CNC machining na Brass: Duk abin da kuke buƙatar sani

Sabuntawa ta ƙarshe: 09/02, lokacin karantawa: 8 mins

Daban-daban kayan aikin injin Brass CNC

Brass wani abu ne da aka yi shi daga ƙarfe biyu, jan ƙarfe da zinc, mai ma'ana.Abubuwan da ke cikin waɗannan karafa biyu ya dogara ne akan abubuwan da ake buƙata na inji da na zahiri.Saboda ƙayyadaddun kaddarorin sa, Brass ya kasance sanannen abu donInjin CNC don samar da abubuwa daban-daban, daga motoci da na'urorin likitanci zuwa jirgin sama.Kowace rana, muna hulɗa da abubuwa da yawa da aka yi da Brass, ciki har da kayan ɗaki, ƙwanƙolin ƙofa, kayan dafa abinci, wayar lantarki, kayan kiɗa, kayan mota, da ƙari da yawa.

A cikin Brass, adadin jan ƙarfe ya fi girma (55 zuwa 95%) fiye da zinc (5 zuwa 45%).Lead wani ƙarfe ne da aka ƙara zuwa Brass a cikin ƙaramin adadin (< 2%).Matsayin jagorar shine don sauƙaƙe Brass don aikin injin CNC, kamar yankan, niƙa, juyawa, da ƙari.

A cikin wannan labarin, za mu yi sharhi,Nau'o'in Brass iri-iri, Kayayyaki, fa'idodi, da aikace-aikacen abubuwan haɗin Brass na CNC Machined.

Nau'ikan makin tagulla na yau da kullun da ake amfani da su a cikin injinan CNC

An raba maki tagulla zuwa rarrabuwa da yawa dangane da zinc, jan karfe, gubar, da abun cikin ƙarfe.Matsakaicin waɗannan abubuwan sun bambanta a cikin kayan aikin jiki da na inji, yana sa su dace da aikace-aikace da yawa.Daga cikin nau'ikan iri-iri, maki hudu, C-360, C-260 & C- 280, da C-646, sune Brass da aka fi amfani dasu a masana'antar CNC.

C-360

Saboda mafi girman injina da ƙarfinsa, shine mafi kyawun nau'in Brass tsakanin sauran.Zinc (kimanin 35%), Lead & Iron (kimanin kashi 3%), da sauran jan karfe sun hada da C 360- Brass.Yawancin aikace-aikacen sa sun kasance a cikin sukurori ta atomatik, kayan kida, kayan aiki, da sassa don na'urorin likita.Duk da haka, saboda abun ciki na gubar, yana da wasu rashin amfani kuma.Alal misali, yana iya zama lokaci-lokaci yana haifar da ƙarewar fashe kuma yana kula da acid.

C-260

Wannan ƙarin tsari na zinc-Copper ya ƙunshi ƙaramin adadin gubar da baƙin ƙarfe.Zinc ya ƙunshi kusan 20% da 1% gubar da baƙin ƙarfe.Domin a tarihi, an yi amfani da shi a cikin harsashi na harsashi, ana kuma san shi da tagulla a cikin masana'antun.Wannan kyakkyawan yanayin zafi na Brass, juriyar lalata, da ƙarfin ɗaure ya sa ya dace da aikace-aikace da yawa, gami da kwasfa na lantarki, kayan ado, maɓalli, tsarin jigilar matsa lamba, da sassan agogo.

C-280

Yana da ƙaƙƙarfan darajar tagulla, da farko an ƙirƙira don rufin ƙwanƙwasa.Rabon jan karfe da zinc a cikin gininsa shine 3:2.

Yana da matukar tasiri don kera kayan aikin ruwa da na gine-gine saboda ƙarfinsa da kyakkyawan juriya na lalata.

C-464

Ana amfani da wannan Brass musamman don samar da sassan jirgin ruwa na ruwa a cikin mahalli masu yawan danshi.

Abun da ke ciki na musamman yana ba da kaddarorin juriya na ban mamaki tare da babban ƙarfi.Ya ƙunshi 59% jan karfe, 40% zinc, 1% tin, da ƙaramin tin.Tabbas, kasancewa mai ƙarfi yana sa injin ɗin CNC ya ɗan ƙara ƙalubale, amma muna da ƙwararrun kayan aikin da ƙwararrun injiniyoyi don sanya shi cikakke.

Amfani

1. Sauƙi don Machining

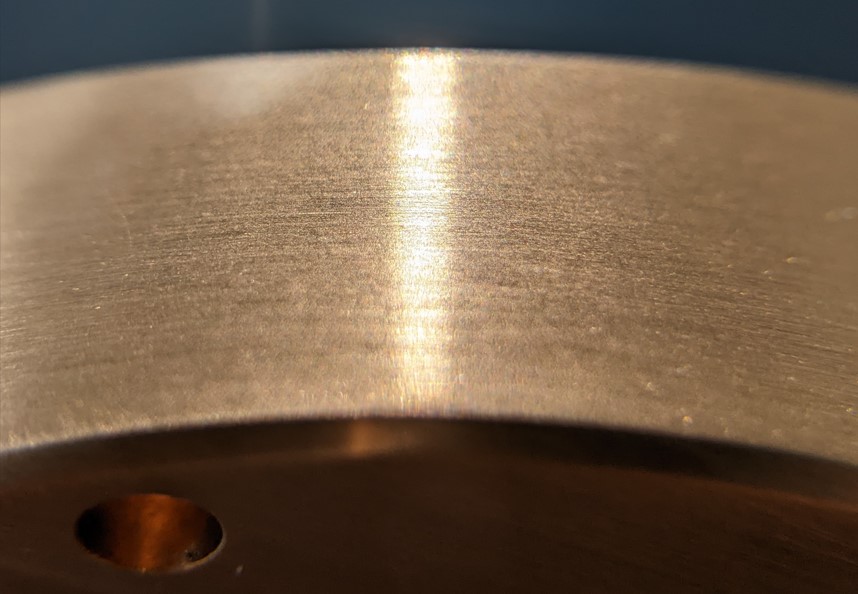

CNC machining na tagulla-sanda

Brass shine ɗayan mafi madaidaiciyar gami don yin aikin injin CNC.C-360 yana da ƙimar injin 100%.Saboda ana iya yin injin Brass a cikin babban sauri kuma yana haɓaka ƙimar kayan cirewa, kyawawan kayan aikin injin sa suna rage lokacin injin.Yawanci, ana amfani da sandunan tagulla azaman kayan aiki kuma ba sa cutar da kayan aikin injin yayin amfani da injin CNC.

2. Kaddarorin iri-iri

Brass ya zo a cikin maki daban-daban tare da halaye daban-daban, gami da tauri, elasticity, da ƙarfi.

Abubuwan da ake buƙata ana iya samun su cikin sauƙi ta hanyar haɗa nau'ikan jan ƙarfe, zinc, gubar, da baƙin ƙarfe.Saboda haka, zabar ma'aunin tagulla mai dacewa don sassan da za a kera yana da sauƙi.

3. Daidaita Machining

Brass yana da kaddarorin da ke ba da gudummawa ga daidaiton daidaiton abubuwan da aka ƙera CNC, gami da ƙarancin nakasawa, babban injin aiki, da ingantaccen juriya.

Saboda haka, Brass-CNC machining wata ingantacciyar hanya ce ta kera samfurin da ke buƙatar tsananin haƙuri.

4. Safe Machining

Ba kamar sauran kayan kamar filastik ba, Brass ba ya samar da abubuwa masu guba yayin aikin CNC.Don haka, yana da lafiya gabaɗaya don yin inji saboda shima abu ne wanda ba shi da walƙiya.

5. Mai jituwa tare da kayan aikin injin

Zaɓin farko don mashin ɗin CNC na sassan tagulla shine guntun aikin sanda.Koyaya, Brass ya dace da kowane nau'in kayan aikin, ko yanke, niƙa, juyawa, hakowa, ko duk wani aiki da ake buƙata don samarwa.Wannan sifa ta Brass tana ba da gudummawa ga mashin ɗin da ba ta da ƙarfi da haɓaka aikin injina.

6. Maimaituwa

Samfuran injin CNC na Brass da abubuwan da aka gyara ana iya sake yin su gaba ɗaya.Don haka, ana iya sake amfani da Brass bayan an sake yin amfani da su lokacin da samfurin rayuwa ya cika.Wani kyakkyawan yanayin shine ikon raba zinc da jan karfe don sake amfani da su.

7. Ya dace da duka babban danshi da zafin jiki

Saboda ba su narke da sauri a yanayin zafi mai zafi (tsawon akalla 800 C), sassan da CNC machining ke samarwa na iya jure wa kalubale na thermal, yana sa su zama kyakkyawan zaɓi don aikace-aikace inda zafin jiki ya zama kalubale ga aiki.Har ila yau, za su iya jure samuwar tsatsa a ƙarƙashin yanayin danshi mai yawa ba tare da rasa kaddarorin su ba.

8. Amfanin ado

Brass yana kyalli kuma yana zuwa da launuka daban-daban, daga ja zuwa rawaya.Wannan saboda adadin zinc yana ƙayyade launi.Sabili da haka, babu buƙatar ƙarin sutura idan aka kwatanta da sauran kayan kamar karfe da filastik.

Rashin amfani

· Halin oxidation na baki yana da haɗari tare da Brass, don haka dole ne a kiyaye shi akai-akai.

· Samfuran tagulla na iya zama masu rauni ga ƙumburi saboda yawan ƙwayar zinc ɗinsu.

· Damuwa na iya tasowa a saman samfurin bayan wani lokaci.

Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙaƙwalwa

Kamar yadda aka ambata a baya, juriya na lalata yana ɗaya daga cikin fa'idodi masu mahimmanci na amfani da Brass don ƙirƙirar samfura da sassa ta amfani da CNC-machining shine hula yana da kyawawan kaddarorin juriya na lalata tare da kyan gani mai kyau.Don haka Yawancin lokuta, ba a buƙatar sutura a saman.Koyaya, zaku iya amfani da goge hannu ko hone a aikace-aikacen ado.

Samfuran Brass bayan ƙarancin ƙarewa.

Aikace-aikace na CNC-Machined Brass sassa

Brass kayayyakin daga CNC machining

Ana amfani da sassan Brass na CNC-Machined a masana'antu daban-daban saboda yawan kaddarorin su.

Abubuwan Wutar Lantarki

Saboda kayan aikin wutar lantarki na Brass, kayan aikin lantarki da yawa kamar Fuse, masu haɗawa, Mai riƙe Plungers, ƙasa, allon allo, sassan mita makamashi, kwas ɗin wuta, da sauransu ana yin su tare da injin CNC na Brass.

Kayan aikin dumama

Na'urorin haɗi masu zafin jiki sun haɗa da ma'aunin zafi da sanyio, muryoyin radiator, masu fitar da iska, masu musayar zafi, bututu, da tankuna.

Abubuwan da ke cikin motoci

Ana iya ƙirƙira ƙafafun, gears, mai tushe bawul, haɗin gwiwa, adaftar, lambobin Odometer, da sauransu tare da injin CNC na Brass.

Plumbing da hardware

Famfon ruwa, Baho, Bututu, Bawul, kofofin shawa, sassan banɗaki, da sauran kayan haɗi.

Shiga da mahada

A cikin masana'antun masana'antu, abubuwan ɗaure kamar su goro, Bolts, sa faranti, flanges, fasteners, da bushings suna da mahimmanci.Ana iya yin waɗannan samfuran daga mashin ɗin CNC na Brass tare da babban matakin daidaito da ƙarancin ƙarewa.

Abubuwan da aka haɗa na Hydraulic:

Pumps, Silinda wutar lantarki, Tsarin jigilar matsi, Pistons, da sauransu.

Soja

Daban-daban na makami mai linzami, harsashin bindiga, alburusai, da sauran su.

Jirgin sama

Jirgin karkashin kasa, birki, & kayan aikin jirgin ruwa, kayan saukarwa, kofofin kaya, da sauransu.

Tsari da gine-gine

Ayyukan gine-ginen suna amfani da injin Brass-CNC, gami da faranti na yatsa, kayan ɗaki na ƙofa, tsarin ruwan sama, Hannun hannu, Balustrades, bangarori, kayan aiki, da rufin rufi.

Sashin Lafiyas

Ko da yake Brass ba a amfani da shi sosai a cikin kayan aikin tiyata, Allura, almakashi, da ƙwanƙwasa, sassa don masu daidaita matsi da na'urorin sarrafa matsa lamba sun yi amfani da sassan tagulla da aka yi da injin CNC.

Sauran aikace-aikace

Sauran kayayyaki da kuma abubuwan da aka yi su ana yin su ne daga injinan CNC na Brass, kamar sassan agogo, abubuwan da suka bambanta kamar kayan kiɗan (Ƙaho, ƙaho na Faransa, trombones, da baritones), Kayan ado, da sauran kayan ado.

Tunani Na Karshe

Fa'idodin samfuran tagulla waɗanda aka yi tare da mashin ɗin CNC sun haɗa da injin su, dacewa da kayan aiki, gajeriyar lokutan sake zagayowar, dorewa, yanayin sake yin amfani da su, kwanciyar hankali mai girma, da sauransu.Bugu da ƙari, ya bayyana a fili yadda suke tare da haɓaka haɓaka da riba a cikin wannan yanayin.Sabili da haka, kayan yana da ƙarancin araha kuma mai amfani, don haka zaka iya tuntube mu ga kowane sarrafa tagulla ta amfani da injin CNC.Bugu da ƙari, ProleanHub yana ba da sabis na ƙwararren CNC Machining don sassan Brass.Anan, injiniyoyinmu masu sarrafa ingancinmu suna lura da kowane matakin injin don kiyaye daidaito da haƙuri.

FAQ's

Ta yaya za mu iya ƙara yawan aiki na CNC machining don Brass sassa?

Yi amfani da kayan aikin da suka dace, yanayi, da kayan aiki lokacin yin injin sassa don ƙara yawan aiki.

Shin CNC machining na Brass shine Zaɓin Dama don Aikina?

Brass yana da kyawawan kaddarorin inji waɗanda suka bambanta bisa ga abun ciki na zinc.Har ila yau, yana da tattalin arziki da sauƙi don aikin CNC.Don haka zai iya dacewa da aikin ku.Kawaisanar da muwane bangare ko samfurin kuke nema.Gogaggun injiniyoyinmu zasu taimake ku.Hakanan zaka iya duba jagorar mu game daCNC jan karfe machining, zai taimaka maka wajen yanke shawara tsakanin tagulla da jan karfe.

Ta yaya zan zaɓi mafi kyawun ma'aunin ƙarfe na ƙarfe?

Ya dogara da aikace-aikacen samfuran da halayen injiniyoyi da na zahiri waɗanda suka haɗa da tauri, ƙarfi, ductility, da haɓakawa.Saboda kowane nau'in gami yana da kaddarorin musamman, zabar mafi kyawun sa na iya zama ƙalubale.

Don haka, bari ƙwararrun mu su yanke shawarar abin da ya fi dacewa don mashin ɗin CNC dangane da buƙatun ku.

Menene abubuwan da ake buƙatar la'akari yayin zabar maki na Brass?

Ya kamata ku yi la'akari da abubuwa huɗu masu mahimmanci na juriya na lalata, ƙarfi, injina, da bayyanar.

Shin abubuwan injina na Brass suna buƙatar kammala saman?

Yawancin abubuwan da aka gyara ba sa buƙatar wani aiki bayan aiwatar da sutura, amma goge hannu zai fi kyau ga kayan ado.

Lokacin aikawa: Juni-27-2022