Yadda ake Kera Ƙarfe na Baya don Wayar Salula —CNC Machining don Salon Ƙarfe na Ƙarfe na Waya

Sabuntawar ƙarshe 09/14, lokacin karantawa: 3min

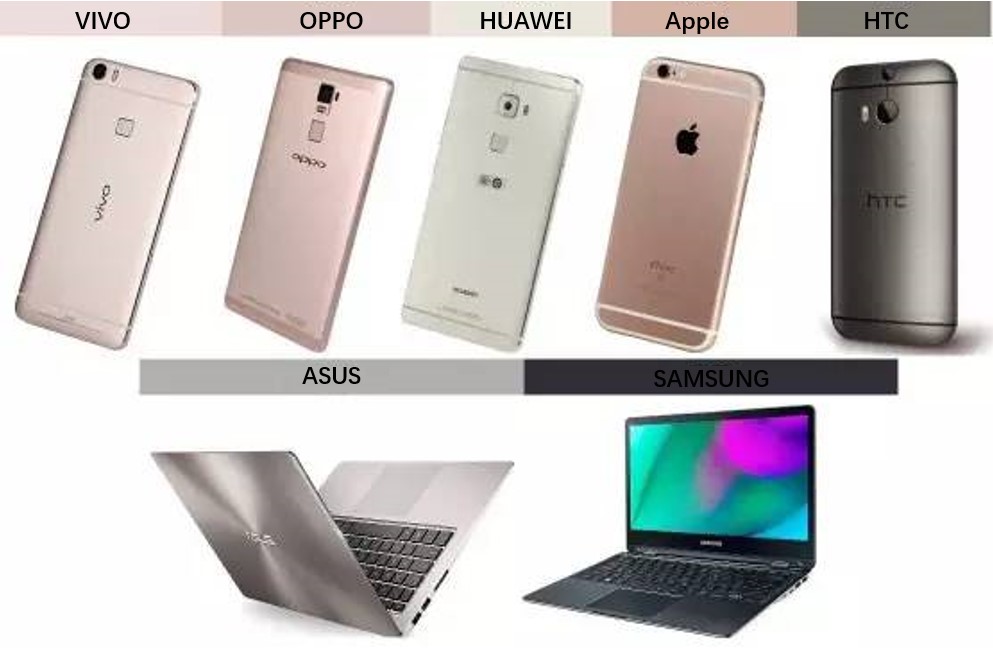

A zamanin yau, yawancin masu kera wayoyin hannu, littafin rubutu da na'urori masu sawa sun fara yin ƙoƙarce-ƙoƙarce kan kayan kwalliyar.Kawai daga filin wayar salula, kayan harsashi na wayar salula kuma a hankali a hankali daga filastik injiniya zuwa canjin karfe.

Juyin halittar harsashi na wayar salula yayin bullowar nau'ikan haɗe-haɗe da yawa: filastik da ƙarfe, gilashin da ƙarfe, duk filastik, duk gilashi, da sauransu, amma a ƙarshe ba su rufe iskar duk kayan ƙarfe ba.Daga ainihin gogewar taɓawa, duk-ƙarfe wayoyin hannu suna da ƙwarewa ta musamman ta fuskoki da yawa, ko bayyanar ko ji sun fi sauran kayan.

Kamfanonin kera na'urorin lantarki sun gabatar da kayan simintin ƙarfe

CNC machining tsari ne kusan mafi kyau duka zabi ga duk-karfe masana'antu.A halin yanzu, duk-karfe gidaje na 3C kayayyakin ana m CNC machined.CNC machining ya zama mafi na kowa machining tsari ga 3C gidaje masana'antun saboda da high dace, high daidaito, da kuma barga machining ingancin.Danna kanCNC machining sabisdon samun cikakken bayani.

A duk-karfe unibody CNC machining tsari aka farko gabatar da Apple - aluminum farantin da aka mutu-jefa daga wani m ginshiƙi na aluminum, wanda aka farko yanke a cikin samfurin na unibody ta daidai machining, kuma kamar yadda jiki a hankali ya dauki siffar. an niƙa sifar madannai da sifofi daban-daban na dabara a jiki.

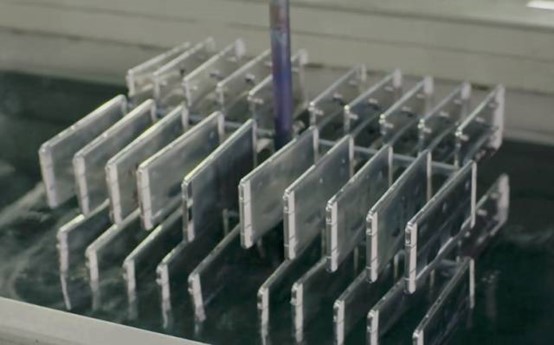

Housing masana'antun bukatar su wuce ta mahara matakai daga shirye-shirye zuwa gama kayayyakin kamar m machining, Semi-m machining, Semi-kammala, karewa, da dai sauransu Sau da yawa, dukan tsari na bukatar fiye da 10 tafiyar matakai don samun ƙãre samfurin, da kuma to. inganta yawan amfanin ƙasa, kowane tsari yana buƙatar kulawa sosai.

Ana samun samfurin da aka gama ta hanyar matakai 12 daga dama zuwa hagu

1. CNC machining pre-tsari aiki: yin tallan kayan kawa da shirye-shirye

Wahalhalun ƙirar ƙirar 3D an ƙaddara ta hanyar tsarin samfurin, wanda ya fi wuyar ƙira kuma ya fi rikitarwa don tsarawa.Kunshin shirye-shiryen ya haɗa da saitin tsari, zaɓin kayan aiki, saitin sauri, nisan abinci na kayan aiki, nisan motsi na kayan aiki, da dai sauransu. Bugu da ƙari, samfurori daban-daban suna da hanyoyi daban-daban na clamping, don haka wajibi ne a tsara kayan aiki mai kyau kafin machining, da wasu. samfurori tare da tsari mai rikitarwa suna buƙatar yin kayan aiki na musamman.

Shirye-shiryen ya haɗa da dukkan tsarin sarrafa samfur.Ko da yake ana aiwatar da bin diddigin ta hanyar CNC ta atomatik, amma shirye-shiryen dole ne su kasance ƙwararrun ma'aikata don aiki, don guje wa gwaji da kuskure da yawa don haɓaka farashi.

2 Babban Tsarin Gudanarwa

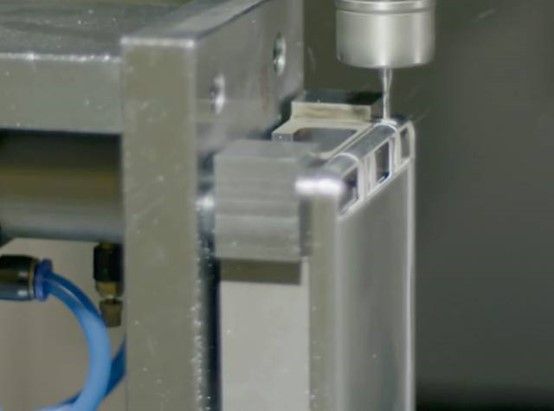

Bidiyon da ke gaba yana nuna manyan hanyoyin injinan CNC da ake buƙata don yin harsashin wayar ƙarfe duka

1) Yin amfani da hakowa mai sauri da cibiyar tapping, an ƙaddamar da farantin aluminum daidai a cikin nau'i mai girma uku na yau da kullum na wani girman girman, shirye don tsari na gaba.

2) Niƙa mai daɗaɗawa: Bayan sanyawa, m niƙa fitar da tsarin rami na ciki, ginshiƙin sakawa haɗe tare da ƙayyadaddun kayan aiki, da niƙa mafi yawan abubuwan da ba su da yawa a waje.

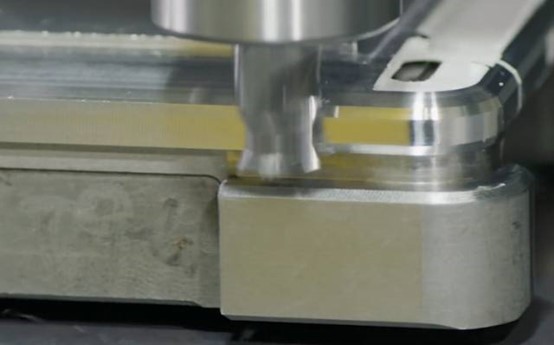

3) Ramin eriya milling: matsalar siginar harsashi-karfe duka yana da wahala, buƙatar niƙa ramin eriya don barin hanyar watsawa don siginar, kiyaye mahimman abubuwan haɗin don tabbatar da ƙarfi da ma'anar jiki gaba ɗaya.

4) CNC Kammala: Kammala milling na ciki rami, waje tsarin, m surface, gefen gefuna, da dai sauransu.

5) gogewa: Yi amfani da kayan aikin injin CNC mai sauri don gogewa, kawar da ƙirar wuka da shirya don fashewar yashi na gaba.

6) fashewar yashi: Ana kula da saman ƙarfe zuwa tasirin fashewar yashi.

7) Ciwon kai:

Primary anodizing: canza launin wayar, anodizing da aluminum zuwa zinariya.Har ila yau inganta kwanciyar hankali na kayan abu

Secondary anodizing: saman jiki don samar da wani m da kuma m oxide fim, sa juriya an kara inganta.

Filastik harsashi gyare-gyaren yin amfani da allura gyare-gyaren tsari, kawai bukatar bude mold iya zama taro samar, da yawan amfanin ƙasa ne sosai high.CNC sarrafa yawan amfanin ƙasa na cikakken jikin ƙarfe an ƙaddara ta hanyar rikitaccen tsari da daidaitattun buƙatun harsashi tare, yana da wahala a cimma wannan babban yawan amfanin ƙasa na harsashi na filastik, don daidaita farashi mai girma, yawancin kamfanonin masana'antu a cikin fuska. na yakin farashin zai zaɓi sayan kayan aikin CNC mai yawa don rage yawan farashi da cimma buƙatun yawan aiki.

Lokacin aikawa: Mayu-11-2022