Aluminiyamu Extrusion Kufotokozera, Ubwino ndi Kuipa

Nthawi yowerenga: 6 min

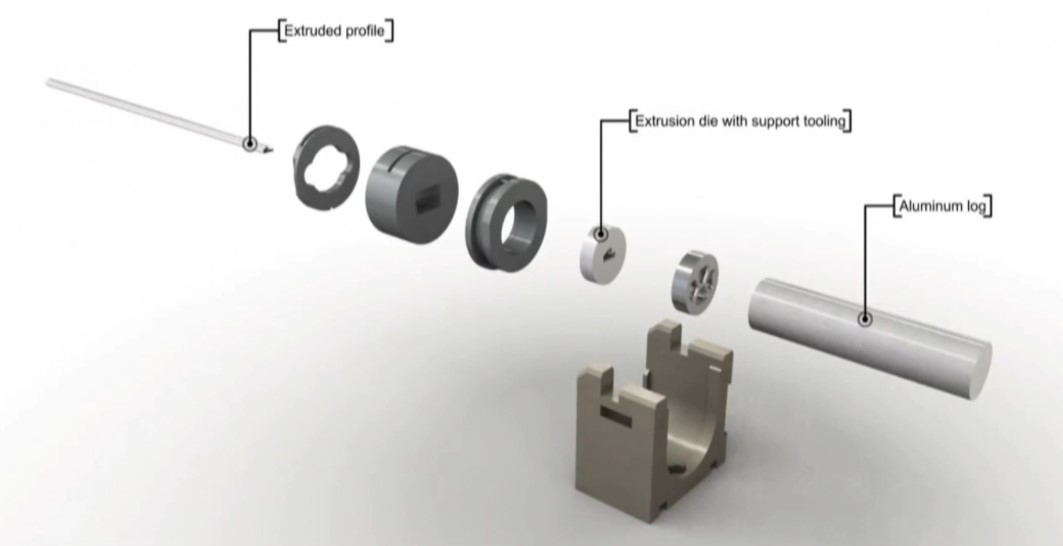

Mfundo ya Aluminium Extrusion

Extrusion ndi njira yopangira kusiyana ndi kuchotsa zinthu.Zida zotenthetsera, monga aluminiyamu, zimakakamizika kudutsa potsegula kuti zipange mawonekedwe owoneka bwino.Mu aluminiyumu extrusion, aluminiyamu yaiwisi yaiwisi imayamba kutenthedwa kenako ndikuwumbidwa mu gawo lomwe mukufunayo poyiyika pakufa pogwiritsa ntchito plunger.Mwachitsanzo, ndondomeko ya aluminium extrusion ndi yofanana ndi kufinya mankhwala otsukira mano;mphamvu yogwiritsidwa ntchito ingafanane ndi mphamvu yogwiritsidwa ntchito pamene mukufinya chubu la mankhwala otsukira mano ndi chala chanu, ndipo pamene mukufinya, mankhwala otsukira m'mano amawonekera ngati mawonekedwe a chubu lotsegula.

Kumene, zinthu zenizeni ndi zovuta kwambiri kuposa izi, pamene muyenera kugwiritsa ntchito zotayidwa extrusion ndondomeko ndi bwino kulankhula ndi injiniya odziwa, akatswiri athu ndi zaka zambiri mu makampani zotayidwa extrusion ndipo akhoza kuyankha mafunso anu mwamsanga, ndipo timapereka antchito yaulere yaulere,mutha kuwona zathutsamba la aluminium extrusion service.Kuti tibwererenso ku mfundoyi, nkhaniyi ikufotokozerani mfundo zina zofunika zokhudzana ndi aluminium extrusion: ndondomeko ya extrusion;mawonekedwe omwe amatha kutulutsa;ubwino ndi kuipa kwake, ndi malangizo ena ogwiritsira ntchito aluminium extrusion.

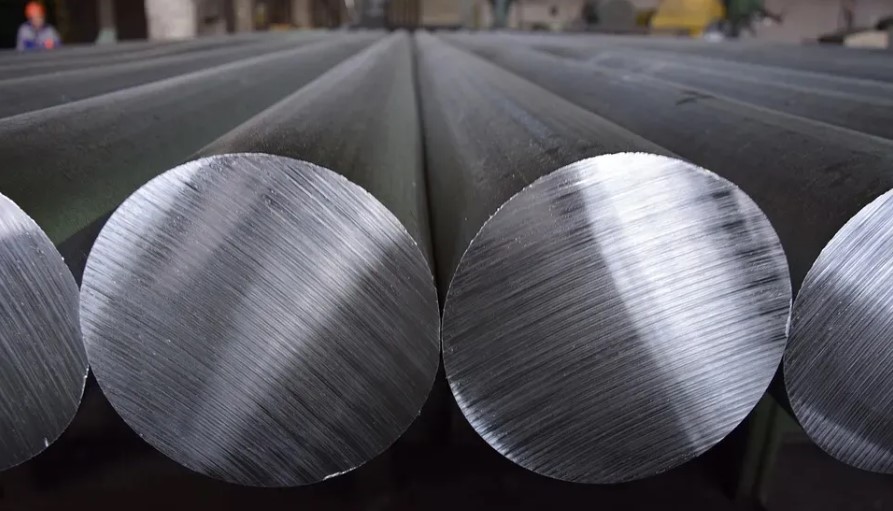

Aluminium Log

Mitundu ya Aluminium Extrusion Molding

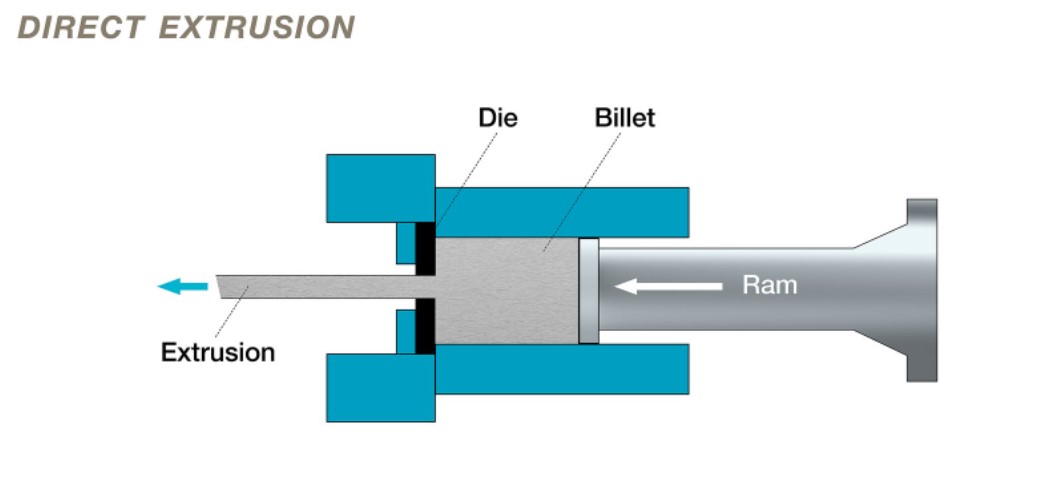

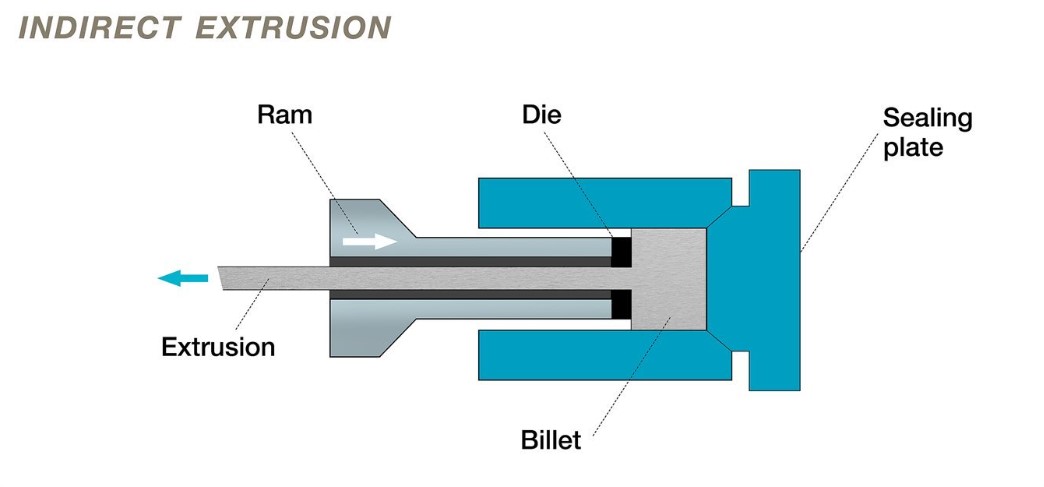

Pali mitundu iwiri ya extrusion process,molunjika ndi mosalunjika.Ndi extrusion yolunjika mutu wakufa umakhalabe wosasunthika ndipo nkhonya yosuntha imakakamiza chitsulo kudutsamo.Mosiyana ndi izi, mu extrusion yosalunjika billet imakhala yosasunthika pamene kufa kumapeto kwa plunger kumayenda motsutsana ndi billet, kupanga mphamvu yofunikira kuti zitsulo zidutse mukufa.

Direct Extrusion

Direct extrusion,amadziwikanso kuti kutsogolo extrusion, ndi ambiri extrusion ndondomeko.Zimagwira ntchito poyika billet mu chidebe chokhala ndi mipanda yokhuthala.Billet imakankhidwa kupyolera mu kufa ndi plunger kapena screw.Choyipa chachikulu cha njirayi ndikuti mphamvu yofunikira kuti itulutse billet ndi yayikulu kuposa yomwe ikufunika ndi njira yosalunjika ya extrusion.chifukwa cha mphamvu yomwe idayambitsidwa ndi kukangana chifukwa cha kufunikira kwa billet kudutsa kutalika konse kwa chotengeracho.Choncho, mphamvu yaikulu yofunikira ili kumayambiriro kwa ndondomekoyi ndipo imachepa pamene billet imagwiritsidwa ntchito.

Indirect Extrusion

Inextrusion yosalunjika(yomwe imadziwikanso kuti reverse extrusion), billet imakhala yosasunthika pomwe kufa kumapeto kwa plunger kumasunthira ku billet, motero kumachotsa mphamvu zosemphana.Izi zimabweretsa zotsatiraziubwino.

1.25% mpaka 30% kugundana kocheperako, komwe kumalola kuti zosoweka zazikulu zitulutsidwe, kuthamanga kwambiri, komanso kuthekera kowonjezera kutulutsa magawo ang'onoang'ono amtanda

2. Mpata wochepa wa kusweka kwa gawo lotuluka chifukwa chopanda kutentha kobwera chifukwa cha kukangana.

3. Moyo wautali wa liner chifukwa cha kuchepa kwachangu

4. Kugwiritsiridwa ntchito kofanana kwa ma billets, kotero kuti zowonongeka zowonongeka ndi madera ozungulira ozungulira sizingachitike.

Zoyipa zake ndi

1. Zowonongeka ndi zowonongeka pamwamba pa billet zingakhudze pamwamba pa extrusion.Kuti athetse vutoli, ma billets amatha kutsukidwa ndi waya, makina, kapena kutsukidwa ndi mankhwala musanagwiritse ntchito

2. Sizosinthasintha monga kutulutsa kwachindunji chifukwa malo odutsamo amachepetsedwa ndi kukula kwakukulu kwa tsinde.

Zomwe Zimakhudza Mawonekedwe a Extrusion

Mawonekedwe ndizomwe zimatsimikizira mtengo wagawo komanso kumasuka kwa extrusion.Pa extrusion ndondomeko, zosiyanasiyana akalumikidzidwa akhoza extruded.Nthawi zambiri, mawonekedwe owonjezera amatha kugawidwa m'magulu atatu.

1. Zolimba, zopanda zotsekera kapena zotsegula (mwachitsanzo, ndodo, mizati, kapena ngodya)

2. Bowo, lokhala ndi void imodzi kapena zingapo (mwachitsanzo, masikweya kapena machubu amakona anayi)

3. Pang'ono pang'ono, zotsekedwa pang'ono (mwachitsanzo, chubu "C" chokhala ndi mipata yopapatiza)

Pakupanga kwenikweni, pali zopinga zingapo zomwe ziyenera kuganiziridwa.Izi zikuphatikizapo:

1. Kukula

2. Maonekedwe

3. Aloyi - Zomwe zimapangidwa ndi zinthu zina zomwe zimawonjezeredwa ku aluminiyamu yoyera kuti iwonjezere mphamvu zake (mwachitsanzo, mphamvu, ndi zina).

4. Extrusion Ratio - Malo a billet / malo a mawonekedwe

5. Mlingo wa Lilime - M'lifupi ndi kuya kwa kusiyana

6. Kulekerera - Malire a kusiyana komwe gawo kapena mankhwala angapangidwe

7. Malizani

8. Coefficient - Mawonekedwe ozungulira / kulemera kwa mita

Aluminium Extrusion Principal

Zowonjezera Aluminium Alloy Options

| 1100 | Ndi yofewa, yosatenthedwa koma imatha kutulutsidwa m'mawonekedwe ovuta komanso owoneka bwino.Alloy iyi imatha kugwiritsidwa ntchito popanga zinthu zowoneka ndi machubu osinthira kutentha. |

| 3003———3000 | aloyi izi kawirikawiri extruded kwa kutentha exchanger machubu okha. |

| 6063 | Zoyenera kukongoletsa, zimakhala ndi mapeto abwino ndipo zimatha kutulutsidwa ndi zinthu zovuta monga makoma owonda kapena mfundo zabwino.Imalimbana ndi dzimbiri, koma ili ndi mphamvu zochepa zowotcherera, ngakhale imawotcherera mosavuta. |

| 6061 | Aloyiyi ndi yamphamvu kuposa 6063 ndipo ndizomwe zimapangidwira kwambiri pamafakitale oyendetsa ndi makina amakina.Aloyi ndi yosavuta extrude ndi kuwotcherera.Zinthu izi kuphatikiza kulimba kwamphamvu kwapang'onopang'ono komanso kutopa kwamphamvu kumapangitsa kuti ikhale nsapato kwa mamembala opangidwa ndi welded, kuphatikiza mafelemu agalimoto, magalimoto ndi ngolo, magalimoto apanjanji ndi mapaipi. |

| 7004 | Mmodzi wa mndandanda wa "otsika mapeto" 7000 mndandanda (Al-Zn) aloyi kuti atolankhani kutentha mankhwala, wololera extrudable ndi mtengo pang'ono kuposa 6061. Mndandanda 7000 mbiri akhala akugwiritsidwa ntchito kwambiri mu malonda katundu, njinga ndi njinga zamoto.7004 alloys ali ndi zokolola zomaliza komanso mphamvu zolimba kuposa 40,000 ndi 50,000 psi, motsatana. |

Ubwino wa Aluminium Extrusion

1. Mkulu wonse mankhwala khalidwe.Extrusion akamaumba akhoza kusintha kapangidwe ndi katundu mawotchi a aluminiyamu.Pambuyo kuzimitsa, longitudinal (extrusion malangizo) mawotchi katundu wa mankhwala extruded ndi apamwamba kwambiri kuposa mankhwala ofanana opangidwa ndi njira zina processing.Poyerekeza ndi kugubuduza, forging ndi njira zina processing, mankhwala extruded ndi apamwamba dimensional molondola ndi zabwino pamwamba.

2. Mankhwala osiyanasiyana.Ma profiles owonjezera amatha kupanga osati mapaipi osavuta, mipiringidzo ndi mawaya, komanso mawonekedwe ovuta kwambiri, mawonekedwe olimba komanso opanda kanthu.Zogulitsa zowonjezera zimapezekanso mumitundu yosiyanasiyana, kuyambira machubu akulu kwambiri ndi ma profiles okhala ndi mainchesi a 500-1000 mm kupita ku mbiri yaying'ono yolondola kwambiri kukula kwa ndodo za machesi.

3. High kupanga kusinthasintha.Kujambula kwa Extrusion kumapereka kusinthasintha kwakukulu.Zogulitsa zamitundu yosiyanasiyana, makulidwe, mawonekedwe ndi mitundu zimatha kupangidwa pamakina amodzi mwa kungosintha kufa.Kuphatikiza apo, ntchito yosinthira kufa ndiyosavuta, yabwino, yopulumutsa nthawi komanso yothandiza.

4. Njirayi ndi yosavuta komanso ndalama zogulira zida ndizochepa.Poyerekeza ndi chitoliro ndi njira kupanga mbiri monga perforation anagubuduza ndi poyambira anagubuduza, extrusion akamaumba ali ndi ubwino yochepa ndondomeko otaya, ochepa zida ndi ndalama otsika.

Kuchepetsa kwa Aluminium Extrusion

1. Osafanana katundu minofu katundu.Osafanana pamwamba, pakati, mutu ndi mchira wa mankhwala extruded chifukwa otaya otaya zitsulo pa extrusion.

2. Mikhalidwe yogwirira ntchito ya kufa kwa extrusion ndi yowawa komanso yosavuta kuvala.Panthawi ya extrusion, billet ili pafupi kutsekedwa ndi kuthamanga kwapamwamba.Panthawi imodzimodziyo, imfa nthawi zambiri imakhala ndi kutentha kwakukulu ndi kukangana kwakukulu panthawi yotentha yotentha, yomwe imakhudza kwambiri mphamvu ndi moyo wautumiki wa imfa.

3. Kuchita bwino kwa kupanga kochepa.Kupatulapo mosalekeza extrusion njira anayamba zaka zaposachedwapa, ochiritsira extrusion njira sangathe kukwaniritsa mosalekeza kupanga.Liwiro la extrusion ndilotsika kwambiri kuposa liwiro logudubuza, ndipo kuwonongeka kwa zidutswa zamtundu wa geometric ndi zokolola za kupanga extrusion ndizochepa.

Prolean imapereka zida zambiri zopangira aluminium extrusion, kuphatikiza zitsulo ndi mapulasitiki.Chonde onanichitsanzo mndandanda wa zipangizotimagwiritsa ntchito.Ngati mukufuna zinthu zomwe sizinalembedwe apa, chonde titumizireni chifukwa titha kukupatsani.

Nthawi yotumiza: May-04-2022