Gear Machining Guide Piav nrog Video, Machining Methods thiab Txheej Txheem

Last updata 09/14, sij hawm nyeem: 9mins

Hauv kev tsim thiab kev ua haujlwm ntawm cov tshuab, lub zog ua ib qho tseem ceeb, rau kev sib hloov tshuab, kom ntseeg tau tias kev ua haujlwm ntawm cov tshuab ua lub luag haujlwm tseem ceeb, kev tsim cov iav yog rau qee yam txiav txim siab tag nrho cov tshuab thiab kev ua haujlwm zoo.

Kab lus no qhia txog rau qhov xwm txheej ntawm cov txheej txheem iav.Gear manufacturing txheej txheem txheej txheem, machining txheej txheem thiab lawv cov yuav tsum tau sib tham, ua ke nrog cov iav manufacturing txheej txheem nyob rau hauv daim ntawv thov ntawm ib tug teeb meem nyob rau hauv cov txheej txheem thiab kev daws teeb meem, muab ib tug yooj yim phau ntawv qhia rau koj iav ua thiab manufacturing, yog li ntawd koj muaj peev xwm xaiv txoj kev zoo, koj tuaj yeem ua tautiv tauj peb cov engineerskom tau txais cov ntaub ntawv hais txog kev tsim khoom siv.

Cov ntsiab lus

1 Daim duab ntawm 6 hom iav tshuab machining

2 Gear manufacturing txheej txheem machining txheej txheem thiab nws cov kev cai

3 Cov teeb meem thiab kev daws teeb meem hauv kev siv cov txheej txheem machining hauv cov txheej txheem tsim khoom

1 Gear Mechanical Processing Method

Gears muaj ntau hom ntawm cov hniav, uas muaj cov hniav zoo nkauj tshaj plaws.Muaj ob hom kev machining loj uas feem ntau siv rau cov duab hniav, uas yog txoj kev sib sau thiab txoj kev sib kis.

1) Milling hniav

Milling cov hniav nrog disc-shaped modulus milling cutter belongs rau txoj kev tsim, thiab cov duab ntawm cov cutter cross-section sib haum mus rau cov duab ntawm cov hniav iav.Cov hniav yog machined tawm.Tom qab milling ib tug hniav ntsis ntawm lub iav, lub indexing mechanism yog manually indexed tig ib tug hniav, thiab ces lwm qhov hniav yog milled, thiab hais txog, mus txog rau thaum xaus ntawm tag nrho cov milling.

Iav machining los ntawm txoj kev milling

- Daim ntawv thov

Txoj kev no muaj kev ua haujlwm tsawg thiab raug, thiab tsuas yog tsim rau ib qho thiab me me batch ntau lawm.

2) Zoo sib tsoo

Tsis tas li ntawd belongs rau txoj kev tsim cov txheej txheem, kev sib tsoo log tsis yooj yim rau hnav, yog li siv tsawg dua.

Kev sib sau thiab sib tsoo iav

3) Hobbing method

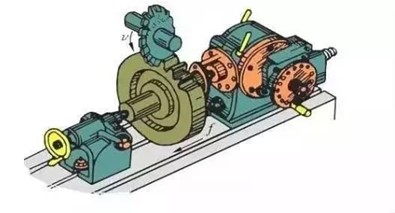

Hobbing method

Cov cuab yeej txiav cov iav blanks thaum hobbing yog ib lub hob, uas yog ib tug cab vim yog lub loj kauv nqa lub kaum sab xis ntawm lub hob.Lub hob yog slotted nyob rau hauv cov kev taw qhia perpendicular mus rau lub kauv zawj, tsim ib tug xov tooj ntawm tej npoo, thiab nws ib txwm profile muaj ib tug khib puab.

Yog li ntawd, thaum lub hob rotates tsis tu ncua, lub iav log tuaj yeem suav tau tias yog qhov txav ntawm qhov khib nyiab ntev ntev.Nyob rau tib lub sijhawm, cov iav cutter txiav los ntawm sab saum toj mus rau hauv qab, ua kom lub meshing kev sib raug zoo ntawm lub khib (hob) thiab lub iav dawb paug, thiab lub hob tuaj yeem ua cov iav involute ntawm lub iav dawb.

Txoj cai ntawm iav hobbing

- Cov yam ntxwv txheej txheem

(1) Lub hobbing processing ntawm txoj kev sib kis muaj qhov ua tau zoo, thiab tsis muaj qhov yuam kev nyob rau hauv lub iav nkhaus ntawm shaping txoj kev milling, yog li qhov kev sib cais raug siab, thiab feem ntau nws tuaj yeem ua cov iav nrog 8 ~ 7 qib. ntawm qhov raug.

(2) Lub hob tuaj yeem ua cov cylindrical zog nrog tib lub module thiab lub siab lub kaum ntse ntse raws li lub hob tab sis nrog cov lej sib txawv.

(3) High productivity hobbing yog nruam txiav, tsis muaj auxiliary lub sij hawm poob, productivity yog feem ntau siab tshaj milling thiab inserting zog.

- Daim ntawv thov

Hobbing yog tsim rau ib qho me me ntau lawm thiab ntau lawm.

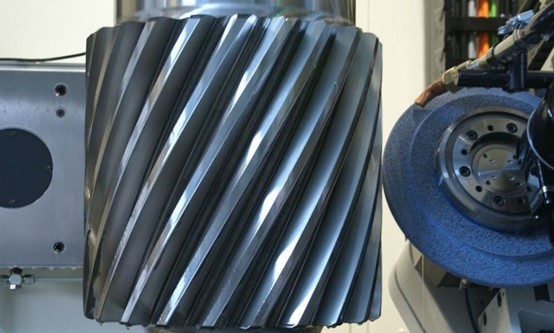

4) Gear shaving

Gear shaving

Hauv kev tsim khoom loj, iav shaving yog ib txoj hauv kev zoo tshaj plaws rau cov hniav uas tsis yog-hardened.Nws lub hauv paus ntsiab lus ua haujlwm yog siv cov riam shaving thiab cov iav kom ua tiav rau kev txav meshing dawb, nrog kev pab los ntawm cov txheeb ze plam ntawm ob, los ntawm cov hniav nto shaving zoo heev chips, txhawm rau txhim kho qhov tseeb ntawm cov hniav nto. .Shaving tuaj yeem tsim cov hniav zoo li lub nruas los txhim kho txoj haujlwm ntawm cov hniav sib cuag.

- Cov yam ntxwv txheej txheem

1. Shaving raug yog feem ntau 6 mus rau 7, nto roughness Ra yog 0.8 mus rau 0.4μm, rau cov xov ntawm unquenched zog.

2. High productivity ntawm shaving, ua ib tug nruab nrab loj iav feem ntau tsuas yog 2 mus rau 4 min, piv nrog rau kev sib tsoo, tuaj yeem txhim kho cov khoom tsim tau ntau dua 10 zaug.

3. Vim tias cov txheej txheem shaving yog dawb meshing, lub tshuab tsis kis mus rau hauv kev txav ntawm cov saw hlau, yog li lub tshuab qauv yog yooj yim, yooj yim los kho lub tshuab.

- Daim ntawv thov

Shaving yog ib txoj kev siv dav rau kev ua tiav cov hniav, tshwj xeeb tshaj yog rau kev tsim cov khoom loj, thiab feem ntau yog siv los ua kom tiav cov iav tsis muaj zog vim nws cov nqi siab.Shaving yog tam sim no siv tsuas yog rau kev ua tiav cylindrical zog, tab sis txoj kev no tau pib siv rau shaving cab iav.Nyob rau hauv thaum ntxov hnub, kuj muaj bar shaving cutters, uas kuj tau siv los ua kom tiav cov cylindrical zog, tab sis vim lawv cov qauv complex, lawv tsis tshua muaj siv tam sim no.

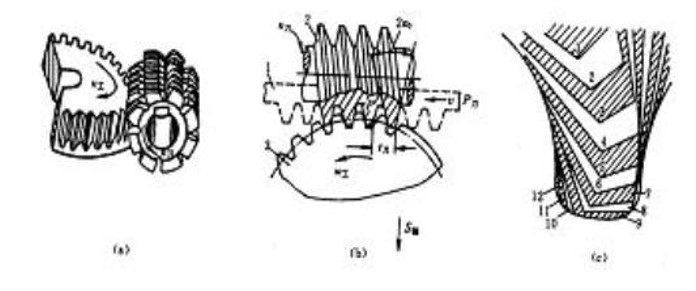

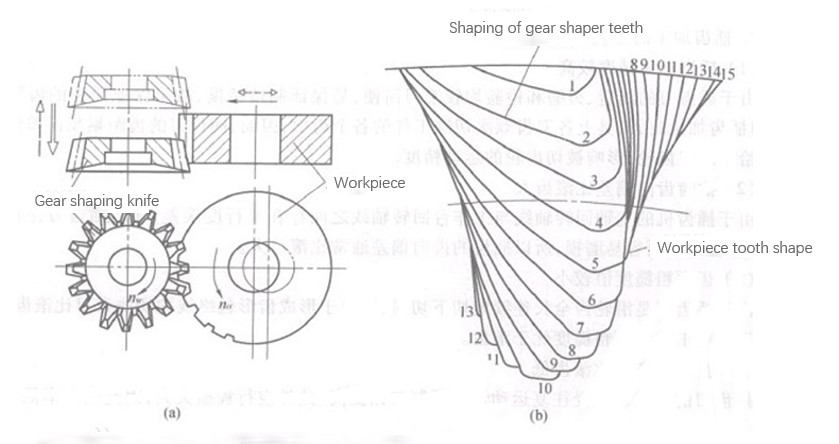

5) Iav shaping

Iav shaping

Iav shaping yog ib hom iav txiav txheej txheem uas feem ntau siv ntxiv rau hobbing.Thaum shaping, lub iav shaper thiab lub workpiece yog sib npaug rau meshing ntawm ib khub ntawm cylindrical zog.Daim ntawv ntawm kev txav ntawm lub workpiece thiab lub iav shaper yog pom nyob rau hauv daim duab a.Thaum lub sij hawm iav shaping, lub cuab tam ua rau ib tug high-ceev reciprocating linear tsab ntawv tsa suab nyob rau hauv cov kev taw qhia ntawm lub workpiece axis thiab txheej txheem tag nrho cov iav hniav profiles ntawm lub workpiece.Nyob rau hauv tus txheej txheem, lub cuab tam tsuas yog txiav tawm ib feem me me ntawm workpiece hniav zawj nrog txhua reciprocation, thiab tus hniav nto nkhaus ntawm lub workpiece hniav zawj yog tsim los ntawm lub hnab ntawv ntawm lub txiav ntug ntawm inserting riam, raws li qhia nyob rau hauv daim duab b. .

Lub hauv paus ntsiab lus ntawm iav shaping

- Daim ntawv thov

Feem ntau hais lus, qhov tsim tau ntawm hobbing yog siab dua li ntawm shaping, vim hais tias shaping yog ib tug reciprocating motion thiab rov qab stroke tsis txiav.Lub iav shaping system tsis tshua muaj nruj thiab cov nyiaj txiav tsis tuaj yeem loj dhau.Txawm li cas los xij, rau cov khoom siv me me (m<2.5 mm), qhov tsim tau zoo ntawm kev ua haujlwm yuav siab dua qhov hobbing.Rau nyias iav, ib daim ntau lawm, hobbing txiav ntev yog loj, tej zaum yuav tsis zoo li shaping.

6) Iav sib tsoo los ntawm txoj kev sib kis

Txoj kev txiav ntawm txoj kev sib kis yog zoo ib yam li hobbing thiab yog ib txoj kev kho hniav, tshwj xeeb tshaj yog rau cov tawv nqaij tawv, uas feem ntau yog tib txoj kev ua tiav.Txoj kev sib kis tuaj yeem siv los zom cov hniav nrog cov cab iav los yog nrog cov conical lossis disc sib tsoo log.

2 Gear manufacturing txheej txheem machining txheej txheem thiab nws cov kev cai

1) Forging ntawm blanks

Lub forging ntawm blanks txheej txheem nyob rau hauv iav manufacturing yog dav siv, feem ntau nyob rau hauv daim ntawv ntawm forging thiab kub embossing.Nrog rau kev txhim kho ntawm cov iav tsim thiab kev siv thev naus laus zis, kev siv tshuab ntoo khaub lig tau maj mam pib siv dav hauv kev tsim cov khoom siv tshuab, tshwj xeeb tshaj yog nyob rau hauv kev ua thiab kev tsim cov kauj ruam ncej hom workpieces.Cov txheej txheem forging ntxhib yuav tsum tau ua haujlwm siab thiab raug kom txo tau tus nqi ntawm cov iav tsim thiab txo cov khoom pov tseg.

Forging ntawm blanks

2) Normalizing

Gear manufacturing yog ib qho nyuaj rau kev tswj cov cua txias ntawm lub workpiece, uas yog cuam tshuam los ntawm ib puag ncig ib puag ncig, cov teeb meem ntawm cov khoom siv, phau ntawv ua haujlwm thiab lwm yam, ua rau muaj qee yam teeb meem rau lub uniformity ntawm lub koom haum cov qauv, yog li nws yog tsim nyog los ua kom sov kho cov hlau. txiav.Cov txheej txheem no siv rau cov txheej txheem isothermal normalizing yog hais txog qhov teeb meem ntawm kev zam kom tsis txhob thermal deformation ntawm iav steel cov ntaub ntawv ntawm qhov tsim nyog kub tom qab iav txiav hardness thiab kev kho cua sov.

3) Cov txheej txheem tig

Gear manufacturing thiab ua rau iav qhov tseeb qhov yuav tsum tau muaj siab, tam sim no nyob rau hauv kev ua cov iav blanks feem ntau yuav tsum tau siv rau CNC tshuab dhos, raws li qhov yuav tsum tau ntawm lub ntsej muag kawg thiab bore rau verticality, txhim kho qhov tseeb ntawm cov hniav dawb paug, los xyuas kom meej qhov zoo ntawm iav manufacturing thiab ua, nrog rau bore, kawg lub ntsej muag, txheej txoj kab uas hla ua zoo, thiab lwm yam.. Txhim kho kev ua hauj lwm zoo ntawm CNC tshuab dhos zoo lav cov txiaj ntsig kev lag luam thiab txo cov khoom siv.

4) Hobbing thiab inserting

Txhawm rau txhim kho lub neej kev pab cuam ntawm lub cuab yeej, tom qab lub hobbing, inserting riam sharpening, nrog rau lub luag hauj lwm ntawm re-txheej technology, txo tus naj npawb ntawm cov cuab yeej hloov, zoo xyuas kom meej lub neej ntawm lub cuab tam, muab ib tug guarantee ntawm ruaj khov ua. , thiab txhawb kev lag luam efficiency ntawm ntau lawm.

5) Shaving

Nyob rau hauv cov txheej txheem ntawm kev tsim cov iav, shaving yog ib qho ntawm cov txheej txheem ua ntau yam, yog siv dav hauv kev tsim cov iav tsim, raws li cov txheej txheem tseem ceeb, shaving muaj qhov zoo, tsis tsuas yog kev ua haujlwm siab, thiab muaj qhov zoo ntawm kev ua tau zoo. cov hniav zoo thiab cov hniav orientation xav tau.

6) Kev kho cua sov

Cov txheej txheem kev kho cua sov, hauv cov txheej txheem kev tsim cov iav, feem ntau yog nitriding, carburizing, quenching tshav kub kev kho mob hauv txoj kev no.Tom qab cov txheej txheem no, qhov nyuaj ntawm lub zog ntawm lub zog yog nce ntau, thiab cov yas toughness ntawm qhov chaw yog qhov zoo heev, uas txhawb nqa lub zog ntawm lub neej ntawm iav thiab ua kom muaj zog tiv thaiv kev qaug zog thiab hnav tsis kam ntawm lub zog.

7) Cov txheej txheem sib tsoo

Cov txheej txheem sib tsoo hauv kev tsim cov iav yog hais txog cov txheej txheem ua tiav rau qee txoj haujlwm, suav nrog txoj kab uas hla sab nraud, sab hauv hauv ob sab phlu thiab lub ntsej muag kawg ntawm lub iav, txhawm rau txhawb kev txhim kho ntawm kev sib dhos thiab kev teeb tsa raug.

8) Kev tshuaj xyuas

Kev tshuaj xyuas yog ib qho tseem ceeb ntawm cov txheej txheem tsim cov iav thiab hais txog kev tshuaj xyuas thiab ntxuav cov hniav, uas feem ntau yog ua ntej cov iav sib dhos.Kev soj ntsuam zoo thiab kev soj ntsuam ntawm cov hniav sib txawv ntawm cov hniav sib txawv, kev siv cov cuab yeej tshuaj ntsuam xyuas, txhim kho cov txiaj ntsig ntawm kev tshuaj xyuas kom tsis txhob muaj teeb meem xws li iav suab nrov.

3 Cov teeb meem thiab kev daws teeb meem hauv kev siv cov txheej txheem machining thaum lub sij hawm tsim khoom

Q: Cov hniav tsis raug

A: Thaum twgtus lej hniav tsis raug, kev saib xyuas ntau dua yuav tsum tau them rau qhov kev xaiv zoo ntawm cov hobs, thiab cov hobs nrog lub kaum sab xis zoo sib xws, tib lub hob siab lub kaum sab xis thiab tib lub hob module yuav tsum tau siv.

Q: Cov hniav loj loj yuam kev

A: Thaum qhov teeb meem ntawmCov hniav loj yuam kev tshwm sim, ces kho lub hob installation lub sij hawm.Txiav txim siab seb lub iav qhov loj me thiab cov kev taw qhia txav ntxiv yog qhov tseeb los xyuas kom meej qhov zoo ntawm cov iav tsim.

Q: Cov hniav zoo li asymmetry

A: Feem ntauhniav zoo asymmetryteeb meem yuav daws tau los ntawm kev kho lub hob.Siv lub hob sharpening grinder nrog cov neeg siab thiab xaiv tus nqi tsim nyog thiab yooj yim-rau-ua haujlwm hob sharpening grinder los txhawb lub hob installation raug thiab hob sharpening zoo.Txhua qhov kev kuaj xyuas kev teeb tsa thiab kev ua haujlwm ntawm kev sib pauv iav, ntxiv dag zog rau kev ruaj ntseg ntawm lub tshuab dhos ua haujlwm, thiab txhim kho tag nrho cov khoom zoo thiab kev ua haujlwm ntawm cov iav tsim.

Post lub sij hawm: May-17-2022