“Passivation is a surface treatment process that enhances metal durability by creating a protective layer, effectively preventing corrosion and enhancing product longevity in various industries.”

One of the critical challenges for metallurgists is to protect the material from corrosion and any other contaminants of the manufacturing processes such as machining, fabricating, and welding creating debris, inclusions, metal oxides, chemicals, grease, and oil. With these, when exposed to air and water, many metals are vulnerable to corrosion. This will cause the metal part under stress and may have a destructive impact during production or on the product’s end use. So, there is a need to protect the metal part from these contaminations and corrosion. One such process is metal passivation, a process of providing a thin and uniform oxide layer to add corrosion resistance, extend part life, remove surface contamination, reduce the risk of part contamination, and extend the system maintenance intervals.

How Does it Work?

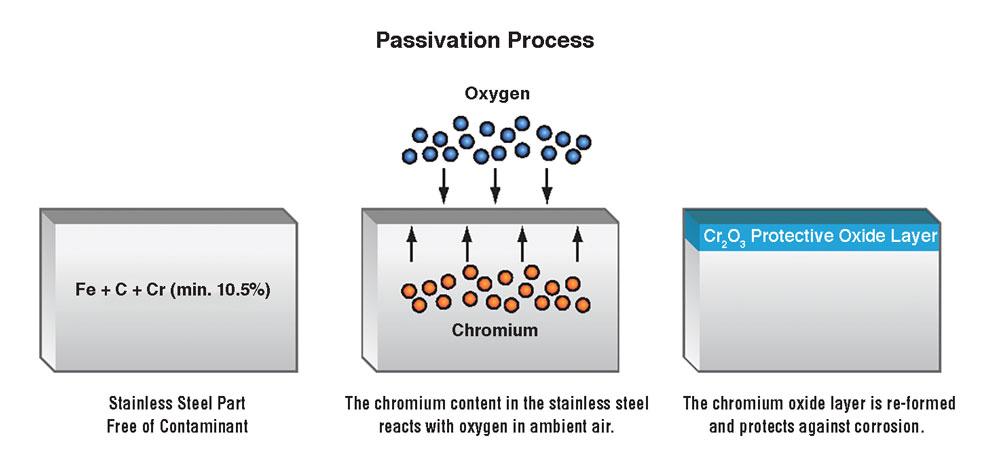

To protect different metal alloys from corrosion, an industrial chemical finishing practice is widely used as a post-fabrication process known as Passivation. In this process, mild oxidants such as nitric and citric acid are generally used. The exogenetic-free iron, sulfides, and other foreign particles from the surface can be taken away by these acids and create an oxide layer or film that will act as a protective shield. This decreases the likelihood that there will be a chemical reaction between the metallic material and the air, which lends the surface protection against corrosion without changing its appearance. The critical part of this process is that the acid should not affect the metal itself.

Steps of the Passivating Process

There are three steps in the passivating process, which will create a completely thin and uniform oxide layer on the metallic surface.

Passivation process

Step 1: Component Cleaning

The metallic part cleaning i.e., removing any surface oils, chemicals or debris left over from machining is the beginning of the passivation process. The component cleaning plays a critical role in this process, without this step, the foreign objects on the surface of the metal will limit the effectiveness of the passivation.

Step 2: Acid Bath Immersion

To remove any free iron particles from the surface, the immersion of the component in an acid bath follows after the cleaning step. There are three common approaches used in this step of the process

Step 3: Nitric Acid Bath

The traditional approach to passivation is Nitric acid, which redistributes the molecular structure of the metal’s surface most effectively. However, due to its classification as a hazardous material, nitric acid has some drawbacks. It emits toxic gases that are hazardous to the environment and might require a longer processing time with special handling.

Step 4: Nitric Acid with Sodium Dichromate Bath

The incorporation of sodium dichromate into nitric acid intensifies the passivation process with some specific alloys. This approach is a less common option, as the sodium dichromate amplifies the hazards of nitric acid bathing.

Step 5: Citric Acid Bath

The citric acid bath is a safer alternative to nitric acid for the passivating process. It does not emit any toxic gases, does not require any special handling and it is also an eco-friendly approach. The compounds of the citric acid passivation, risked organic growth and molds, for which it has struggled to gain acceptance. In recent years, innovations have eliminated these problems, making it a cost-effective approach.

To restore the metal’s corrosion resistance to its raw material state, regardless of the applied approach, this bathing process produces a chemical reaction on the surface of the component. This will add a thin and uniform layer of an oxide film with little to iron molecule presence.

Try Prolean Now!

What Are the Passivation Methodologies?

- Tank Immersion: The component will be immersed in a tank that has the chemical solution and it is advantageous for treating all the fabrication surfaces at the same time for uniformity of finish and optimum corrosion resistance.

- Circulation: It is precisely recommended for piping that will carry the corrosive liquids, in which the chemical solution is circulated through a system of pipework.

- Spray Application: The chemical solution is sprayed on the component surface. The proper acid disposal and safety procedures are essential for this type of methodology and it is advantageous for on-site treatment.

- Gel Application: By brushing on pastes or gels to the component surface, manual treatment can be accomplished. It is advantageous for spot treatment of welds and other intricate areas that require manual detail.

What materials can be Passivated?

- Anodizing of Aluminium and Titanium.

- Ferrous materials such as steel.

- Stainless steel, which can have a chrome oxide surface.

- Nickel, some applications have nickel fluoride.

- Silicone, Silicone Dioxide which is used in the semiconductor industry.

Applications of Passivating Process

Parts after passivating surface treatment

For enhanced durability and longevity, a range of industries capitalizes on components that manufacturers have finished manufacturing with a passivation process.

Medical

In the healthcare sector, to decrease harmful cross-contamination on medical equipment, professionals use the passivation process. The oxide layer on passive surfaces safeguards against microscopic contaminants, leading to a clean and smooth surface that is easier to sterilize.

Food and Beverage

The sanitary requirements are essential factors for many industries. To reduce the risk of corrosion and rust compromising equipment or handled final products, the passivation of components is paramount.

Aerospace Industry

The components that may require passivation are Stainless Steel parts, Actuators, Hydraulic Actuators, Landing gear components, Control rods, Exhaust components in jet engines, and Cockpit fasteners.

Heavy Equipment

Ball Bearings and Fasteners

Military

Firearms and Military equipment

Energy Sector

Power distribution and Transmission

Pros and Cons of Passivating Process

Pros

- Removal of leftover contaminants after machining

- Increase Corrosion Resistance

- Reduced the risk of contamination during the manufacturing process

- Enhanced component performance

- Uniform and smooth finish/appearance

- Shiny surface

- Easy to clean surface

Cons

- Passivation is not effective at stripping contaminants from welded parts.

- According to the specified metal alloy, the temperature and type of the chemical bath have to be maintained. This will increase the cost and complexity of the process.

- The acid bath can damage some metal alloys, which have low chromium and nickel content. So, they cannot be passivated.

Try Prolean Now!

Summing Up

Passivation is a crucial surface treatment that protects parts or products from corrosion and contaminants. The process involves using mild oxidants, such as nitric and citric acid, to remove foreign particles and create a protective oxide layer. This layer guards against chemical reactions with air, extending the lifespan and performance of metal components.

You can use different methodologies to achieve a passivation finish, including tank immersion and spray application. Furthermore, it crucial part of industries like medicine, food and beverage, aerospace, and energy.

FAQs

Is passivation the same as pickling?

No, the Pickling process removes all the debris, flux, and other contaminants from the surface of the welded parts and gets them ready for passivation. Pickling can’t protect the steel from corrosion, it only cleans the surface for passivation.

Does passivation make stainless steel corrosion-proof?

No, there is no such thing as 100% corrosion-proof. However, stainless steel parts have an exceptionally long lifespan due to the passivation process.

Is the passivation of stainless steel optional?

No, passivation is an essential process for stainless steel components. The component will be susceptible to attack from corrosion in a very short period without a passivating process.

0 Comments