Menene Maganin Zafi kuma Yaya Sassan Suke Amfanuwa Daga gare shi?

Lokacin karantawa: 5mins

Ma'aikatar kula da zafi

Bayanin Maganin Zafi

Maganin zafi wani tsari ne da ke amfani da dumama da sanyaya mai sarrafawa don canza tsarin kristal na karafa da kayan haɗin ƙarfe (kamar ƙarfe da aluminum).A tsawon lokaci, an samar da hanyoyi daban-daban.Dangane da kayan aiki da tsarin magani, maganin zafi zai iya ba da fa'idodi da yawa,ciki har da ƙãra taurin, ingantacciyar juriya mai zafi, haɓakar ductility, da ƙarfin abu mafi girma.

Kodayake yawancin mutane ba su san menene maganin zafi ba, hakika yana da mahimmanci na tsarin masana'antu.Ana iya amfani da shi a matakai daban-daban na tsarin masana'antu don canza wasu kaddarorin ƙarfe ko gami.Wasu sanannun masana'antu waɗanda maganin zafi ke taka muhimmiyar rawa sun haɗa dajirgin sama, mota, hardware(kamar zato da gatari),kwamfutoci, jirage masu saukar ungulu, sojoji, da masana’antar mai da iskar gas.

Yaya Maganin Zafi yake Aiki?

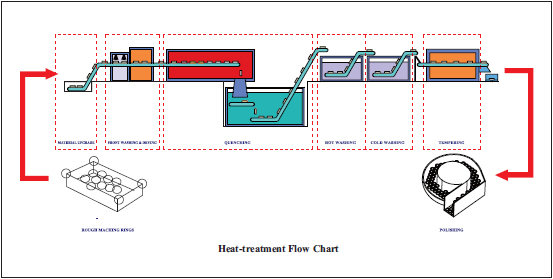

Jadawalin Gudun Jiyya na Zafi

An ambata a baya cewa maganin zafi shine ainihin canji na kayan jiki na ƙarfe ta hanyar sarrafa dumama ko sanyaya, kuma a zahiri maganin zafi yana aiki akan wannan ƙa'ida mai sauƙi.Kodayake akwai nau'ikan maganin zafi da yawa, suna bin irin wannan tsari.A takaice,Maganin zafi yana aiki ta dumama karfe, riƙe shi a yanayin zafin, sannan sanyaya shi baya.Dalilin da ya sa kaddarorin sassan karfe ke canzawa yayin wannan tsari shine cewa yanayin zafi yana canza microstructure na karfe, wanda ke taka muhimmiyar rawa a cikin kayan aikin injiniya na kayan.

Tsawon lokacin da karfen yake dumama ana kiransa “lokacin jiƙa“.Tsawon lokacin jiƙa yana taka muhimmiyar rawa a cikin kaddarorin ƙarfe, saboda ƙananan ƙarfe na ƙarfe da aka jiƙa na dogon lokaci ya bambanta da na ƙarfe da aka jiƙa na ɗan gajeren lokaci.A gefe guda, tsarin sanyaya bayan lokacin jiƙa shima yana da tasiri akan sakamakon ƙarfe.Ana iya sanyaya ƙarfe da sauri, wanda ake kira quenching, ko kuma ana iya sanyaya shi a hankali a cikin tanderu don tabbatar da cewa an sami sakamakon da ake so.Haɗin zafin zafin jiki, lokacin jiƙa, yanayin sanyi da lokacin sanyaya duk suna taka rawa wajen samar da abubuwan da ake so a cikin ƙarfe ko gami.

Don taƙaitawa, tsarin maganin zafi yana buƙatar matakai na asali guda uku,dumama, jiƙa, da sanyaya.

Matakan zafi

Tsarin microstructure na gami yana canzawa yayin aikin maganin zafi.Dumama yana biye da ƙayyadaddun bayanan thermal.A wannan lokacin karfe na iya zama a cikin jihohi daban-daban guda uku, cakuda injina, ingantaccen bayani, ko haɗin duka biyun.Kowace jiha tana kawo halaye daban-daban kuma ana iya canza jihar ta hanyar dumama bisa ga jadawalin lokaci.

Matsayin Jiki

Manufar lokacin jiƙa shine kiyaye ƙarfe a daidai zafin jiki har sai an kafa tsarin da ake so na ciki.Tsawon lokacin ya dogara da buƙatun.Misali, nau'in kayan da girman sashi, lokacin da girman sashin ya fi girma, ana buƙatar ƙarin lokaci.Babban yawancin sassa yana ɗaukar tsayi don isa ga zafin da ake buƙata.

Matakin sanyaya

A lokacin lokacin sanyaya, kuna buƙatar kwantar da ƙarfe zuwa yanayin zafin jiki, amma akwai hanyoyi daban-daban don yin hakan dangane da nau'in ƙarfe.Yana iya buƙatar matsakaicin sanyaya, gas, ruwa, daskararru ko haɗin su.Yawan sanyaya ya dogara da karfe da kanta da matsakaicin sanyaya.Sabili da haka, zaɓin da kuka yi a cikin sanyaya abu ne mai mahimmanci a cikin aikin da ake so na karfe.

Hanyoyi da Fa'idodin Maganin Zafi Na Jama'a

Akwai dabarun maganin zafi da yawa don zaɓar daga.Kowannen su yana dauke da wasu halaye.Mafi yawan hanyoyin magance zafi sun haɗa da:

Taurare

Daya daga cikin mafi yawan nau'ikan maganin zafi,wannan yana ƙara taurin ƙarfe ko gami kuma yana sanya shi ƙasa da ƙwanƙwasa.Gabaɗaya, don tauraruwar saman ba tare da ayyukan tauraruwa na gaba ba, galibi kuma aka sani da nitriding, shine yaɗuwar nitrogen a cikin saman saman ƙarfe na musamman na gami, yana haifar da ƙasa mai ƙarfi da tushe mai laushi ba tare da ƙarin magani ba.

Haushi

Tempering shine tsari na rage taurin wuce kima da taurin da ke haifarwa yayin aikin taurin.Har ila yau an rage matsi na ciki.Gabaɗaya, fushi shine mataki na ƙarshe na aiwatar da hardening.Yana da tsarin maganin zafi wanda ke taimakawa wajen inganta ƙarfin ƙarfe.Abubuwan da ke da ƙarfe na ƙarfe galibi suna da wahala, amma galibi suna da ƙarfi don wasu aikace-aikace.Tempering yana taimakawa wajen canza taurin, raguwa da ductility na karfe.Wannan shi ne don sauƙaƙe tsarin.

Annealing

Annealing yana laushi ƙarfe.Yana sa ƙarfe ya fi dacewa da aikin sanyi da kafawa.Hakanan yana haɓaka machinability, ductility da taurin metal.A cikin aikin annealing, karfe yana zafi sama da babban zafin jiki mai mahimmanci sannan kuma a sanyaya shi a hankali.

Daidaitawa

Normalizing wani nau'i ne na annealing.Ana amfani da shi donsauƙaƙa damuwa na ciki wanda ya haifar ta hanyar matakai kamar walda, simintin gyare-gyare ko quenching. Karfe na al'ada ya fi ƙarfi da ƙarfi fiye da ƙarfe da aka goge.A cikin wannan tsari, ƙarfe yana dumama zuwa zafin jiki 40 ° C fiye da babban zafinsa.A wannan yanayin, karfe yana dumama zuwa 200 ° F, sama da zafin jiki.Ma'aikacin yana kula da ƙarfe a matsanancin zafin jiki har sai canji ya faru.Wannan tsarin maganin zafi yana buƙatar sanyaya iska bayan dumama.

A matsayin jagora a cikin maganin zafi, ProLean Hub yana ba da sabis na magance zafi da yawa.Wuraren mu suna kula da ɓangarorin kowane girma zuwa daidaitattun ma'auni kuma suna ba da ingantaccen, sakamako mai maimaitawa.Ayyukanmu na magance zafi suna sarrafawa ta hanyar wasu injiniyoyi da masu fasaha a cikin masana'antu, tare da kwarewa da ƙwarewa don ba da tallafi mai mahimmanci da fahimtar gaskiya game da bukatun abokan cinikinmu.Kuna iya ziyartar muShafin Maganin Zafidon ƙarin bayani, ko za ku iyamagana kai tsaye da daya daga cikin injiniyoyinmu.

Lokacin aikawa: Afrilu-22-2022