'anta ba su da duk injunan da ake buƙata, shi / ta za su haɗa da farashin fitar da wasu ayyukan.Bugu da kari, idan tsarin ya rage darajar injin, to wannan kudin kuma za a sanya shi cikin farashi na karshe.Wannan shine dalilin da ya sa wasu ƙananan sassa galibi suna da tsada sosai.

4 Bukatun haƙuri

Maƙasudin shine burin kowane tsarin injin CNC.Koyaya, wannan tsari yana zuwa akan farashi.Masu kera za su ƙara farashin sau da yawa dangane da matakin haƙuri da kuke buƙata.Idan kana buƙatar daidaito mafi girma, kamar +/- 0.001 mm, masana'anta na iya buƙatar amfani da kayan aiki daban-daban da kayan aiki.Hakanan yana iya buƙatar ƙarin lokaci don isa daidaitattun da ake buƙata.Daidaiton haƙurinmu na yau da kullun ya bambanta daga +/- 0.02mm zuwa 0.1mm, dangane da buƙatun abokin ciniki.

5 Sashe mai rikitarwa da girma

Daban-daban da kyawawan sassa kuma na iya haɓaka farashi sosai.Wannan shi ne saboda matakai masu yawa waɗanda ke buƙatar yin aiki idan aka kwatanta da sassa masu sauƙi.Abu ne mai sauqi don tsara sassan da ba dole ba da tsada a lokacin ƙirar ƙirar injin, don haka ana ba da shawarartambaya da injiniyoyinmua wancan lokacin don kera sassan da kuke buƙata da inganci.

6 Ƙarin jiyya da matakan ƙarewa

Wasu aikace-aikacen suna buƙatar sassan da za a yi aikin bayan jiyya kamar maganin zafi, shirye-shiryen saman da shafa don inganta ayyukansu, aiki da ƙawa.Abubuwan da aka bayar na ProLean TECHsashin da aka gama ya haɗa da: zanen, anodizing, chrome plating, metallizing and chrome sputtering, blackening, allo printing, water transfer print, da sauransu.

CNC machining ta amfani daPROLEAN'TECHNOLOGY.

A cikin PROLEAN TECH, Muna sha'awar kamfaninmu da ayyukan da muke ba abokan cinikinmu.Don haka, muna saka hannun jari sosai a sabbin ci gaba a cikin injinan CNC kuma muna da injiniyoyi masu kwazo a hannunku.Tuntube mu kyautazance.

Prolean's hangen nesa shine ya zama jagorar samar da mafita na Masana'antar Buƙatu.Muna aiki tuƙuru don sanya masana'anta cikin sauƙi, sauri, da adana farashi daga samfuri zuwa samarwa.

Lokacin aikawa: Maris 24-2022