Isikhokelo soMatshini weGear Cacisa ngeVidiyo, iindlela zokuSebenza kunye neNkqubo

Uhlaziyo lokugqibela 09/14, ixesha lokufunda: 9mins

Kwimveliso kunye nokusebenza koomatshini, iigiya njengenxalenye ebalulekileyo, ukujikeleza koomatshini, ukuqinisekisa ukusebenza okuqhelekileyo koomatshini kudlala indima ephambili, ukwenziwa kweegiya kukumisela umgangatho uwonke woomatshini kunye nokusebenza kakuhle.

Eli nqaku lazisa iimeko ezintandathu zeendlela zokulungisa izixhobo.Iindlela zokwenziwa kwenkqubo yokwenziwa kweegiya, iinkqubo zoomatshini kunye neemfuno zabo ziyaxoxwa, zidityaniswe nenkqubo yokwenziwa kweegiya ekusetyenzisweni kweengxaki eziqhelekileyo kwinkqubo yokusetyenzwa kunye nezicwangciso zesisombululo, ukunika isikhokelo esilula sokusetyenzwa kwesixhobo sakho kunye nokuvelisa, ukuze ukwazi khetha inkqubo eyiyo, unako kwakhonaqhagamshelana neenjineli zethuukufumana ulwazi olunxulumene nokuveliswa kwezixhobo.

Umxholo

1 Umzobo weentlobo ezi-6 zoomatshini bomatshini

2 Inkqubo yokwenziwa kweGear inkqubo yomatshini kunye neemfuno zayo

3 Iingxaki eziqhelekileyo kunye nezisombululo ekusetyenzisweni kweenkqubo zomatshini kwinkqubo yokuvelisa izixhobo

1 iGear Mechanical Processing Method

Iigiya zineendlela ezahlukeneyo zokumila kwezinyo, ezibandakanya ukumila kwezinyo yeyona ixhaphakileyo.Kukho iintlobo ezimbini eziphambili zeendlela zobuchwephesha eziqhele ukusetyenziswa kwiimilo zezinyo ezibandakanya, ezizezi indlela yokubumba kunye nendlela yokusasaza.

1)Ukusila amazinyo

Amazinyo okugaya nge-disc-shaped modulus milling cutter yeyendlela yokwenza, kwaye imilo ye-cutter cross-section ihambelana nokumila kwamazinyo egiya.Amazinyo enziwe ngoomatshini.Emva kokugaya enye incam yezinyo yegiya, indlela yokulinganisa isalathisi ngesandla ukuze iguqule izinyo, kwaye enye i-slot yezinyo iyasilwa, njalo njalo, de kube sekupheleni kwayo yonke i-milling.

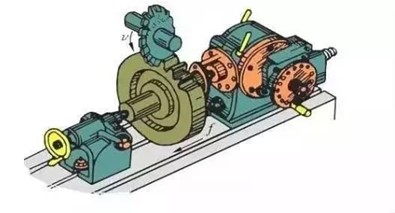

Umatshini wegiya ngendlela yokugaya

- Isicelo

Le ndlela inokusebenza okuphantsi kunye nokuchaneka, kwaye ifanelekile kuphela kwisiqwenga esisodwa kunye nokuveliswa kwebhetshi encinci.

2) Ukusila ngobume

Ikwayeyendlela yokwenza inkqubo, ivili lokugaya akukho lula ukunxiba, ngoko ke ukusetyenziswa kancinci.

Ukwenza kunye nezixhobo zokusila

3)Indlela yokuzonwabisa

Indlela yokuzonwabisa

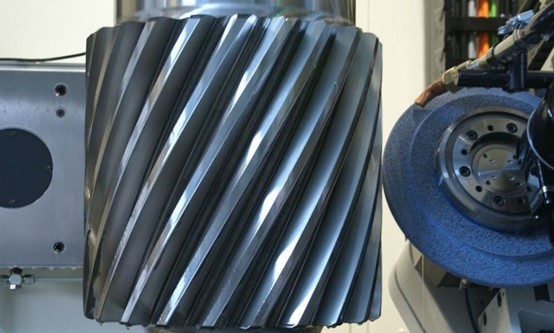

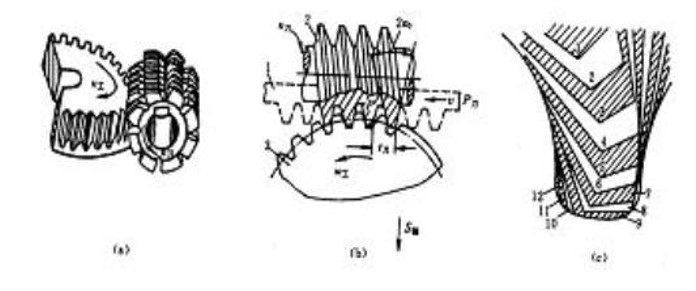

Isixhobo sokusika izikhewu zegiya ngexesha lokubhoboza sisitovu, esiyintshulube ngenxa ye-angle enkulu yokunyusa i-spiral ye-hob.I-hob ifakwe kwi-directional perpendicular to spiral groove, yenza iindawo ezininzi zokusika, kwaye iprofayili yayo eqhelekileyo ine-rack shape.

Ke ngoko, xa i-hob ijikeleza ngokuqhubekayo, amavili egiya anokuthathwa njengentshukumo yerakhi ende engapheliyo.Kwangaxeshanye, igeya yokusika isika ukusuka phezulu ukuya ezantsi, igcina ubudlelwane be-meshing phakathi kwe-rack (hob) kunye ne-gear engenanto, kwaye i-hob inokuqhuba imilo yegiya engabalulekanga kwisixhobo esingenanto.

Umgaqo wokubhobhoza izixhobo

- Iimpawu zenkqubo

(1) Ukucutshungulwa kwe-hobbing yendlela yokusasaza kunokuchaneka okuphezulu, kwaye akukho mpazamo yethiyori kwijika legiya lendlela yokubumba yokusila, ngoko ke ukuchaneka kokwahlula kuphezulu, kwaye ngokubanzi kunokuqhuba iigiya ezinamanqanaba angama-8 ~ 7. yokuchaneka.

(2) Isitovu sinokuqhuba iigiya zecylindrical ezinemodyuli efanayo kunye ne-angle yoxinzelelo njenge hob kodwa ngamanani amazinyo ahlukeneyo.

(3) I-hobbing yemveliso ephezulu kukusika ngokuqhubekayo, akukho kulahlekelwa kwexesha elincedisayo, imveliso ngokubanzi iphezulu kunokugaya kunye nokufaka iigiya.

- Isicelo

I-Hobbing ifanelekile kwimveliso ye-single-lot encinci kunye nemveliso yobuninzi.

4)Ukucheba izixhobo

Ukucheba izixhobo

Kwimveliso yobuninzi, ukuchetywa kweegiya kuyindlela eqhelekileyo yokugqiba iindawo zamazinyo ezingenalukhuni.Umgaqo wayo wokusebenza kukusebenzisa imela yokutsheva kunye negiya ekufuneka isetyenziselwe intshukumo yasimahla yemeshing, ngoncedo lwesiliphu esihambelanayo phakathi kwezi zibini, ukusuka kumphezulu wezinyo ukucheba iitshiphusi ezintle kakhulu, ukuze kuphuculwe ukuchaneka kwendawo yezinyo. .Ukutsheva kunokwenza amazinyo amile okwegubu ukuphucula indawo yokudibana nezinyo.

- Iimpawu zenkqubo

1. Ukucheba ukuchaneka ngokuqhelekileyo ku-6 ukuya ku-7, uburhabaxa bomhlaba u-Ra ngu-0.8 ukuya kwi-0.4μm, ukugqitywa kweegiya ezingacinywanga.

2. Imveliso ephezulu yokucheba, ukusetyenzwa kwesixhobo sobungakanani obuphakathi ngokuqhelekileyo kuphela i-2 ukuya kwi-4 min, xa kuthelekiswa nokusila, kunokuphucula imveliso ngamaxesha angaphezu kwe-10.

3. Ngenxa yokuba inkqubo yokucheba i-meshing yamahhala, umatshini awusasazeki kwintshukumo yekhonkco lokuqhuba, ngoko ke isakhiwo somatshini silula, kulula ukulungisa umatshini.

- Isicelo

Ukucheba yindlela esetyenziswa ngokubanzi yokugqiba amazinyo egiya, ngakumbi ukuveliswa okuqhubekayo komthamo omkhulu, kwaye ngokuqhelekileyo isetyenziselwa ukugqiba iigiya ezingaqiniwanga ngenxa yokusebenza kwayo kweendleko eziphezulu.Ukutsheva okwangoku kusetyenziswa ikakhulu ukugqiba iigiya zecylindrical, kodwa le ndlela ibisetyenziselwa ukutsheva iigiya zeentshulube.Kwiintsuku zokuqala, kwakukho nabasiki bebha, ababesetyenziselwa ukugqiba iigiya ze-cylindrical, kodwa ngenxa yesakhiwo sabo esinzima kakhulu, azifane zisetyenziswe ngoku.

5)Ukumila kweegiya

Ukubunjwa kweegiya

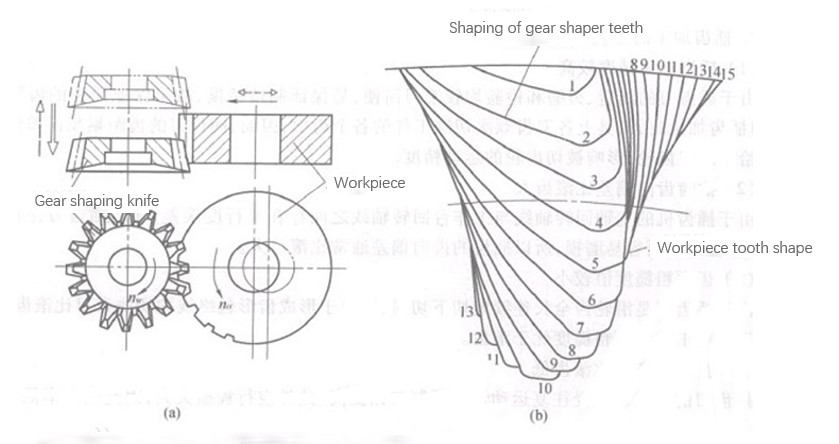

Ukubunjwa kwegiya luhlobo lwenkqubo yokusika igiya edla ngokusetyenziswa ukongezelela kwi-hobbing.Xa ubumba, i-gear shaper kunye ne-workpiece ilingana ne-meshing yeperi ye-cylindrical gears.Ubume bentshukumo yomsebenzi kunye ne-gear shaper iboniswe kuMzobo a.Ngexesha lokubunjwa kwegiya, isixhobo senza isantya esiphezulu esibuyisela umva intshukumo kwicala le-axis yomsebenzi kwaye siqhuba zonke iiprofayili zezinyo legiya kwindawo yokusebenza.Kwinkqubo, isixhobo sinqumla kuphela inxalenye encinci ye-workpiece yezinyo groove kunye nokuphindaphinda nganye, kwaye ijika le-tooth surface ye-workpiece yezinyo groove yenziwe yimvulophu yomgca wokusika wemela yokufaka, njengoko kubonisiwe kuMfanekiso b. .

Umgaqo wokubunjwa kwegiya

- Isicelo

Ngokuqhelekileyo, ukuveliswa kwe-hobbing kuphezulu kunokwakheka, kuba ukubunjwa kuyintshukumo ehambelanayo kwaye i-stroke yokubuya ayinqumli.Inkqubo yokubunjwa kwegiya ayiqinanga kwaye inani lokusika alikwazi ukuba likhulu kakhulu.Nangona kunjalo, kwiigiya ezincinci zemodulus (m<2.5 mm), imveliso yokubunjwa ingaba phezulu kuneyokubhobhoza.Kwiigiya ezibhityileyo, imveliso yesiqwenga esinye, ubude bokusika bukhulu, busenokungabi namveliso njengokubunjwa.

6) Isixhobo sokusila ngokusasaza indlela

Ukunqunyulwa kwendlela yokusabalalisa kufana neyokubhobhoza kwaye kuyindlela yokugqiba izinyo, ngokukodwa kwiigesi ezilukhuni, ezidla ngokuba yindlela yokugqiba kuphela.Indlela yokusasaza ingasetyenziselwa ukucola amazinyo ngeegiya zeentshulube okanye ngamavili e-conical okanye idisc.

2 Inkqubo yokwenziwa kweGear inkqubo yomatshini kunye neemfuno zayo

1)Ukwenziwa kwezithuba

Ukwenziwa kwenkqubo engenanto ekuvelisweni kwezixhobo kusetyenziswa kakhulu, ngokuqhelekileyo kuhlobo lokubumba kunye ne-embossing eshushu.Ngophuhliso oluthe ngcembe lokwenziwa kweegiya kunye nokulungiswa kwetekhnoloji, itekhnoloji yokuqengqeleka ngokuthe ngcembe iqalise ukusetyenziswa ngokubanzi kwimveliso yeeshafti zoomatshini, ngakumbi ekusetyenzweni nasekuvelisweni kohlobo lomsebenzi we-shaft.Inkqubo yokwenziwa ngokurhabaxa ifuna ukusebenza kakuhle kunye nokuchaneka kokunciphisa iindleko zokwenziwa kwezixhobo kunye nokunciphisa inkcitho yemithombo.

Ukwenziwa kwezithuba

2)Ukuqheleka

Ukuveliswa kweGear kunzima ukulawula izinga lokupholisa le-workpiece, ephenjelelwa yimeko engqongileyo, iingxaki zezixhobo, umsebenzi wezandla kunye nezinye izinto, ezibangela imiqobo ethile kwi-uniform yesakhiwo sombutho, ngoko ke kuyimfuneko ukufudumala ukunyanga isinyithi. ukusika.Le nkqubo isetyenziswe kwinkqubo ye-isothermal normalizing ibhekisela kwingxaki yokuphepha ukuguqulwa kwe-thermal yezixhobo zentsimbi kwiqondo lokushisa elifanelekileyo emva kobunzima bokusika i-gear kunye nokulungiswa kokushisa ukushisa.

3)Ukuguqula inkqubo

Ukwenziwa kweegiya kunye nokusetyenzwa kweemfuno zokuchaneka kokubekwa kwegiya kuphezulu, okwangoku ekusetyenzweni kwezikhewu zegiya ngokuqhelekileyo kufuneka zifakwe kwi-lathe ye-CNC, ngokweemfuno zobuso bokugqibela kunye nokuzala ngokuthe nkqo, ukuphucula ukuchaneka kwezinyo elingenanto, ukuqinisekisa umgangatho wokwenziwa kwezixhobo kunye nokulungiswa, kubandakanywa ukubhoboza, ubuso bokuphela, umgangatho wokucubungula i-diameter yangaphandle, njl. njl.

4)Ukuhobha nokufaka

Ukuze kuphuculwe ubomi benkonzo isixhobo, emva hobbing, ukufaka imela ukulola, kunye nendima re-ukwaleka iteknoloji, ukunciphisa inani isixhobo endaweni, ukuqinisekisa ngokufanelekileyo ubomi isixhobo, ukunika isiqinisekiso processing oluzinzileyo. , kunye nokukhuthaza impumelelo yezoqoqosho kwimveliso.

5)Ukucheba

Kwinkqubo yokugqiba yokwenziwa kweegiya, ukucheba yenye yeendlela eziqhelekileyo zokusetyenzwa, isetyenziswa kakhulu kwimveliso yezixhobo, njengenkqubo ephambili yokuvelisa, ukucheba kuneengenelo ezinamandla, hayi ukusebenza okuphezulu kuphela, kwaye kunenzuzo yokubalula ukuyifumana. ubume bezinyo kunye neemfuno zokuqhelaniswa nezinyo.

6)Unyango lobushushu

Inkqubo yokunyanga ubushushu, kwiindlela zokwenziwa kweegiya, eyona ixhaphakileyo kwi-nitriding, carburizing, ukucima unyango lobushushu ngezi ndlela.Emva kwale nkqubo, ukuqina komphezulu wegiya konyuka kakhulu, kwaye ukuqina kweplastiki yeziko kuphuculwe kakhulu, okukhuthaza ukwandiswa kobomi begiya kwaye komeleza ngokufanelekileyo ukuxhathisa ukudinwa kunye nokunganyangeki kweegiya.

7)Inkqubo yokugaya

Inkqubo yokugaya kwimveliso yegesi ibhekisela kwinkqubo yokugqiba izikhundla ezithile, kubandakanywa nobubanzi bangaphandle, umgca wangaphakathi kunye nobuso bokuphela kwesixhobo, ukwenzela ukukhuthaza ukuphuculwa kokudibanisa kunye nokuchaneka kokufakela.

8)Ukuhlolwa

Ukuhlolwa yinxalenye ebalulekileyo yenkqubo yokwenziwa kweegiya kwaye kubhekiselele ekuhlolweni nasekucocweni amazinyo, adla ngokuqhutywa phambi kokuba kuhlanganiswe igiya.Ukuqwalaselwa ngokubanzi kunye nohlalutyo lokuphambuka kwe-tooth fit, ukusetyenziswa kwesixhobo sokuhlola ngokubanzi, ukuphucula ukusebenza kokuhlolwa ukukhusela iingxaki ezifana nengxolo yegesi.

I-3 Iingxaki eziqhelekileyo kunye nezisombululo ekusebenziseni iinkqubo zomatshini ngexesha lokuvelisa izixhobo

Umbuzo: Inani elingachanekanga lamazinyo

A: Xa iinombolo yezinyo ayichanekanga, ingqwalasela engakumbi kufuneka ihlawulwe ekukhethweni okunengqiqo kwee-hobs, kunye ne-hobs ene-angle ye-helix efanayo, i-angle yoxinzelelo lwe-hob efanayo kunye nemodyuli ye-hob efanayo kufuneka isetyenziswe.

Umbuzo: Impazamo yokumila kwezinyo elikhulu

A: Xa ingxaki yekwenzeka impazamo yokumila kwezinyo elikhulu, emva koko ulungelelanise i-engile yokufakela i-hob ngexesha.Qinisekisa ukuba ubungakanani begiya engenanto kunye nesalathiso esongezelelweyo sokuhamba sichanekile ukuqinisekisa umgangatho wokwenziwa kweegiya.

Umbuzo: I-asymmetry yezinyo

A: Into eqhelekileyoi-asymmetry yezinyoingxaki ingasonjululwa ngokulungelelanisa isitovu.Sebenzisa igrinder yokulola isitovu ngokuchaneka okuphezulu kwaye ukhethe igrinder yokulola isitovu esinexabiso elifanelekileyo kwaye kulula ukuyisebenzisa ukukhuthaza ukuchaneka kofakelo lwesitovu kunye nomgangatho wokulola isitovu.Kuyo yonke indawo jonga ukufakwa kunye nokusebenza kwegiya yokutshintshiselana, yomeleza uzinzo lokusebenza kwelathe, kunye nokuphucula umgangatho uwonke kunye nokusebenza kakuhle kokwenziwa kwezixhobo.

Ixesha lokuposa: May-17-2022