Ukukhethwa kweyona ishidi yentsimbi ye-CNC machining

Sep 19,2022, ixesha lokufunda:7 imiz

Iphepha lesinyithi lezinto ezahlukeneyo

Akukho mpendulo ichanekileyo kumbuzo wezona zinto zibalaseleyo zomatshini we-CNC.Eyona nto ingcono igqitywe yinkqubo yomatshini efunekayo, ukusetyenziswa kwesiphelo, kunye neenkcukacha zenxalenye.

Oomatshini be-CNC banokusebenza ngentsimbi, iplastiki, iinkuni, iiseramikhi, i-composites, kunye nefayibha.Nangona kunjalo, iiPlastiki kunye neentsimbi zezona zinto zisetyenziswa kakhulu kwimveliso ye-CNC.Eli nqaku liza kuxubusha kuphela indlela yokukhetha i-sheet metal, kuquka yonke imiba yendlela yokukhetha, ukulungiswa kwezinto eziphathekayo, kunye nezinye iindlela ezingcono kakhulu zentsimbi.

Izinto ekufuneka ziqwalaselwe

Zininzi izinto ekufuneka ziqwalaselwe ngelixa usenza isigqibo malunga nemathiriyeli efanelekileyo yakhoCNC machining iprojekthi.

Izinto zinokwahlulwa zibe ziindidi ezintlanu.

- Iinkcukacha zamacandelo

- Imisebenzi yomatshini efunekayo

- Ukuphela kokusetyenziswa kwezicelo

- Iipropati ezifunekayo

- Iindleko

1. Iinkcukacha zamacandelo

Ukukhetha i-sheet metal kuxhomekeke kakhulu kwiinkcukacha zamacandelo afunekayo, ahlala ephethe iinkcukacha ezithile zokusebenza kwazo.Ezinye iinkcukacha ezibalulekileyo zibandakanya ubukhulu, ubukhulu, ukunyamezela, kunye nokugqiba umphezulu.Ngelixa ukhetha iinketho ze-sheet metal, ezi nkcukacha kufuneka ziqwalaselwe.Uhlobo ngalunye lwesinyithi luneempawu ezahlukeneyo.Ezi mpawu kufuneka zitshekishwe ukufumanisa ukuba ziyahambelana neenkcukacha zamalungu.

Ukuba amalungu akho aya kusetyenziswaumphezulu owenziwe ngoomatshini, emva koko ungakhetha iphepha elinomphezulu ogqwesileyo ogqibeleleyo.Noko ke, ukuba umphezulu ukugqiba ezifanaumgubo wokugquma, Ukufakwa kweZinc, kwaye ukupeyinta iyakusetyenziswa, unokufuna ukujonga ukuba zeziphi imathiriyeli ezinokwenzeka kukugqiba okufunekayo komphezulu.Ngokufanayo, kufuneka ujonge ubungakanani, ubukhulu, kunye nonyamezelo olufikelelekayo okanye hayi ngohlobo lwephepha lesinyithi olikhethayo kwiprojekthi yakho.

2. Imisebenzi yomatshini efunekayo

CNC machining nge sheet metal

Ngokutsho kuyilo lwamacandelo, okufunekayo CNC imisebenzi machining inokuchongwa, ezifana ukugaya,ukujika, ukugrumba, kunye nabanye.Iphepha lesinyithi olikhethayo kufuneka lihambelane nomsebenzi ofunekayo womatshini we-CNC.Umzekelo, ukuba ukhetha intsimbi ethile engahambelaniyo nomatshini, ixesha lakho kunye nemali iya kuchithwa.Umzekelo, Ukuqina ngundoqo kumacandelo akho, kwaye ukhetha ishidi lentsimbi elukhuni, kodwa kamva elingenakukwazi ukuvelisa ukunyamezela okufunekayo ngelixa ulungisa.

Ngoko ke, kufuneka uchonge ukuba yeyiphi imisebenzi yomatshini efunekayo kwaye luhlobo luni lwesinyithi oluhambelana naloo misebenzi.

Iimpawu zentsimbi zinefuthe ekusebenzeni, ukuqina, kunye nokusebenza kakuhle kwamalungu.Ngokubhekiselele kwiinketho zentsimbi ye-CNC machining,ukusetyenziswa kokuphela kweziceloAmalungu yingqwalasela ebalulekileyo.Ngaphambi kokukhetha uhlobo lwephepha lesinyithi, kufuneka uqwalasele izinto ezimbini ezibalulekileyo phantsi kokusetyenziswa kokuphela kokusetyenziswa.

· Okusingqongileyo

Kufuneka ujongane neemeko zokusingqongileyo apho iinxalenye ziya kuqashwa ekugqibeleni.Kuba okusingqongileyo kuphembelela ukumelana nobushushu, ukuxhathisa ukubola, ukuxhathisa imichiza, kunye nokuvezwa kwe-UV-ray, into yokusingqongileyo isenokungabalulekanga kangako ukuba iindawo zakho zisetyenziswa ngaphakathi.Nangona kunjalo, kuya kufuneka uqwalasele ukuguquguquka kobushushu bokusetyenziswa kwangaphandle, imitha ye-UV, ukufuma, kunye nokuvezwa kweekhemikhali.

Ngenxa yoko, ukhetho lwe-sheet metal kufuneka lukwazi ukunyamezela ezi meko zokusebenza.Umzekelo, ukuba ufuna iindawo eziza kusetyenziswa ngaphandle, kufuneka uqinisekise ukuba izinto ozikhethayo azichaphazeli ukunyamezela ngeemeko zangaphandle ezifana nokushisa kunye nomswakama.

· Amandla oomatshini

Ngolunye uqwalaselo kwizicelo zokusetyenziswa kokuphela.Isixhobo kufuneka sigcine amandla afanelekileyo omatshini kubo bonke ubomi bemveliso.Ngokusekelwe ekusetyenzisweni kwamacandelo, unokubala amandla afunekayo omatshini kunye nezinto ezinokunika loo mandla.

3. Iipropati ezifunekayo

Ilungu ngalinye lifuna uluhlu lwalo lweepropati ukuze lisebenze.Ngenxa yoko, iipropathi ezifunwayo zecandelo kufuneka zihambelane okanye ziwele ngaphakathi koluhlu lweempawu zetsimbi zeShithi (zomzimba, oomatshini, kunye neekhemikhali) ngelixa ukhetha eyona CNC sheet sheet metal.

Iimpawu zomzimba zeshiti lesinyithi, njengamandla okuqina, umlinganiselo wobunzima bobunzima, ukuxhatshazwa kunye nokukrazula, kunye nokuguquguquka, kuya kugqitywa ngumba wokusetyenziswa kwamacandelo.Ngokubanzi, icwecwe elinzima kakhulu linamandla amakhulu omatshini, kodwa umda wobunzima bamalungu nawo kufuneka uqwalaselwe.Ngoko ke, ikhondo elicetyiswayo lesenzo kukuthelekisa amandla omatshini kunye nomlinganiselo wamandla obunzima.

Makhe sixoxe ngeempawu ezibalulekileyo ekufuneka ziqwalaselwe ngexesha lokukhetha.

· Ubunzima

Ukuba ishidi lesinyithi lizalisekisa imfuneko yamandla kumacandelo, ngoko ubunzima kufuneka bucatshangelwe ngokusekelwe kwisicelo.Umzekelo, izinto kufuneka zibe khaphukhaphu kakhulu ukuba iinxalenye zezomoya.

· Ubuchule

Uphawu olulandelayo lubuchule bezinto eziphathekayo.Izixhobo zobuchule obuphezulu zenza ukuba kube lula ukwenziwa kwe-CNC kwaye kunceda ukugcina ukunyamezelana okuqinileyo.Ngoko ke, i-machinability ye-sheet metal nayo inendima kwinkqubo yokhetho.Enye into eza kunye nokuchaneka kukuhambelana nezixhobo kuba ukuba ucinga ngezinto ezinzima kakhulu, ezinokutshabalalisa izixhobo zokusebenza.

· Ukuziphatha ngokushushu

Hlola iimpawu ze-thermal kunye nombane zezinto eziphathekayo ezizalisekisa iimeko zokusebenza kwizicelo zokugqibela.Qwalasela i-conductivity yombane, indawo yokunyibilika, kunye nokwandiswa kwe-thermal Coefficient.Ukuba ukhetha imathiriyeli enendawo yokunyibilika ephantsi kwaye amalungu akho asebenza kumaqondo obushushu aphezulu, oko kunokukhokelela ekusileleni.Ngexesha elifanayo, qwalasela ukuqhutyelwa kombane ngokwesicelo esifunwayo.

4. Iindleko

Iindleko yingqwalasela ephambili xa ukhetha elona phepha lentsimbi lisebenza ngomatshini weCNC.Izinto ezininzi ziyafumaneka kuluhlu lwamaxabiso olwahlukeneyo oluhlangabezana nazo zonke iimfuno zamalungu afunekayo.Ke, Iindleko kufuneka ziqwalaselwe kunye nezinye izinto.Kuyimfuneko ukuhlalutya Iindleko zeshiti zesinyithi ezisekelwe kwiipropati zabo, ezifana nobuqili, amandla, ubunzima, ubunzima, kunye nabanye.

Umzekelo, iAluminiyam lolona khetho lungcono kuba ixabisa ngaphantsi kune-titanium, nangona zombini izixhobo zihlangabezana neemfuno zamandla-kuya-ubunzima bokukhetha icwecwe lentsimbi kwiindawo zangaphakathi zenqwelomoya.

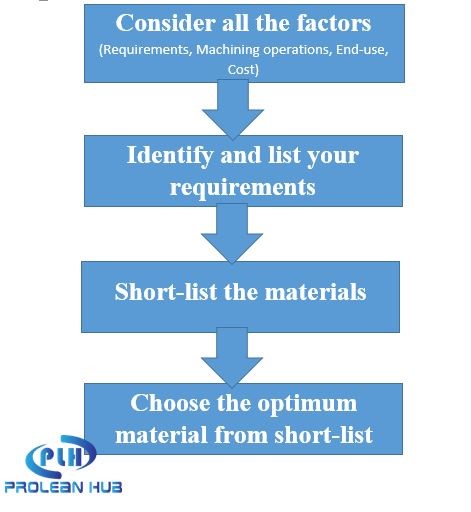

Isikhokelo esinamanyathelo amathathu ekukhetheni elona phepha lentsimbi

Ngaphezulu, sixoxe ngazo zonke izinto ezibalulekileyo eziphembelela inkqubo yokukhetha i-sheet metal kunye nokwenza isigqibo sokuba zeziphi iintlobo ze-sheet metal ezinokuthi zilungele nayiphi na iprojekthi ye-CNC yomatshini.

Ngokusekwe kwizinto ezichaphazelayo, kukho amanyathelo amathathu abalulekileyo onokuthi uwalandele ukukhetha elona phepha lentsimbi kwiprojekthi yakho.

Itshati equkuqelayo yenkqubo yokhetho

Inyathelo 1: Dwelisa iimfuno zakho.

Sixoxile ukuba imfuno yecandelo ingundoqo xa ukhetha izinto ezilungileyo ze-CNC.Kufuneka ibe yeyona nto iphambili kuwe.Ke, dwelisa zonke iimfuno ezinje ngokuqina, ubulukhuni, ubunzima, ukuqina, ukugqiba komphezulu, kunye nabanye.

Umzekelo:

| Iipropati ezifunekayo | Ixabiso/ Inkcazo |

| Tensile strength | Phantsi(< 100 MPa), ephakathi (< 500 MPa), okanye phezulu (> 500 MPa).Ungalungisa amandla okuqina afunekayo kuluhlu ( okt, X ukuya ku Y MPa ) |

| Amandla acinezelayo | Khetha kuPhantsi, ophakathi, nophezulu, okanye inokuba luluhlu oluchaziweyo. |

| Ukuqina | Khetha kuPhantsi, ophakathi, nophezulu, okanye inokuba luluhlu oluchaziweyo( oko kukuthi, X ukuya kuY HRB ) |

| Umlinganiselo wamandla kubunzima | Phantsi, phakathi, okanye phezulu.Kungcono ukucacisa uluhlu lwamalungu abuthathaka, njengamacandelo ezixhobo zonyango. |

| Ukugqitywa komphezulu | Njengomatshini, ukufakwa, ukupeyinta, umgubo wokugquma okanye naluphi na olunye uhlobo, kwiindawo ezibuthathaka ezifana nenqwelomoya, Kungcono ukucacisa uluhlu lwamanani arhabaxa afunekayo (Ra). |

| Ubuchule | Chaza ukuba loluphi uhlobo lobuchule olufunekayo kwiphepha lesinyithi (eliphezulu, eliphakathi, eliphantsi) |

| Ukunyamezelana | ± X ukuya kuY mm |

| Ukolula | Iphezulu, iphakathi, okanye iphantsi. |

Ngokusisiseko, Dwelisa iimfuno ngokuchaza uluhlu okanye udidi (Phantsi, eliphakathi, naphezulu).Enye into kukuba ungadwelisa nayiphi na imfuneko, ungapheleli kulo mzekelo ungasentla.

Inyathelo 2: Yenza uluhlu olufutshane lwezixhobo

Makhe sijonge kwiindidi eziqhelekileyo zeshiti lesinyithi elisetyenziswa kwi-CNC machining.Ngoku dwelisa iintlobo ezahlukeneyo zetsimbi ngokuhambelana neenkcukacha ezidweliswe kwangaphambili.Uluhlu lwezixhobo kufuneka luhambelane neemfuno.

· Aluminiyam

I-Aluminiyam ibonelela ngomlinganiselo ophezulu wamandla-kubunzima, ubuchwephesha, i-ductility, i-thermal & conductivity yombane, ukumelana nokugqwala, kunye nokusebenza kakuhle kweendleko.Inokwenziwa ngokukhawuleza ngoomatshini kwaye isetyenziswe kumashishini amaninzi, kubandakanywa iimoto, i-aerospace, ukwakha, izixhobo zasekhaya, umkhosi, umbane kunye nombane.

· Yenziwe ngentsimbi eshayinayo

Intsimbi engatyiwayo ibonelela ngamandla omatshini aPhezulu, ukuqina, ukuxhathisa kwe-thermal, ukuguga nokukrazuka, kunye nokuqina.Insimbi engenasici inomphezulu okhangayo ogqityiweyo olula kwaye unethoni yesilivere eqaqambileyo.Nangona kunjalo, uhlobo lwe-alloy luchaphazela neempawu ezithile.Ii-alloys ezintathu ezithandwa kakhulu yi-1215, 12L14, kunye ne-1018.

· Ubhedu

I-Brass ibonelela ngobuchule obugqwesileyo, ukomelela okuphezulu, ukuxhathisa impembelelo, kunye nokumelana nokucheba.Idume kakhulu kwimveliso ephantsi-ingxabano, isibheno sobuhle, kunye nemveliso yokunyamezelana ngokungqongqo kuMbane, i-Electronics, i-Automotive, ukukhusela, i-aerospace, i-architecture, unyango, i-Plumbing, kunye namanye amashishini amaninzi.

· I-Titanium

Olona ncedo luphambili lwe-titanium lukwazi ukugcina ubushushu obugqithisileyo, imichiza, kunye nokufuma kwemekobume ngaphandle kokutshintsha iipropathi zayo.Inamanqanaba aphezulu e-biocompatibility, umlinganiselo wamandla-kubunzima, kunye nokuxhathisa ukubola, okwenza ukuba ilungele izithuthi, i-aerospace, kunye namashishini ezonyango.

· Ubhedu

Nangona ibuthathaka kwizinto ezinjengeeasidi, i-halogen sulfides, kunye nezisombululo ze-ammonia, i-copper ineempawu ezinkulu ze-thermal kunye nezombane, i-machinability ephezulu, i-corrosion resistance, kunye nesibheno esibomvu esibomvu esibomvu.Ingasetyenziselwa iiradiyetha, iivalvu zombane, ukufudumeza kunye neenkqubo zokupholisa, kunye nezixhobo zombane ezahlukeneyo.

· Abanye

Ngaphandle kwezi, kukho iintsimbi ezahlukeneyo ezineempawu ezizodwa, ezifanaUbhedu, iZinc, kunye neMagnesium.

Inyathelo lesi-3: Khetha elona phepha lentsimbi kuluhlu olufutshane

Khetha imathiriyeli ezanelisa ngcono zonke iimfuno emva kokunciphisa ukhetho lwesinyithi seshiti elenziwe ngezinto ezahlukeneyo.Xa usenza isigqibo, yithathele ingqalelo ixabiso.Ukuba amaxabiso ehla kakhulu, unganakho ukuthomalalisa kwiimfuno ezithile ngaphandle kokuncama ukusebenza.Nangona kunjalo, ukuba iindawo zinovakalelo, kufuneka ufumane imathiriyeli ehambelana kakhulu neemfuno.

Ingcamango yokugqibela

Ukukhetha olona cwecwe lwesinyithi lweprojekthi yakho yomatshini ye-CNC lukhohlisayo kakhulu.Ibandakanya ukuthathela ingqalelo izinto ezahlukeneyo, kodwa ngeProlean, ilula kakhulu kunokuba ucinga, ibonelela ngeenkonzo zomatshini zeCNC ngaphezulu kwe50+ yesinyithi kunye nealloys.Sinomatshini amacandelo kwiinkcukacha zakho ngokunyamezela okungqongqo.Iinjineli zethu ezinamava ziya kukunceda ukhethe ezona mathiriyeli zibalaseleyo kuhlahlo lwabiwo-mali lwakho kunye neempawu ozifunayo.

Ii-FAQ's

Leliphi icwecwe elinokuba lelona lilungileyo kwiprojekthi yam yomatshini ye-CNC?

Akukho sisombululo esinye.Icwecwe elifanelekileyo leprojekthi yakho ye-CNC liya kuxhomekeka kwizinto ezininzi eziguquguqukayo, kubandakanywa iimfuno zakho kunye neempawu zohlobo oluthile lweshiti lesinyithi.Umzekelo, iAluminiyam inokuba sesona sinyithi silungileyo seendawo zangaphakathi zenqwelomoya, ngelixa icwecwe lentsimbi linokuba lolona khetho lungcono kumalungu olwakhiwo.Ngokwenene, kuxhomekeke ngokupheleleyo kwiimfuno zakho.

Zeziphi izinto ezibalulekileyo ekufuneka ziqwalaselwe ngelixa ukhetha eyona ilungileyosheet metal kumatshini weCNC?

Kukho izinto ezahlukeneyo ezinje ngeemfuno zakho, ukusetyenziswa kokuphela kokusetyenziswa, ukubanakho kobugcisa bokuvelisa, Iindleko, kunye nezinye ezininzi.

Zeziphi ezinye iintlobo eziqhelekileyo zeshiti lentsimbi ezisetyenziswa kumatshini weCNC?

Ezona zixhobo zidumileyo zentsimbi ezisetyenziswa kumatshini we-CNC yintsimbi, iAluminiyam, ubhedu, i-titanium, ubhedu, i-zinc, kunye nobhedu.

Ixesha lokuposa: Sep-19-2022