Vim li cas CNC Machining yog qhov tseem ceeb rau kev lag luam Robotics

Lub sij hawm nyeem: 5 min

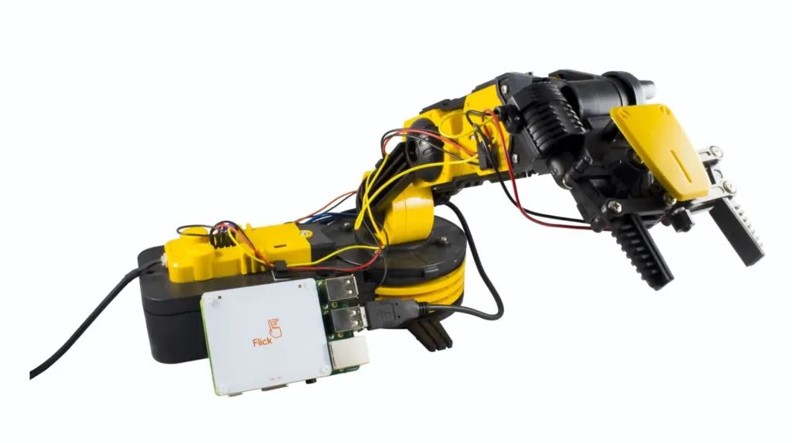

Robotic caj npab

Niaj hnub no, cov neeg hlau zoo li nyob txhua qhov chaw - ua haujlwm hauv cov yeeb yaj kiab, tshav dav hlau, kev tsim khoom noj, thiab txawm nyob hauv cov chaw tsim khoom uas tsim lwm cov neeg hlau.Ib qho ntawm cov laj thawj tseem ceeb uas cov neeg hlau tau cog lus yog vim tias lawv tuaj yeem tsim los rau ntau lub hom phiaj thiab yog li muaj kev sib txawv kiag li.Proleanhub muaj ntau xyoo ntawm kev paub hauv machining thiab tsim cov neeg hlau.Qhov blog no yuav txhais lub ntsiab lus thiab kev siv ntawm CNC machining rau kev lag luam neeg hlau.Yog tias koj muaj kev xav tau ntawm kev tsim khoom, thov koj xav dawbtiv tauj peb cov engineersrau daim ntawv tsocai dawb.

CNC machining yog tailor-made rau robots

CNC machining tuaj yeem tsim qhov chaw nrog lub sijhawm ua haujlwm ceev heev.Thaum koj tau npaj cov qauv 3D, cov chaw tsim khoom tuaj yeem pib cov txheej txheem kev kos npe rau CNC kev tsim khoom thiab yuav cov khoom siv raw khoom ua ke.Nrog kev pab los ntawm CNC machining, neeg hlau Cheebtsam tuaj yeem tsim tau rau kev xa tawm sai, uas tso cai rau kev hloov pauv sai ntawm cov qauv thiab xa sai ntawm kev cai neeg hlau qhov chaw rau kev siv tshwj xeeb.

Lwm qhov zoo ntawm CNC machining yog nwsmuaj peev xwm los tsim cov khoom raws nraim rau specification.Qhov kev tsim khoom no yog qhov tseem ceeb tshwj xeeb rau cov neeg hlau, qhov uas qhov tseeb qhov tseeb yog qhov tseem ceeb rau kev tsim cov neeg hlau ua haujlwm siab.Precision CNC machining tuaj yeem tswj nruj kam rau ua ntawm +/- 0.015mm.

Nto tiav yog lwm qhov laj thawj siv CNC machining los tsim cov khoom siv neeg hlau.Kev sib cuam tshuam cov khoom yuav tsum muaj kev sib txhuam tsis tshua muaj, thiab precision CNC machining tuaj yeem tsim qhov chaw nrog qhov roughness tsawg li Ra 0.8 μm, thiab txawm tias qis dua nrog kev ua haujlwm tom qab kev kho mob xws li polishing.Hauv qhov sib piv, kev tuag-casting (ua ntej ua tiav cov txheej txheem) feem ntau ua rau nto roughness ze rau 5 μm.Hlau 3D luam ntawv ua rau ntau rougher nto tiav.

Thaum kawg,hom khoom siv hauv cov neeg hlau yog zoo tagnrho rau CNC machining.Cov neeg hlau yuav tsum muaj peev xwm txav tau thiab nqa cov khoom tsis tu ncua, uas yuav tsum muaj cov ntaub ntawv muaj zog, tawv.Cov khoom tsim nyog no tau ua tiav zoo tshaj plaws los ntawm kev ua qee yam hlau thiab yas, raws li tau piav qhia hauv Cov Khoom Siv hauv qab no.Tsis tas li ntawd, cov neeg hlau feem ntau yog siv rau cov hom phiaj kev cai lossis kev ua haujlwm me me, uas ua rau CNC machining ib qho kev xaiv zoo rau cov khoom siv neeg hlau.

Hom Robot Parts Ua los ntawm CNC machining

Nrog rau ntau qhov ua tau zoo, ntau yam sib txawv ntawm cov neeg hlau tau hloov zuj zus.Muaj ob peb yam tseem ceeb ntawm cov neeg hlau uas nquag siv.

Articulated robotsmuaj ib sab caj npab nrog ntau lub pob qij txha, uas yog ib yam uas ntau tus neeg tau pom ua ntej.

Tseem muajSCARA (Selective Compliance Articulated Robot Arm) neeg hlau,uas tuaj yeem txav khoom ntawm ob lub dav hlau sib luag.SCARA muaj qhov ntsug ntsug siab vim tias lawv txav mus rau kab rov tav.

Delta robotsmuaj cov pob qij txha nyob rau hauv qab, uas ua rau lub caj npab teeb thiab muaj peev xwm txav tau sai.

Gantry lossis Cartesian robotsmuaj linear actuators uas txav ntawm 90 degrees rau ib leeg.

Txhua yam ntawm cov neeg hlau no muaj qhov sib txawv ntawm kev tsim kho thiab daim ntawv thov sib txawv, tab sis feem ntau muaj plaub yam tseem ceeb uas ua rau cov neeg hlau.

1) robotic caj npab

2) kawg-effector

3) motors

4) kev cai clamps thiab fixtures

1 Robotic Arm

Robotic caj npab sib txawv heev hauv daim ntawv thiab kev ua haujlwm, yog li siv ntau yam sib txawv.Txawm li cas los xij, ib yam uas lawv muaj sib xws yog lawv lub peev xwm txav khoom lossis ua haujlwm ntawm lawv, thiab qhov sib txawv ntawm cov caj npab robotic txawm muaj npe tom qab peb tus kheej: lub xub pwg nyom, lub luj tshib thiab dab teg tig thiab tswj kev txav ntawm cov khoom hauv. nruab nrab.

Robotic Arm

Cov yam ntxwv ntawm cov cuab yeej cuab yeej cuab tam yuav tsum muaj zog thiab muaj zog kom lawv nqa tau cov khoom los yog siv zog.Vim tias cov ntaub ntawv siv los ua kom tau raws li cov kev cai no (steel, aluminium thiab qee cov yas), CNC machining yog qhov kev xaiv zoo.Cov khoom me me, xws li lub zog lossis cov kabmob hauv cov pob qij txha, lossis qhov chaw ntawm lub tsev nyob ib ncig ntawm caj npab, tuaj yeem ua CNC machined.

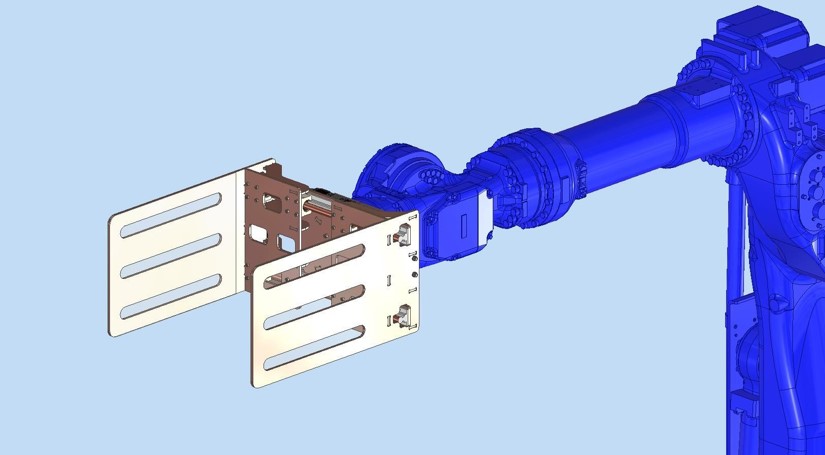

2 End-effector

Qhov kawg-effector yog ib qhodaim ntawv txuasuas txuas mus rau qhov kawg ntawm tus neeg hlau caj npab.End-effectors tso cai rau koj los kho qhov ua haujlwm ntawm koj cov neeg hlau rau kev ua haujlwm sib txawv yam tsis tas yuav tsim ib tus neeg hlau tshiab.Lawv tuaj yeem yog grippers, graspers, nqus tsev lossis suction khob.Qhov kawg-effectors feem ntau muaj CNC machined Cheebtsam ua los ntawm hlau (feem ntau yog txhuas) (ntxiv rau cov khoom xaiv tom qab).Ib qho ntawm cov khoom no txuas mus tas li mus rau qhov kawg ntawm lub caj npab neeg hlau.Qhov tseeb gripper, suction khob los yog lwm yam end-effector (los yog array ntawm end-effectors) haum rau hauv cov khoom no kom nws tuaj yeem tswj tau los ntawm caj npab neeg hlau.Qhov kev teeb tsa no nrog ob yam sib txawv ua rau nws yooj yim dua los hloov pauv cov txiaj ntsig sib txawv, yog li tus neeg hlau tuaj yeem hloov kho rau cov ntawv thov sib txawv.Koj tuaj yeem pom qhov no hauv daim duab hauv qab no, qhov chaw ua haujlwm ntawm tus neeg hlau tuaj yeem hloov tau yooj yim los ntawm kev sib pauv cov txiaj ntsig kawg.

End-effector: Carton gripper

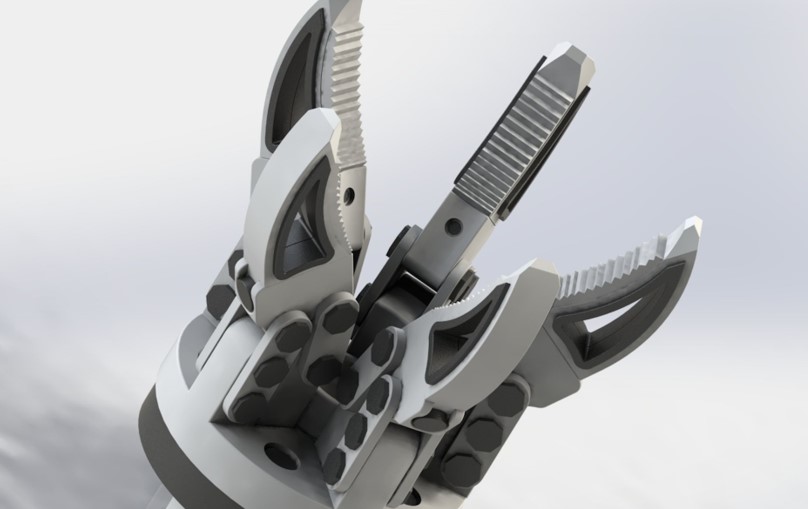

End-effector: 5-lub puab tsaig manipulator

3 lub cev muaj zog

Txhua tus neeg hlau xav tau lub cev muaj zog los tsav lub zog ntawm nws txhais tes thiab pob qij txha.Cov motors lawv tus kheej muaj ntau qhov chaw txav, ntau yam uas tuaj yeem ua CNC machined.Feem ntau, machined vaj tse ntawm lub cev muaj zog, machined bracket siv los txuas rau cov neeg hlau caj npab, thiab txawm tias cov bearings thiab shafts feem ntau CNC machined.Cov ncej tuaj yeem ua rau ntawm lub tshuab dhos kom txo tau txoj kab uas hla lossis ntawm lub tshuab milling ntxiv cov yam ntxwv xws li cov yuam sij lossis cov qhov.Thaum kawg, lub zog uas hloov lub cev muaj zog rau cov neeg hlau pob qij txha lossis lwm qhov chaw tuaj yeem yog CNC machined los ntawm milling, EDM lossis hobbing machine.

Servo motors rau lub zog tsav neeg hlau

4 Kev Cai Jigs thiab Fixtures

Txawm hais tias tsis yog ib feem ntawm tus neeg hlau nws tus kheej, feem ntau cov neeg hlau ua haujlwm xav tau kev cai jigs thiab fixtures.Tej zaum koj yuav xav tau lub fixture los tuav qhov chaw nyob rau hauv qhov chaw thaum tus neeg hlau ua haujlwm ntawm ib feem.Koj tseem tuaj yeem siv cov khoom sib dhos kom meej qhov chaw ntawm ib qho ntawm ib lub sijhawm, uas feem ntau tsim nyog rau cov neeg hlau tuaj tos lossis muab tso rau hauv.Vim tias lawv feem ntau yog ib qho kev cai qhov chaw, CNC machining yog qhov zoo tagnrho rau fixturing.Lub sij hawm txhuas yog luv luv, thiab CNC machining feem ntau yooj yim ua tiav ntawm ib daim ntawm cov khoom siv, feem ntau yog txhuas.

Hauv Summary

CNC machining yog qhov tseem ceeb rau kev loj hlob sai ntawm kev lag luam neeg hlau.Nws yog qhov zoo tshaj plaws nyob rau hauv cov nqe lus ntawm kev tsim khoom sai, ua haujlwm zoo, thiab ua tiav qhov chaw siab thaum lub sij hawm tsim cov khoom siv neeg hlau.Hauv kev tsim cov neeg hlau, CNC machining feem ntau yog siv rau plaub ntu: neeg hlau caj npab, qhov kawg-effectors, motors, thiab kev cai fixtures thiab fixtures.Qhov blog no piav qhia txog qhov tseem ceeb ntawm CNC machining rau kev lag luam neeg hlau thiab cov ntawv thov scenarios.Yog tias koj muaj CNC machining xav tau, koj tuaj yeemmus saib peb nplooj ntawv pabcuam CNC or upload koj cov ntaub ntawv CADncaj qha mus kom tau qhov tseeb hais.

Post lub sij hawm: May-09-2022