CNC machining ntawm tooj dag: Txhua yam koj yuav tsum paub

Xeem tshiab: 09/02, sij hawm nyeem: 8 mins

Ntau yam Brass CNC-machined Cheebtsam

Brass yog ib qho alloy ua los ntawm ob hlau, tooj liab thiab zinc, nyob rau hauv sib txawv proportions.Cov ntsiab lus ntawm ob cov hlau no nyob ntawm qhov xav tau cov khoom siv kho tshuab thiab lub cev.Vim nws cov khoom tshwj xeeb, Brass tau yog cov khoom siv nrov rauCNC machining los tsim ntau yam khoom, los ntawm tsheb thiab khoom siv kho mob mus rau aircraft.Txhua hnub, peb cuam tshuam nrog ntau yam khoom ua los ntawm tooj dag, nrog rau cov rooj tog zaum, qhov rooj, cov khoom siv hauv chav ua noj, cov khoom siv hluav taws xob, cov twj paj nruag, cov khoom pib, thiab lwm yam.

Hauv tooj dag, qhov feem ntawm tooj liab yog siab dua (55 txog 95%) dua li zinc (5 txog 45%).Lead yog lwm cov hlau ntxiv rau Brass hauv qhov tsawg (< 2%).Lub luag haujlwm ntawm cov hlau lead yog ua kom tooj dag yooj yim rau cov txheej txheem CNC machining, xws li txiav, milling, tig, thiab lwm yam.

Hauv tsab xov xwm no, peb yuav nthuav dav,Ntau hom Brass, Khoom, zoo, thiab kev siv ntawm CNC Machined Brass Cheebtsam.

Ntau hom tooj dag qib siv hauv CNC machining

Cov qib tooj dag tau muab faib ua ntau yam kev faib tawm raws li zinc, tooj liab, txhuas, thiab hlau cov ntsiab lus.Cov ntsiab lus ntawm cov ntsiab lus no txawv ntawm lub cev thiab cov khoom siv kho tshuab, ua rau lawv haum rau ntau yam kev siv.Ntawm ntau hom, plaub qibC-360, C-260 & C-280, thiab C-646, yog cov Brass feem ntau siv hauv CNC manufacturing.

C-360

Vim nws superior machinability thiab lub zog, nws yog hom Brass zoo tshaj plaws ntawm lwm tus.Zinc (kwv yees li 35%), Lead & Iron (kwv yees li 3%), thiab cov tooj liab ntxiv ua kom muaj cov C 360- Brass.Feem ntau ntawm nws daim ntawv thov muaj nyob rau hauv tsis siv neeg screws, Musical instruments, hardware, thiab cov khoom siv kho mob.Txawm li cas los xij, vim yog cov ntsiab lus txhuas, nws muaj qee qhov tsis zoo thiab.Piv txwv li, qee zaus nws tuaj yeem tsim cov nplaim tawg thiab ua rau cov kua qaub.

C-260

Qhov no ntxiv zinc-copper formulation muaj ib qho me me ntawm cov hlau lead thiab hlau.Zinc muaj txog 20% thiab 1% txhuas thiab hlau.Vim tias keeb kwm, nws tau siv rau hauv cov mos txwv cartridges, nws kuj tseem hu ua cartridge tooj dag ntawm cov tuam txhab.Qhov no Brass zoo thermal conductivity, corrosion kuj, thiab tensile zog ua rau nws haum rau ntau daim ntaub ntawv, xws li hluav taws xob sockets, costume hniav nyiaj hniav kub, nyees khawm, siab conveyor systems, thiab saib qhov chaw.

C-280

Nws yog qib tooj dag muaj zog, pib tsim rau lub nkoj hull hauv ob sab phlu.Qhov piv ntawm tooj liab rau zinc hauv nws qhov kev tsim kho yog 3: 2.

Nws yog qhov zoo heev rau kev tsim khoom marine thiab architectural Cheebtsam vim nws lub zog siab thiab zoo heev corrosion kuj.

C-464

Cov tooj dag no tshwj xeeb yog siv los tsim cov nkoj nkoj nkoj hauv ib puag ncig nrog cov dej noo siab.

Nws qhov tshwj xeeb muaj pes tsawg leeg muab cov khoom tshwj xeeb corrosion kuj nrog rau lub zog siab.Nws muaj 59% tooj liab, 40% zinc, 1% tin, thiab tsawg heev tin.Tau kawg, ua kom muaj zog ua rau CNC machining nyuaj me ntsis, tab sis peb muaj cov cuab yeej tshwj xeeb thiab cov kws tshaj lij engineers los ua kom nws zoo meej.

Qhov zoo

1. Yooj yim rau Machining

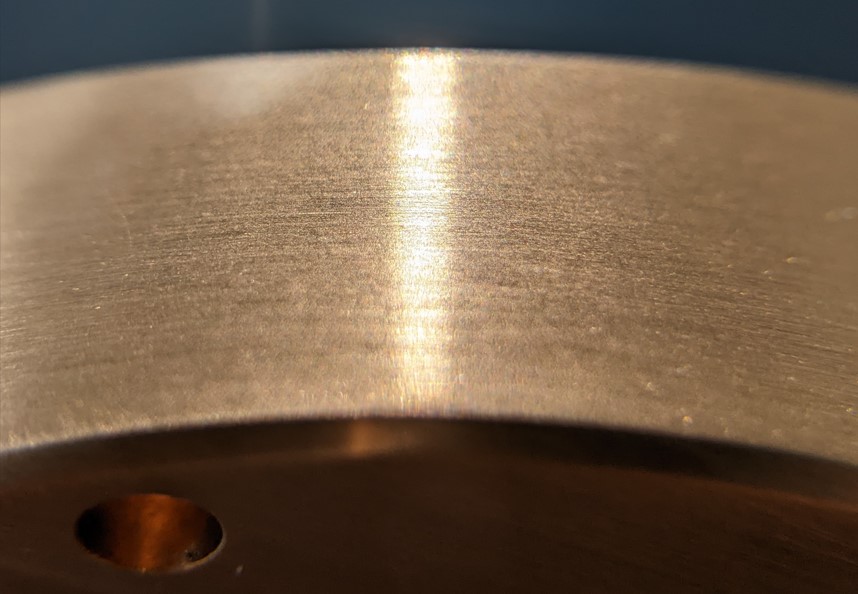

CNC machining ntawm tooj dag pas nrig

Brass yog ib qho ntawm cov khoom siv yooj yim tshaj plaws los ua CNC machining.C-360 muaj 100% machinability tus nqi.Vim hais tias tooj dag tuaj yeem raug machined ntawm high speeds thiab txhim khu cov khoom tshem tawm tus nqi, nws zoo heev machinability zog txo lub sij hawm machining.Feem ntau, tooj dag pas nrig yog siv los ua cov khoom ua haujlwm thiab tsis ua mob rau cov cuab yeej machining thaum siv lub tshuab CNC.

2. Ntau yam khoom

Brass tuaj nyob rau hauv ntau qib nrog ntau yam ntxwv, xws li hardness, elasticity, thiab lub zog.

Cov khoom tsim nyog tau yooj yim ua tiav los ntawm kev sib xyaw sib txawv ntawm tooj liab, zinc, txhuas, thiab hlau.Yog li ntawd, xaiv cov qib tooj dag tsim nyog rau cov khoom yuav tsum tau tsim yog yooj yim.

3. Precise Machining

Brass muaj cov khoom uas ua rau muaj kev ruaj ntseg ntawm CNC machined Cheebtsam, nrog rau qhov tsis muaj deformation coefficient, siab machinability, thiab zoo heev cuam tshuam.

Yog li ntawd, Brass-CNC machining yog ib txoj hauv kev ua tau zoo los tsim cov khoom lag luam uas yuav tsum muaj kev zam nruj.

4. Safe Machining

Tsis zoo li lwm yam ntaub ntawv xws li yas, tooj dag tsis tsim tshuaj lom byproducts thaum CNC machining.Yog li, nws muaj kev nyab xeeb nkaus rau machining vim nws tseem yog cov khoom tsis muaj txim.

5. Tau tshaj cov cuab yeej machining

Thawj qhov kev xaiv rau CNC machining ntawm tooj dag qhov chaw yog pas nrig ua haujlwm.Txawm li cas los xij, tooj dag yog sib xws nrog txhua yam ntawm cov cuab yeej, txawm tias txiav, milling, tig, drilling, lossis lwm yam haujlwm uas yuav tsum tau ua.Cov yam ntxwv ntawm Brass no ua rau muaj kev sib txhuam tsis sib xws thiab ua kom zoo dua qub.

6. Kev rov ua dua tshiab

Brass CNC-machined cov khoom thiab cov khoom siv rov ua dua tshiab.Yog li, tooj dag tuaj yeem rov qab siv dua tom qab rov ua dua thaum cov khoom lag luam lub neej ua tiav.Lwm qhov zoo tshaj plaws yog qhov muaj peev xwm cais cov zinc thiab tooj liab rau rov siv dua.

7. Haum rau ob qho tib si high noo noo thiab kub

Vim tias lawv tsis yaj sai sai ntawm qhov kub thiab txias (tsawg kawg 800 C), cov khoom tsim los ntawm CNC machining tuaj yeem tiv taus cov teeb meem thermal, ua rau lawv yog qhov kev xaiv zoo tshaj plaws rau kev siv qhov kub thiab txias yog qhov nyuaj rau kev ua haujlwm.Tsis tas li ntawd, lawv tuaj yeem tiv taus qhov tsim ntawm xeb nyob rau hauv cov dej noo siab yam tsis tau poob lawv cov khoom.

8. Aesthetic kom zoo dua

Lub Brass yog gleaming thiab tuaj nyob rau hauv ntau yam xim, los ntawm liab mus rau daj.Qhov no yog vim tus nqi ntawm zinc txiav txim siab xim.Yog li ntawd, tsis tas yuav muaj txheej txheej ntxiv piv rau lwm cov ntaub ntawv xws li hlau thiab yas.

Qhov tsis zoo

· Cov tshuaj tiv thaiv oxidation dub yog qhov pheej hmoo nrog tooj dag, yog li nws yuav tsum tau khaws cia ntau zaus.

· Cov khoom siv tooj dag tej zaum yuav muaj kev cuam tshuam rau dezincification vim lawv cov zinc concentration siab.

· Kev ntxhov siab tawg tuaj yeem tshwm sim ntawm cov khoom lag luam tom qab qee lub sijhawm.

Nto Finishes thiab Post-Processing ntawm tooj dag qhov chaw

Raws li tau hais dhau los, Corrosion kuj yog ib qho txiaj ntsig zoo ntawm kev siv tooj dag los tsim cov khoom siv thiab cov khoom siv CNC-machining yog lub kaus mom muaj cov khoom zoo heev corrosion kuj nrog lub zog zoo heev.Yog li feem ntau, tsis muaj txheej yuav tsum tau rau saum npoo.Txawm li cas los xij, koj tuaj yeem siv tes polishing lossis Hone hauv cov ntawv thov zoo nkauj.

Cov khoom siv tooj dag tom qab ua tiav tsawg kawg.

Kev siv ntawm CNC-Machined Brass qhov chaw

Cov khoom siv tooj dag los ntawm CNC machining

CNC-Machined Brass qhov chaw yog siv nyob rau hauv ntau yam lag luam vim lawv ntau yam khoom.

Hluav taws xob Cheebtsam

Vim hais tias ntawm cov khoom siv hluav taws xob ntawm tooj dag, ntau yam khoom siv hluav taws xob xws li Fuse, connectors, Plungers, earthing, panels, power meter parts, power sockets, and others are made with CNC machining of Brass.

Cov khoom siv cua sov

Cov khoom siv kub kub muaj xws li cov ntsuas cua sov, cov tub ntxhais radiator, cov evaporators, cov khoom siv hluav taws xob, cov raj, thiab cov tso tsheb hlau luam.

Automotive Cheebtsam

Log, iav, valve stems, couplings, adapters, Odometer tiv tauj, thiab lwm yam tuaj yeem tsim nrog CNC machining ntawm tooj dag.

Cov kav dej thiab kho vajtse

Cov kav dej, cov kav dej, cov kav dej, cov kav dej, cov qhov rooj da dej, chav dej faib, thiab lwm yam khoom siv.

Koom nrog thiab txuas

Hauv kev lag luam kev lag luam, cov ntsiab lus fastening xws li txiv ntseej, Bolts, hnav daim hlau, flanges, fasteners, thiab bushings yog qhov tseem ceeb.Cov khoom no tuaj yeem ua los ntawm CNC machining ntawm tooj dag nrog qib siab ntawm qhov raug thiab ua tiav.

Hydraulic Cheebtsam:

Cov twj tso kua mis, lub tog raj kheej fais fab, Lub tshuab nqus tsev siab, Pistons, thiab lwm yam.

Tub rog

Ntau yam khoom siv foob pob hluav taws, casing rau phom, mos txwv primers, thiab ntau ntxiv.

Lub dav hlau

Aircraft undercarriage, nres, & cockpit Cheebtsam, tsaws iav, cargo qhov rooj, thiab lwm yam.

Cov qauv thiab architecture

Kev tsim vaj tsev siv tooj dag- CNC machining, suav nrog ntiv tes daim hlau, rooj tog rooj tog, lub tshuab dej nag, Tes tuav, Balustrades, panels, fittings, thiab vov tsev.

Cov khoom siv kho mobs

Txawm hais tias tooj dag tsis siv ntau hauv cov cuab yeej phais, koob, txiab, thiab daim tawv nqaij, cov khoom siv rau kev tswj xyuas qhov siab thiab cov cuab yeej tswj siab siv tooj dag ua nrog CNC machining.

Lwm daim ntawv thov

Lwm cov khoom thiab cov khoom siv yog tsim los ntawm CNC machining ntawm tooj dag, xws li moos qhov chaw, cov khoom sib txawv xws li cov twj paj nruag (Trumpets, Fabkis horns, trombones, thiab baritones), Cov hniav nyiaj hniav kub, thiab lwm yam khoom zoo nkauj.

Kev xav zaum kawg

Cov txiaj ntsig ntawm cov khoom siv tooj dag ua nrog CNC machining suav nrog lawv cov machinability, cov cuab yeej sib raug zoo, lub sijhawm luv luv, ua haujlwm ntev, rov ua dua tshiab, qhov ruaj khov, thiab lwm yam.Tsis tas li ntawd, nws yog qhov tseeb tias lawv sib sau ua ke nce cov khoom lag luam thiab cov txiaj ntsig zoo li cas.Yog li ntawd, cov khoom siv kuj pheej yig thiab siv tau, yog li koj tuaj yeem ua tau tiv tauj peb rau txhua qhov kev ua tooj dag siv lub tshuab CNC.Tsis tas li ntawd, ProleanHub muaj kev pabcuam CNC Machining rau tooj dag qhov chaw.Ntawm no, peb cov kws tswj xyuas kev ua haujlwm zoo saib xyuas txhua kauj ruam machining kom tswj tau tus qauv thiab kev ua siab ntev.

FAQ's

Yuav ua li cas peb thiaj li ua tau zoo ntawm CNC machining rau tooj dag qhov chaw?

Siv cov cuab yeej tsim nyog, cov xwm txheej, thiab cov cuab yeej siv thaum ua cov khoom kom ua tau zoo.

Puas yog CNC machining ntawm tooj dag txoj kev xaiv rau kuv qhov project?

Brass muaj cov cuab yeej zoo heev uas sib txawv raws li cov ntsiab lus ntawm zinc.Nws kuj yog kev lag luam thiab yooj yim rau CNC machining.Yog li nws tuaj yeem haum koj qhov Project.Tsuas yogqhia rau peb paubyam khoom lossis cov khoom koj tab tom nrhiav.Peb cov kws tshaj lij engineers yuav pab koj.Koj tuaj yeem tshawb xyuas peb phau ntawv qhia txog lubCNC tooj liab machining, nws yuav pab koj txiav txim siab ntawm tooj dag thiab tooj liab.

Kuv yuav xaiv qhov zoo tshaj plaws tooj dag alloy qib?

Nws nyob ntawm cov khoom siv thiab cov khoom tsim nyog thiab lub cev zoo, suav nrog hardness, lub zog, ductility, thiab conductivity.Vim tias txhua hom alloy muaj cov khoom tshwj xeeb, xaiv cov qib zoo tshaj plaws tuaj yeem nyuaj.

Yog li, cia peb cov kws tshaj lij txiav txim siab qhov twg yog qhov zoo tshaj plaws rau CNC machining raws li koj xav tau.

Dab tsi yog qhov yuav tsum tau xav txog thaum xaiv cov qib Brass?

Koj yuav tsum xav txog plaub yam tseem ceeb ntawm kev tiv thaiv corrosion, lub zog, machinability, thiab tsos.

Puas machined Cheebtsam ntawm Brass xav tau Deg xov?

Cov khoom feem ntau tsis xav tau cov txheej txheem tom qab ua tiav, tab sis tes polishing yuav zoo dua rau cov khoom ornamental.

Post lub sij hawm: Jun-27-2022