Ukuthuthukisa Idizayini Yezingxenye Zensimbi Yeshidi - Imihlahlandlela Yokuklama Ishidi Lensimbi

Isikhathi esilinganiselwe sokufunda: amaminithi angu-9, amasekhondi angu-48.

Lapho uklama izingxenye zomkhiqizo, kubalulekile ukucabangela kalula ukwenziwa.Zama ukucabanga ngezindlela zokwenza kube lula ukucutshungulwa, kodwa futhi ukonga impahla, kanye nokukhulisa amandla ngaphandle kwe-scrap.Ngenxa yalokho, abaklami kufanele banake izici ezilandelayo zokukhiqiza

Ukuhleleka kwezingxenye zensimbi zeshidi kubhekisela ezingeni lobunzima bokusika, ukugoba kanye nokwelula izingxenye.Inqubo enhle kufanele iqinisekiseukusetshenziswa okuncane kwezinto ezibonakalayo, inani elincane lezinqubo, ukwakheka okulula kwesikhunta, isikhathi eside sokuphila kanye nekhwalithi yomkhiqizo ezinzile.Ngokuvamile, ithonya elibaluleke kakhulu ekucutshungulweni kwezingxenye zensimbi yizinto ezibonakalayo, ingxenye yejometri, ubukhulu kanye nezidingo zokunemba.

Indlela yokucabangela ngokugcwele izidingo nezici zenqubo yokucubungula lapho uklama isakhiwo sezingxenye zensimbi yeshidi elincane, iziqondiso eziningana zokuklama zinconywa lapha.

1 imihlahlandlela yejiyomethri elula

Ukwakheka kwejometri kwendawo yokusika kulula, kulula futhi kulula ukusika, indlela yokusika ifushane, futhi ivolumu yokusika incane.Ngokwesibonelo,umugqa oqondile ulula kunejika, indilinga ilula kune-ellipse namanye amajika aphezulu, futhi umumo ojwayelekile ulula kunomumo ongajwayelekile.(bheka Umfanekiso 1).

(a) Isakhiwo esingenangqondo (b) Isakhiwo esithuthukisiwe

(Umfanekiso 1)

Isakhiwo se-Fig. 2a senza umqondo owengeziwe kuphela lapho ivolumu inkulu;uma kungenjalo, uma ushaya, ukusika kuyahlupha;ngakho-ke, isakhiwo esiboniswe ku-Fig.2b sifanelekile ukukhiqizwa kwevolumu encane.

(a) Isakhiwo esingenangqondo (b) Isakhiwo esithuthukisiwe

(Umfanekiso 2)

2 Umhlahlandlela wokulondoloza impahla (umhlahlandlela wokuvumelanisa wokubhoboza nokusika izingxenye)

Ukonga izinto ezingavuthiwe kusho ukwehlisa izindleko zokukhiqiza.Izinsalela ze-off-cut zivame ukulahlwa njengemfucumfucu, ngakho-ke ekwakhiweni kwezingxenye zeshidi elincane,ama-off-cuts kufanele ancishiswe.Ukwenqatshwa kokubhoboza kuyancishiswa ukuze kuncishiswe ukulahlwa kwezinto ezibonakalayo.Ikakhulukazi umthamo wezingxenye ezinkulu ngaphansi komphumela wezinto ezibonakalayo ubalulekile, nciphisa ama-off-cut ngezindlela ezilandelayo:

1)Yehlisa ibanga phakathi kwamalungu amabili ancikene (bheka Umfanekiso 3).

(a) Isakhiwo esingenangqondo (b) Isakhiwo esithuthukisiwe

(Umfanekiso 3)

2) Ukuhlelwa okunekhono (bheka umfanekiso 4).

(a) Isakhiwo esingenangqondo (b) Isakhiwo esithuthukisiwe

(Umdwebo 4)

3) Ukususwa kwezinto ezindizeni ezinkulu zezinto ezincane

(a) Isakhiwo esingenangqondo (b) Isakhiwo esithuthukisiwe

(Umfanekiso 5)

3 Imihlahlandlela eyanele yokuqina kwamandla

1) unqenqema olugobile olunonqenqema olugobile kufanele lugweme indawo yokuguquguquka

(Umdwebo6)

2) uma ibanga phakathi kwezimbobo ezimbili lincane kakhulu, kukhona ithuba lokuqhekeka ngesikhathi sokusika.

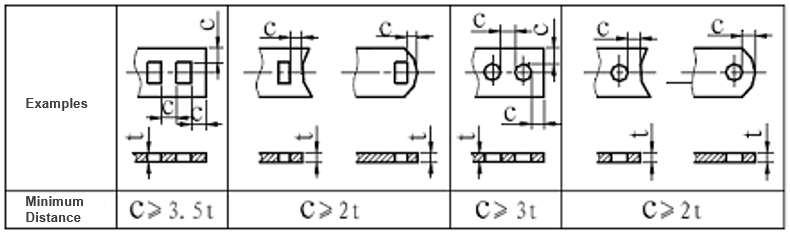

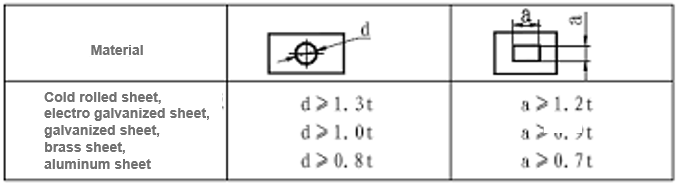

Umklamo weukubhoboza izimbobo engxenyeni kufanele kucatshangelwe ukushiya unqenqema lwembobo ibanga kanye nesikhala sembobo ukuze kugwenywe ukuqhekeka ngezibhakela.Ibanga elincane phakathi konqenqema lwembobo yokubhoboza kanye nokuma kwengxenye linqunyelwe ukubunjwa okuhlukene kwengxenye kanye nembobo.Lapho unqenqema lwembobo yokubhoboza lungahambisani nomkhawulo wengxenye yomumo, ibanga elincane akufanele libe ngaphansi kobukhulu bezinto t;uma ihambisana, akufanele ibe ngaphansi kuka-1.5 t.Ibanga elincane lonqenqema lwembobo kanye nezikhala zembobo zikhonjisiwe kuthebula.

(Umdwebo7)

Iimbobo eyindilinga iyona eqine kakhulu futhi kulula ukuyikhiqiza nokuyinakekela, futhi izinga lokuvula liphansi.Imbobo yesikwele inezinga eliphezulu lokuvula, kodwa ngenxa yokuthi i-engeli engu-90 degree, unqenqema lwekhona kulula ukuguga futhi lugoqe, okubangela ukuba isikhunta silungiswe futhi simise umugqa wokukhiqiza.Futhi imbobo ene-hexagonal evula i-engeli yayo engu-120 degree enkulu kuno-90 degrees kunembobo yesikwele evulekayo eqine kakhulu, kodwa izinga lokuvula emaphethelweni kunembobo yesikwele liyancipha kancane.

3) ama-slats amancane futhi amade anokuqina okuphansi futhi kulula ukukhiqiza imifantu lapho usika, ikakhulukazi ukuguga okujulile kwethuluzi.

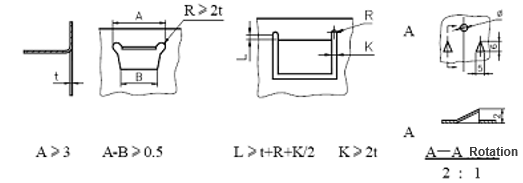

Ukujula nobubanzi bengxenye ephumayo noma ehlehlisiwe yengxenye yokubhoboza, ngokuvamile, akumele kungabi ngaphansi kuka-1.5t (t uwugqinsi lwempahla), futhi kufanele futhi kugweme ukusikwa okuwumngcingo nokude okunemigodi emincane kakhulu futhi emincane kakhulu ukuze kwandiswe. amandla onqenqema engxenye ehambisanayo yokufa.Bheka Umfanekiso (8).

Ngensimbi evamile A ≥ 1.5t;ngensimbi ye-alloy A ≥ 2t;ngethusi, i-aluminium A ≥ 1.2t;t - ukujiya kwempahla.

Umfanekiso(8)

4 Iziqondiso ezithembekile zokubhoboza

Umfanekiso 9a oboniswe kuukucubungula isibhakela semi-circular isakhiwo se-tangent kunzima.Ngoba kudinga ukuzimisela okunembile kokuma okuhlobene phakathi kwethuluzi nomsebenzi.Ukulinganisa okunembile kokuma akudli isikhathi kuphela, kodwa okubaluleke nakakhulu, amaphutha ethuluzi angaguga futhi afake, ukunemba ngokuvamile akufinyeleli ezidingweni eziphezulu kangaka.Uma isakhiwo esinjalo sichezukile kancane emishinini, ikhwalithi inzima ukuqinisekisa futhi ukubukeka kokusika kumpofu.Ngakho-ke, isakhiwo esiboniswe ku-Figure 9b kufanele sisetshenziswe, esingaqinisekisa ikhwalithi yokucubungula ukubhoboza okuthembekile.

(a) Isakhiwo esingenangqondo (b) Isakhiwo esithuthukisiwe

(Umfanekiso 9)

5 Gwema imihlahlandlela yommese onamathelayo (imihlahlandlela yokumisa izingxenye zokungena)

Phakathi ingxenye isibhakela futhi ukusika kuzovela inkinga ithuluzi kanye ingxenye bonding cross-tight.Isixazululo:(1) shiya umthambeka othile;(2) indawo yokusika exhunyiwe(bheka uMdwebo 10 nomfanekiso 11).

(a) Isakhiwo esingenangqondo (b) Isakhiwo esithuthukisiwe (a) Isakhiwo esingenangqondo (b) Isakhiwo esithuthukisiwe

(Figure10) (Figure11)

Lapho i-lap yenziwe ngenqubo yokubhoboza kanye nendlela yokusika ibe yi-90 ° onqenqemeni lokugoba, ukukhethwa kwezinto kufanele kunake izinto akufanele kube nzima kakhulu, ngaphandle kwalokho kulula ukuphuka ekugobeni kwe-angle efanele.Kufanele iklanywe endaweni yenqubo yonqenqema olugobile ukuvimbela ukugqashuka ekhoneni lokugoqa.

(Umfanekiso12)

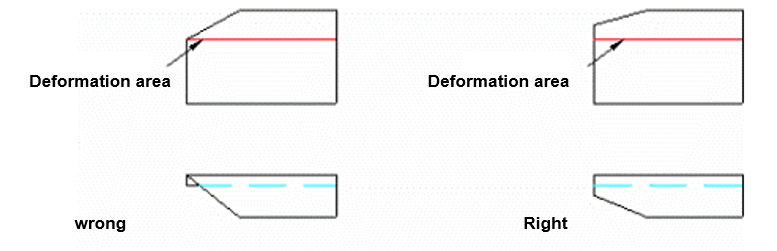

6 onqenqemeni olugobile imihlahlandlela yendawo yokusika eqondile

Ishidi enqubweni yokusika ngemuva kwenqubo ejwayelekile yokubumba, njengokugoba.Unqenqema olugobayo kufanele lube yi-perpendicular endaweni yokusika, ngaphandle kwalokho ingozi yokuqhekeka ezimpambanweni zomgwaqo iphakeme..Uma izidingo eziqondile zingahlangabezwana ngenxa yeminye imikhawulo,indawo yokusika kanye nokuphambana konqenqema olugobayo kufanele kuklanywe ikhoneni eliyindilinga, i-radius yayo inkulu kunokujiya kabili kwepuleti.

7 Iziqondiso zokugoba ngobumnene

Ukugoba umqansa kudinga amathuluzi akhethekile, nezindleko eziphezulu.Ukwengeza, i-radius encane kakhulu egobayo ijwayele ukuqhekeka kanye nokushwabana ebusweni obungaphakathi (bheka uMdwebo 13 kanye noMfanekiso 14).

(a) Isakhiwo esingenangqondo (b) Isakhiwo esithuthukisiwe

(Umfanekiso 13)

(a) Isakhiwo esingenangqondo (b) Isakhiwo esithuthukisiwe

(Umfanekiso14)

8Imihlahlandlela yokugwema imiphetho encane eyindilinga

Imiphetho yezingxenye zepuleti elincanyana kuvame ukugoqwa kwesakhiwo, esinezinzuzo eziningi.(1) qinisa ukuqina;(2) gwema imiphetho ebukhali;(3) enhle.Nokho, onqenqemeni iphuma kufanele sinake amaphuzu amabili, omunye engaba kufanele ibe mkhulu kunezikhathi 1.5 ukushuba ipuleti;okwesibili akusiyo nxazonke ngokuphelele, ukuze ukucubungula kube nzima, Umfanekiso 15b ubonisa unqenqema olugoqiwe kunonqenqema olugoqiwe olulula ukulucubungula.

(a) Isakhiwo esingenangqondo (b) Isakhiwo esithuthukisiwe

(Umfanekiso15)

9 Imihlahlandlela ye-slot edge ayigobi

Unqenqema olugobayo kanye nonqenqema lwembobo yembobo ukuze luhlukaniswe ibanga elithile, inani elinconyiwe irediyasi egobayo kanye nokujiya kodonga oluphindwe kabili.Indawo yokugoba iyinkimbinkimbi yisimo samandla, futhi amandla aphansi.Umphumela we-notch wembobo ye-slot nawo kufanele ukhishwe kule ndawo.Kokubili yonke imbobo yembobo kude nonqenqema olugobayo, kodwa nembobo yembobo kuwo wonke unqenqema olugobayo (bheka uMdwebo 16).

(a) Isakhiwo esingenangqondo (b) Isakhiwo esithuthukisiwe

(Umdwebo16)

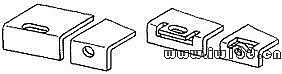

10 Imihlahlandlela yokukhiqiza izakhiwo eziyinkimbinkimbi

Isakhiwo sesikhala siyizici eziyinkimbinkimbi kakhulu, ngokugoba ukwakha kunzima.Ngakho-ke,zama ukuklama isakhiwo ngendlela elula ngangokunokwenzeka, esimweni sokungeyona inkimbinkimbi, inhlanganisela etholakalayo yezingxenye, okungukuthi, inani lezingxenye ezilula zepuleti elincane eline-welding, i-bolting nezinye izindlela zokuhlanganisa ndawonye.Isakhiwo sikaFig. 20b kulula ukusicubungula kunokwakheka kweFig. 17a.

(a) Isakhiwo esingenangqondo (b) Isakhiwo esithuthukisiwe

(Umfanekiso17)

11 Gwema imigqa eqondile ukuze ungene eziqondisweni zezingxenye

Isakhiwo sepuleti elincanyana linobubi bokuqina okugobayo okuphambene.Isakhiwo esikhulu esiyisicaba kulula ukugoba ukungazinzi.Okunye futhi kuzogoba ukuphuka.Ngokuvamile sebenzisa i-pressure groove ukuze uthuthukise ukuqina kwayo.Ukuhlelwa kwe-groove kunethonya elikhulu emphumeleni wokuthuthukisa ukuqina.Umgomo oyisisekelo wokuhlelwa kwe-groove ukugwema uqonde endaweni ngaphandle kwemigodi.Ibhande elincane lokuqina okuphansi lidlula kalula libe yi-eksisi ye-inertia yakho konke ukuntengantenga kwamapuleti.Ukungazinzi kuhlale kuzungeza i-axis ye-inertia, ngakho-ke, ukuhlelwa kwe-groove yokucindezela kufanele kunqamule le-axis ye-inertia futhi yenze ibe mfushane ngangokunokwenzeka.Esakhiweni esiboniswe kuMfanekiso 18a, kwakheka imichilo emincane eminingi endaweni ngaphandle kwezikhala zokucindezela.Ngaphakathi kwalezi zimbazo, ukuqina okugobayo kwepuleti lonke akuthuthukisiwe.Isakhiwo esiboniswe ku-Fig. 18b asinazo izimbazo ze-inertia ezingase zibe namandla axhumene, futhi i-Fig. 19 ibonisa umumo nokuhlelwa kwe-groove evamile, nomthelela wokuqina wokuqina okhuphukayo ukusuka kwesokunxele kuye kwesokudla, futhi ukuhlelwa okungajwayelekile kuyindlela esebenzayo yokugwema uqonde phakathi. .

(a) Isakhiwo esingenangqondo (b) Isakhiwo esithuthukisiwe

(Umfanekiso18)

(Umfanekiso19)

12 Imihlahlandlela yokuhlelwa kokuqhubeka kwe-pressure groove

Amandla okukhathala okuphela kwe-groove yokucindezela abuthakathaka, futhi uma i-groove yokucindezela ixhunyiwe, ingxenye yokuphela kwayo izoqedwa.Umfanekiso 20 yibhokisi lebhethri elolini, lingaphansi komthwalo oguquguqukayo, Umdwebo 20a isakhiwo ku-pressure groove ekupheleni komonakalo wokukhathala.Isakhiwo esikuMdwebo 20b asinayo le nkinga.Iziphetho ze-groove yomfutho ophakeme kufanele zigwenywe futhi, lapho kunokwenzeka, i-groove yokucindezela inwetshelwe emngceleni (bheka uMdwebo 21).Ukungena kwe-groove yokucindezela kuqeda ukuphela okubuthakathaka.Kodwa-ke, ukuphambana kwezikhala zokucindezela kufanele kube kukhulu ngokwanele ukuze kunciphe ukusebenzisana phakathi kwezikhala (bheka Umfanekiso 22).

(a) Isakhiwo esingenangqondo (b) Isakhiwo esithuthukisiwe

(Umfanekiso20)

(a) Isakhiwo esingenangqondo (b) Isakhiwo esithuthukisiwe

(Umfanekiso21)

(a) Isakhiwo esingenangqondo (b) Isakhiwo esithuthukisiwe

(Umfanekiso22)

13 Inkomba ye-Spatial pressure groove

Ukungazinzi kwesakhiwo sendawo akukhawulelwe esicini esithile, ngakho-ke, ukubeka i-groove yokucindezela kuphela endizeni eyodwa akukwazi ukufeza umphumela wokuthuthukisa ikhono lokulwa nokuqiniswa kwesakhiwo sonke.Isibonelo, ezakhiweni ezimise okwe-U- kanye no-Z eziboniswe kuMfanekiso 23, ukungazinzi kwazo kuzokwenzeka eduze kwemiphetho.Isixazululo sale nkinga ukuklama i-groove yokucindezela njengendawo (bheka umdwebo 23b isakhiwo.)

(a) Isakhiwo esingenangqondo (b) Isakhiwo esithuthukisiwe

(Umfanekiso23)

14 Isiqondiso sokunciphisa kancane

Imibimbi iyenzeka lapho ukuguqulwa kwengxenye kuvinjelwa kakhulu epuletini elincanyana.Isixazululo ukusetha ama-grooves amancane okucindezela eduze kwe-crease, ukuze kuncishiswe ukuqina kwendawo futhi kunciphise ukuvinjelwa kokuguqulwa (bona Umfanekiso 24).

(a) Isakhiwo esingenangqondo (b) Isakhiwo esithuthukisiwe

(Umfanekiso24)

15 Imihlahlandlela yokumisa yezingxenye zokubhoboza

1) Ubuncane bokubhoboza ububanzi noma ubude obuncane obuhlangothini bembobo eyisikwele

Ukubhoboza kufanele kukhawulwe ngamandla we-punch, futhiubukhulu be-punch akufanele bube buncane kakhulu, ngaphandle kwalokho i-punch izolimala kalula.Idayamitha yokubhoboza encane kanye nobude obuncane bezinhlangothi buboniswa etafuleni.

* t ukushuba kwento, ubuncane besayizi yesibhakela ngokuvamile abukho ngaphansi kuka-0.3mm.

I-2) Umgomo wokubhoboza we-notch

I-punching notch kufanele izame ukugwema amakhona abukhali, njengoba kuboniswe emfanekisweni.Ifomu elikhonjiwe kulula ukufinyeza impilo yesevisi ye-die, futhi ikhona elibukhali kulula ukukhiqiza imifantu.Kufanele kushintshwe kube njengoba kukhonjisiwe kumfanekiso b.

R ≥ 0.5t (t - ukujiya kwempahla)

a Fig. b Fig.

Amakhona acijile kufanele agwenywe ekubunjweni nasekubhoreni ingxenye ebhontshiwe.Ekuxhumekeni komugqa oqondile noma ijika ukuze ube nokuxhumeka kwe-arc eyindilinga, i-radius ye-arc R ≥ 0.5t.(t ukujiya kodonga)

Ukugoba kweshidi lensimbi ngokusebenzisaI-PROLEAN'TECHNOLOGY.

Kwa-PROLEAN TECH, sinentshisekelo ngenkampani yethu namasevisi esiwanikeza amakhasimende ethu.Ngakho, sitshala imali eningi ekuthuthukisweni kwakamuva kubuchwepheshe bethu futhi sinonjiniyela abazinikele onakho.

Umbono ka-Prolean uwukuba umhlinzeki wesixazululo oholayo we-On-Demand Manufacturing.Sisebenza kanzima ukwenza ukukhiqiza kube lula, kusheshe, futhi kongiwe kusuka ku-prototyping kuye ekukhiqizeni.

Isikhathi sokuthumela: Mar-30-2022