CAPABILITIES

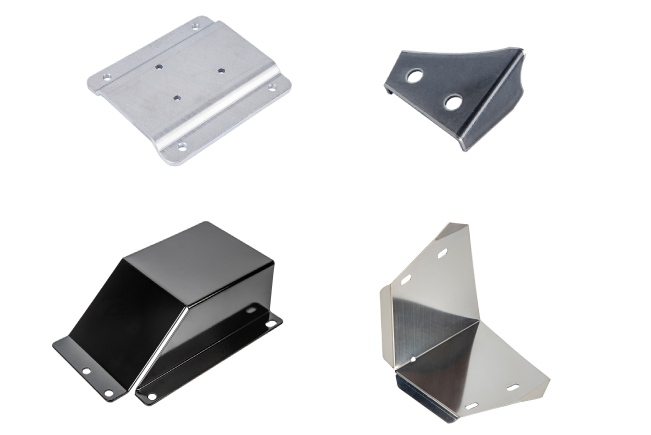

Sheet Metal Service

We provide sheet metal cutting and forming services from prototypes to on-demand production of sheet metal parts. Start a one-hour CNC quote from a real engineer, and get your parts made

- ISO 9001:2015 certificated

- Lead time as fast as one day

- Aluminium, Steel, Stainless Steel and more

- Sheet Metal Cutting (Laser, Waterjet), Stamping, Bending, Welding

All uploads are secure and confidential.

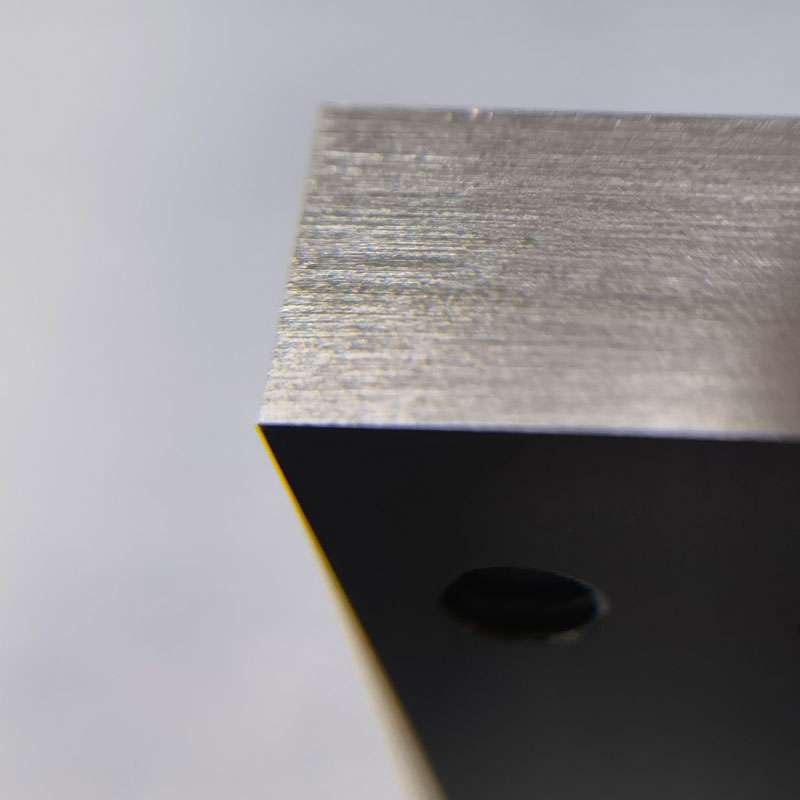

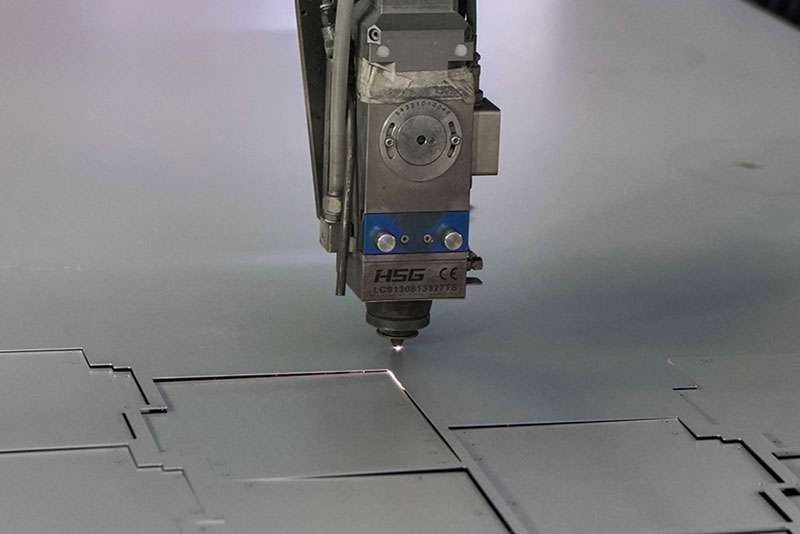

Laser Cutting Service

Our laser cutting service are able to deliver high-precision cutting and engraving on materials such as aluminum steel, coppe and more

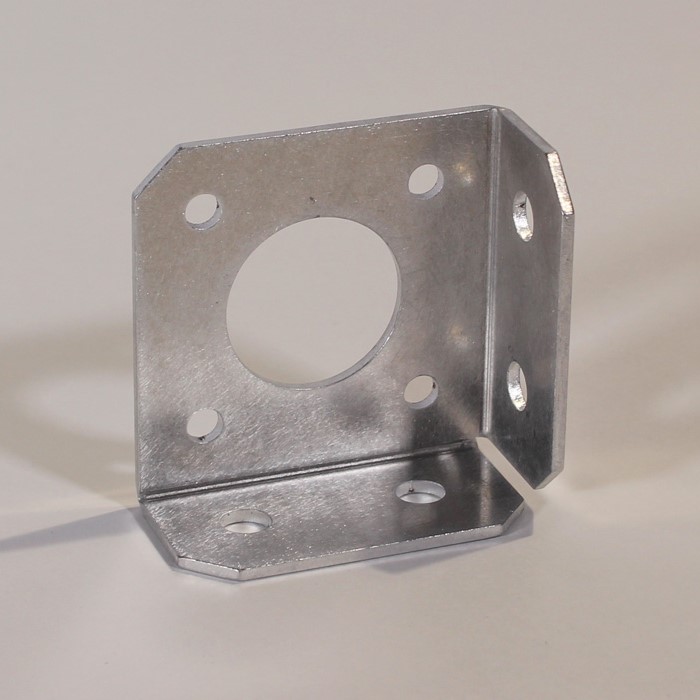

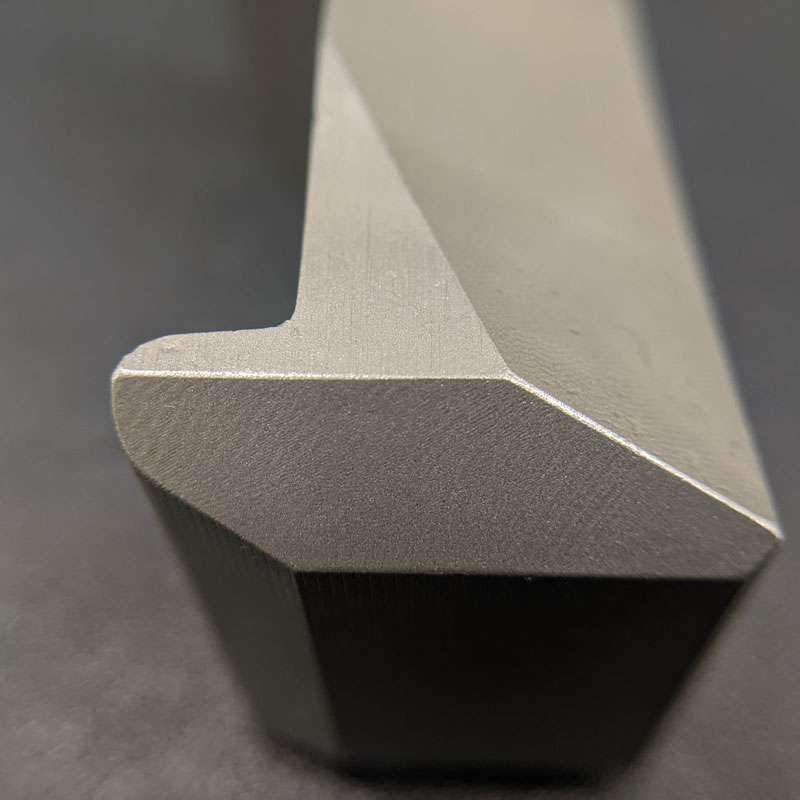

Sheet Metal Bending

Deliver accurate angles with our bending services, achieving a final product that fits within tight tolerances

Stamping Service

Stamping service is a rapid process that generates parts with complex geometries at relatively lower costs.

Waterjet Cutting

High precision CNC waterjet cutting service cut through sheet metals without leaving burn marks

Welding Service

If you need to create a joint on the Metal & alloy pieces for your project, the Welding process is the right choice!

Why Choose Our sheet Metal Fabrication Service

Are you looking to create actual parts and products from your 2D or 3D design? Our sheet metal fabrication might be the best approach for you.

Sheet metal fabrication refers to the creation of the desired shape from the steps of the manufacturing process. It involves various alternatives for each step, such as cutting, bending, joining, and surface finish. But, choosing the right type of process helps optimize the fabrication’s functionality and cost. Prolean makes it easy for you. We decide the best steps for your project based on your requirements.

Our Sheet Metal Fabrication Capabilities

Features |

Info |

| Bend angle | 1° |

| Thickness | 0.1mm-20mm |

| Part size limit | 6000mm*4000mm |

Sheet Metal Fabrication Materials

Aluminum

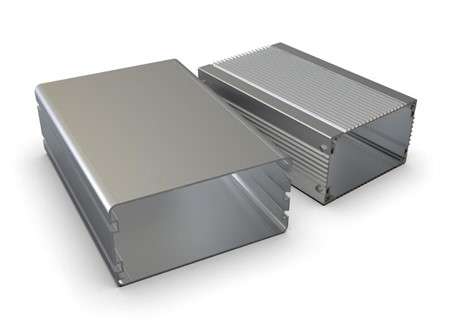

Prolean’s Aluminum Sheet Metal Fabrication Service is your gateway to precision-crafted, durable components. Marrying cutting-edge technology with seasoned craftsmanship, we transform raw aluminum sheets into masterpieces, ensuring reliability and aesthetic finesse in every creation.

Subtypes: 5052, 5083, 6061, 6082

Brass

Prolean offers Brass Sheet Metal Fabrication Services, focusing on precision and durability. Using quality brass sheets, we ensure reliable and long-lasting products suited for various applications.

Golden shiny color, low friction, excellent Machinability, and high electrical & thermal conductivity. Brass can be easily machined and the best choice for low-friction applications.

Subtypes: C360, H59, H62

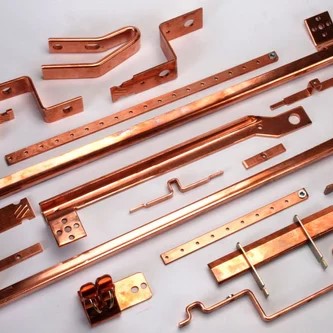

Copper

Our Copper Sheet Metal Fabrication Service transforms quality copper sheets into durable components. Trust us for dependable solutions tailored to diverse needs

It offers good strength, hardness, and excellent corrosion resistance with superior heat and thermal conductivity. It also has a very appealing aesthetic.

Subtypes: 101, C110

Steel

For robust and lasting results, Prolean’s Steel Sheet Metal Parts service crafts precision components from premium steel sheets, ensuring strength and quality in every piece.

High mechanical strength, toughness, resistance to wear and fatigue, and sturdiness. In addition to carbon, other alloying elements can be added depending on the needed mechanical and physical qualities.

Subtypes: 1018, SPCC

Stainless Steel

Rely on Prolean’s Stainless Steel Sheet Metal Parts service for corrosion-resistant components that combine strength with a polished finish, ideal for both functionality and aesthetics

High mechanical strength, Thermal, Wear, and Corrosion resistance. Stainless steel is low-cost and can be machined easily. Parts made from Stainless steel are durable and do not lose that strength over time.

Subtypes: 301, 304, 316

Finishing Options For Sheet Metal Part

We provide various surface finish options for your sheet metal project. If your required surface treatment is not listed below, feel free to contact us for more options.

As the machined or deburring

The machined or deburring finish is the standard finish where unwanted attach chips are removed with deburring tools, and sharp edges are chamfered to smooth the surface (3.2 μm).

Bead Blasted

Bead blasting produces a matte texture, removing all the marks of machining tools. It applies to ABS, Aluminum, Brass, Stainless Steel, and Steel parts.

Anodizing

Anodizing involves adding an aluminum oxide coating to aluminum and its alloys. The layers, which come in various colors, increase strength and shield the surface from corrosion.

Powder coating

Powder coating is the electrostatically applying of dry powder to the surface. It produces a thin layer providing excellent resistance to wear, corrosion, and abrasion.

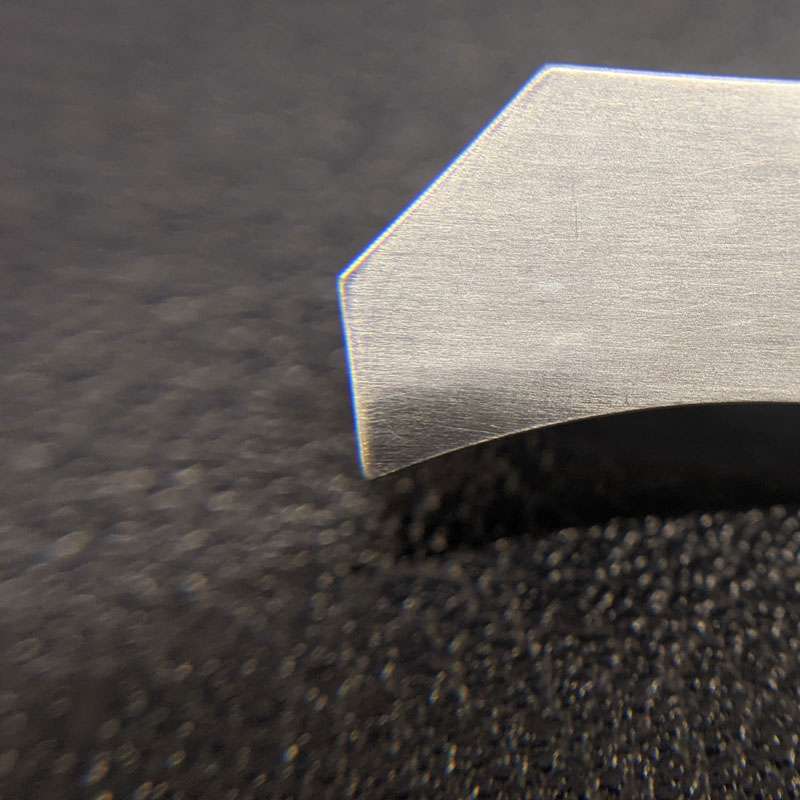

Polishing

Physical rubbing of a metal surface to create a shiny surface is called a polishing surface finish. It increases the reflectivity and does not affect the dimensional stability of parts.

Brushing

Brushing is achieved by applying an abrasive brush to the metal surface, which produces a unidirectional satin finish. And it is not recommended for highly corrosive materials.

Smooth machining

Smooth machining is done by controlling the machining process, such as feed rate & cutting speed. It minimizes the tool marks and risk of corrosion.

Black-Oxide

Black oxide finish reduces surface reflectivity and offers mild corrosion protection. It involves adding a thin layer of magnetite to the surface.

Fine machining

The higher-precision machines produce delicate machining surfaces by utilizing sharper tools and regulating feed rate and cutting speed. Surface roughness up to Ra 0.8 μm can be maintained with smooth machining.

More

Provides a random, non-linear texture with a shiny, high gloss finish. However, it might be unable to create sharp corners and pockets

Sheet Metal Fabrication Tolerances

Dimension detail |

Tolerance(+/-) |

| Edge to edge, single surface | 0.005 inch |

| Edge to hole, single surface | 0.005 inch |

| Hole to hole, single surface | 0.002 inch |

| Bend to edge / hole, single surface | 0.010 inch |

| Edge to feature, multiple surface | 0.030 inch |

| Over formed part, multiple surface | 0.030 inch |

3 Ways to Ensure Perfection

Standards

Metals: ISO-2768 fH (fine)

Plastics: ISO-2768 mK (medium)

Metric threads tolerances: ISO 965-1 standard UN Threads Tolerances: ASME B1.1-2003 standard

Knurling: ISO13444:2012 standard.

Our factory is ISO 9001:2015 certificated

Inspection and Protection

Constant visual inspection conditions

Quantification of cosmetic surface quality

Process requirements

Part cleaning and Protection

Quality Inspection Report

Inspection Confirmation

Dimensional confirmation

Appearance confirmation

Quality documentation

Technology Overview

Introduction

Are you looking to create actual parts and products from your 2D or 3D design? Then, sheet metal fabrication might be the best approach for you.

Sheet metal fabrication refers to the creation of the desired shape from steps of the manufacturing process. It involves various alternatives for each step, such as cutting, bending, joining, and surface finish. But, choosing the right type of process helps optimize the fabrication’s functionality and cost. ProLean makes it easy for you. We decide the best steps for your project based on your requirements.

What is Sheet Metal Fabrication?

Sheet metal fabrication is converting the metal sheet into the desired shape. The process involves more than one step while manipulating the sheet metal to form the body, such as cutting, bending, welding, surface treatment, and many more, depending upon the complexity of the required shape.

The fabrication of sheet metal begins with drawings (2D& 3D). However, before starting the actual fabrication, manufacturers develop a 3D such as a CAD file. The 3D of desire shape provides guidance on what actions should be made, which strategy is the most appropriate and practical, which manufacturing steps are needed, and many other things.

Advantages

• Sheet metal fabrication is the low-cost and effective approach for prototype development and large-scale production.

• The finished part or product made of sheet metal has a high strength-to-weight ratio.

• Sheet metal fabrication offers a wide range of material options to create the desired shape.

Fabrication Steps

The steps of sheet metal fabrication begin with preparing a complete blueprint of required parts. For example, it might be the paper drawing or CAD-3D containing all dimensions. Then, it requires identifying the manufacturing steps such as cutting, bending, welding, assembly, & surface treatment.

Cutting the sheet metal is the step where the actual fabrication starts. Cutting the sheet metal into pieces as the dimension in the drawing can be achieved with various approaches such as CNC cutting, Laser cutting, and Water-jet cutting. After the Cutting operations, the cutting pieces need to be joined to form the shape with Riveting & welding. Other processes, such as bending and turning, are involved if angular or complex shapes are required. If holes are present in the shape, punching or drilling operations are used to create them.

Assembly of components is done to produce the desired shape according to the design of parts or products. Last but not least, surface finishing procedures, including plating, deburring, powder coating, or painting, must be carried out.

Applications

Several industries use sheet metal fabrication processes to create parts and the final product.

- Automotive

- Aerospace

- Defense

- Agriculture

- Medical

- Home appliances

- Construction

- Electrical & electronics

See why customers dig us

I am delighted with the Service from Prolean regarding the prototype development for my research. I have never expected this type of regular communication and quality of service from any manufacturer.

I will be associated further with my upcoming projects! Thanks to the ProLean.

-Gresham Green, Individual Engineer

Last year I looked for custom manufacturers for laser cutting services on the internet and found ProLean.

I get help with great patience and understanding, which may be why I am still working with Prolean on various laser-cutting and bending tasks for my current sheet-metal fabrication project.

-RupakDhital, Owner at Awai Auto Trading

The HVAC Cabinet was marvelous, within the critical tolerance, and the surface finish was excellent.

The supply duct connection, seal, and evaporator coil cover all worked as expected. I will recommend your service to my friends and other HVAC Businesses.

Thank you for your Exceptional service and communication.

-Dilara Ayden, Owner of Delta Engineering

It was a pleasure to collaborate with Prolean to manufacture enclosures for electronic appliances. As a purchasing manager of EPCOS electronics, I am impressed with the integrity, communication, service, and quality that they continually deliver.

I believe that regardless of size and production volume, they consistently uphold the same level of service and fulfill their commitments.

-Elias Weber, Purchasing manager at EPCOS electronics

The 15″ steel conveyors are perfect. The parts were fabricated accurately as per the drawing and provided specifications. Weld is exceptionally accurate and falls within tolerance parameters.

The conveyor had markings on each component, making assembly simple. I appreciate the excellent service you provided.

-Scarlett Scott, Quality control Engineer at Yancoal Industry

An excellent job regarding manufacturing cans for our energy drinks products. I get the delivery within 14 days.

The stamping looks good, and the desired strength has been maintained within the range. I will continue your service for the next batch as well. I want to share that the pricing was under my budget. Thank you, Prolean, for contributing to our start-up.

-Kartik Gupta, Product designer at Vital Beverage

Similar to the product, the service was exceptional. The delivery of oxygen-cylinder prototypes within ten days was not what I had anticipated; it is unbelievable. We are testing the prototype and will collaborate with Prolean for the large-scale production.

Excellent service, and I greatly appreciate the workmanship and product quality. Thank you!

Shu Chuan, Mechanical Engineer at AMS Composite Cylinders

Prolean has met all the expectations regarding all the complex sheet metal fabrication work presented by our service department.

The quick response from prolean has allowed us to meet our client's needs. In addition, I have often found that their engineers are always ready to think out-of-the-box to provide excellent service.

-Christina Smith, Mechanical Engineer at Marlin steel wire

Sheet Metal Fabrication FAQ

What are the Material Options for Sheet Metal Fabrication at Prolean?

We have various material options for Water- jet cutting to contribute to your project: Nylon, Carbon Steel, Stainless Steel, Aluminum and its alloys, Nickel, Silver, Copper, Brass, Titanium, and more.

What are the fabrication steps you offer?

What is the range of sheet metal thickness for fabrication?

Can you assist me with the prototype design?

What types of products can you produce?

Related Blog

Custom Metal Stamping: A Practical Guide

Uncover why custom metal stamping is an economical fabrication method?

How to Bend Aluminum Sheets – 5 Efficient Techniques

Learn How to Bend Aluminum Sheets? Different Bending Techniques

Metal Stamping Costs: Estimate Your Project Accurately?

Explore the key factors influencing metal stamping costs to optimize your project for affordability.

Get Your Parts Made Today

All uploads are secure and confidential.