Aluminium Extrusion E Hlalositsoe, Melemo le Melemo

Nako ea ho bala: 6 mets

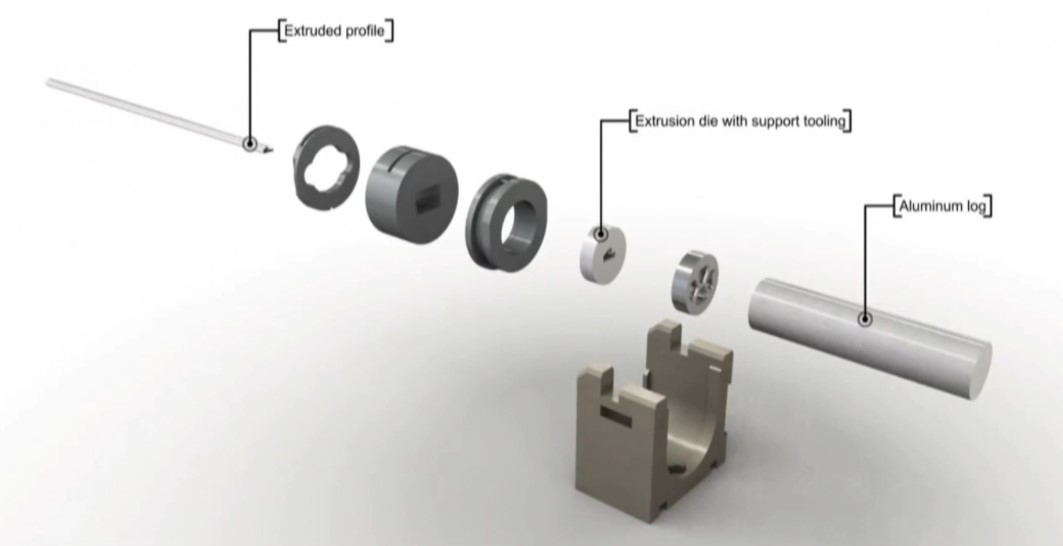

Molao-motheo oa Aluminium Extrusion

Extrusion ke mokhoa oa ho theha ho fapana le mokhoa oa ho tlosa thepa.Lintho tse futhumetseng, joalo ka aluminium, li qobelloa ka lesoba ho etsa profil e bōpehileng.Ka aluminium extrusion, aluminium e tala e qala ho futhumatsoa ebe e bōptjoa hore e be karolo e lakatsehang ka ho e sutumelletsa ka thipa e sebelisa plunger.Ka mohlala, ts'ebetso ea aluminium extrusion e tšoana le ho pepeta sesepa sa meno;matla a sebelisoang a ka tšoantšoa le matla a sebelisoang ha u petetsa tube ea sesepa sa meno ka monoana, 'me ha u petetsa, sesepa sa meno se hlaha ka sebōpeho sa phallo ea tube.

Ha e le hantle, boemo ba sebele bo rarahane haholo ho feta bona, ha o hloka ho sebelisa mokhoa oa aluminium extrusion ho molemo ho buisana le moenjiniere ea nang le phihlelo, baenjiniere ba rona ba na le phihlelo ea lilemo tse mashome lefapheng la aluminium extrusion mme ba ka araba lipotso tsa hau kapele, mme re fana ka atšebeletso ea mahala ea quote,o ka sheba ronaleqephe la tšebeletso ea aluminium extrusion.Ho khutlela ntlheng, sehlooho sena se tla u hlalosetsa lintlha tse ling tsa motheo mabapi le extrusion ea aluminium: mokhoa oa extrusion;libopeho tse ka fetisoang;melemo le mathata, le malebela a mang a ho sebelisa extrusion ea aluminium.

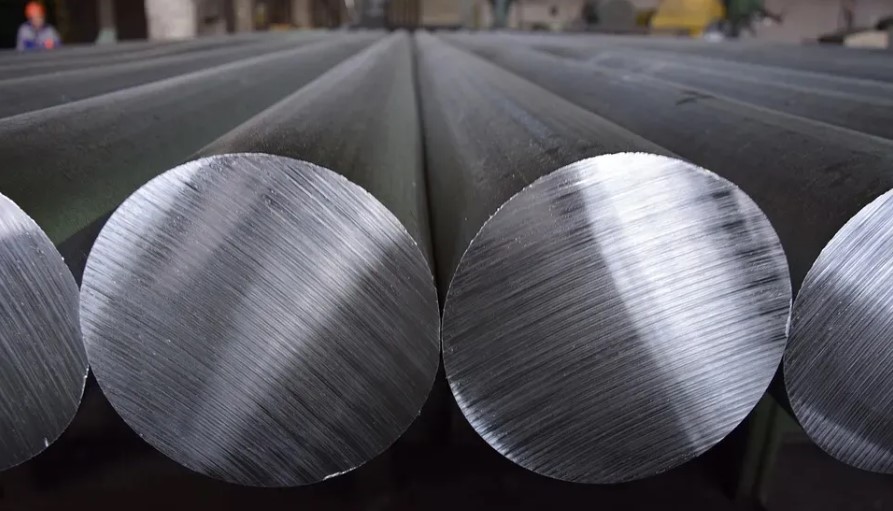

Aluminium Log

Mefuta ea Aluminium Extrusion Molding

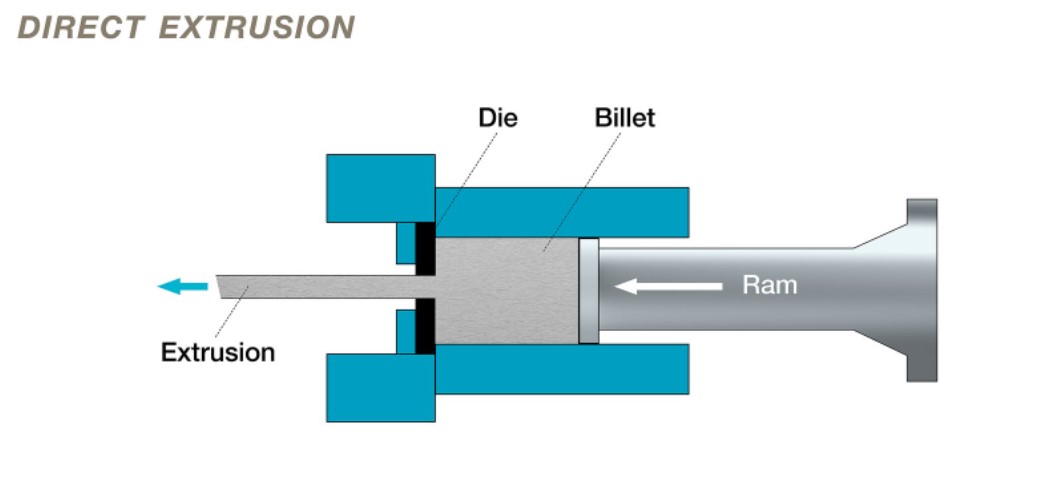

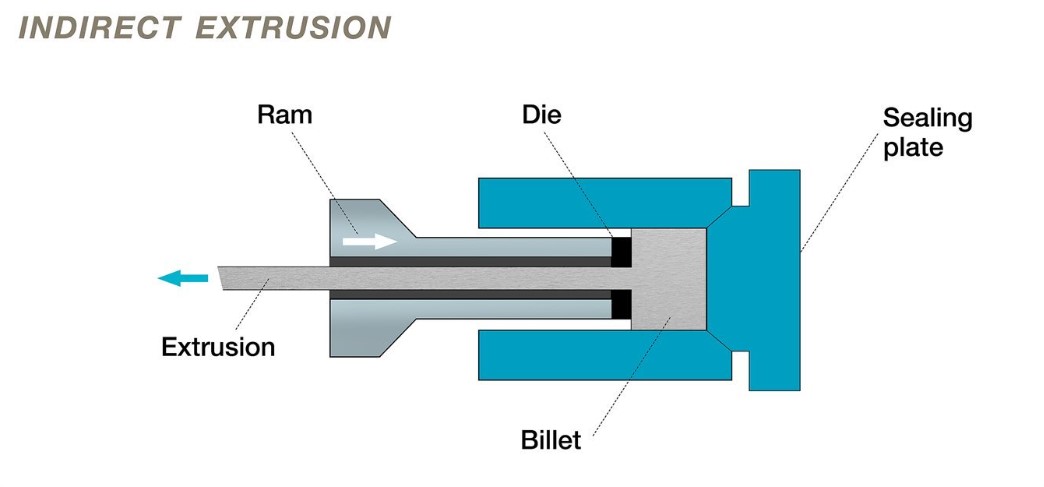

Ho na le mefuta e 'meli ea mekhoa ea extrusion,e tobileng le e sa tobang.Ka extrusion e tobileng hlooho ea lefu e lula e eme 'me punch e tsamaeang e qobella tšepe ka eona.Ka lehlakoreng le leng, ka extrusion e sa tobang billet e lula e eme ha lefu le qetellong ea plunger le tsamaea khahlanong le billet, e leng se etsang hore ho be le khatello e hlokahalang hore tšepe e phalle ka har'a lefu.

Extrusion e otlolohileng

Extrusion e tobileng,e tsejoang hape e le "extrusion" ea pele, ke ts'ebetso e tloaelehileng ea extrusion.E sebetsa ka ho beha billet ka har'a setshelo se nang le marako a teteaneng.Billet e sutumetsoa ka har'a lefi ka plunger kapa screw.Bothata bo ka sehloohong ba ts'ebetso ena ke hore matla a hlokahalang ho ntša billet a maholo ho feta a hlokahalang ka mokhoa o sa tobang oa extrusion.ka lebaka la matla a hlahisoang ke khohlano ka lebaka la tlhoko ea hore billet e fete bolelele bohle ba sekepe.Ka hona, matla a mangata a hlokahalang ke qalong ea ts'ebetso mme a fokotseha ha billet e sebelisoa.

Extrusion e sa tobang

Inextrusion e sa tobang(hape e tsejwa e le reverse extrusion), billet e dula e eme ha die e qetellong ya plunger e leba ho billet, kahoo e tlosa matla a ho hohlana.Sena se fella ka tse latelangmelemo.

1.25% ho isa ho 30% e fokolang ea likhohlano, e lumellang hore likheo tse kholo li atolosoe, lebelo le phahameng, le bokhoni bo eketsehileng ba ho ntša likarolo tse nyenyane tsa sefapano.

2. Monyetla o fokolang oa ho robeha ha karolo e kantle ka lebaka la ho se be teng ha mocheso o hlahisoang ke khohlano.

3. Bophelo bo bolelele ba lijana tsa likepe ka lebaka la ho se sebetse hantle

4. Tšebeliso e tšoanang ea li-billet, kahoo ho na le menyetla e fokolang ea hore ho be le mefokolo ea extrusion le libaka tse pota-potileng.

Mefokolo ke

1. Litšila le mefokolo holim'a billet li ka ama bokaholimo ba extrusion.Ho rarolla bothata bona, li-billet li ka hlatsuoa ka terata, tsa etsoa ka mochini, kapa tsa hloekisoa ka lik'hemik'hale pele li sebelisoa

2. Ha e feto-fetohe joaloka extrusion e tobileng hobane sebaka sa cross-sectional se lekanyelitsoe ke boholo bo boholo ba kutu.

Lintlha tse Amang Sebopeho sa Extrusion

Shape ke eona ntho e khethollang karolo ea litšenyehelo le boiketlo ba extrusion.Nakong ea ts'ebetso ea extrusion, mefuta e fapaneng ea libopeho e ka fetisoa.Ka kakaretso, libopeho tse extruded li ka aroloa ka mekhahlelo e meraro.

1. E tiile, e se nang likheo tse koetsoeng kapa masoba (ke hore, lithupa, maballo kapa likhutlo)

2. Sekoti, se nang le sekheo se le seng kapa ho feta (ke hore, li-tubes tse sekoere kapa tse khutlonnetsepa)

3. Sekoti, se nang le likheo tse koetsoeng hanyenyane (ke hore, "C" e nang le likheo tse nyenyane)

Ha e le hantle, ho na le litšitiso tse 'maloa tse lokelang ho tsotelloa.Tsena li kenyelletsa:

1. Boholo

2. Sebopeho

3. Alloy - Sebopeho sa lik'hemik'hale tsa likarolo tse ling tse kentsoeng aluminium e hloekileng ho ntlafatsa thepa ea eona (mohlala, matla, joalo-joalo)

4. Karolelano ea Extrusion - Sebaka sa billet / sebaka sa sebopeho

5. Karolelano ea Leleme - Bophara le botebo ba lekhalo

6. Mamello - Moeli oa phapang eo karolo kapa sehlahisoa se ka hlahisoang ho eona

7. Qetella

8. Coefficient - Sebopeho sa sebopeho / boima ka mithara

Aluminium Extrusion Principal

Likhetho tsa Aluminium Alloy tse fetisitsoeng

| 1100 | E bonolo, ha e phekolehe ka mocheso empa e ka fetisetsoa ka libopeho tse rarahaneng ka bokaholimo bo botle bo benyang.Alloy ena e ka sebelisoa bakeng sa lintho tsa ponahalo le li-tubes tsa mocheso oa mocheso. |

| 3003——3000 | motsoako ona hangata extruded bakeng sa mocheso exchanger methapo feela. |

| 6063 | E loketse merero ea mokhabiso, e na le sepakapaka se setle 'me e ka fetisoa ka likarolo tse rarahaneng tse kang marako a mosesaane kapa lintlha tse ntle.Ha e khone ho bola, empa e na le matla a tlase a weld, le hoja e cheseha habonolo. |

| 6061 | Alloy ena e matla ho feta 6063 mme ke sesebelisoa se seholo sa meralo bakeng sa liindasteri tsa lipalangoang le tsa mochini.The alloy ho bonolo ho extrude le weld.Mehaho ena e kopantsoeng le boima bo phahameng ba ho robeha le matla a matla a mokhathala a etsa hore e be seeta bakeng sa litho tsa meralo e cheselitsoeng, ho kenyeletsoa liforeimi tsa likoloi, tsa literaka le litereilara, likoloi tsa literene le liphaephe. |

| 7004 | E 'ngoe ea letoto la li-alloys tsa "low end" 7000 (Al-Zn) tse nang le mocheso oa khatiso o phekolehang, ka mokhoa o utloahalang oa extrudable 'me o bitsa chelete e nyenyane ho feta 6061. Letoto la 7000 esale le sebelisoa haholo indastering ea thepa ea lipapali, libaesekele le lithuthuthu.Li-alloys tse 7004 li na le chai ea ho qetela le matla a tsitsitseng ho feta 40,000 le 50,000 psi, ka ho latellana. |

Molemo oa Aluminium Extrusion

1. Boleng bo phahameng ka kakaretso ba sehlahisoa.Extrusion molding e ka ntlafatsa sebopeho le thepa ea mochini ea aluminium.Ka mor'a ho tima, thepa ea mechine ea longitudinal (extrusion direction) ea lihlahisoa tse hlahisitsoeng e phahame haholo ho feta ea lihlahisoa tse tšoanang tse hlahisoang ke mekhoa e meng ea ho sebetsa.Ha ho bapisoa le mekhoa ea ho roala, ea forging le mekhoa e meng ea ho lokisa, lihlahisoa tse extruded li na le ho nepahala ho holimo le boleng bo botle ba bokaholimo.

2. Mefuta e mengata ea lihlahisoa.Li-profiles tse fetisitsoeng ha li khone ho hlahisa liphaephe tse bonolo feela, mekoallo le lithapo, empa hape le libopeho tse rarahaneng haholo, lihlahisoa tse tiileng le tse se nang letho.Lihlahisoa tse atolositsoeng li boetse li fumaneha ka boholo bo fapaneng, ho tloha ho li-tubes tse kholo haholo le li-profile tse nang le bophara ba 500-1000 mm ho ea ho li-profiles tse nepahetseng haholo tse lekanang le lithupa tsa lipapali.

3. Ho fetoha ha maemo a phahameng a tlhahiso.Extrusion molding e fana ka phetoho e kholo.Lihlahisoa tsa libopeho tse fapaneng, boholo, litlhaloso le mefuta e sa tšoaneng li ka hlahisoa mochine o le mong ka ho fetola feela lefu.Ntle le moo, ts'ebetso ea phetoho ea die e bonolo, e bonolo, e boloka nako ebile e sebetsa hantle.

4. Mokhoa ona o bonolo 'me letsete la thepa le tlaase.Ha ho bapisoa le mekhoa ea tlhahiso ea liphaephe le profil e kang perforation rolling le groove rolling, extrusion molding e na le melemo ea ho phalla ha nako e khutšoanyane, palo e nyenyane ea lisebelisoa le lichelete tse tlaase.

Moeli oa Aluminium Extrusion

1. Lintho tse sa tšoaneng tsa lihlahisoa tsa lihlahisoa.Sebaka se sa tsitsang, setsi, hlooho le mohatla oa lihlahisoa tse extruded ka lebaka la ho phalla ho sa tšoaneng ha tšepe nakong ea extrusion.

2. Maemo a ho sebetsa a extrusion die a thata ebile a tloaetse ho apara.Nakong ea ts'ebetso ea extrusion, billet e sebakeng se haufi le ho koaloa ka khatello e phahameng ea tee.Ka nako e ts'oanang, lefu le atisa ho ba tlas'a mocheso o phahameng le likhohlano tse kholo nakong ea ts'ebetso e chesang ea extrusion, e amang haholo matla le bophelo ba tšebeletso ea lefu.

3. Ts'ebetso e tlase ea tlhahiso.Ntle le mokhoa o tsoelang pele oa extrusion o entsoeng lilemong tsa morao tjena, mokhoa o tloaelehileng oa extrusion o ke ke oa finyella tlhahiso e tsoelang pele.Lebelo le akaretsang la extrusion le tlase haholo ho feta lebelo la rolling, mme tahlehelo ea sekhechana sa geometri le lihlahisoa tsa tlhahiso ea extrusion li tlase.

Prolean e fana ka mefuta e mengata ea lisebelisoa bakeng sa extrusion ea aluminium, ho akarelletsa le tšepe le polasetiki.Ka kopo bonasampole lethathamo la thepare sebelisa.Haeba u hloka boitsebiso bo sa thathamisoang mona, ka kopo ikopanye le rona kaha re tla khona ho u fa eona.

Nako ea poso: May-04-2022