Iintlobo ezi-6 zeplastiki ziyafa, ngaba uyazazi zonke?

Ixesha lokufunda eliqikelelweyo:4 imizuzu, 8 imizuzwana

Ukusetyenziswa kweplastiki kuyanda, kwaye inani leemveliso zeplastiki liyenyuka.Nangona kunjalo, ukuyila kunye nokuveliswa kweemveliso zeplastiki kunzima kakhulu, kwaye iplastiki iyafa kufuneka isetyenziswe ngokusekelwe kwiimpawu zeemveliso zeplastiki ezahlukeneyo.Iinkonzo zokubumba inaliti yeProlean zibonelela ngenye indlela eyongayo nethembekileyo.Iinjineli zethu zinamashumi eminyaka yamava kushishino lokubumba inaliti,qhagamshelana nathi namhlanjekwisicatshulwa sasimahla.

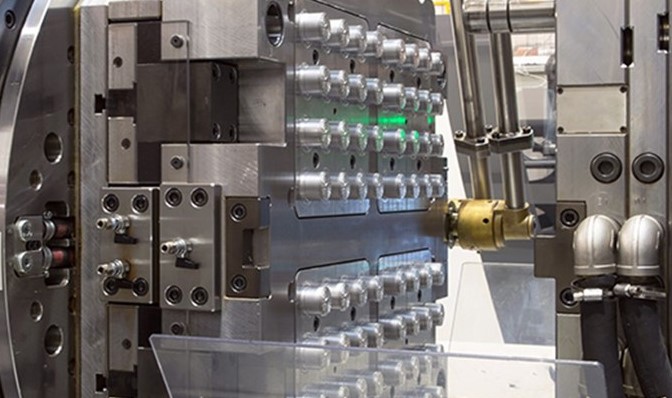

Iplastiki yokufasisixhobo sokuvelisa iimveliso zeplastiki.Kwinaliti yokubumba, ifa ibotshelelwa kumatshini wokubumba, iplastiki etyhidiweyo igalelwe kumngxunya wokubumba kwaye ipholile kwaye ibunjwe kumngxunya, emva koko ukufa okungaphezulu kunye nokusezantsi kuyahlukaniswa, kwaye imveliso ikhutshwa kumngxunya ngokusebenzisa umngxuma. inkqubo ye-ejector kwaye ishiya i-die, kwaye ekugqibeleni i-die ivalwe kwakhona kwisitofu esilandelayo.

Umatshini wokubumba wokutofa, Umthombo ovela: wilimedia

Isitofu sokungunda

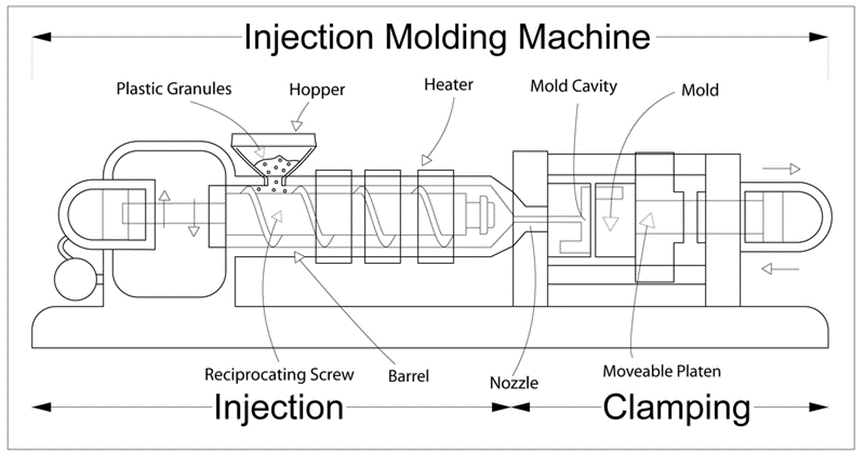

Lolona hlobo luqhelekileyo lwesixhobo sokubumba esisetyenziselwa ukuveliswa kweengxenye ze-thermoplastic.Isixhobo esihambelanayo sokwenza isitofu sokubumba ngumatshini wokubumba inaliti.Iplastiki ifudunyezwa kuqala kwaye inyibilikiswe kumbhobho oshushu womatshini wokubumba inaliti, kwaye emva koko ityhalwe ngesikrufu okanye iplunger yomatshini wokubumba inaliti, ngombhobho womatshini wokubumba inaliti kunye nenkqubo yokugalela yokubumba kwindawo yokubumba, iplastiki ipholile kwaye iqiniswe, kwaye imveliso ikhutshwe kwi-mold.Ulwakhiwo lwalo ngokuqhelekileyo lubandakanyaiindawo zokubumba, inkqubo yokugalela, iindawo ezikhokelayo, ukutyhala ngaphandle, inkqubo yokulawula ubushushu, inkqubo yokukhupha, iindawo ezixhasayo kunye namanye amalungu., kwaye ukuveliswa kwenziwa ngentsimbi yeplastiki yokubumba.Indlela yokulungisa inaliti idla ngokusebenza kuphela kwimveliso yeemveliso ze-thermoplastic.

Indawo yesicelo: iimveliso zeplastiki eziveliswe inkqubo yokubumba inaliti ibanzi kakhulu, ukusuka kwiimfuno zemihla ngemihla ukuya kuzo zonke iintlobo zezixhobo zombane ezintsonkothileyo, iinxalenye ze-auto, njl.njl zonke zenziwe ngenaliti yokungunda, yeyona ndlela isetyenziswa kakhulu kwimveliso yeemveliso zeplastiki.

Vuthela uMngundo

Vuthela ukungunda

Isixhobo esihambelana nokubunjwa kokuvuthela sihlala sibizwa ngokuba ngumatshini wokubumba weplastiki, kwaye ukubumba ukuvuthela kusebenza kuphela kwimveliso yeemveliso ze-thermoplastic.

Indawo yesicelo:ezifana neebhotile zesiselo, iimveliso zemichiza yemihla ngemihla, kunye nezinye iintlobo zezingxobo zokupakisha

Ivuthelo lokukhupha

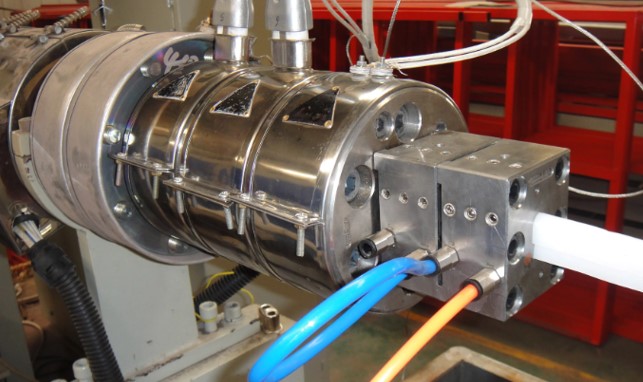

Extruder yeplastiki

Izixhobo zemveliso yi-extruder yeplastiki, umgaqo wokunyibilikisa iplastiki eqinileyo phantsi kweemeko zokufudumeza kunye nokujikelezwa kwesijivu kunye noxinzelelo, iplastiki, kwaye wenze iimveliso zeplastiki eziqhubekayo kunye necandelo elifanayo lomnqamlezo njengemilo yomlomo. fa ngokusebenzisa imilo ethile umlomo die.Izinto zayo zokuvelisa ikakhulu ziquka intsimbi ye-carbon structural, izixhobo ze-alloy, njl.

Indawo yesicelo:Uhlobo lokubumba olusetyenziselwa ukubumba kunye nokuvelisa iimveliso zeplastiki zemilo eqhubekayo, ebizwa ngokuba yi-extrusion molding machine head, esetyenziswa ngokubanzi ekuqhutyweni kwemibhobho, imivalo, i-monofilaments, iipleyiti, iifilimu, i-wire kunye ne-cable cladding, iiprofayili, njl.

I-blister Mold

Ifilim evuthelweyo extrusion kufa

Luhlobo lokungunda olusebenzisa iphepha leplastiki okanye ipleyiti njengemathiriyeli ekrwada ukubumba iimveliso zeplastiki ezilula.Umgaqo wayo kukusebenzisa indlela yokuvula i-vacuum okanye indlela yokwenza umoya ocinezelweyo ukwenza ipleyiti yeplastiki okanye i-sheet egxininiswe kwi-concave mold okanye i-convex mold, kwimeko yokufudumeza kunye nokuthambisa i-deformation kunye nokunamathisela kwi-mold cavity ukuze ufumane iimveliso zokubumba ezifunekayo.Uxinzelelo lwe-blister mold luphantsi, ngoko ke i-mold material ininzi yenziwe nge-aluminium ephosiweyo okanye i-non-metal material, kwaye isakhiwo silula.

Indawo yesicelo:isetyenziswa ikakhulu kwimveliso yezinto eziyimfuneko zemihla ngemihla, ukutya, iithoyi, kunye nezinye iimveliso zokupakisha.

Ukunyanzeliswa ngundo

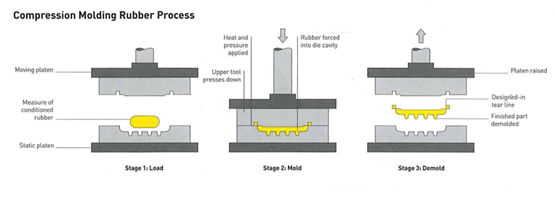

Inkqubo yeRubber yokuBumba ngokucinezela

Isixhobo se-Compression mold ngumatshini wokubumba woxinzelelo.Ukunyanzeliswa kwendlela yokubumba isekelwe kwiimpawu zeplastiki, ukubumba kushushu kwiqondo lokushisa lokubumba (ngokubanzi kwi-103 ° 108 °), kwaye emva koko i-powder yokulinganisa i-compression ifakwe kwi-mold cavity kunye negumbi lokuzalisa.Xa i-mold ivaliwe, iplastiki iyathamba kwaye i-viscous phantsi kobushushu obuphezulu kunye noxinzelelo, kwaye iphiliswe kwaye ibunjwe kwimilo yemveliso oyifunayo emva kwexesha elithile.

Iinkalo zesicelo: Iimolds zenaliti yoxinzelelo zisetyenziswa kakhulu ekufakeni izinto zombane.Izinto ezisetyenziswayo xa kusenziwa imibumbo yokucinezela ziyafana nezo zisetyenziswa kwiinaliti zokubumba.

Ukubumba i-polystyrene eyandisiweyo kakhulu

Kungundo osebenzisa imathiriyeli ekrwada ye-EPS (impahla ye-bead eyenziwe nge-polystyrene kunye ne-ejenti yokuvuthela) ukubumba imathiriyeli yokupakisha yogwebu yeemilo ezahlukeneyo ezinqwenelekayo.

Umgaqo-siseko kukuba i-EPS inokubunjwa ngumphunga kwi-mold.Izinto ezisetyenziselwa ukwenziwa kwezi bumba ziphosa i-aluminium, insimbi engenasici, ubhedu, njl.

Indawo yesicelo:ubukhulu becala isetyenziselwa ukuvelisa iimveliso zokupakisha imveliso.

Ubuchwephesha kunye nobuchule bukaProlean bunceda iinkampani ukuba zivelise ezona ndawo zibunjiweyo zeplastikhi ezinobunzima obunjiweyo.Sinikezela ngeenkonzo zokubumba iinaliti zeplastiki eziphucukileyo njengokubumba iifoti ezininzi kunye nokubumba ngaphezulu koyilo oluntsonkothileyo lokungunda.Faka nje eyakhoiifayile zeCADkwaye ufumane ucaphulo olukhawulezayo lwasimahla kunye nokubonisana kwiinkonzo ezinxulumeneyo.

Ixesha lokuposa: Apr-02-2022