Xaiv cov ntawv zoo tshaj plaws rau CNC machining

Sep 19, 2022, sij hawm nyeem:7 nqi

Sheet hlau ntawm cov khoom sib txawv

Tsis muaj cov lus teb meej rau cov lus nug ntawm cov khoom siv zoo tshaj plaws rau CNC machining.Cov khoom siv zoo tshaj plaws yog txiav txim siab los ntawm cov txheej txheem machining uas xav tau, daim ntawv thov kawg, thiab cov lus qhia tshwj xeeb.

CNC tshuab tuaj yeem ua haujlwm nrog hlau, yas, ntoo, ceramics, composites, thiab fiber ntau.Txawm li cas los xij, Yas thiab hlau yog cov khoom siv tshaj plaws hauv CNC manufacturing.Kab lus no yuav tham txog tsuas yog cov txheej txheem xaiv cov ntawv hlau, suav nrog txhua yam ntawm kev xaiv txoj hauv kev, kev ua kom zoo ntawm cov khoom siv, thiab qee qhov kev xaiv zoo tshaj plaws ntawm cov ntawv hlau.

Tej yam uas yuav tsum tau xav txog

Ntau yam yuav tsum tau txiav txim siab thaum txiav txim siab txog cov khoom siv zoo rau kojCNC machining qhov project.

Cov yam tseem ceeb tuaj yeem muab faib ua tsib pawg.

- Cov specifications

- Yuav tsum tau ua haujlwm machining

- Xaus kev siv

- Yuav tsum muaj khoom

- Nqi

1. Cov specifications

Sheet hlau xaiv hnyav nyob ntawm seb qhov yuav tsum tau ua, uas ib txwm tuav qee qhov tshwj xeeb rau lawv txoj haujlwm.Qee qhov tshwj xeeb tseem ceeb suav nrog qhov loj me, thickness, kam rau ua, thiab nto tiav.Thaum xaiv cov ntawv hlau xaiv, cov kev qhia tshwj xeeb no yuav tsum tau xav txog.Txhua hom ntawv hlau muaj qhov sib txawv.Cov khoom no yuav tsum tau kuaj xyuas seb lawv puas phim cov khoom specifications.

Yog tias koj cov khoom yuav raug sivas-machined nto tiav, tom qab ntawd koj tuaj yeem xaiv daim ntawv nrog qhov zoo tshaj plaws nto tiav.Txawm li cas los xij, yog tias nto tiav xws lihmoov txheej, Zinc plating, thiab pleev xim yuav siv tau, tej zaum koj yuav xav mus xyuas cov ntaub ntawv twg yog ua tau rau qhov yuav tsum tau deg tiav.Ib yam li ntawd, koj yuav tsum tau xyuas qhov loj, thickness, thiab kam rau ua tiav los yog tsis nrog hom ntawv hlau uas koj xaiv rau koj qhov project.

2. Yuav tsum tau ua haujlwm machining

CNC machining nrog cov ntawv hlau

Raws li kev tsim ntawm qhov chaw, Yuav tsum tau ua haujlwm CNC machining tuaj yeem txheeb xyuas, xws li milling,tig, drilling, thiab lwm yam.Cov ntawv hlau uas koj xaiv yuav tsum tau sib xws nrog kev ua haujlwm CNC machining.Piv txwv li, yog tias koj xaiv qee qhov tshwj xeeb hlau tsis sib haum nrog machining, koj lub sijhawm thiab nyiaj txiag yuav raug nkim.Piv txwv li, Hardness yog tus yuam sij rau koj qhov chaw, thiab koj xaiv cov ntawv hardened steel, tab sis tom qab ntawd tsis tuaj yeem tsim qhov yuav tsum tau ua siab ntev thaum machining.

Yog li, koj yuav tsum txheeb xyuas qhov kev ua haujlwm machining yuav tsum tau ua thiab hom ntawv hlau twg yog qhov sib xws nrog cov haujlwm ntawd.

Cov yam ntxwv hlau cuam tshuam rau kev ua haujlwm, durability, thiab kev ua haujlwm ntawm qhov chaw.Hais txog cov ntawv hlau xaiv rau CNC machining,kev siv kawgntawm qhov chaw yog qhov tseem ceeb rau kev txiav txim siab.Ua ntej xaiv hom ntawv hlau, koj yuav tsum xav txog ob yam tseem ceeb hauv kev siv kawg.

· Ib puag ncig

Koj yuav tsum tau hais txog cov xwm txheej ib puag ncig uas cov khoom yuav raug ua haujlwm thaum kawg.Vim hais tias ib puag ncig cuam tshuam rau kev tiv thaiv tshav kub, tiv thaiv corrosion, tshuaj tiv thaiv, thiab UV-ray raug, cov khoom ib puag ncig yuav tsis yog qhov tseem ceeb yog tias koj cov khoom siv hauv tsev.Txawm li cas los xij, koj yuav tsum xav txog kev siv sab nraum zoov kub hloov pauv, hluav taws xob UV, av noo, thiab tshuaj lom neeg raug.

Yog li ntawd, xaiv cov ntawv hlau yuav tsum muaj peev xwm ua tau raws li cov kev ua haujlwm no.Piv txwv li, yog tias koj xav tau qhov chaw uas yuav siv sab nraum zoov, koj yuav tsum xyuas kom meej tias cov khoom koj xaiv tsis cuam tshuam rau kev kam rau sab nraud xws li cua sov thiab noo noo.

· Mechanical Strength

Nws yog lwm qhov kev txiav txim siab hauv kev siv kawg.Cov khoom siv yuav tsum tuav lub zog txhua yam tsim nyog thoob plaws hauv lub neej ntawm cov khoom.Raws li kev siv cov khoom siv, koj tuaj yeem txheeb xyuas qhov xav tau ntawm lub zog thiab cov khoom siv uas tuaj yeem muab lub zog ntawd.

3. Yuav tsum muaj khoom

Txhua feem xav tau nws tus kheej ntau yam ntawm cov khoom rau functionality.Yog li ntawd, cov khoom uas xav tau ntawm ib feem yuav tsum sib phim lossis poob rau hauv qhov ntau ntawm Sheet hlau khoom (lub cev, tshuab, thiab tshuaj) thaum xaiv qhov zoo tshaj plaws CNC ntawv hlau.

Cov yam ntxwv ntawm lub cev ntawm cov ntawv hlau, xws li lub zog tensile, lub zog-rau-qhov hnyav piv, hnav thiab tsim kua muag, thiab yoog raws, yuav raug txiav txim los ntawm daim ntawv thov ntawm cov khoom.Feem ntau, cov ntawv hlau hnyav dua muaj lub zog siv tshuab ntau dua, tab sis qhov txwv qhov hnyav yuav tsum tau txiav txim siab.Yog li ntawd, qhov kev pom zoo ntawm kev nqis tes ua yog sib piv cov cuab yeej siv zog thiab lub zog-rau-qhov hnyav piv.

Cia peb tham txog qee yam tseem ceeb los xav txog thaum lub sijhawm xaiv.

· Qhov hnyav

Yog tias cov ntawv hlau ua tiav qhov kev xav tau ntawm lub zog rau cov khoom, ces qhov hnyav yuav tsum raug txiav txim siab raws li daim ntawv thov.Piv txwv li, cov khoom siv yuav tsum yog lub teeb heev yog tias cov khoom siv rau lub dav hlau.

· Machineability

Cov yam ntxwv tom ntej yog machinability ntawm cov khoom.Cov ntaub ntawv machinability siab ua rau CNC machining yooj yim dua thiab pab tswj kom nruj nruj.Yog li, lub machinability ntawm cov ntawv hlau kuj muaj lub luag haujlwm hauv cov txheej txheem xaiv.Lwm yam uas tuaj nrog machinability yog compatibility nrog cov cuab yeej vim yog tias koj xav txog cov khoom siv tawv heev, uas tuaj yeem rhuav tshem cov cuab yeej machining.

· Thermal cwj pwm

Tshawb xyuas cov khoom siv thermal thiab hluav taws xob cov yam ntxwv uas ua tiav cov haujlwm ua haujlwm hauv cov ntawv thov zaum kawg.Xav txog qhov hluav taws xob conductivity, melting point, thiab thermal expansion coefficient.Yog tias koj xaiv cov khoom uas tsis tshua muaj melting point thiab koj cov khoom ua haujlwm ntawm qhov kub thiab txias, qhov ntawd yuav ua rau tsis ua haujlwm.Nyob rau tib lub sijhawm, xav txog cov hluav taws xob conductivity raws li daim ntawv thov xav tau.

4. Nqi

Tus nqi yog qhov tseem ceeb thaum xaiv cov ntawv hlau zoo tshaj plaws rau CNC machining.Ntau cov ntaub ntawv muaj nyob rau hauv ntau tus nqi sib txawv uas ua tau raws li txhua qhov xav tau ntawm qhov xav tau.Yog li, Tus Nqi yuav tsum suav nrog nrog rau lwm yam.Nws yog ib qho tsim nyog los soj ntsuam cov nqi ntawm cov ntawv hlau raws li lawv cov khoom, xws li machinability, lub zog, hardness, qhov hnyav, thiab lwm yam.

Piv txwv li, Aluminium yog qhov kev xaiv zoo tshaj plaws vim nws tsis tshua kim tshaj titanium, txawm tias ob qho khoom ua tau raws li qhov xav tau ntawm lub zog-rau-hnyav rau kev xaiv cov ntawv hlau rau sab hauv cov khoom siv dav hlau.

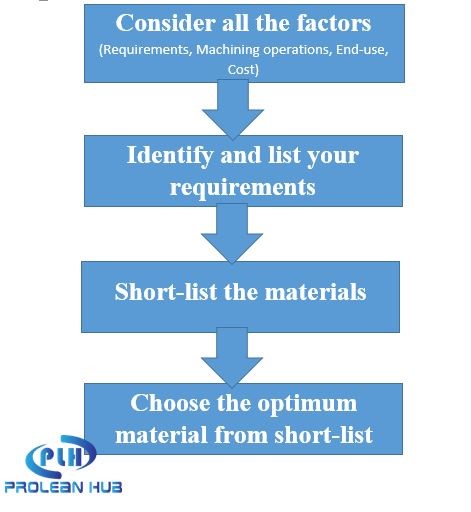

Daim ntawv qhia peb kauj ruam los xaiv koj cov ntawv zoo tshaj plaws

Saum toj no, peb tau tham txog txhua yam tseem ceeb uas cuam tshuam rau cov txheej txheem xaiv cov ntawv hlau thiab txiav txim siab seb hom ntawv hlau twg yuav zoo rau txhua qhov haujlwm CNC machining.

Raws li cov txiaj ntsig cuam tshuam, muaj peb kauj ruam tseem ceeb uas koj tuaj yeem ua raws los xaiv cov ntawv hlau zoo tshaj plaws rau koj qhov project.

Flow-chart rau txheej txheem xaiv

Kauj Ruam 1: Sau koj cov kev xav tau.

Peb tau tham txog qhov yuav tsum tau ua yog qhov tseem ceeb thaum xaiv cov khoom siv CNC zoo tshaj plaws.Nws yuav tsum yog koj qhov tseem ceeb tshaj plaws.Yog li, sau tag nrho cov kev xav tau xws li Lub Zog, Hardness, lub teeb yuag, elasticity, nto tiav, thiab lwm yam.

Piv txwv:

| Yuav tsum muaj khoom | Tus nqi / Specification |

| Tensile zog | Tsawg(< 100 MPa), nruab nrab (< 500 MPa), lossis siab (> 500 MPa).Koj tuaj yeem kho qhov xav tau lub zog tensile nyob rau hauv ntau yam (xws li, X rau Y MPa) |

| Compressive zog | Xaiv los ntawm qis, nruab nrab, thiab siab, lossis nws kuj tuaj yeem ua tau raws li qhov ntau. |

| Hardness | Xaiv los ntawm qis, nruab nrab, thiab siab, lossis nws kuj tuaj yeem ua tau raws li qhov ntau(ie, X to Y HRB) |

| Lub zog-rau-qhov hnyav piv | Tsawg, nruab nrab, lossis siab.Nws yog qhov zoo dua los qhia qhov ntau yam rau qhov chaw rhiab, xws li cov khoom siv kho mob. |

| Nto xov | Raws li machined, plating, painting, hmoov txheej los yog lwm yam, rau rhiab qhov chaw xws li aircraft, nws yog zoo dua los qhia ib tug ntau yam ntawm yuav tsum tau roughness tooj (Ra). |

| Machineability | Qhia meej yam ntawm machinability yuav tsum tau ntawm cov ntawv hlau (siab, nruab nrab, qis) |

| Ua siab ntev | ± X rau Y mm |

| Elasticity | Siab, nruab nrab, lossis qis. |

Yeej, Sau cov kev xav tau los ntawm kev qhia ntau yam lossis qeb (qis, nruab nrab, thiab siab).Lwm qhov yog tias koj tuaj yeem sau txhua qhov kev xav tau, tsis txwv rau qhov piv txwv saum toj no.

Kauj Ruam 2: Qhia luv luv cov ntaub ntawv

Cia peb saib ntau hom ntawv hlau siv hauv CNC machining.Tam sim no sau ntau hom hlau nyob rau hauv txoj kab nrog rau cov lus qhia ua ntej.Daim ntawv teev cov khoom siv yuav tsum sib haum nrog cov kev xav tau.

· Aluminium

Aluminium muaj lub zog-rau-hnyav piv, machinability, ductility, thermal & hluav taws xob conductivity, corrosion kuj, thiab nqi-zoo.Nws tuaj yeem siv tau sai thiab siv tau ntau yam kev lag luam, suav nrog tsheb, aerospace, kev tsim kho, khoom siv hauv tsev, tub rog, hluav taws xob, thiab hluav taws xob.

· Stainless hlau

Stainless hlau muab cov neeg kho tshuab siab zog, toughness, thermal kuj, hnav thiab tsim kua muag, thiab ruaj khov.Stainless hlau muaj ib tug txaus nyiam nto tiav uas yog yooj yim thiab muaj ib tug kaj xim nyiaj.Txawm li cas los xij, hom alloy kuj cuam tshuam rau qhov tshwj xeeb zoo.Peb cov alloys nrov tshaj plaws yog 1215, 12L14, thiab 1018.

· tooj dag

Brass muaj machinability zoo heev, siab tensile zog, cuam tshuam tsis kam, thiab shear kuj.Nws yog qhov nrov heev rau kev tsim kev sib txhuam qis, kev ua kom zoo nkauj, thiab kev ua siab ntev rau kev tsim khoom hauv Hluav Taws Xob, Hluav Taws Xob, Automotive, tiv thaiv, aerospace, architecture, kho mob, kav dej, thiab ntau yam lag luam.

· Titanium

Lub ntsiab kom zoo dua ntawm titanium yog nws muaj peev xwm txhawb nqa huab cua sov, tshuaj, thiab noo noo ib puag ncig yam tsis hloov nws cov khoom.Nws muaj qib siab ntawm biocompatibility, lub zog-rau-qhov hnyav piv, thiab corrosion kuj, ua rau nws zoo tagnrho rau tsheb, aerospace, thiab kev kho mob kev lag luam.

· Tooj

Txawm hais tias nws tsis muaj zog tiv thaiv cov tshuaj xws li acids, halogen sulfides, thiab ammonia daws, tooj liab muaj qhov zoo ntawm thermal thiab hluav taws xob zoo, kev ua haujlwm siab, kev tiv thaiv corrosion, thiab lub teeb ci liab liab.Nws tuaj yeem siv rau cov tshuab hluav taws xob, hluav taws xob li qub, cua sov thiab cua txias, thiab cov khoom siv hluav taws xob sib txawv.

· Lwm tus

Dhau li ntawm cov no, muaj cov hlau sib txawv nrog cov khoom tshwj xeeb, xws liBronze, Zinc, thiab Magnesium.

Kauj Ruam 3: Xaiv cov ntawv hlau zoo tshaj plaws los ntawm cov npe luv

Xaiv cov khoom uas zoo tshaj plaws txaus siab rau txhua yam kev xav tau tom qab nqaim qhov kev xaiv ntawm cov ntawv hlau ua los ntawm ntau yam ntaub ntawv.Thaum txiav txim siab, coj tus nqi mus rau hauv tus account.Yog tias tus nqi poob qis, koj tuaj yeem cuam tshuam rau qee qhov kev xav tau yam tsis muaj kev cuam tshuam kev ua haujlwm.Txawm li cas los xij, yog tias cov khoom muaj rhiab heev, koj yuav tsum nrhiav cov khoom siv uas haum rau cov kev xav tau.

Kev xav kawg

Kev xaiv cov ntawv hlau zoo tshaj plaws rau koj qhov project CNC machining yog qhov nyuaj heev.Nws suav nrog kev txiav txim siab sib txawv, tab sis nrog Prolean, nws yooj yim dua li koj xav, muab CNC machining cov kev pabcuam rau ntau tshaj 50+ hlau & alloys.Peb tuaj yeem tshuab cov khoom rau koj cov specifications nrog nruj kam rau ua.Peb cov kws tshaj lij engineers yuav pab koj xaiv cov ntaub ntawv zoo tshaj plaws hauv koj cov peev nyiaj thiab cov yam ntxwv xav tau.

FAQ's

Cov ntawv hlau twg yuav yog qhov zoo tshaj plaws rau kuv txoj haujlwm CNC machining?

Tsis muaj ib qho kev daws teeb meem.Cov ntawv hlau tsim nyog rau koj qhov project CNC yuav cia siab rau ntau qhov sib txawv, suav nrog koj cov kev xav tau thiab cov yam ntxwv ntawm ib hom ntawv hlau.Piv txwv li, Aluminium tuaj yeem yog cov hlau zoo tshaj plaws rau cov khoom siv dav hlau sab hauv, hos cov ntawv hlau yuav yog qhov kev xaiv zoo tshaj plaws rau cov khoom siv.Yeej, nws nyob ntawm koj qhov kev xav tau.

Dab tsi yog qhov tseem ceeb uas yuav tsum tau xav txog thaum xaiv qhov zoo tshaj plawsdaim hlau rau CNC machining?

Muaj ntau yam xws li koj cov kev xav tau, kev siv kawg, kev ua tau zoo ntawm kev tsim khoom, Nqi, thiab ntau ntxiv.

Dab tsi yog qee hom ntawv hlau siv hauv CNC machining?

Cov ntawv hlau nrov tshaj plaws siv hauv CNC machining yog steel, Aluminium, tooj dag, titanium, tooj liab, zinc, thiab tooj.

Post lub sij hawm: Sep-19-2022