CNC machining of Brass: Konke odinga ukukwazi

Isibuyekezo sokugcina: 09/02, isikhathi sokufunda: 8 imiz

Izingxenye ezihlukahlukene zomshini we-Brass CNC

Ithusi ingxubevange eyenziwe ngezinsimbi ezimbili, ithusi ne-zinc, ngezilinganiso eziguquguqukayo.Okuqukethwe kwalezi zinsimbi ezimbili kuncike ezintweni ezifunwayo zemishini nezomzimba.Ngenxa yezakhiwo zayo ezihlukile, i-Brass ibe yinto ethandwayoCNC imishini ukukhiqiza izingxenye ezihlukahlukene, kusukela ezimotweni namathuluzi ezokwelapha kuye ezindizeni.Nsuku zonke, sisebenzisana nezinto eziningi ezenziwe nge-Brass, okuhlanganisa ifenisha, izibambo zomnyango, izinto zasekhishini, izintambo zikagesi, izinsimbi zomculo, izingxenye zezimoto, nokunye okuningi.

Ku-Brass, ingxenye yethusi iphakeme (55 kuya ku-95%) kune-zinc (5 kuya ku-45%).Umthofu ungenye insimbi eyengezwe kwi-Brass ngenani eliphansi (< 2%).Iqhaza lomthofu ukwenza i-Brass ibe lula kunqubo yemishini ye-CNC, njengokusika, ukugaya, ukujika, nokunye.

Kulesi sihloko, sizobheka kabanzi,Izinhlobo ezahlukahlukene Zethusi, Izakhiwo, izinzuzo, kanye nokusetshenziswa kwezingxenye ze-CNC Machined Brass.

Izinhlobo ezijwayelekile zamamaki ethusi asetshenziswa kumishini ye-CNC

Amabanga ethusi ahlukaniswe ngezigaba eziningana ngokusekelwe ku-zinc, ithusi, umthofu, kanye nokuqukethwe kwensimbi.Izilinganiso zalokhu okuqukethwe ziyahlukahluka ngezakhiwo ezingokomzimba nezomshini, okuzenza zifanelekele inhlobonhlobo yezinhlelo zokusebenza.Phakathi kwezinhlobo ezahlukene, amamaki amane, C- 360, C- 260 & C- 280, kanye ne-C-646, yiBrass esetshenziswa kakhulu ekukhiqizeni i-CNC.

C-360

Ngenxa yobuchwepheshe bayo obuphezulu namandla, iwuhlobo oluhle kakhulu lwe-Brass phakathi kwezinye.I-Zinc (cishe 35%), iLead & Iron (cishe 3%), kanye nethusi elisele lakha ukwakheka kwe-C 360- Brass.Iningi lezinhlelo zalo zokusebenza bezingezikulufu ezizenzakalelayo, izinsimbi zomculo, ihadiwe, nezingxenye zemishini yezokwelapha.Nokho, ngenxa yokuqukethwe okuholayo, inobubi obuthile futhi.Isibonelo, kwesinye isikhathi ingakhiqiza indawo eqhekekile futhi iyazwela kuma-asidi.

C-260

Lokhu kwakhiwa okwengeziwe kwe-zinc-copper kuqukethe inani elincane lomthofu nensimbi.I-Zinc iqukethe cishe u-20% no-1% umthofu nensimbi.Ngoba ngokomlando, ibisetshenziswa kuma-cartridges ezinhlamvu, yaziwa nangokuthi i-cartridge brass phakathi kwabakhiqizi.Le-Brass ekwazi ukumelana nokushisa kahle, ukumelana nokugqwala, namandla aqinile okuyenza ifanelekele izinhlelo eziningi zokusebenza, okuhlanganisa amasokhethi kagesi, ubucwebe bemvunulo, izinkinobho, amasistimu okudlulisa umfutho, nezingxenye zewashi.

C-280

Yibanga eliqinile lethusi, elaqale lathuthukiswa ulwelwesi lwemikhumbi yesikebhe.Isilinganiso sethusi ne-zinc ekwakhiweni kwayo ngu-3: 2.

Isebenza kahle kakhulu ekukhiqizeni izingxenye zasolwandle nezakhiwo ngenxa yamandla ayo aphezulu kanye nokumelana nokugqwala okuhle kakhulu.

C-464

Le Brass isetshenziselwa ukukhiqiza izingxenye zemikhumbi yemikhumbi ezindaweni ezinamazinga aphezulu omswakama.

Ukwakheka kwayo okuyingqayizivele kunikeza izakhiwo ezingavamile zokumelana nokugqwala kanye namandla aphezulu.Yakha 59% yethusi, 40% zinc, 1% tin, futhi tin kancane kakhulu.Kunjalo, ukuqina kwenza ukusebenza kwe-CNC kube inselele, kodwa sinamathuluzi akhethekile nonjiniyela abangongoti bokuyenza iphelele.

Izinzuzo

1. Easy for Machining

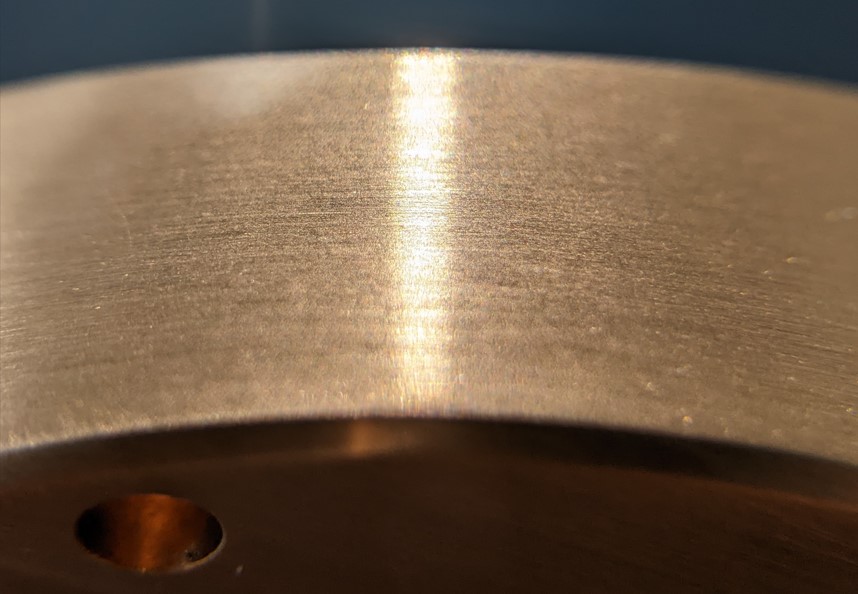

CNC machining of induku yethusi

I-Brass ingenye yama-alloys aqonde kakhulu ukwenza imishini ye-CNC.I-C-360 inesilinganiso sokusebenza esingu-100%.Ngenxa yokuthi i-Brass ingenziwa ngomshini ngesivinini esiphezulu futhi ithuthukise izinga lempahla ekhiphekayo, izici zayo ezinhle kakhulu zokuklama zinciphisa kakhulu isikhathi somshini.Ngokuvamile, izinti zethusi zisetshenziswa njengengxenye yokusebenza futhi azilimazi amathuluzi omshini uma usebenzisa umshini we-CNC.

2. Izinhlobonhlobo zezakhiwo

I-Brass iza ngamamaki ahlukene enezici ezihlukahlukene, okuhlanganisa ubulukhuni, ukunwebeka, namandla.

Izakhiwo ezidingekayo zifinyeleleka kalula ngokuhlanganisa amanani ahlukene ethusi, i-zinc, umthofu, nensimbi.Ngakho-ke, ukukhetha ibanga lethusi elifanele lezingxenye ezizokwenziwa kulula.

3. Imishini Eqondile

I-Brass inezakhiwo ezinomthelela ekuzinzeni kobukhulu bezingxenye zomshini ze-CNC, okuhlanganisa i-coefficient ephansi yokuguqulwa, ukusebenza kahle okuphezulu, kanye nokumelana nomthelela omuhle kakhulu.

Ngakho-ke, ukwenza imishini ye-Brass-CNC kuyindlela ephumelelayo yokwenza umkhiqizo odinga ukubekezelelana okuqinile.

4. Imishini Ephephile

Ngokungafani nezinye izinto ezifana nepulasitiki, i-Brass ayikhiqizi izinto ezinobuthi ngesikhathi somshini we-CNC.Ngakho-ke, iphephe ngokuphelele ekwenzeni imishini ngoba futhi iyimpahla engenanhlansi.

5. Ihambisana namathuluzi omshini

Inketho yokuqala ye-CNC machining yezingxenye zethusi yizicucu zomsebenzi wenduku.Kodwa-ke, i-Brass iyahambisana nazo zonke izinhlobo zamathuluzi, noma ngabe ukusika, ukugaya, ukuphenduka, ukubhola, nanoma yikuphi okunye ukusebenza okudingekayo ekukhiqizeni.Lesi sici se-Brass sinomthelela ekwenziweni kwemishini engashayisani nokwandisa ukusebenza kahle kwemishini.

6. Ukusebenziseka kabusha

Imikhiqizo yomshini we-CNC ye-Brass kanye nezingxenye zigaywa kabusha ngokuphelele.Ngakho-ke, i-Brass ingasetshenziswa kabusha ngemva kokugaywa kabusha lapho umjikelezo wempilo yomkhiqizo usuphelile.Esinye isici esihle kakhulu yikhono lokuhlukanisa i-zinc nethusi ukuze zisetshenziswe kabusha.

7. Ifanele kokubili umswakama ophezulu kanye nezinga lokushisa

Ngenxa yokuthi azincibiliki ngokushesha emazingeni okushisa aphezulu (amelana okungenani no-800 C), izingxenye ezikhiqizwe umshini we-CNC zingamelana nezinselele zokushisa, okuzenza zibe ukukhetha okuhle kwezinhlelo zokusebenza lapho izinga lokushisa liyinselele yokusebenza.Futhi, bangakwazi ukumelana nokwakheka kokugqwala ngaphansi kwezimo eziphakeme zomswakama ngaphandle kokulahlekelwa izakhiwo zabo.

8. Inzuzo yobuhle

I-Brass iyacwebezela futhi iza ngemibala ehlukahlukene, kusukela kobomvu kuye kophuzi.Lokhu kungenxa yokuthi inani le-zinc linquma umbala.Ngakho-ke, asikho isidingo sokumboza okwengeziwe uma kuqhathaniswa nezinye izinto ezifana nensimbi nepulasitiki.

Ukubi

· Ukusabela kwe-oxidation emnyama kuyingozi nge-Brass, ngakho-ke kufanele igcinwe njalo.

· Imikhiqizo yethusi ingase ibe sengcupheni yokukhishwa yizinki ngenxa yokugcwala kwayo kwe-zinc ephezulu.

· Imifantu yengcindezi ingase ivele ebusweni bomkhiqizo ngemva kwesikhathi esithile.

I-Surface Finishes kanye Ne-Post-Processing yezingxenye Zethusi

Njengoba kushiwo ngaphambili, ukumelana nokugqwala kungenye yezinzuzo ezibalulekile zokusebenzisa i-Brass ukwakha imikhiqizo nezingxenye kusetshenziswa i-CNC- machining isigqoko sinezakhiwo ezinhle kakhulu zokumelana nokugqwala nesigqoko esikhanga kakhulu.Ngakho-ke Ezimweni Eziningi, akukho ukunamathela okudingekayo phezulu.Kodwa-ke, ungasebenzisa ukupholisha ngesandla noma i-Hone ezinhlelweni zokuhlobisa.

Imikhiqizo yethusi ngemuva kokuqedwa okuncane.

Ukusetshenziswa kwezingxenye ze-CNC-Machined Brass

Imikhiqizo yethusi evela kumishini ye-CNC

Izingxenye ze-CNC-Machined Brass zisetshenziswa ezimbonini ezahlukahlukene ngenxa yobubanzi bazo bezakhiwo.

Izingxenye zikagesi

Ngenxa yezakhiwo zikagesi ze-Brass, izakhi zikagesi eziningana ezifana ne-Fuse, izixhumi, ama-Holder Plungers, umhlaba, amabhodi wephaneli, izingxenye zamamitha wamandla, amasokhethi kagesi, nezinye zenziwa nge-CNC machining ye-Brass.

Imishini yokushisisa

Izinsiza ezisezingeni eliphezulu zifaka ama-thermostat, ama-radiator cores, ama-evaporator, izishintshi zokushisa, amashubhu, namathangi.

Izingxenye zezimoto

Amasondo, amagiya, iziqu ze-valve, ama-couplings, ama-adaptha, othintana nabo be-Odometer, nokunye kungadalwa nge-CNC machining ye-Brass.

Amapayipi kanye nehadiwe

Ompompi bamanzi, Obhavu, Amapayipi, Amavalvu, iminyango yeshawa, izingxenye zokugezela, nezinye izesekeli.

Ukujoyina nezixhumanisi

Embonini yokukhiqiza, izakhi zokubopha ezifana namantongomane, ama-Bolts, amapuleti okugqoka, ama-flanges, ama-fasteners, nama-bushings abalulekile.Le mikhiqizo ingenziwa ngemishini ye-CNC ye-Brass enezinga eliphakeme lokunemba kanye nesiphetho esibushelelezi.

Izingxenye ze-Hydraulics:

Amaphampu, amasilinda Amandla, amasistimu okuhambisa ingcindezi, amaPistons, nokunye.

Ezempi

Izingxenye ezihlukahlukene zemicibisholo, isikhwama sezibhamu, iziqalo zezinhlamvu, nokunye okuningi.

Izindiza

Impahla yendiza ethwala ngaphansi, amabhuleki, kanye ne-cockpit, amagiya okuhlala, iminyango yezimpahla, njll.

Isakhiwo kanye nezakhiwo

Ukuqaliswa kwezakhiwo kusebenzisa imishini ye-Brass- CNC, okuhlanganisa amapuleti eminwe, ifenisha yezicabha, amasistimu wamanzi emvula, Ama-Handrails, ama-Balustrades, amaphaneli, okokufaka, nokufulela.

Ingxenye Yezokwelaphas

Nakuba i-Brass ingasetshenziswa kakhulu ezintweni zokuhlinza, Izinaliti, izikele, nezikali, izingxenye zezilawuli zokucindezela kanye namadivayisi okulawula ingcindezi asebenzisa izingxenye zethusi ezenziwe ngomshini we-CNC.

Ezinye izinhlelo zokusebenza

Eminye imikhiqizo kanye nezingxenye zenziwa nge-CNC machining Yethusi, njengezingxenye zewashi, izingxenye ezihlukile njengezinsimbi Zomculo (Amacilongo, izimpondo zesiFulentshi, ama-trombones, nama-baritones), ubucwebe, nezinye izinto zokuhlobisa.

Imicabango yokugcina

Izinzuzo zemikhiqizo yethusi eyenziwe ngemishini ye-CNC ihlanganisa ukusebenziseka kwayo, ukuhambisana kwamathuluzi, izikhathi zomjikelezo omfushane, ukuqina, imvelo egaywa kabusha, ukuzinza kobukhulu, nokunye.Ngaphezu kwalokho, kuyacaca ukuthi ngokuhlanganyela bakhulisa kanjani umkhiqizo kanye nenzuzo kuleso simo.Ngakho-ke, indaba iyathengeka futhi iyasebenza, ngakho-ke ungakwazi Xhumana nathi nganoma yikuphi ukucubungula kwethusi kusetshenziswa umshini we-CNC.Ngaphezu kwalokho, i-ProleanHub inikeza insizakalo yobungcweti ye-CNC Machining yezingxenye ze-Brass.Lapha, onjiniyela bethu bokulawula ikhwalithi baqapha isinyathelo ngasinye sokwenza imishini ukuze kugcinwe izinga nokubekezelelana.

Imibuzo Evame Ukubuzwa

Singakwazi kanjani ukwandisa ukukhiqiza kwe-CNC machining yezingxenye ze-Brass?

Sebenzisa amathuluzi afanele, izimo, kanye nezinto zokusebenza lapho wenza izingxenye ukuze wandise ukukhiqiza.

Ingabe ukwenziwa kwe-CNC kwe-Brass kuyisinqumo esilungile sephrojekthi yami?

I-Brass inezakhiwo ezinhle kakhulu zemishini ezihluka ngokuya ngokuqukethwe kwe-zinc.Iphinde ukonga futhi kulula CNC machining.SO ingalingana neProjekthi yakho.Njesaziseiyiphi ingxenye noma umkhiqizo owufunayo.Onjiniyela bethu abanolwazi bazokusiza.Ungahlola futhi umhlahlandlela wethu mayelana neCNC yethusi machining, kuzokusiza ekwenzeni isinqumo phakathi kwethusi nethusi.

Ngingalikhetha kanjani ibanga elingcono kakhulu le-alloy yethusi?

Kuncike ekusetshenzisweni kwemikhiqizo kanye nezimfanelo ezidingekayo zomshini nezomzimba, okuhlanganisa ubulukhuni, amandla, i-ductility, kanye nokusebenza.Ngoba uhlobo ngalunye lwengxubevange lunezinto ezihlukile, ukukhetha ibanga elingcono kakhulu kungaba inselele.

Ngakho-ke, ake ochwepheshe bethu banqume ukuthi yikuphi okungcono kakhulu kwemishini ye-CNC ngokusekelwe ezidingweni zakho.

Yiziphi izinto ezidingekayo okufanele zicatshangelwe ngenkathi kukhethwa amamaki e-Brass?

Kufanele ucabangele izici ezine ezibalulekile zokumelana nokugqwala, amandla, ukusebenziseka kalula, kanye nokubukeka.

Ingabe izingxenye zomshini ze-Brass zidinga ukuqedwa kwe-Surface?

Izingxenye eziningi azidingi noma yikuphi ukucutshungulwa kokunamathela, kodwa ukupholisha ngesandla kungaba ngcono ezintweni zokuhlobisa.

Isikhathi sokuthumela: Jun-27-2022