Kuvandudza Dhizaini yeSheet Metal Zvikamu - Sheet Metal Design Guidelines

Inofungidzirwa nguva yekuverenga: 9 maminetsi, 48 masekonzi.

Paunenge uchigadzira zvikamu zvechigadzirwa, zvakakosha kufunga nezvekureruka kwekugadzira.Edza kufunga nzira dzekuita kuti zvive nyore kugadzirisa, asiwo kuchengetedza zvinhu, uye kuwedzera simba pasina zvimedu.Nekuda kweizvozvo, vagadziri vanofanirwa kutarisisa kune zvinotevera zvigadzirwa zvekugadzira

Sheet metal parts' machinability zvinoreva kuoma kwekucheka, kukotama uye kutatamuka kwezvikamu.Nzira yakanaka inofanira kuva nechokwadikushoma kushandiswa kwezvinhu, kushomeka kwehuwandu hwemaitiro, dhizaini yakapusa ye mold, hupenyu hwepamusoro uye yakagadzikana mhando yechigadzirwa.Kazhinji, iyo inonyanya kukosha pesvedzero pakugadziriswa kwesimbi simbi zvikamu kuita kwezvinhu, chikamu chejometri, saizi uye nekurongeka zvinodiwa.

Nzira yekunyatsofunga nezvezvinodiwa uye maitiro ekugadzirisa maitiro paunenge uchigadzira chimiro chechidimbu chesimbi chesimbi zvikamu, mazano akawanda ekugadzira anokurudzirwa pano.

1 nyore geometry nhungamiro

Iyo yakapfava geometric chimiro chekucheka kwepamusoro, zvakanyanya nyore uye zviri nyore kutema pasi, kupfupika kwenzira yekucheka, uye kudiki vhoriyamu yekucheka.Semuyenzaniso,mutsara wakatwasuka uri nyore pane curve, denderedzwa iri nyore pane ellipse nemamwe macurve epamusoro-soro, uye chimiro chenguva dzose chiri nyore pane chimiro chisina kujairika.(ona Mufananidzo 1).

(a) Chimiro chisina musoro (b) Chimiro chakavandudzwa

(Mufananidzo 1)

Chimiro cheFig. 2a chinopa pfungwa huru chete kana vhoriyamu yakakura;kana zvisina kudaro, pakubaya, kucheka kunonetsa;saka, chimiro chinoratidzwa muFig.2b chakakodzera kugadzirwa kwevhoriyamu shoma.

(a) Chimiro chisina musoro (b) Chimiro chakavandudzwa

(Mufananidzo 2)

2 Chinyorwa chekuchengetedza dhairekitori (conformation gwara rekurova nekucheka zvikamu)

Kuchengetedza zvigadzirwa zvinoreva kuderedza mutengo wekugadzira.Zvimedu zve-off-cuts zvinowanzoraswa semarara, saka mukugadzirwa kwezvinhu zvakatetepa mapepa,ma-off-cuts anofanira kuderedzwa.Kurambwa kwezvibhakera kunoderedzwa kuderedza kutambisa zvinhu.Kunyanya muhuwandu hwezvikamu zvakakura pasi pezvakagadzirwa zvakakosha, kuderedza-kubvisa-kubvisa nenzira dzinotevera:

1) Deredza chinhambwe pakati penhengo mbiri dziri pedyo (ona Mufananidzo 3).

(a) Chimiro chisina musoro (b) Chimiro chakavandudzwa

(Mufananidzo 3)

2) Kuronga kweunyanzvi (ona mufananidzo 4).

(a) Chimiro chisina musoro (b) Chimiro chakavandudzwa

(Mufananidzo 4)

3) Kubviswa kwezvinhu mundege huru kune zvidiki zvinhu

(a) Chimiro chisina musoro (b) Chimiro chakavandudzwa

(Mufananidzo 5)

3 Yakakwana simba kuomarara nhungamiro

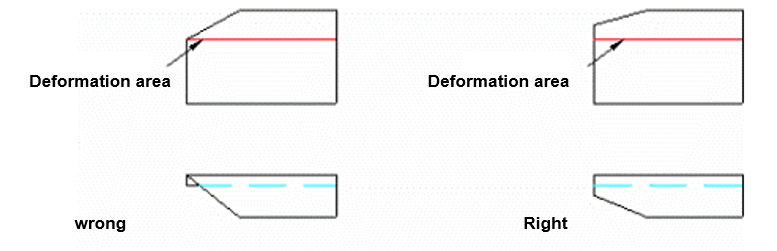

1) mupendero wakakotama une beveled mupendero unofanirwa kudzivirira nzvimbo yekuchinja

(Mufananidzo6)

2) kana chinhambwe pakati pemakomba maviri chakanyanya kudiki, pane mukana wekuputika panguva yekucheka.

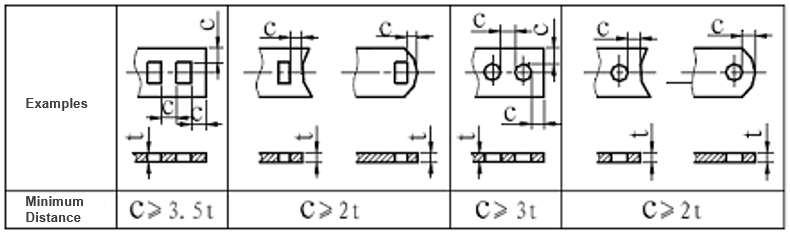

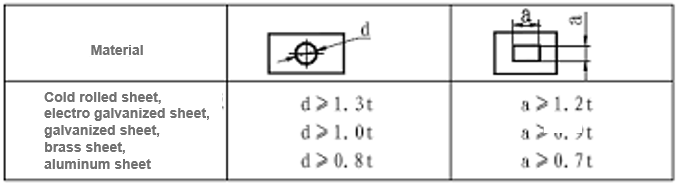

Magadzirirwo ekubaya maburi pachikamu kunofanirwa kutariswa kuti kusiye akakodzera buri kumucheto chinhambwe uye nepakati pegomba kudzivirira kurovera kwakatsemuka.Chinhambwe chidiki pakati pemupendero wegomba rekurovera uye chimiro chechikamu chinoganhurwa nemhando dzakasiyana dzechikamu negomba.Kana mupendero wegomba rekurovera usingafananidzi kumucheto kwechimiro chechikamu, nhambwe shoma haifanirwe kunge iri pasi pehupfu hwezvinhu t;painofanana, haifanirwe kunge isingasviki 1.5 t.Hurefu hwegomba kumucheto uye nzvimbo yepakati inoratidzwa mutafura.

(Mufananidzo7)

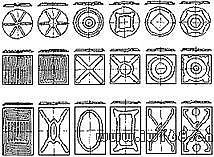

Thegomba rakatenderedza ndiro rakasimba kwazvo uye riri nyore kugadzira nekuchengetedza, uye mwero wekuvhura wakaderera.Iyo square hole ine yakanyanya kuvhura mwero, asi nekuti iri 90 degree angle, kona yekona iri nyore kupera nekudonha, zvichiita kuti mold igadziriswe uye kumisa mutsara wekugadzira.Uye gomba rine mativi matanhatu rinovhura kona yaro 120 madhigirii makuru kupfuura 90 madhigirii pane skweya gomba kuvhura kwakasimba, asi mwero wekuvhura mupendero kupfuura buri resikweya ushoma zvishoma.

3) akaonda uye akareba slats ane kuomarara kwakaderera zvakare nyore kugadzira kuputika kana uchicheka, kunyanya kupfeka kwakakomba pachishandiswa.

Kudzika uye hupamhi hwechikamu chakabudikira kana kudzoreredzwa chechikamu chekubaya, kazhinji, hachifanirwe kunge chiri pasi pe1.5t (t ndiko ukobvu hwezvinhu), uye inofanirawo kudzivirira matete uye marefu akachekwa ane uye akanyanya kutetepa grooves kuti awedzere. simba rekumucheto kwechikamu chinowirirana chefa.Ona Mufananidzo (8).

Nokuda kwesimbi yakawanda A ≥ 1.5t;nokuda kwesimbi yealloy A ≥ 2t;yendarira, aruminiyamu A ≥ 1.2t;t - kuwanda kwezvinhu.

Mufananidzo(8)

4 Mazano akavimbika ekubaya

Mufananidzo 9a unoratidzwa muiyo semi-denderedzwa tangent chimiro punching processing yakaoma.Nekuti inoda kurongeka kwakaringana kwechinzvimbo pakati pechishandiso uye workpiece.Kuyera kwakaringana kwekumisikidza hakusi kungotora nguva chete, asi zvinonyanya kukosha, chishandiso chinogona kupfeka uye zvikanganiso zvekuisa, iko kurongeka kazhinji hakusviki zvakanyanya zvinodiwa.Kamwe chimiro chakadaro chinenge chatsauka zvishoma kubva mukugadzira, hutano hwakaoma kuvimbisa uye chimiro chekucheka chakashata.Naizvozvo, chimiro chinoratidzwa muMufananidzo 9b chinofanirwa kushandiswa, chinogona kuve nechokwadi chekuvimbika kwe punching processing quality.

(a) Chimiro chisina musoro (b) Chimiro chakavandudzwa

(Mufananidzo 9)

5 Dzivisa mirairo yebanga inonamira (iyo yekumisikidza nhungamiro yezvikamu zvekupinda)

Pakati pechikamu kubaya uye kucheka kuchaonekwa dambudziko rekushandisa uye chikamu bonding cross-tight.Mhinduro:(1) kusiya kumwe kutenuka;(2) kucheka kwepamusoro kwakabatana(ona Mufananidzo 10 uye Mufananidzo 11).

(a) Chimiro chisina musoro (b) Chimiro chakanatsiridzwa (a) Chimiro chisina musoro (b) Chimiro chakanatsiridzwa.

(Mufananidzo10) (Mufananidzo11)

Kana gumbo richiitwa mukuita nekurova uye nzira yekucheka mu90 ° yekukotama kumucheto, kusarudzwa kwezvinhu kunofanirwa kutarisisa kune izvo zvinhu hazvifanirwe kunge zvakanyanya kuoma, zvikasadaro zviri nyore kutyora pakona chaiyo bend.Inofanirwa kugadzirwa munzvimbo ye curved edge process yakachekwa kudzivirira kuputika pakona yekupeta.

(Mufananidzo12)

6 bending edge yakatwasuka yekucheka pamusoro nhungamiro

Sheti mukucheka maitiro mushure meiyo yakawanda kuenderera mberi kuumba maitiro, sekukotama.Kupeta mupendero kunofanirwa kunge kuri perpendicular kune yekucheka nzvimbo, zvikasadaro njodzi yekupwanya pamharadzano inokwidziridzwa..Kana zvakamira zvakamira zvisingakwanisi kuitwa nekuda kwezvimwe zvirambidzo,nzvimbo yekucheka uye mharadzano yemucheto wekukotama inofanira kugadzirwa kona yakakomberedzwa, radius iyo yakakura kudarika kaviri kukora kweplate.

7 Mirayiridzo yekukotama zvinyoro

Kukotama kwakadzika kunoda maturusi akakosha, uye mutengo wakakwira.Pamusoro pezvo, diki diki rekukotama radius rinowanzo kuputika uye kuunyana mukati mechiso (ona Mufananidzo 13 uye Mufananidzo 14).

(a) Chimiro chisina musoro (b) Chimiro chakavandudzwa

(Mufananidzo13)

(a) Chimiro chisina musoro (b) Chimiro chakavandudzwa

(Mufananidzo14)

8Nhungamiro dzekudzivirira madiki akatenderedzwa mipendero

Mipendero yezvikamu zvakatetepa ndiro inowanzotenderedzwa edges chimiro, iyo ine huwandu hwezvakanakira.(1) kusimbisa kuomarara;(2) dzivisa mativi akapinza;(3) akanaka.Nekudaro, iyo yakatenderedzwa mupendero inofanirwa kuterera kune maviri mapoinzi, imwe ndiyo radius inofanira kunge yakakura kupfuura 1.5 nguva ukobvu hwendiro;chechipiri haina kutenderera zvachose, kuitira kuti kugadzirisa kuome, Mufananidzo 15b unoratidza mupendero wakatenderedzwa pane iwo wakapetwa mupendero uri nyore kugadzirisa.

(a) Chimiro chisina musoro (b) Chimiro chakavandudzwa

(Mufananidzo15)

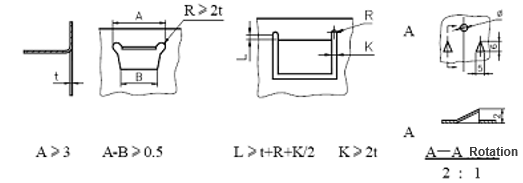

9 Slot kumucheto kwete kupeta nhungamiro

Kupeta mupendero uye slot hole mupendero kuti upatsanurwe neimwe chinhambwe, kukosha kwakakurudzirwa ndiyo radius yekupeta uye kaviri ukobvu hwemadziro.Nzvimbo yekukotama yakaomeswa nemamiriro esimba, uye simba rakaderera.Notch mhedzisiro yegomba slot inofanirawo kubviswa munzvimbo ino.Ose ari maviri buri rese kubva kumucheto wekupeta, asiwo gomba rekubhejera kumucheto kwese kunokombama (ona Mufananidzo 16).

(a) Chimiro chisina musoro (b) Chimiro chakavandudzwa

(Mufananidzo16)

10 Complex chimiro musanganiswa kugadzira nhungamiro

Chimiro chemuchadenga chakanyanya kuomarara zvikamu, zvachose nekukotama kuumba kwakaoma.Naizvozvo,edza kugadzira chimiro chiri nyore sezvinobvira, muchiitiko chekusaomeswa, kunowanikwa kusanganiswa kwezvikamu, ndiko kuti, nhamba yezvidimbu zvitete zvakapfava zvine welding, bolting uye dzimwe nzira dzekubatanidza pamwe chete.Chimiro chemufananidzo 20b chiri nyore kugadzirisa pane chimiro chemufananidzo 17a.

(a) Chimiro chisina musoro (b) Chimiro chakavandudzwa

(Mufananidzo17)

11 Nzvenga mitsetse yakatwasuka kupinda nhungamiro yezvikamu

Iyo yakatetepa ndiro chimiro ine dhizaini yehurombo husina kuchinjika hwekukotama kuoma.Yakakura flat chimiro chiri nyore kukotama kusagadzikana.Kuwedzera kuchaita zvakare bend fracture.Kazhinji shandisa pressure groove kuvandudza kuoma kwayo.Kurongeka kwe groove kune simba guru pamigumisiro yekuvandudza kuoma.Iyo yakakosha musimboti wekurongeka kwegorofu ndeyekunzvenga yakananga munzvimbo isina migodhi.Iyo bhendi nhete yekuomarara kwakaderera kuburikidza iri nyore kuve axis yeinertia yeplate rese rinobhenda kusagadzikana.Kusagadzikana nguva dzose kunotenderera kune axis ye inertia, saka, kurongeka kwekumanikidzika groove kunofanira kugura iyi axis ye inertia uye kuita kuti ive pfupi sezvinobvira.Muchimiro chinoratidzwa muMufananidzo 18a, mitsetse yakatetepa yakawanda inoumbwa munzvimbo isina kudzvanywa.Kutenderedza matemo aya, iko kugonya kuomarara kwendiro yese hakuna kuvandudzwa.Chimiro chinoratidzwa muFig. 18b hachina mikana yakabatana yekumisa inertia maaxes, uye mufananidzo 19 unoratidza maumbirwo akajairika groove uye marongero, nekuomarara kwekusimudzira kunowedzera kubva kuruboshwe kuenda kurudyi, uye kurongeka kusiri kwemaitiro inzira inoshanda yekunzvenga nepakati. .

(a) Chimiro chisina musoro (b) Chimiro chakavandudzwa

(Mufananidzo18)

(Mufananidzo19)

12 Nhungamiro yepressure groove kuenderera mberi kuronga

Kusimba kwekuneta kwemagumo ekumanikidza groove hakuna simba, uye kana groove yekumanikidza yakabatanidzwa, chikamu chekuguma kwayo chichabviswa.Mufananidzo 20 ibhokisi rebhatiri parori, riri pasi pesimba remutoro, Mufananidzo 20a chimiro mune yekumanikidza groove kupera kuneta kukuvara.Chimiro chiri mumufananidzo 20b hachina dambudziko iri.Mamiriro emawere ekumanikidza anofanirwa kudziviswa uye, pazvinobvira, giroove yekumanikidza inotambanudzirwa kusvika kumuganhu (ona Mufananidzo 21).Kupinda kwekumanikidza groove kunobvisa kupera kusina simba.Zvisinei, mharadzano yezvitsigiro zvekumanikidzika inofanira kuva yakakura zvakakwana kuitira kuti kuwirirana pakati pezvikwata zvideredze (ona Mufananidzo 22).

(a) Chimiro chisina musoro (b) Chimiro chakavandudzwa

(Mufananidzo20)

(a) Chimiro chisina musoro (b) Chimiro chakavandudzwa

(Mufananidzo21)

(a) Chimiro chisina musoro (b) Chimiro chakavandudzwa

(Mufananidzo22)

13 Spatial pressure groove criterion

Kusagadzikana kwechimiro chepakati hakungogumiri pane chimwe chinhu, saka, kuisa groove yekumanikidza chete pane imwe ndege haigone kuwana mhedzisiro yekuvandudza kupesana-kukanganisa kugona kwechimiro chose.Semuenzaniso, muU- uye Z-maumbirwo akaratidzwa mumufananidzo 23, kusagadzikana kwavo kuchaitika pedyo nemicheto.Mushonga wedambudziko iri kugadzira groove yekumanikidza senzvimbo (ona Fig. 23b chimiro.)

(a) Chimiro chisina musoro (b) Chimiro chakavandudzwa

(Mufananidzo23)

14 Nhungamiro yekuderera zvishoma

Wrinkles inoitika kana chikamu deformation ichidzivirirwa zvakanyanya pandiro yakatetepa.Mhinduro ndeyekumisikidza akati wandei madiki epressure grooves padhuze necrease, kuitira kuti kuderedze kuomarara kwenzvimbo uye kuderedza deformation yekuvhara (ona Mufananidzo 24).

(a) Chimiro chisina musoro (b) Chimiro chakavandudzwa

(Mufananidzo24)

15 Mirayiridzo yekumisikidza yekubaya zvikamu

1) Minimum punching dhayamita kana shoma padivi kureba kweskweya gomba

Kurova kunofanira kuderedzwa nesimba repunch, uyesaizi yepunch haifanirwe kunge iri diki, kana zvisina kudaro punch ichakuvadzwa nyore nyore.Minimum punching dhayamita uye zvishoma kureba divi rinoratidzwa mutafura.

* t ndiko kukora kwechinhu, hushoma saizi yepunch kazhinji haisi pasi pe0.3mm.

2) Kurova notch musimboti

Punching notch inofanira kuedza kudzivisa makona akapinza, sezvinoratidzwa mumufananidzo.Yakanongedza fomu iri nyore kupfupisa hupenyu hwesevhisi yefa, uye kona inopinza iri nyore kuburitsa mitswe.Inofanira kuchinjwa kuita sezvakaratidzwa mumufananidzo b.

R ≥ 0.5t (t - zvinhu ukobvu)

a Fig. b Fig.

Makona akapinza anofanirwa kudziviswa muchimiro uye kubhowa kwechikamu chakaroverwa.Pakubatanidza mutsara wakatwasuka kana curve kuti uve nedenderedzwa arc connection, radius yearc R ≥ 0.5t.(t ndiko kukora kwemadziro)

Sheet simbi kubhenda nekushandisaPROLEAN'TECHNOLOGY.

PaPROLEAN TECH, isu tine shungu nekambani yedu uye masevhisi atinopa kune vatengi vedu.Saka nekudaro, tinodyara mari yakawanda mukufambira mberi kwazvino muhunyanzvi hwedu uye tine mainjiniya akazvipira kwauri.

Chiono chaProlean ndechekuve anotungamira mhinduro mupi weOn-Demand Manufacturing.Tiri kushanda nesimba kuita kuti kugadzira kuve nyore, nekukurumidza, uye kuchengetedza mari kubva ku prototyping kusvika pakugadzira.

Nguva yekutumira: Mar-30-2022