Ukuphucula uYilo lwaMacandelo eNtsimbi yeShiti-Izikhokelo zoYilo lweShiti

Ixesha lokufunda eliqikelelweyo: imizuzu eli-9, imizuzwana engama-48.

Xa uyila iinxalenye zemveliso, kubalulekile ukuqwalasela ngokulula ukwenza.Zama ukucinga ngeendlela zokwenza kube lula ukusetyenzwa, kodwa kunye nokugcina izinto eziphathekayo, kunye nokwandisa amandla ngaphandle kwe-scrap.Ngenxa yoko, abaqulunqi kufuneka banikele ingqalelo kule miba ilandelayo yokuvelisa

Amacandelo esinyithi enziwe ngobuchule abhekiselele kwiqondo lobunzima bokusika, ukugoba kunye nokwelula amalungu.Inkqubo elungileyo kufuneka iqinisekiseukusetyenziswa kwezinto ezincinci, inani elincinci leenkqubo, uyilo olulula lokungunda, ubomi obuphezulu kunye nomgangatho wemveliso ozinzile.Ngokubanzi, eyona mpembelelo ibalulekileyo ekuqhubekekeni kwamacandelo esinyithi kukusebenza kwezinto, inxalenye yejometri, ubungakanani kunye neemfuno zokuchaneka.

Indlela yokuqwalasela ngokupheleleyo iimfuno kunye neempawu zenkqubo yokucubungula xa kuyilwa isakhiwo samacandelo esinyithi esincinci, izikhokelo ezininzi zoyilo ziyacetyiswa apha.

1 izikhokelo zejometri ezilula

Indlela elula yejometri yendawo yokusika, ilula ngakumbi kwaye ilula ukusika, imfutshane indlela yokusika, kunye nomthamo omncinci wokusika.Umzekelo,umgca othe tye ulula kunegophe, isangqa silula kune-ellipse kunye nezinye ii-curves eziphezulu, kwaye imilo eqhelekileyo ilula kunemilo engaqhelekanga.(jonga uMfanekiso 1).

(a) Ubume obungenangqiqo (b) Ubume obuphuculweyo

(Umfanekiso 1)

Isakhiwo somfanekiso we-2a senza ingqiqo ngakumbi xa umthamo ukhulu;kungenjalo, xa ubetha, ukusika kuyinkathazo;ngoko ke, isakhiwo esiboniswe kwi-Fig.2b sifanelekile kwimveliso yomthamo omncinci.

(a) Ubume obungenangqiqo (b) Ubume obuphuculweyo

(Umfanekiso 2)

2 Isikhokelo sogcino lwezinto (isikhokelo sokungqubana nokubethelwa kunye neenxalenye zokusika)

Ukugcina imathiriyeli ekrwada kuthetha ukunciphisa iindleko zokwenziwa.Izilaphu zokusikwa zihlala zilahlwa njengenkunkuma, ngoko ke kuyilo lwamacandelo amancinci,i-off-cuts kufuneka icuthwe.Ukulahlwa ngamanqindi kuncitshiswe ukunciphisa inkunkuma yezinto.Ngokukodwa kumthamo wamacandelo amakhulu phantsi kwefuthe lezinto eziphathekayo kubalulekile, ukunciphisa i-off-cuts ngeendlela ezilandelayo:

1) Nciphisa umgama phakathi kwamalungu amabini akufutshane (jonga umfanekiso 3).

(a) Ubume obungenangqiqo (b) Ubume obuphuculweyo

(Umfanekiso 3)

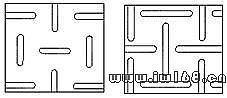

2) Ukucwangciswa kobuchule (jonga umfanekiso 4).

(a) Ubume obungenangqiqo (b) Ubume obuphuculweyo

(Umfanekiso 4)

3) Ukususwa kwezinto kwiindiza ezinkulu kwizinto ezincinci

(a) Ubume obungenangqiqo (b) Ubume obuphuculweyo

(Umfanekiso 5)

3 Izikhokelo zokuqina kokuqina okwaneleyo

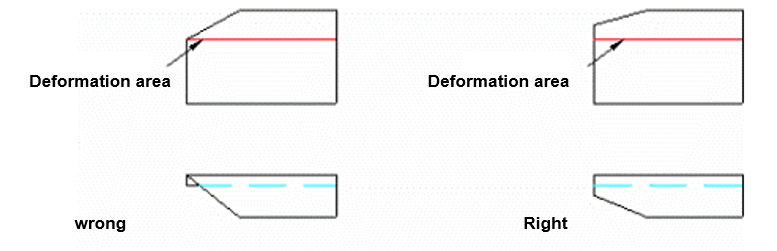

I-1) i-edge yokugoba kunye ne-beveled edge kufuneka igweme indawo yokuguqulwa

(Umfanekiso6)

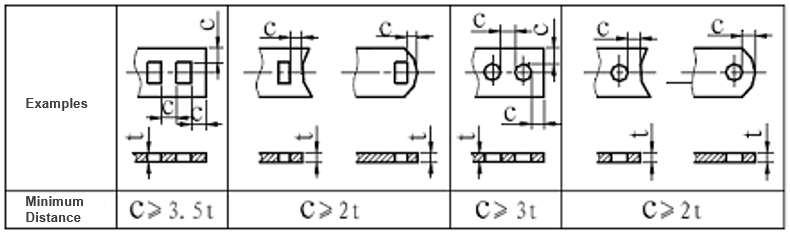

2) ukuba umgama phakathi kwemingxuma emibini incinci kakhulu, kukho ithuba lokuqhawula ngexesha lokusika.

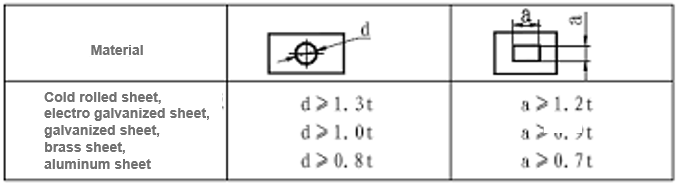

Uyilo lweimingxuma yokugqobhoza kwindawo kufuneka ithathelwe ingqalelo ukushiya umgama ofanelekileyo wecala lomngxuma kunye nesithuba semingxuma ukuphepha ukugqobhoza iintanda.Ubuncinci umgama phakathi komda womngxuma wokubhoboza kunye nokumila kwenxalenye ukhawulelwe yimilo eyahlukeneyo yenxalenye kunye nomngxuma.Xa umda womngxuma wokubhoboza ungahambelani nomda wemilo yenxalenye, umgama omncinci kufuneka ungabi ngaphantsi kobunzima bezinto t;xa ihambelana, kufuneka ingabi ngaphantsi kwe-1.5 t.Ubuncinane bomgama wongqameko lomngxuma kunye nesithuba semingxuma sibonisiwe kwitheyibhile.

(Umfanekiso7)

Iumngxuma ongqukuva ngowona uqinileyo kwaye kulula ukwenza kunye nokugcina, kwaye izinga lokuvula liphantsi.Umngxuma wesikwere unomlinganiselo ophezulu wokuvula, kodwa ngenxa yokuba i-angle ye-90 degree, i-edge yekona ilula ukuba igugile kwaye idibanise, ibangela ukuba i-mold ilungiswe kwaye imise umgca wokuvelisa.Kwaye umngxuma onehexagonal ovula i-engile yawo ye-120 degree degree ngaphezulu kwe-90 degrees kunomngxuma osisikwere ovula okuqinileyo, kodwa izinga lokuvula emphethweni kunomngxuma osisikwere lihlwempuzekile kancinane.

3) ii-slats ezincinci kunye nezide ezinobunzima obuphantsi nazo zilula ukuvelisa iintanda xa usika, ingakumbi ukunxiba okunzulu kwisixhobo.

Ubunzulu kunye nobubanzi bendawo ephumayo okanye ehoxisiweyo yenxalenye yokugqobhoza, ngokubanzi, kufuneka ingabi ngaphantsi kwe-1.5t (t bubukhulu bezinto), kwaye kufuneka kwakhona kuthintelwe ukusika okumxinwa kunye nokude kunye nemijelo emxinwa kakhulu ukuze kwandiswe. ukuqina komphetho wenxalenye ehambelanayo yokufa.Jonga uMfanekiso (8).

Ngentsimbi eqhelekileyo A ≥ 1.5t;kwintsimbi ye-alloy A ≥ 2t;ngenxa yobhedu, i-aluminium A ≥ 1.2t;t - ubukhulu bezinto eziphathekayo.

Umfanekiso(8)

4 Izikhokelo zokubetha ezithembekileyo

Umfanekiso 9a oboniswe kwiisemi-setyhula tangent isakhiwo ukubhobhoza processing kunzima.Ngenxa yokuba ifuna ukuzimisela okuchanekileyo kwendawo ehambelanayo phakathi kwesixhobo kunye nomsebenzi.Umlinganiselo ochanekileyo wokumisa awudli nje ixesha elide, kodwa okona kubaluleke kakhulu, isixhobo siyakwazi ukunxiba kunye neempazamo zokufakela, ukuchaneka ngokuqhelekileyo akufikeleli kwiimfuno eziphezulu.Nje ukuba isakhiwo esinjalo siphambuke kancinci kwi-machining, umgangatho unzima ukuqinisekisa kwaye imbonakalo yokusika imbi.Ngoko ke, isakhiwo esiboniswe kwi-Figure 9b kufuneka sisetyenziswe, esinokuqinisekisa umgangatho othembekileyo wokupakisha.

(a) Ubume obungenangqiqo (b) Ubume obuphuculweyo

(Umfanekiso 9)

5 Ziphephe izikhokelo zemela encangathi (izikhokelo zokumisela iindawo zokungena)

Embindini wecandelo lokubetha kunye nokusika kuya kuvela ingxaki yesixhobo kunye necandelo lokudibanisa ukuqina.Isisombululo:(1) shiya ithambeka elithile;(2) ukusika umphezulu odibeneyo(jonga uMzobo 10 kunye noMzobo 11).

(a) Ulwakhiwo olungenangqiqo (b) Ulwakhiwo oluphuculweyo (a) Ulwakhiwo olungenangqiqo (b) Ulwakhiwo oluphuculweyo.

(Umfanekiso10) (umzobo11)

Xa i-lap yenziwe ngenkqubo kunye ne-punching kunye nendlela yokusika ibe yi-90 ° edge edge, ukukhethwa kwezinto kufuneka kuhlawule ingqalelo kwizinto eziphathekayo akufanele kube nzima kakhulu, ngaphandle koko kulula ukuphuka kwi-engile egobileyo.Kufuneka uyilwe kwindawo yenkqubo egobileyo egobileyo ukuthintela ukugqabhuka kwikona ye-fold.

(Umfanekiso12)

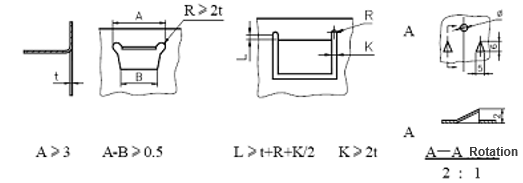

6 ukugoba izikhokelo zomphezulu wokusika ngokuthe nkqo

Iphepha kwinkqubo yokusika emva kwenkqubo yokubumba ngokubanzi, njengokugoba.Umphetho wokugoba kufuneka ube yi-perpendicular kumphezulu wokusika, ngaphandle koko umngcipheko wokuqhekeka kwindawo yokuhlangana uphakanyisiwe..Ukuba iimfuno ezithe nkqo azinakufezekiswa ngenxa yezinye izithintelo,indawo yokusika kunye ne-intersection ye-edge yokugoba kufuneka yenziwe ikona ejikeleziweyo, i-radius yayo inkulu ngaphezu kokuphindwe kabini ubukhulu bepleyiti.

7 Izikhokelo zokugoba ngobunono

Ukugoba umnqantsa kufuna izixhobo ezikhethekileyo, kunye neendleko eziphezulu.Ukongezelela, i-radius encinci kakhulu yokugoba ijwayele ukuqhekeka kunye nokushwabana ebusweni obungaphakathi (jonga uMzobo 13 kunye noMzobo 14).

(a) Ubume obungenangqiqo (b) Ubume obuphuculweyo

(Umfanekiso13)

(a) Ubume obungenangqiqo (b) Ubume obuphuculweyo

(Umfanekiso14)

8Izikhokelo zokuthintela imiphetho ejikelezayo encinci

Imiphetho yamacandelo epleyiti encinci idla ngokuqengqeleka kwimiphetho yesakhiwo, eneenzuzo ezininzi.(1) ukomeleza ukuqina;(2) ziphephe iindawo ezibukhali;(3) intle.Nangona kunjalo, umgca ogqityiweyo kufuneka ubeke ingqalelo kumanqaku amabini, enye i-radius kufuneka ibe nkulu kunamaxesha angama-1.5 ubukhulu beplate;okwesibini ayingqukuvanga ngokupheleleyo, ukwenzela ukuba kube nzima ukucutshungulwa, uMzobo 15b ubonisa i-edge esongiweyo kunomphetho osontiweyo olula ukuwenza.

(a) Ubume obungenangqiqo (b) Ubume obuphuculweyo

(Umfanekiso15)

9 I-Slot edge ayigobi izikhokelo

Umphetho wokugoba kunye ne-slot hole edge ukuba yahlulwe ngumgama othile, ixabiso elicetyiswayo yiradiyasi yokugoba kunye nobukhulu obuphindwe kabini bodonga.Indawo yokugoba iyinkimbinkimbi yimeko yamandla, kwaye amandla aphantsi.Isiphumo se-notch somngxuma wokukrola kufuneka singabandakanywa kule ndawo.Zombini umngxuma wokugoba uphela kude nomngcelele ogobayo, kodwa nomngxuma wokugoba kuwo wonke umphetho wokugoba (jonga uMfanekiso 16).

(a) Ubume obungenangqiqo (b) Ubume obuphuculweyo

(Umfanekiso16)

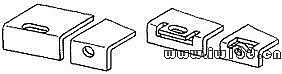

10 Izikhokelo zokwenziwa kolwakhiwo oluntsonkothileyo

Ulwakhiwo lwesithuba lunamacandelo antsonkothileyo, ngokupheleleyo ngokugoba ukwenza kunzima.Ngoko ke,zama ukuyila isakhiwo ngokulula kangangoko, kwimeko ye-non-complicated indibaniselwano ekhoyo yamacandelo, oko kukuthi, inani lamacandelo alula amacwecwe amancinci kunye ne-welding, i-bolting kunye nezinye iindlela zokudibanisa kunye.Ubume bomfanekiso we-20b kulula ukusetyenzwa kunesakhiwo somfanekiso we-17a.

(a) Ubume obungenangqiqo (b) Ubume obuphuculweyo

(Umfanekiso17)

11 Yiphephe imigca ethe tye ukuze ungene kwizikhokelo zecandelo

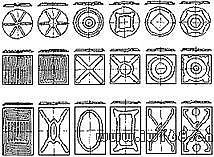

Ulwakhiwo lwepleyiti ebhityileyo inobunzima bokugoba okulambathayo okunqamlezayo.Isakhiwo esikhulu esicaba kulula ukugoba ukungazinzi.Ngaphezu koko kuya kugoba ukwaphuka.Ngokuqhelekileyo sebenzisa i-pressure groove ukuphucula ukuqina kwayo.Ukulungiswa kwe-groove kunempembelelo enkulu kwisiphumo sokuphucula ukuqina.Umgaqo osisiseko wokucwangciswa kwegroove kukuphepha ngokuthe ngqo kwindawo ngaphandle kweegrooves.Ibhanti emxinwa yokuqina okuphantsi kulula ukuba ibe yi-axis ye-inertia yepleyiti ebotsheleyo yonke ukungazinzi.Ukungazinzi kuhlala kujikeleza i-axis ye-inertia, ngoko ke, ukulungiswa kwe-groove yoxinzelelo kufuneka kunqumle le ngqungquthela ye-inertia kwaye yenze ibe mfutshane kangangoko kunokwenzeka.Kwisakhiwo esiboniswe kwi-Figure 18a, imicu emincinci emininzi yenziwa kwindawo ngaphandle koxinzelelo.Ukujikeleza kwezi zembe, ukugoba kokuqina kwepleyiti yonke akuphuculwanga.Ulwakhiwo oluboniswe kwisazobe se-18b asinakho ukudityaniswa kweezembe ze-inertia, kwaye umfanekiso we-19 ubonisa iimilo eziqhelekileyo zegroove kunye nolungelelwaniso, kunye nesiphumo sokuqinisa ukuqina sinyuka ukusuka ekhohlo ukuya ekunene, kunye nolungiselelo olungafanelekanga yindlela esebenzayo yokuphepha ngqo ukuya ngaphaya. .

(a) Ubume obungenangqiqo (b) Ubume obuphuculweyo

(Umfanekiso18)

(umzobo19)

12 Izikhokelo zokuqhubekeka koxinzelelo lwegroove

Amandla okukhathala kokuphela kwe-groove yoxinzelelo abuthathaka, kwaye ukuba i-groove yoxinzelelo ixhunyiwe, inxalenye yesiphelo sayo iya kupheliswa.Umzobo we-20 yibhokisi yebhetri kwilori, ixhomekeke kumthwalo oguqukayo, uMzobo we-20a isakhiwo kwi-groove yoxinzelelo ekupheleni komonakalo wokudinwa.Ulwakhiwo olukuMfanekiso 20b alunayo le ngxaki.Iziphelo zoxinzelelo oluphezulu kufuneka ziphetshwe kwaye, apho kunokwenzeka, igroove yoxinzelelo yandiswe kumda (jonga uMfanekiso 21).Ukungena kwe-groove yoxinzelelo kuphelisa isiphelo esibuthathaka.Nangona kunjalo, i-intersection ye-slots yoxinzelelo kufuneka ibe nkulu ngokwaneleyo ukwenzela ukuba intsebenziswano phakathi kweendawo zokubeka iyancipha (jonga umfanekiso we-22).

(a) Ubume obungenangqiqo (b) Ubume obuphuculweyo

(Umfanekiso20)

(a) Ubume obungenangqiqo (b) Ubume obuphuculweyo

(Umfanekiso21)

(a) Ubume obungenangqiqo (b) Ubume obuphuculweyo

(Umfanekiso22)

13 Umlinganiselo woxinzelelo lwesithuba

Ukungazinzi kwesakhiwo sendawo akukhawulelwanga kwinkalo ethile, ngoko ke, ukubeka i-groove yoxinzelelo kuphela kwindiza enye ayikwazi ukufikelela umphumo wokuphucula amandla okuchasa ukutshatyalaliswa kwesakhiwo sonke.Ngokomzekelo, kwizakhiwo ezine-U kunye ne-Z eziboniswe kwi-Figure 23, ukungazinzi kwazo kuya kwenzeka kufuphi nemida.Isisombululo sale ngxaki kukuyila igroove yoxinzelelo njengesithuba (jonga umfanekiso we-23b isakhiwo.)

(a) Ubume obungenangqiqo (b) Ubume obuphuculweyo

(Umfanekiso23)

14 Isikhokelo sokunciphisa ngokuyinxenye

Imibimbi iyenzeka xa i-partial deformation ithintelwe kakhulu kwipleyiti encinci.Isisombululo kukuseta iigrooves ezininzi ezincinci kufutshane ne-crease, ukuze kuncitshiswe ukuqina kwendawo kunye nokunciphisa umqobo wokuguqula (jonga uMzobo 24).

(a) Ubume obungenangqiqo (b) Ubume obuphuculweyo

(Umfanekiso24)

15 Izikhokelo zoqwalaselo kwiindawo zokungqinga

1) Ubuncinci bedayamitha yokubetha okanye ubude becala obuncinci bomngxuma osisikwere

Ukubetha kufuneka kukhawulwe ngamandla e-punch, kwayeubukhulu be-punch akufanele bube buncinci, ngaphandle koko i-punch iya konakala lula.Ubuncinci bedayamitha yokungqinga kunye nobude becala buboniswe kwitheyibhile.

* t bubunzima bezinto eziphathekayo, ubuncinci besayizi yepunch ngokubanzi abukho ngaphantsi kwe-0.3mm.

2) Umgaqo-siseko wokubetha

Ukubetha inotshi kufuneka uzame ukuphepha iikona ezibukhali, njengoko kuboniswe kumfanekiso.Ifom ekhonjiweyo ilula ukunciphisa ubomi benkonzo yokufa, kwaye ikona elibukhali lilula ukuvelisa iintanda.Kufuneka itshintshwe ibe njengoko kubonisiwe kumfanekiso b.

R ≥ 0.5t (t - ubukhulu bezinto)

a Fig. b Fig.

Iikona ezibukhali kufuneka ziphetshwe kwimilo kunye nokubhoboza inxalenye ephothiweyo.Ekudibaneni komgca ochanekileyo okanye i-curve ukuze ube noqhagamshelwano lwe-arc circular, i-radius ye-arc R ≥ 0.5t.(t yimathiriyeli yodonga ubukhulu)

Sheet metal ukugoba ngokusebenzisaIPROLEAN'TECHNOLOGY.

Kwi-PROLEAN TECH, siyayithanda inkampani yethu kunye neenkonzo esizinikezela kubathengi bethu.Ngaloo ndlela, sityala imali eninzi kwinkqubela phambili yamva nje kwitekhnoloji yethu kwaye sineenjineli ezizinikeleyo onazo.

Umbono kaProlean kukuba ngumboneleli wesisombululo okhokelayo kwi-On-Demand Manufacturing.Sisebenza nzima ukwenza imveliso ibe lula, ikhawuleza, kunye neendleko-zokonga ukusuka kwiprototyping ukuya kwimveliso.

Ixesha lokuposa: Mar-30-2022