“Extrusion is a forming process as opposed to a material removal process. Heated material, such as aluminum, is forced through an opening to form a shaped profile. In aluminum extrusion, raw aluminum is first heated and then shaped into the desired part by pushing it through a die using a plunger.”

Aluminum extrusion can be understood with one example that It is similar to squeezing toothpaste; the force applied can be likened to the force applied when you squeeze a tube of toothpaste with your finger, and when you squeeze, the toothpaste appears in the shape of a tube opening. Of course, the actual situation is much more complicated than this, when you need to use the aluminum extrusion process it is best to communicate with an experienced engineer, our engineers have decades of experience in the aluminum extrusion industry and can answer your questions quickly, and we offer a free quote service, you can check our aluminum extrusion service page. To get back to the point, this article will explain to you some basic facts about aluminum extrusion: the extrusion process; the shapes that can be extruded; the advantages and disadvantages, and some tips for using aluminum extrusion.

What are the Types of Aluminum Extrusion Molding?

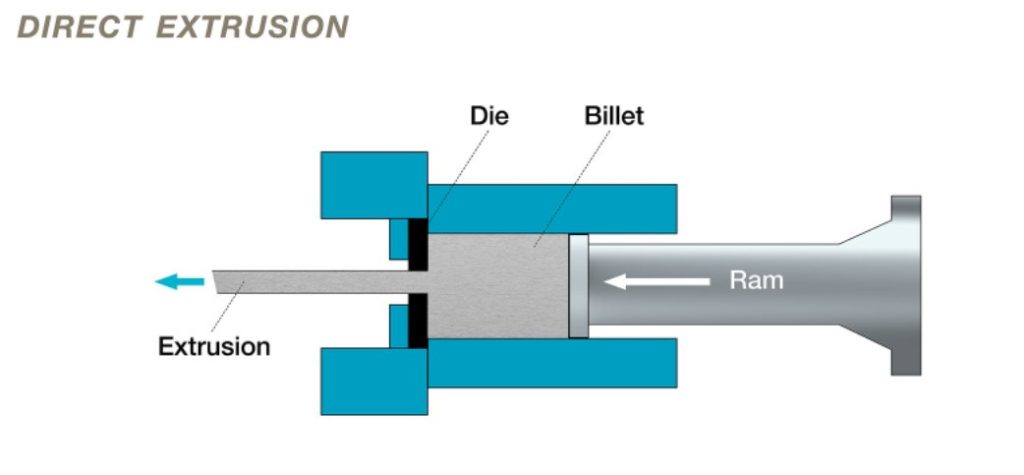

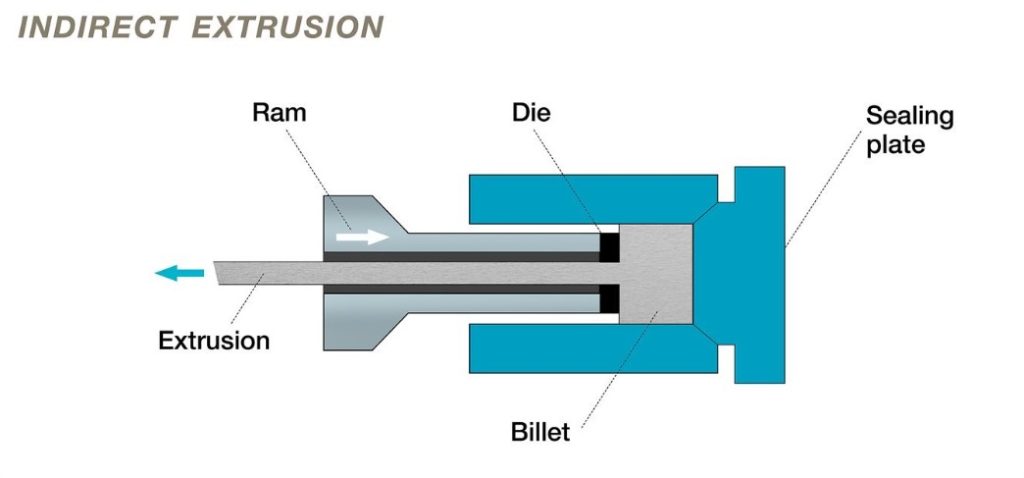

There are two types of extrusion processes, direct and indirect. With direct extrusion, the die head remains stationary and the moving punch forces the metal through it. In contrast, in indirect extrusion the billet remains stationary while the die at the end of the plunger moves against the billet, creating the pressure needed for the metal to flow through the die.

Direct extrusion, also known as forward extrusion, is the most common extrusion process. It works by placing the billet into a thick-walled container. The billet is pushed through the die by a plunger or screw. The main disadvantage of this process is that the force required to extrude the billet is greater than that required by the indirect extrusion process because of the force introduced by friction due to the need for the billet to pass through the entire length of the vessel. Therefore, the maximum force required is at the beginning of the process and decreases as the billet is used up.

Indirect Extrusion

In indirect extrusion (also known as reverse extrusion), the billet remains stationary while the die at the end of the plunger moves toward the billet, thus eliminating frictional forces. This results in the following advantages.

- 25% to 30% less friction, which allows for larger blanks to be extruded, higher speeds, and increased ability to extrude smaller cross-sections

- Less likelihood of extruded part breakage due to the absence of heat generated by friction

- Longer vessel liner life due to less wear

- More uniform use of billets, so extrusion defects and coarse-grained peripheral areas are less likely to occur

The disadvantages are

- Impurities and defects on the surface of the billet can affect the surface of the extrusion. To solve this problem, the billets can be wire brushed, machined, or chemically cleaned before use

- It is not as versatile as direct extrusion because the cross-sectional area is limited by the maximum size of the stem

Try Prolean Now!

Factors Affecting Extrusion Shape

Shape is the determining factor in part cost and ease of extrusion. During the extrusion process, a variety of shapes can be extruded. In general, extruded shapes can be divided into three categories.

1. Solid, with no closed voids or openings (i.e., rods, beams, or corners)

2. Hollow, with one or more voids (i.e., square or rectangular tubes)

3. Semi-hollow, with partially closed voids (i.e., a “C” shaped tube with narrow gaps)

In actual manufacturing, several constraints need to be considered. These include:

- Size

- Shape

- Alloy – The chemical composition of the other elements added to pure aluminum to enhance its properties (e.g., strength, etc.)

- Extrusion Ratio – The area of the billet/area of the shape

- Tongue Ratio – The width and depth of the gap

- Tolerance – The limit of variation to which a part or product can be produced

- Surface Finish

- 8. Coefficient – Shape circumference/weight per meter

Aluminum Extrusion Principle

Extruded Aluminum Alloy Options

Alloy 1100 is soft and non-heat treatable, ideal for complex shapes and appearance items. Alloy 3003 is used for heat exchanger tubes, while 6063, known for its decorative appeal and good surface finish, is suited for detailed extrusions but has lower weld strength. Alloy 6061 is a strong, versatile material used extensively in transportation and structural applications due to its ease of extrusion and welding. The 7004 alloy, part of the 7000 series, is heat-treatable and commonly used in the sporting goods industry, offering high strength and durability.

| 1100 | It is soft, and non-heat treatable but can be extruded into complex shapes with a good shiny surface. This alloy can be used for appearance items and heat exchanger tubes. |

| 3003——3000 | this alloy is usually extruded for heat exchanger tubes only. |

| 6063 | Ideal for decorative purposes, has a good surface finish and can be extruded with complex features such as thin walls or fine details. It is corrosion-resistant but has low weld strength, although it is easily welded. |

| 6061 | This alloy is stronger than 6063 and is a major structural material for the transportation and machined parts industries. The alloy is easy to extrude and weld. These properties combined with high fracture toughness and good fatigue strength make it a shoe for welded structural members, including automotive, truck and trailer frames, railroad cars, and pipelines. |

| 7004 | One of a series of “low end” 7000 series (Al-Zn) alloys that are press heat treatable, reasonably extrudable, and cost slightly more than 6061. The 7000 series has historically been widely used in the sporting goods, bicycle, and motorcycle industries. 7004 alloys have ultimate yield and tensile strengths above 40,000 and 50,000 psi, respectively. |

Try Prolean Now!

Benefits of Aluminum Extrusion

1. High overall product quality. Extrusion molding can improve the structure and mechanical properties of aluminum. After quenching, the longitudinal (extrusion direction) mechanical properties of extruded products are much higher than those of similar products produced by other processing methods. Compared with rolling, forging, and other processing methods, extruded products have higher dimensional accuracy and good surface quality.

2. A wide range of products. Extruded profiles can produce not only simple pipes, bars, and wires but also very complex cross-sectional shapes, and solid and hollow profile products. Extruded products are also available in a wide range of sizes, from very large tubes and profiles with diameters of 500-1000 mm to ultra-small precision profiles the size of matchsticks.

3. High production flexibility. Extrusion molding offers a great deal of flexibility. Products of different shapes, sizes, specifications, and varieties can be produced on the same machine by simply changing the die. In addition, the die change operation is simple, convenient, time-saving, and efficient.

4. The process is simple and the investment in equipment is low. Compared with pipe and profile production processes such as perforation rolling and groove rolling, extrusion molding has the advantages of short process flow, a small number of equipment, and low investment.

Limitation of Aluminum Extrusion

1. Uneven product tissue properties. Uneven surface, center, head, and tail of extruded products due to uneven flow of metal during extrusion.

2. The working conditions of the extrusion die are harsh and prone to wear. During the extrusion process, the billet is in a near-closed state with a high tee pressure. At the same time, the die is usually subjected to high temperatures and large friction during the hot extrusion process, which greatly affects the strength and service life of the die.

3. Low production efficiency. Except for the continuous extrusion method developed in recent years, the conventional extrusion method cannot achieve continuous production. The general extrusion speed is much lower than the rolling speed, and the geometric scrap loss and yield of extrusion production are low.

Summing Up

Prolean offers a wide range of materials for aluminum extrusion, including metals and plastics. Please see the sample list of materials we use. If you need material that is not listed here, please contact us as we will likely be able to source it for you.

0 Comments