Blog and News

We regularly update articles and news related to the prototyping and manufacturing industry. You’re free to leave any comments or contact us for more details.

All uploads are secure and confidential.

Custom Metal Stamping: A Practical Guide

Uncover why custom metal stamping is an economical fabrication method?...

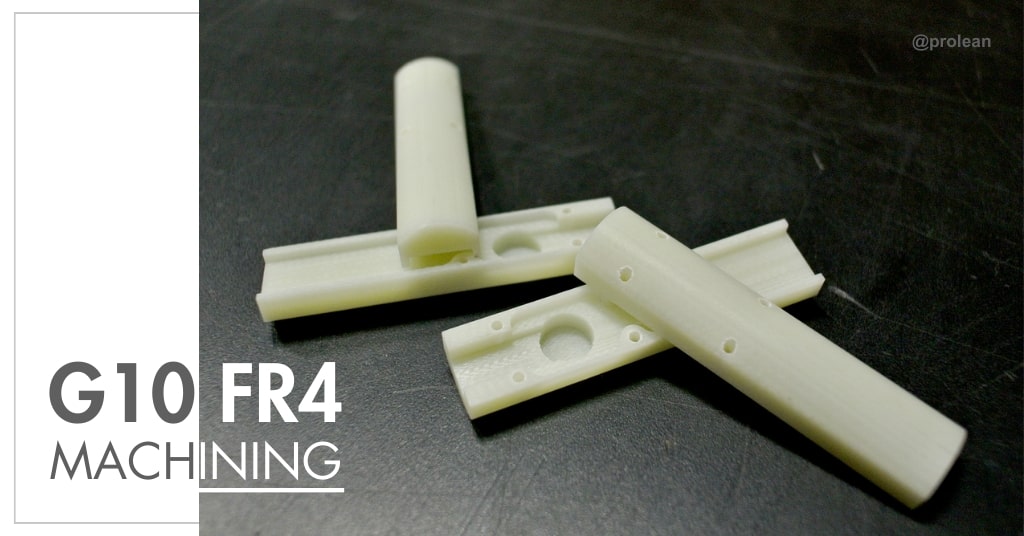

G10 Fr4: Epoxy Glass Laminates Machining

G10/Fr4 are high-performing electrical grades of epoxy resins...

Exploring Diverse Applications of Surface Grinding

Explore the diverse applications of surface grinding through this detailed guide...

Metal Casting: Definition, Types, Metals, Pros & Cons

Casting has primed to design parts with remarkable strengths at an affordable price...

How to Bend Aluminum Sheets – 5 Efficient Techniques

Learn How to Bend Aluminum Sheets? Different Bending Techniques...

Rubber Compression Molding: In-depth Details

The details of Rubber Compression Molding, advantages, applications, etc...

What is Liquid Silicone Rubber Molding? Methods and Advantages

Explore Liquid Silicone Rubber Molding in detail...

How to make a Plastic Product Prototype?

Learn how to make a plastic product prototype in this detailed guide...

Horizontal vs. Vertical Milling – Understanding Key Similarities and Differences

Similarities and differences on Horizontal vs. vertical milling?...