CAPABILITIES

Swiss Turning Service

Prolean’s Swiss Turning services focus on manufacturing high-precision complex parts with competitive prices in quantities ranging from small batches of prototypes to full production runs.

Our Swiss machines are capable of producing extremely small parts with extreme precision. Therefore, it is the best machining approach if you need parts with a diameter of less than 1.25”.

All uploads are secure and confidential.

What is Swiss Turning?

Try Prolean Now!

How to Order Parts?

Get a free quote from a real engineer; once we receive your design, our engineer will review it and send you a quote as fast as one hour.

Get A Quote Within 12 Hours

Upload your design or email our engineer directly and get your quotes as fast as one hour.

Start Production

Your parts will be made once your orders are confirmed. Besides, you will get real-time order updates of the production status from our order tracking system.

Receive Your Part

After all parts pass QC inspection, they will be well packed from transportation accidents. Then, your custom parts are delivered straight to your doorstep.

Swiss Turning Materials Options

| Aluminum | Steel | Stainless Steel | Other Metals | Plastics |

| Al6061 | 1018 | 303 | Titanium Ti-6Al-4V (TC4) | PVC |

| Al6063 | 1045 | 304 | Brass C360 | NYLON |

| Al6082 | A36 | 316 | Brass C2680 | POM-M, POM-C |

| Al7075 | D2 | 316L | Alloy Steel 4140 | PTFE |

| Al2024 | A2 | 410 | Alloy Steel 4340 | PEEK |

| Al5083 | 20Cr | 17-4PH | Copper C110 | HDPE |

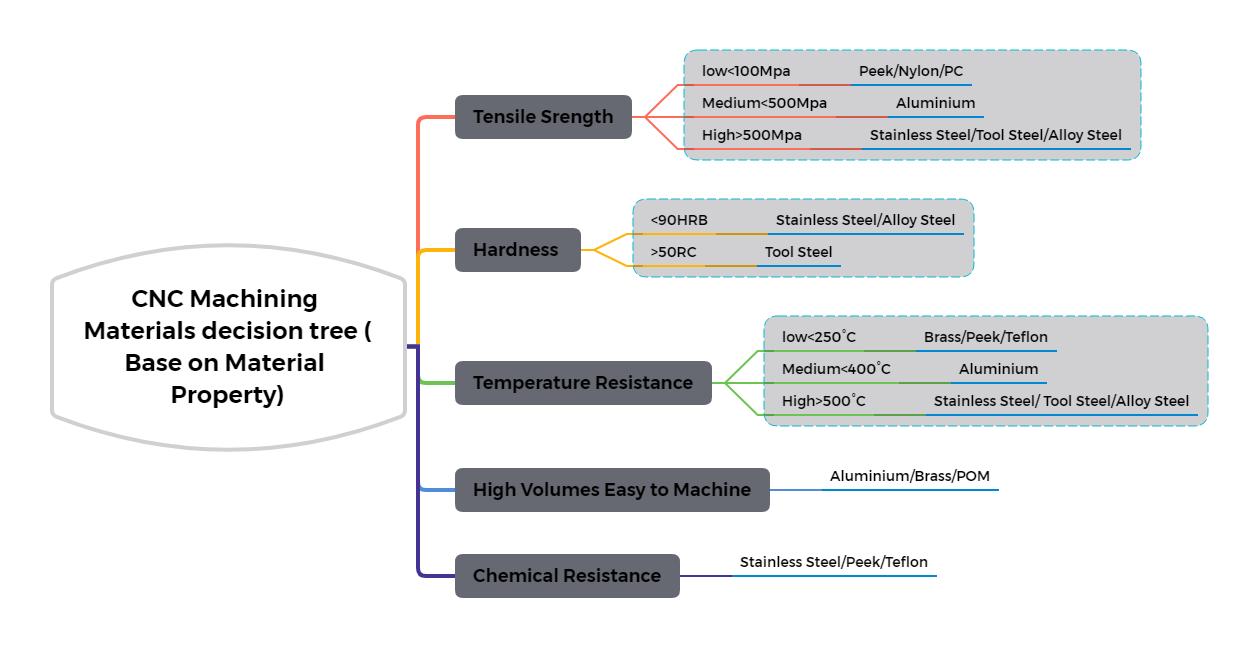

Swiss Turning Material Guide

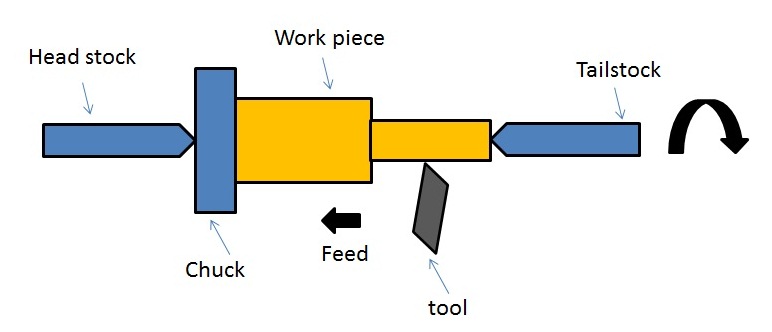

Swiss Turning vs Conventional Turning

Swiss lathe offers distinct advantages over Conventional Turning, making it an ideal choice for intricate and precision machining. Discover the key features that set Swiss Turning apart:

Swiss Turning

Conventional Turning

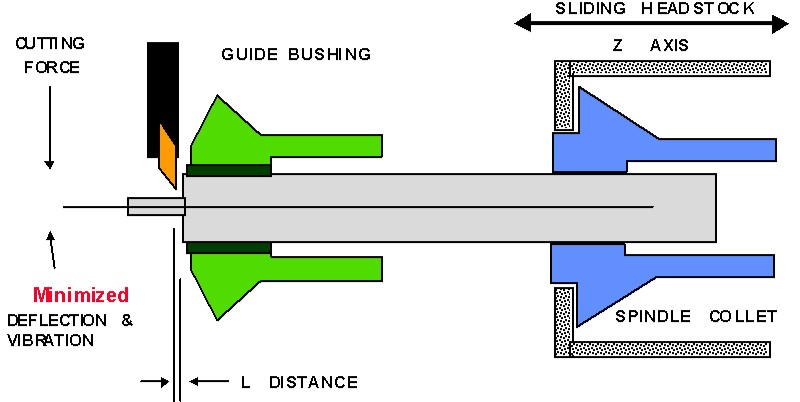

- Advanced Headstock Design: Swiss lathes feature a moving headstock, allowing precise repositioning along the z-axis during the machining process.

- Segmented Machining Process: Swiss machining ensures high consistency and accuracy, ideal for CNC-turned parts with stringent tolerances.

- Superior Guide Bushing Support: swiss style lathe reduces deflection and allows deeper cuts in a single pass, perfect for machining slender parts.

- Enhanced Cycle Times: Swiss style lathe offer multi-axis capabilities (ranging from 7 to 13 axes) significantly reduce manufacturing times for complex geometries.

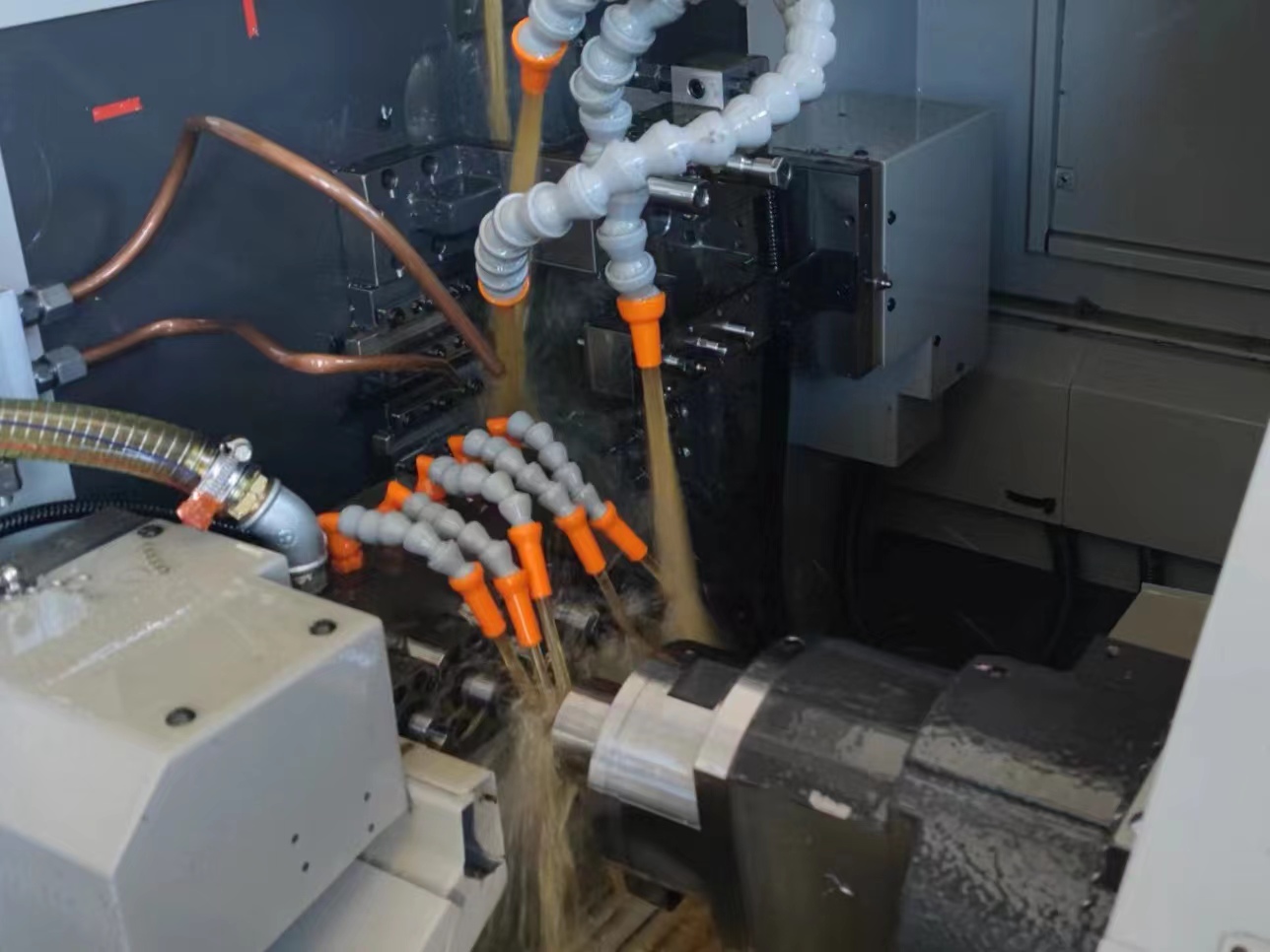

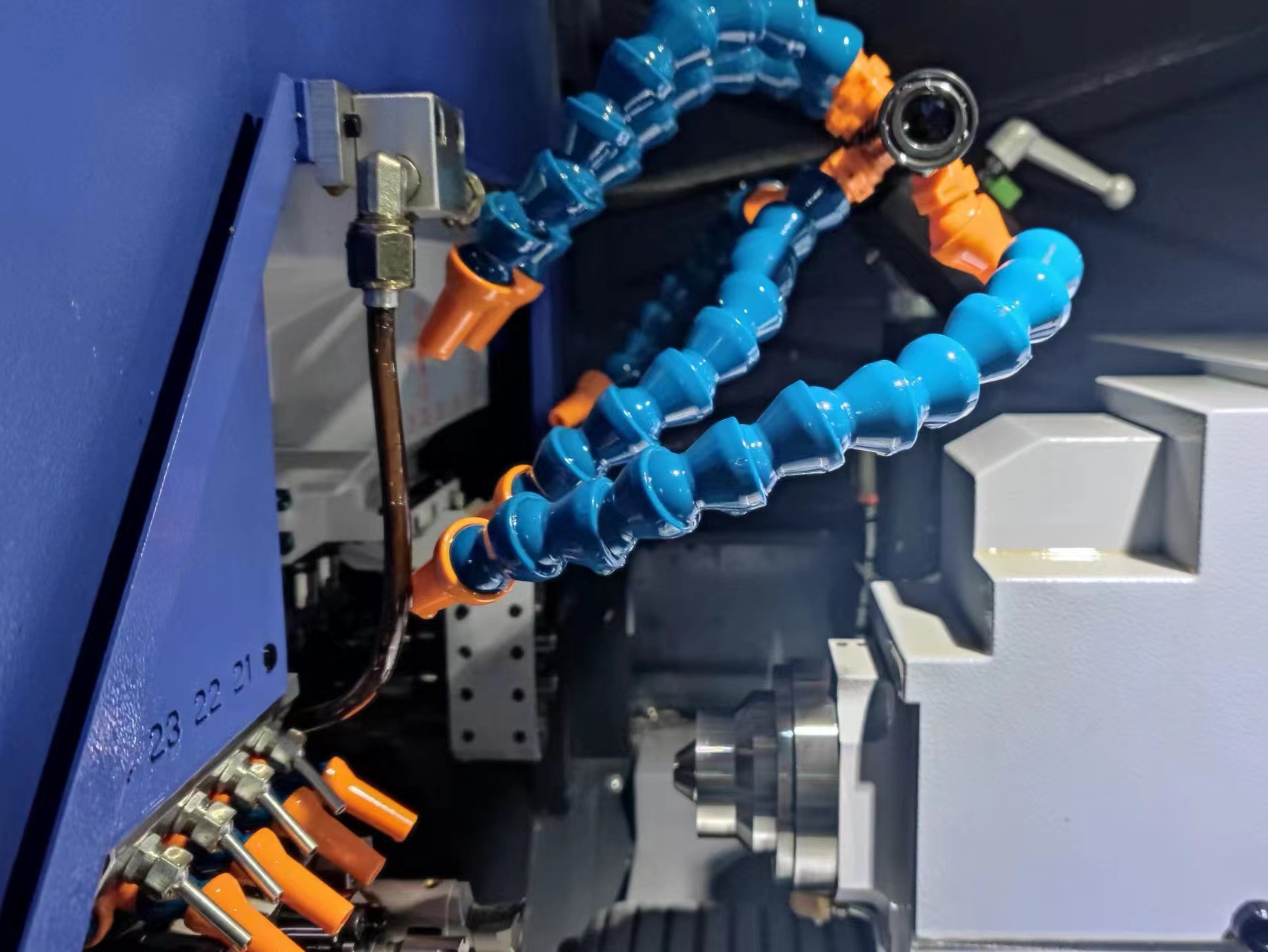

- Oil-based Coolant System: Swiss turn offers better lubrication, reduces friction and heat generation, enhancing tool life and part quality.

- Reduced Post-Processing: Produces fine and precise parts, often eliminating the need for secondary finishing processes.

- Cost-Effectiveness for Large Runs: Ideal for high-volume production of complex parts, offering long-term economic benefits despite the higher initial cost.

Benefit of Using Swiss Turning

Swiss turning service employs swiss-type lathes for efficiently producing small, intricate parts. This technique is characterized by several significant benefits:

- High Precision: Enhanced precision due to reduced deflection.

- Part Consistency: Delivers uniform quality across large batches.

- Complex Part Production: Equipped for manufacturing complex parts with its multi-axis and tool capabilities.

- Synchronous Operations: Increases efficiency with simultaneous operations.

- Less Secondary Processing: Reduces the necessity for additional post-machining processes.

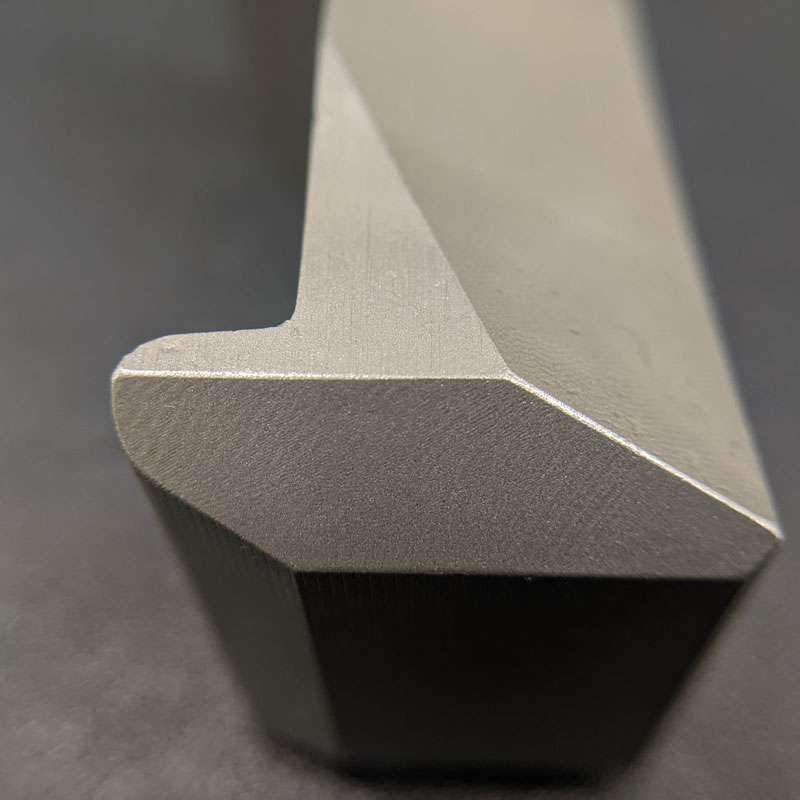

- Improved Surface Finish: Achieves better finishes at higher operational speeds.

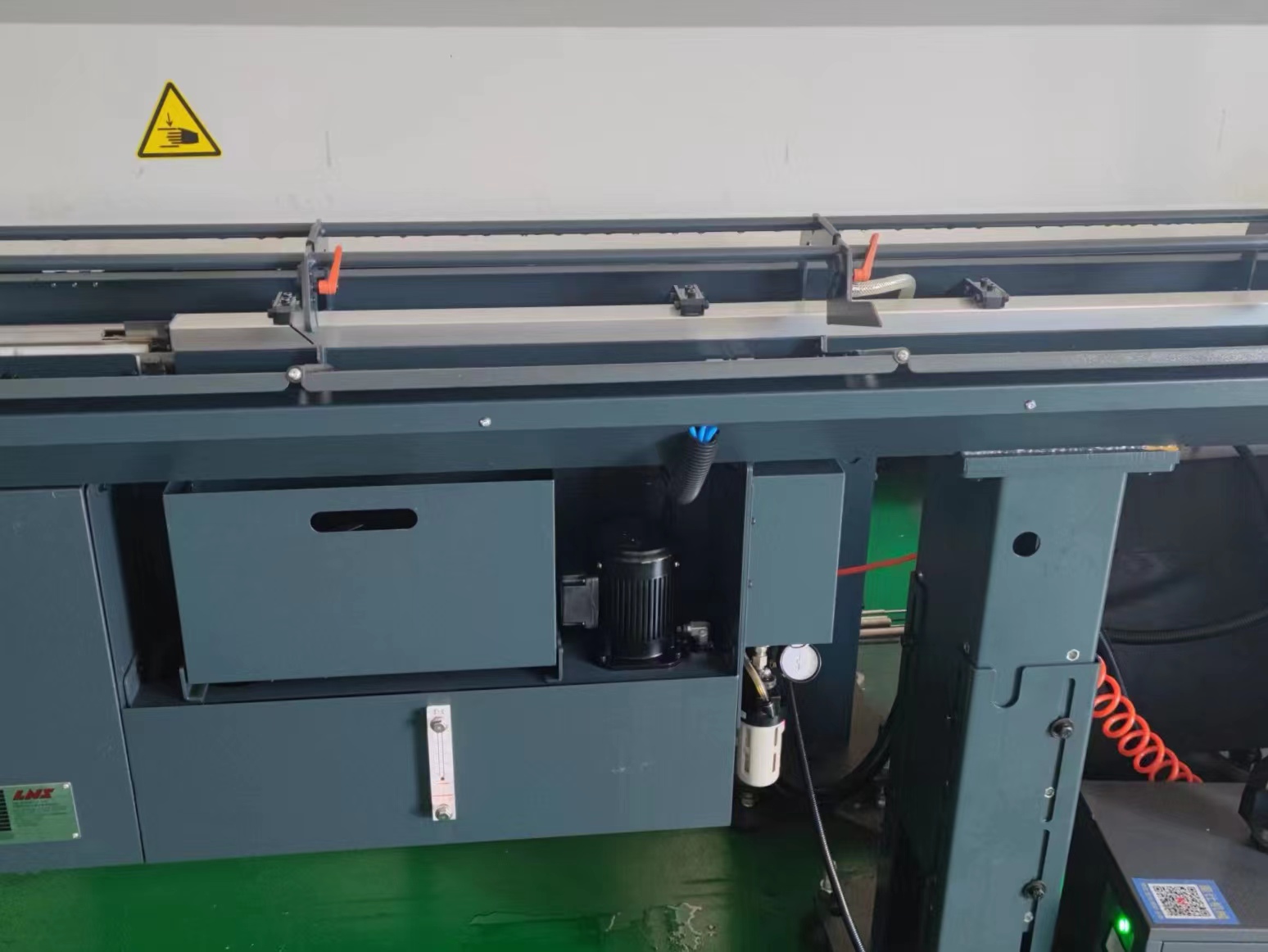

- Automation: Features like automatic bar feeders and CAM programming minimize the need for manual intervention.

Try Prolean Now!

Swiss Turning Finishing Options

As the machined or deburring

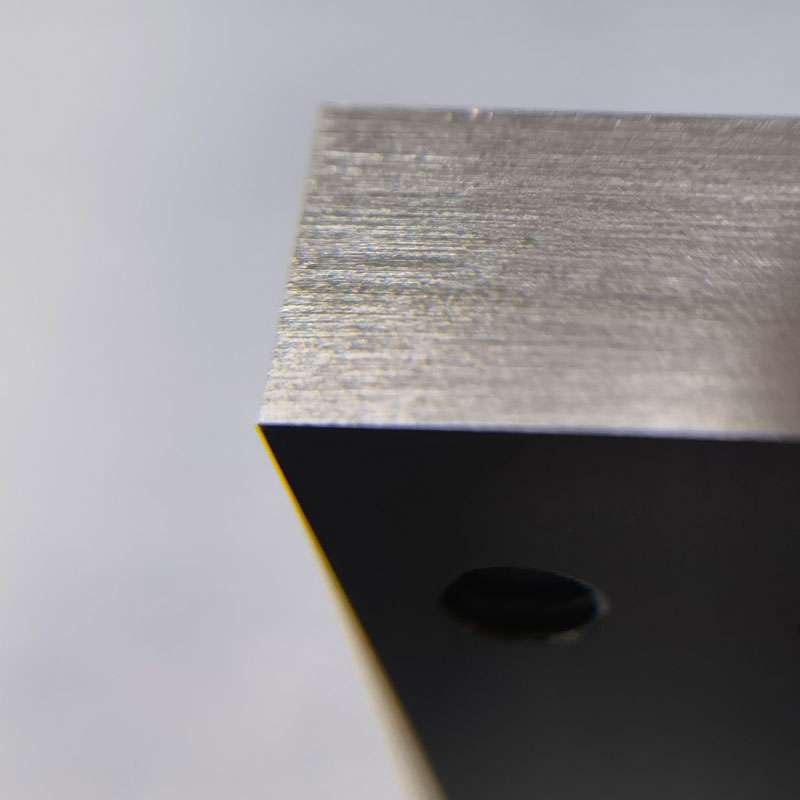

The machined or deburring finish is the standard finish where unwanted attach chips are removed with deburring tools, and sharp edges are chamfered to smooth the surface (3.2 μm).

Bead Blasted

Bead blasting produces a matte texture, removing all the marks of machining tools. It applies to ABS, Aluminum, Brass, Stainless Steel, and Steel parts.

Anodizing

Anodizing involves adding an aluminum oxide coating to aluminum and its alloys. The layers, which come in various colors, increase strength and shield the surface from corrosion.

Powder coating

Powder coating is the electrostatically applying of dry powder to the surface. It produces a thin layer providing excellent resistance to wear, corrosion, and abrasion.

Polishing

Physical rubbing of a metal surface to create a shiny surface is called a polishing surface finish. It increases the reflectivity and does not affect the dimensional stability of parts.

Brushing

Brushing is achieved by applying an abrasive brush to the metal surface, which produces a unidirectional satin finish. And it is not recommended for highly corrosive materials.

Smooth machining

Smooth machining is done by controlling the machining process, such as feed rate & cutting speed. It minimizes the tool marks and risk of corrosion.

Black-Oxide

Black oxide finish reduces surface reflectivity and offers mild corrosion protection. It involves adding a thin layer of magnetite to the surface.

Electro-less Nickel Plating

A thin layer of Nickel is created on the surface from a nickel-containing solution without electrolysis. Electro-less nickel plating provides a shiny appearance, excellent hardness, abrasive, wear, and corrosion-resistance to the substrate material.

Alodine

Provides excellent corrosion resistance property to the aluminum parts with greenish-gold color. It is the low-cost and quick surface finishing approach.

Electroplating

Electroplating increases the hardness of the steel &aluminum parts. It offers excellent corrosion, wears, and abrasion resistance.

Nickel plating

Make the parts super resistive to corrosion. It enhances mechanical strength, hardness, wear resistance, lubricity, and ductility. Nickel plating is applicable in different materials, including Steel, aluminum, copper, and brass.

Passivation

Enhance the appearance and functionality of the parts. After Passivation, parts of Steel and its alloys become super resistive from corrosion.

Yellow Chromate conversion coating

A shiny appearance with goldish color provides excellent corrosion resistance. It is applied on the surface of aluminum, magnesium, and their alloys. A layer of chromate also enhances the conductivity of parts

PTFE (Teflon) Coating

The Teflon layer on the parts offers excellent corrosion resistance, water resistance, and non-stickiness with a non-reactive surface.

Fine machining

The higher-precision machines produce delicate machining surfaces by utilizing sharper tools and regulating feed rate and cutting speed. Surface roughness up to Ra 0.8 μm can be maintained with smooth machining.

Laser Cladding

Provides excellent corrosion, wear, and abrasion resistance. Laser Cladding is also effective for treating minor surface imperfections such as cavities, tiny cracks, and rust damage.

Sanding

Provides a random, non-linear texture with a shiny, high gloss finish. However, it might be unable to create sharp corners and pockets

More

Provides a random, non-linear texture with a shiny, high gloss finish. However, it might be unable to create sharp corners and pockets

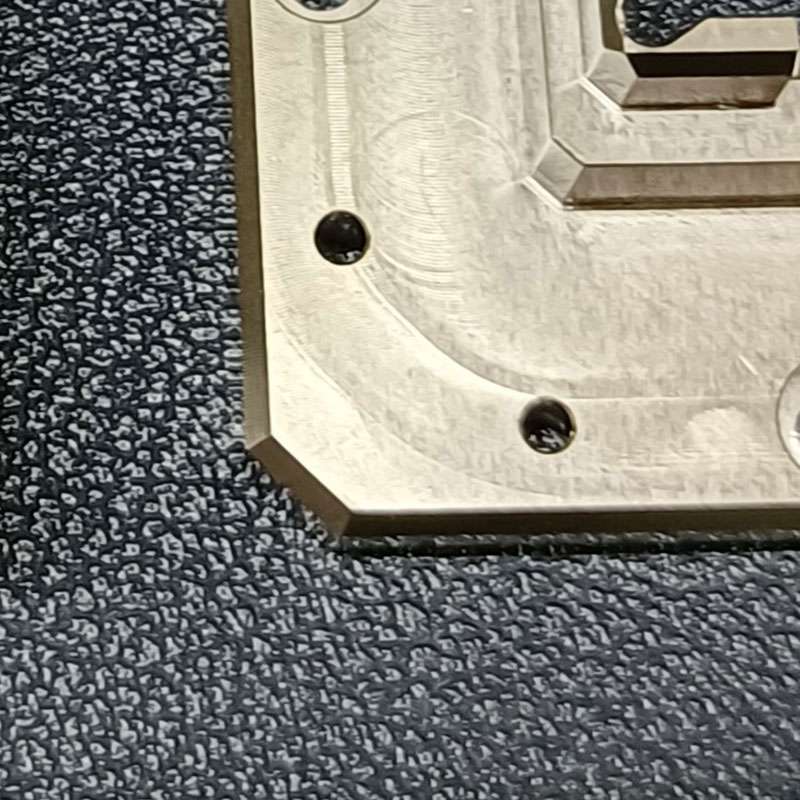

3 Ways to Ensure Perfection

Standards

GENERAL TOLERANCE

For metals, the standard is ISO-2768 fH (fine)

For plastics, the standard is ISO-2768 mK (medium)

Metric threads tolerances:ISO 965-1 standard UN Threads Tolerances: ASME B1.1-2003 standard

knurling: ISO13444:2012 standard Our factory is ISO 9001:2015 certificated

Visual inspection and Protection

Constant visual inspection conditions

Quantification of cosmetic surface quality

Process requirements

Part cleaning and Protection

Quality Inspection Report

Inspection Confirmation

Dimensional confirmation

Appearance confirmation

Quality documentation

Try Prolean Now!

See why customers dig us

Yesterday, I received the parts for my musical instruments. These are incredibly consistent and accurate.

The delivery timing and quality of the CNC machining service amaze me. I would recommend Prolean with my other business friends too. Thank you!

-Ema Alves, Owner at Conserve the Sound

Prolean has been manufacturing numerous customized components for my metal-workshop machines for the past two years, and I have found that they are excellent with their CNC machining services.

I am delighted with the level of quality they offer and the precision of the customized machine parts.

-Mason Lucas, Purchasing manager at Alpha Manufacturing

ProLean has consistently provided me with excellent milling service using their 5-axis CNC machine. I've worked with many contract manufacturers, but other than ProLean, I've never found accurate tolerance on my parts.

We were able to satisfy our client's needs thanks to Prolean's prompt reaction. Additionally, I frequently found that their engineers are always willing to innovate creatively to deliver top-notch service.

-Tanesha Adesina, Technical manager at Bossard Technology

I needed a quick prototype for my research, but I had no idea that their CNC machines were so sophisticated and could produce it in just three days. The prototype was quite precise and fell within the tolerances of the CAD I provided.

Thumbs up! Not just selling, nothing else count for them; Service Service Service, first!

-Jason Barrett, Individual Mechanical Engineer

I have been collaborating with ProLean to produce PCB boards for our business For the last year. Continuous technical assistance and communication with the manufacturing.

Engineers and mechanics help us continuously satisfy our customers' expectations. I hope that this collaboration continues for a very long time.

-Rugen Thakur, Mechanical Engineer at Cipsa- Tech.

The heat sink was marvelous, within the critical tolerance, and the surface finish was excellent. The fan position, seal, and fin structure all performed as intended. I'll tell my friends and other electronics companies about your service.

I appreciate your exceptional communication and CNC-Machining service.

-Blake Henderson, Product Designer at MechaTronix,

It's challenging to describe the Prolean in a few words, but the three stand out: Fantastic, Amazing, and Perfect.

The best addition to our firm has been Prolean. With their cutting-edge 5-axis CNC machine, they are providing the service of replacing and installing new components in our pharmaceutical development industry with accuracy and cleanliness as their top concerns.

-Jose Gaonkar, Mechanical Engineer at Cadila Pharmaceuticals

I purchased several custom CNC-machined parts for mechanical tools from Prolean, and I want to remark that their quality and accuracy were far superior to those of some of the more prominent machine tool manufacturers.

Prolean's engineers could explain everything to me in a language I could comprehend, even though I am not a mechanist and may have asked the wrong questions.

-Evert Wagner, Product Designer at HYDAC Supplier

Related Blog

Horizontal vs. Vertical Milling – Understanding Key Similarities and Differences

Similarities and differences on Horizontal vs. vertical milling?

POM CNC Machining: Process, Applications & Advantages

Explore the ways of POM CNC machining in manufacturing

Laser Cutting Of Nylon: Technique, Process, Applications & Benefits

How nylon laser Cutting brings economical pros?

Get Your Parts Made Today

All uploads are secure and confidential.