Kusarudzwa kweakanakisa sheet simbi yeCNC machining

Sep 19,2022, nguva yekuverenga:7 mins

Sheet simbi yezvinhu zvakasiyana

Iko hakuna mhinduro chaiyo kumubvunzo wezvakanakisa zvinhu zveCNC machining.Izvo zvakanakisa zvinhu zvinotemerwa neinodiwa machining process, kupera kwekushandisa, uye chikamu chakatemwa.

CNC michina inogona kushanda nesimbi, plastiki, huni, ceramics, macomposites, uye faibha.Nekudaro, maPlasitiki nesimbi ndizvo zvinonyanya kushandiswa mukugadzira CNC.Ichi chinyorwa chichakurukura chete shizha simbi yekusarudza maitiro, kusanganisira ese maficha esarudzo nzira, optimization yezvinhu, uye dzimwe dzakanakisa shizha simbi dzimwe nzira.

Zvinhu zvokufunga nezvazvo

Zvinhu zvakati wandei zvinofanirwa kutariswa paunenge uchifunga nezvezvinhu zvakakunakira iweCNC machining project.

Zvinhu zvacho zvinogona kukamurwa muzvikamu zvishanu.

- Zvikamu zvinotsanangurwa

- Inodiwa machining mashandiro

- Kupedzisa-kushandisa zvikumbiro

- Zvinodiwa zvivakwa

- Mutengo

1. Zvikamu zvinotsanangurwa

Sheet simbi kusarudzwa kunoenderana zvakanyanya neinodiwa zvikamu zvakatemerwa, izvo zvinogara zvine zvimwe zvakatemwa zvekushanda kwavo.Zvimwe zvakakosha zvakatemwa zvinosanganisira saizi, ukobvu, kushivirira, uye kupera kwepamusoro.Paunenge uchisarudza sarudzo dzesimbi simbi, izvi zvinongedzo zvinoda kutariswa.Mhando yega yega yepepa simbi ine zvinhu zvakasiyana.Zvinhu izvi zvinofanirwa kutariswa kuti zvionekwe kuti zvinoenderana here nezvinorehwa nezvikamu.

Kana zvikamu zvako zvichashandiswaas-machined surface finish, ipapo iwe unogona kusarudza shiti rine yakanakisa yepamusoro kupera.Zvisinei, kana pamusoro kupedzisa zvakadaipoda kupfeka, Zinc plating,uye kupenda ichaiswa, ungangoda kutarisa kuti ndezvipi zvinhu zvinogoneka pakupedzisa kunodiwa kwepamusoro.Saizvozvo, iwe unofanirwa kutarisa saizi, ukobvu, uye kushivirira zvinogoneka kana kwete nerudzi rwesimbi pepa rauri kusarudzira purojekiti yako.

2. Inodiwa machining mashandiro

CNC machining ane sheet simbi

Zvinoenderana nekugadzirwa kwezvikamu, Inodiwa CNC machining mashandiro anogona kuzivikanwa, senge kugaya,kutendeuka, kuchera, nezvimwewo.Iyo simbi sheet yaunosarudza inofanirwa kuenderana neinodiwa CNC machining mashandiro.Semuenzaniso, kana ukasarudza imwe simbi isingaenderane nemachining, nguva yako nemari zvinopera.Semuenzaniso, Kuoma ndiyo kiyi yezvikamu zvako, uye iwe unosarudza iyo yakaomeswa simbi pepa, asi gare gare iyo haigone kuburitsa inodiwa kushivirira uchigadzira.

Saka, iwe unofanirwa kuona kuti ndeapi machining mashandiro anodiwa uye ndeapi mhando yesimbi simbi inowirirana neaya mavhisi.

Metal maitiro anokanganisa kushanda, kusimba, uye kugona kwezvikamu.Nezve sheet simbi sarudzo dzeCNC machining,magumo ekushandisa zvikumbirozvezvikamu zvinhu zvakakosha kufunga.Usati wasarudza rudzi rwesimbi pepa, iwe unofanirwa kufunga nezve zvinhu zviviri zvakakosha pasi pekupedzisira-kushandisa maapplication.

· Environment

Iwe unofanirwa kugadzirisa mamiriro ezvakatipoteredza umo zvikamu zvichashandiswa pakupedzisira.Nekuti nharaunda inokanganisa kupisa kwekupisa, kushorwa kwemarara, makemikari kuramba, uye UV-ray kuratidzwa, iyo yemamiriro ekunze inogona kunge isiri iyo yakakosha kana zvikamu zvako zvikashandiswa mukati.Nekudaro, iwe unofanirwa kufunga nezve kushandiswa kwekunze kushanduka kwekushisa, UV radiation, humidity, uye kuratidzwa kwemakemikari.

Nekuda kweizvozvo, kusarudzwa kwesimbi pepa kunofanirwa kukwanisa kutsungirira mamiriro ezvinhu aya ekushanda.Semuenzaniso, kana iwe uchida zvikamu zvichashandiswa kunze, unofanirwa kuve nechokwadi kuti izvo zvaunosarudza hazvikanganisi kushivirira nemamiriro ekunze akadai sekupisa uye unyoro.

· Mechanical Simba

Icho chimwe chinotariswa mukupedzisira-kushandisa maapplication.Izvo zvinhu zvinofanirwa kuchengetedza simba rakakodzera remuchina mukati mehupenyu hwechigadzirwa.Kubva pakushandiswa kwezvikamu, iwe unogona kuverenga inodiwa mechanical simba uye zvinhu zvinogona kupa iyo simba.

3. Zvinodiwa zvivakwa

Chikamu chimwe nechimwe chinoda huwandu hwayo hwezvivakwa zvekushanda.Nekuda kweizvozvo, izvo zvinodiwa zvechikamu zvinofanirwa kuenderana kana kuwira mukati meiyo Sheet simbi zvivakwa (zvemuviri, zvemichina, uye kemikari) uchisarudza yakanakisa CNC sheet simbi.

Hunhu hwemuviri hweshizha simbi, senge tensile simba, simba-kusvika-huremu reshiyo, kupfeka uye kubvarura kuramba, uye kuchinjika, inozotemwa nechikamu chekushandisa chezvikamu.Kazhinji, inorema sheet simbi ine simba remuchina rakakura, asi zvikamu zvehuremu zvinofanirwa kutariswa.Nokudaro, nzira yakakurudzirwa yekuita ndeyekuenzanisa simba remagetsi uye simba-kusvika-uremu reshiyo.

Ngatikurukurei zvimwe zvinhu zvakakosha zvekufunga nezvazvo panguva yekusarudza.

· Kurema

Kana simbi yesimbi ichizadzisa simba rinodiwa kune zvikamu, saka uremu hunofanira kutariswa zvichienderana nekushandiswa.Semuenzaniso, zvinhu zvacho zvinofanirwa kuve zvakareruka zvakanyanya kana zvikamu zviri zvendege.

· Machinability

Chinotevera hunhu ndiko machinability ezvinhu.Yakakwira machinability zvinhu zvinoita kuti CNC machining ive nyore uye inobatsira kuchengetedza kwakasimba kushivirira.Saka, iyo machinability yesimbi simbi zvakare ine basa mukuita sarudzo.Chimwe chinhu chinouya nemachinability kuenderana nemidziyo nekuti Kana iwe ukafunga iyo yakanyanya kuomarara zvinhu, izvo zvinogona kuparadza machining maturusi.

· Thermal maitiro

Ongorora zvinhu 'zvinopisa uye zvemagetsi maitiro anozadzisa mamiriro ekushanda mukushandisa kwekupedzisira.Funga nezvemagetsi conductivity, kunyungudika, uye kupisa kwekuwedzera Coefficient.Kana ukasarudza chinhu chine nzvimbo yakaderera yekunyungudika uye zvikamu zvako zvichishanda pakupisa kwakanyanya, izvo zvinogona kukonzera kukundikana.Panguva imwecheteyo, funga nezvekugadzirisa magetsi maererano nechikumbiro chaunoda.

4. Mutengo

Mutengo chinhu chakakosha chekufungisisa pakusarudza iyo yakanakisa sheet simbi yeCNC machining.Zvishandiso zvakawanda zvinowanikwa mumitengo yakasiyana-siyana inosangana nezvose zvinodiwa zvikamu 'zvinodiwa.Saka, Mutengo unofanirwa kutariswa pamwe chete nezvimwe zvinhu.Izvo zvinodiwa kuti uongorore Mutengo wepepa simbi zvichienderana nemidziyo yavo, senge machinability, simba, kuoma, uremu, nezvimwe.

Semuyenzaniso, Aluminium ndiyo yakanakisa sarudzo sezvo isingadhure pane titanium, kunyangwe zvese zviri zviviri zvinosangana nesimba-ku-kurema zvinodiwa pakusarudza sheet simbi yemukati mendege zvikamu.

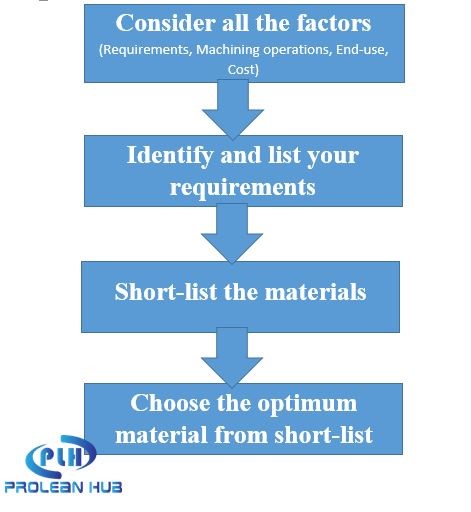

Gwaro rematanho matatu ekusarudza yako yakanakisa simbi simbi

Pamusoro, takakurukura zvese zvakakosha zvinhu zvinopesvedzera shizha simbi yekusarudza maitiro uye kusarudza kuti ndeapi marudzi emapepa simbi angave akanakira chero CNC machining chirongwa.

Zvichienderana nezvinokonzeresa, pane matanho matatu akakosha aunogona kutevera kuti usarudze yakanakisa sheet simbi yepurojekiti yako.

Kuyerera-chati yemaitiro ekusarudza

Danho 1: Nyora zvaunoda.

Takakurukura kuti chikamu chinodiwa ndicho chakakosha pakusarudza yakanakisa CNC zvinhu.Chinofanira kunge chiri chekutanga chako.Saka, nyora zvese zvinodiwa seSimba, Kuoma, kureruka, elasticity, kupera kwepasi, nezvimwe.

Muenzaniso:

| Zvinodiwa zvivakwa | Kukosha/ Kutsanangura |

| Tensile Simba | Low(< 100 MPa), yepakati (<500 MPa), kana yakakwirira (>500 MPa).Iwe unogona kugadzirisa inodiwa tensile simba mumhando (kureva, X kusvika Y MPa) |

| Kudzvinyirira simba | Sarudza kubva Pazasi, zvepakati, uye nepamusoro, kana zvakare inogona kuve yakatarwa siyana. |

| Kuoma | Sarudza kubva Pazasi, zvepakati, uye nepamusoro, kana zvakare inogona kuve yakatarwa siyana(kureva, X kusvika kuY HRB) |

| Simba-ku-kurema reshiyo | Yakaderera, yepakati, kana yakakwirira.Zviri nani kutsanangura huwandu hwezvikamu zvinonzwisisika, sezvikamu zvemidziyo yekurapa. |

| Surface finishing | Seyakagadzirwa nemichina, plating, pendi, poda coating kana chero mamwe marudzi, kune dzakasimba zvikamu senge ndege, Zviri nani kudoma huwandu hunodiwa hukasha manhamba (Ra). |

| Machinability | Taura kuti ndeupi rudzi rwemachinability inodiwa papepa simbi (Yakakwirira, yepakati, yakaderera) |

| Kushivirira | ± X kusvika Y mm |

| Elasticity | Pamusoro, pakati, kana pasi. |

Chaizvoizvo, Nyora izvo zvinodikanwa nekutsanangura renji kana chikamu (Yakaderera, yepakati, uye yakakwirira).Chimwe chinhu ndechekuti iwe unogona kunyora chero chinodiwa, kwete kuganhurirwa kumuenzaniso uri pamusoro.

Danho rechipiri: Nyora pfupi zvinyorwa

Ngatitarisei mhando dzakajairwa dzesimbi simbi inoshandiswa muCNC machining.Zvino nyora mhando dzesimbi dzakasiyana-siyana maererano nezvakarongwa kare.Rondedzero yemidziyo inofanirwa kuenderana nezvinodiwa.

· Aluminium

Aluminium inopa yakakwira simba-ku-huremu reshiyo, machinability, ductility, thermal & magetsi conductivity, corrosion resistance, uye mutengo-kushanda.Inogona kukurumidza kugadzirwa uye kushandiswa mumaindasitiri mazhinji, anosanganisira emotokari, aerospace, kuvaka, midziyo yemumba, mauto, magetsi, uye zvemagetsi.

· Simbi isina ngura

Simbi isina simbi inopa Yakakwira mechini simba, kuoma, kupisa kwekupisa, kupfeka uye kubvarura kuramba, uye kusimba.Simbi isina tsvina ine inoyevedza yepamusoro pekupedzisira iri nyore uye ine inopenya sirivha toni.Nekudaro, iyo mhando yealloy inokanganisawo iwo chaiwo hunhu.Iwo matatu anonyanya kufarirwa alloys ndeye 1215, 12L14, uye 1018.

· Brass

Brass inopa yakanakisa machinability, yakakwirira tensile simba, kukanganisa kupikisa, uye shear kuramba.Iyo ine mukurumbira zvakanyanya kune yakaderera-kukweshana kugadzira, aesthetic kukwezva, uye yakasimba kushivirira kugadzirwa muMagetsi, Zvemagetsi, Mota, dziviriro, aerospace, zvivakwa, zvekurapa, Plumbing, uye mamwe akawanda maindasitiri.

· Titanium

Chakanyanya mukana wetitanium ndechekuti inogona kuchengetedza yakanyanyisa kupisa, makemikari, uye mwando nharaunda pasina kuchinja maitiro ayo.Iyo ine yakakwira mazinga ebiocompatibility, simba-ku-huremu reshiyo, uye corrosion kuramba, zvichiita kuti ive yakakodzera kune mota, aerospace, uye maindasitiri ekurapa.

· Mhangura

Kunyangwe isina kusimba pakurwisa zvinhu zvakaita seasidhi, halogen sulfides, uye ammonia mhinduro, mhangura ine hukuru hwekupisa uye hwemagetsi hunhu, hukuru hwemachinability, corrosion resistance, uye kupenya kwakatsvuka kwebrown kukwezva.Inogona kushandiswa kune radiators, mavharuvhu emagetsi, kudziyisa uye kutonhora masisitimu, uye akasiyana midziyo yemagetsi.

· Vamwe

Kunze kweizvi, kune simbi dzakasiyana dzine zvinhu zvakasiyana, zvakadaiBronze, zinc, uye Magnesium.

Danho rechitatu: Sarudza yakanakisa sheet simbi kubva pane pfupi-rondedzero

Sarudza izvo zvinonyatso kugutsa zvese zvinodiwa mushure mekupfupisa pasi sarudzo yepepa simbi yakagadzirwa nezvinhu zvakasiyana.Paunenge uchiita sarudzo, funga nezve mutengo wacho.Kana mitengo yakadzikira zvakanyanya, unogona kukanganisa pane zvimwe zvinodiwa pasina kupa basa.Nekudaro, kana zvikamu zvacho zvine hunyoro, unofanirwa kutsvaga izvo zvinonyatsoenderana nezvinodiwa.

Pfungwa yekupedzisira

Kusarudzwa kweakanakisa sheet simbi kune yako CNC machining purojekiti yakaoma.Inosanganisira kufunga zvinhu zvakasiyana, asi neProlean, iri nyore kupfuura zvaungafungidzira, ichipa CNC machining masevhisi anopfuura makumi mashanu+ simbi & alloys.Isu tinokwanisa muchina zvikamu kune ako mataurirwo nekushivirira kwakasimba.Mainjiniya edu ane ruzivo achakubatsira iwe kusarudza zvakanakisa zvinhu mukati mebhajeti yako uye zvaunoda maficha.

FAQ's

Nderipi simbi simbi ingave yakanyanya kunaka kune yangu CNC machining chirongwa?

Hapana kana imwe mhinduro.Iyo yakakodzera sheet simbi yeprojekti yako yeCNC inotsamira pane akati wandei, kusanganisira zvaunoda uye maitiro eimwe mhando yepepa simbi.Semuyenzaniso, Aluminium inogona kunge iri simbi yakanakisa yezvikamu zvemukati zvendege, nepo simbi yesimbi ingave sarudzo yakanakisa yezvimiro.Chaizvoizvo, zvinoenderana zvachose nezvido zvako.

Ndezvipi zvinhu zvakakosha zvekufunga nezvazvo paunenge uchisarudza zvakanakisasheet metal yeCNC machining?

Pane zvinhu zvakasiyana senge zvaunoda, magumo-ekushandisa maapplication, tekinoroji kugona kwekugadzira, Mutengo, uye zvimwe zvakawanda.

Ndeapi mamwe marudzi akajairika emashizha esimbi anoshandiswa muCNC machining?

Iyo inonyanya kufarirwa pepa simbi zvinhu zvinoshandiswa muCNC machining isimbi, Aluminium, ndarira, titanium, mhangura, zingi, uye bhuronzi.

Nguva yekutumira: Sep-19-2022