Aluminium Extrusion piav qhia, Pros thiab Cons

Lub sij hawm nyeem: 6 mins

Txoj Cai ntawm Aluminium Extrusion

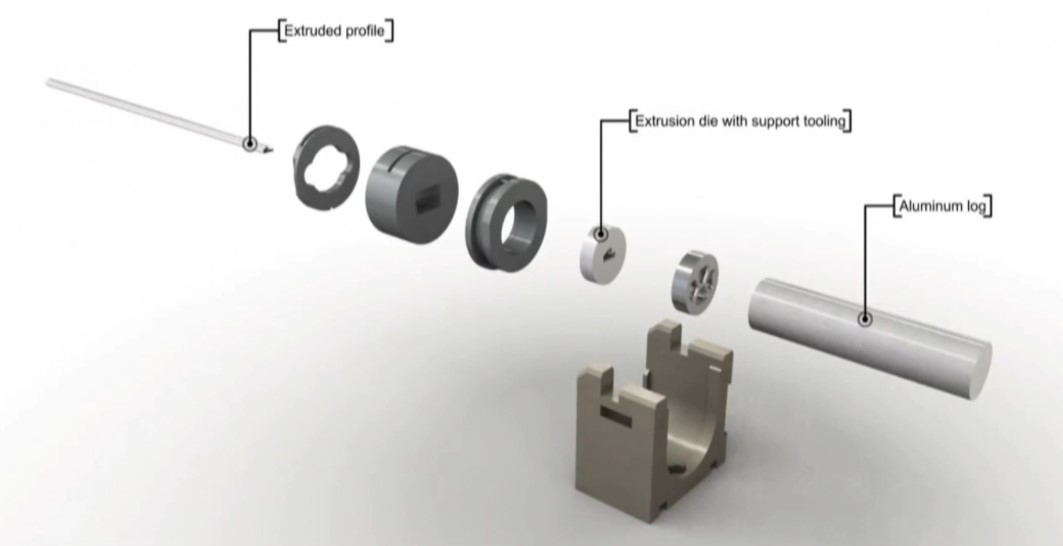

Extrusion yog txheej txheem txheej txheem uas tsis yog txheej txheem tshem tawm cov khoom.Cov khoom siv cua sov, xws li txhuas, raug yuam los ntawm qhov qhib los ua ib qho profile.Nyob rau hauv txhuas extrusion, raw aluminium yog thawj rhuab thiab ces zoo li tus mus rau hauv qhov xav tau los ntawm kev thawb nws los ntawm ib tug tuag siv lub plunger.Piv txwv li, cov txheej txheem ntawm txhuas extrusion zoo ib yam li cov tshuaj txhuam hniav;lub zog thov tuaj yeem piv rau lub zog siv thaum koj nyem lub raj ntawm cov tshuaj txhuam hniav nrog koj tus ntiv tes, thiab thaum koj nyem, cov tshuaj txhuam hniav zoo nkaus li zoo li lub raj qhib.

Tau kawg, qhov teeb meem tiag tiag yog qhov nyuaj dua li qhov no, thaum koj yuav tsum siv cov txheej txheem aluminium extrusion nws yog qhov zoo tshaj plaws los sib txuas lus nrog tus kws tshaj lij engineers, peb cov engineers muaj ntau xyoo dhau los ntawm kev lag luam aluminium extrusion thiab tuaj yeem teb koj cov lus nug sai, thiab peb muab akev pabcuam pub dawb,koj tuaj yeem tshawb xyuas pebaluminium extrusion kev pabcuam nplooj.Yuav kom rov qab mus rau lub ntsiab lus, tsab xov xwm no yuav piav qhia rau koj qee qhov tseeb ntawm aluminium extrusion: txheej txheem extrusion;cov duab uas tuaj yeem raug extruded;qhov zoo thiab qhov tsis zoo, thiab qee cov lus qhia rau kev siv aluminium extrusion.

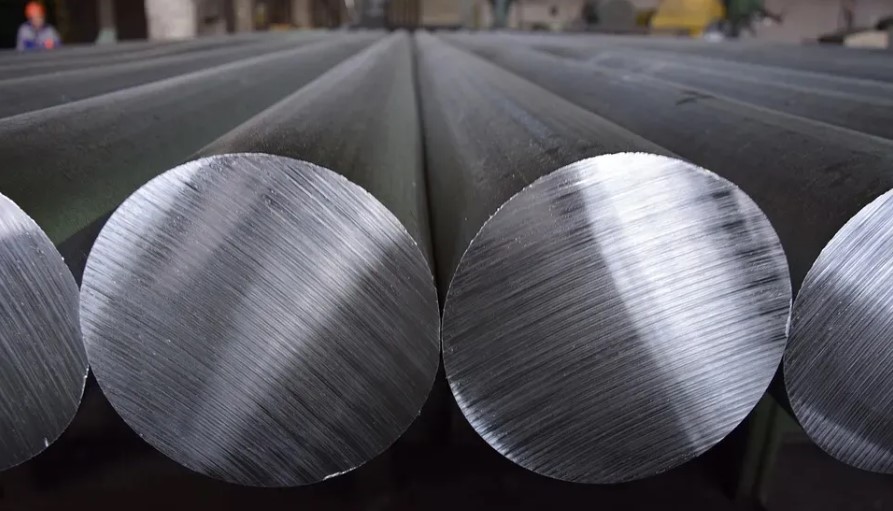

Aluminium Log

Hom ntawm Aluminium Extrusion Moulding

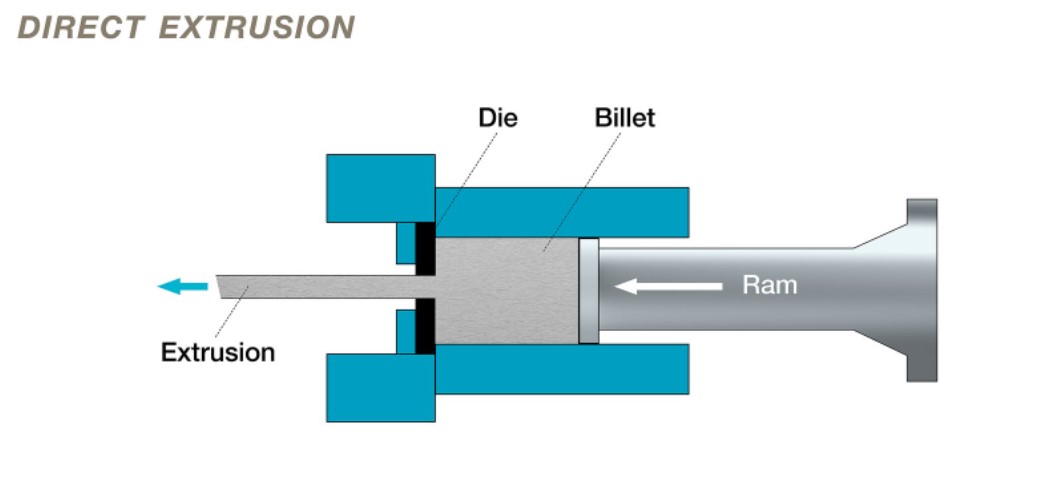

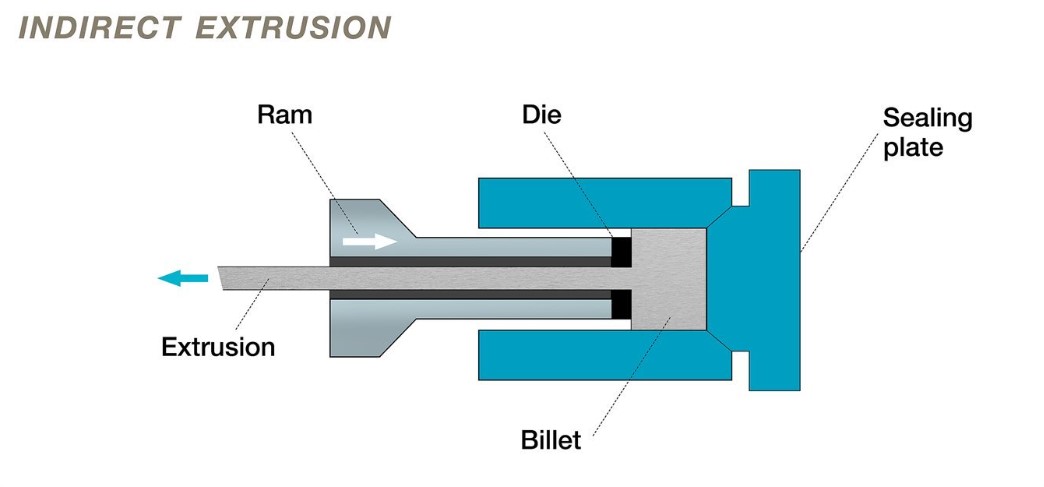

Muaj ob hom txheej txheem extrusion,ncaj thiab tsis ncaj.Nrog ncaj qha extrusion lub taub hau tuag tseem nyob ruaj khov thiab txav punch yuam cov hlau los ntawm nws.Nyob rau hauv sib piv, indirect extrusion lub billet tseem nyob ruaj ruaj thaum lub sij hawm tuag ntawm qhov kawg ntawm lub plunger tsiv tawm tsam lub billet, tsim kom muaj lub siab xav tau rau cov hlau ntws los ntawm cov tuag.

Direct Extrusion

Direct extrusion,tseem hu ua forward extrusion, yog cov txheej txheem extrusion feem ntau.Nws ua haujlwm los ntawm kev tso lub billet rau hauv lub thawv tuab-walled.Lub billet yog thawb los ntawm qhov tuag los ntawm lub plunger los yog ntsia hlau.Lub ntsiab tsis zoo ntawm cov txheej txheem no yog tias lub zog yuav tsum tau extrude lub billet yog ntau tshaj qhov yuav tsum tau los ntawm indirect extrusion txheej txheemvim yog lub zog nkag los ntawm kev sib txhuam vim qhov xav tau rau lub billet kom dhau los ntawm tag nrho ntev ntawm lub nkoj.Yog li ntawd, lub siab tshaj plaws quab yuam yuav tsum yog nyob rau hauv thaum pib ntawm tus txheej txheem thiab txo qis raws li lub billet yog siv.

Indirect Extrusion

Inindirect extrusion(tseem hu ua thim rov qab extrusion), lub billet tseem nyob ruaj khov thaum lub sijhawm tuag ntawm qhov kawg ntawm lub plunger txav mus rau lub billet, yog li tshem tawm cov kev sib txhuam.Qhov no ua rau cov hauv qab noqhov zoo.

1.25% mus rau 30% kev sib txhuam tsawg dua, uas tso cai rau cov blanks loj dua yuav tsum tau extruded, siab dua, thiab muaj peev xwm ua rau extrude me me hla ntu

2. Tsawg dua qhov extruded qhov tawg vim qhov tsis muaj cua sov tsim los ntawm kev sib txhuam

3. Lub neej ntev ntawm cov hlab ntsha vim tsis hnav tsawg

4. Ntau hom kev siv cov billets, yog li extrusion defects thiab coarse-grained peripheral cheeb tsam tsis tshua muaj tshwm sim.

Qhov tsis zoo yog

1. impurities thiab tsis xws luag nyob rau saum npoo ntawm billet tuaj yeem cuam tshuam rau saum npoo ntawm extrusion.Yuav kom daws tau qhov teeb meem no, cov billets tuaj yeem yog hlau txhuam, machined, los yog tshuaj ntxuav ua ntej siv

2. Nws tsis yog ntau yam raws li qhov ncaj qha extrusion vim qhov chaw hla ntu yog txwv los ntawm qhov siab tshaj plaws ntawm cov qia.

Cov yam ntxwv cuam tshuam rau Extrusion Shape

Cov duab yog qhov txiav txim siab nyob rau hauv ib feem nqi thiab yooj yim ntawm extrusion.Thaum lub sij hawm extrusion txheej txheem, ntau yam duab yuav extruded.Feem ntau, cov duab extruded tuaj yeem muab faib ua peb pawg.

1. Khoom, tsis muaj qhov khoob khoob khoob lossis qhov qhib (piv txwv li, pas nrig, kab teeb, lossis kaum)

2. Hollow, nrog ib lossis ntau qhov khoob (piv txwv li, square lossis rectangular raj)

3. Semi-hollow, nrog ib feem kaw voids (piv txwv li, ib tug "C" zoo li lub raj nrog nqaim khoob)

Hauv kev tsim khoom tiag tiag, muaj ntau qhov kev txwv uas yuav tsum tau xav txog.Cov no suav nrog:

1. Loj

2. Cov duab

3. Alloy - Cov tshuaj muaj pes tsawg leeg ntawm lwm cov ntsiab lus ntxiv rau cov ntshiab txhuas los txhim kho nws cov khoom (xws li, lub zog, thiab lwm yam)

4. Extrusion Ratio - Qhov chaw ntawm lub billet / cheeb tsam ntawm cov duab

5. Qhov sib piv tus nplaig – Qhov dav thiab qhov tob ntawm qhov sib txawv

6. Kev kam rau siab – Qhov kev txwv ntawm kev hloov pauv uas ib feem lossis cov khoom tuaj yeem tsim tau

7. Ua tiav

8. Coefficient - Cov duab ncig / qhov hnyav ib 'meter'

Aluminium Extrusion Tus Thawj Coj

Extruded Aluminium Alloy Options

| 1100 | Nws yog mos, tsis yog cua sov kho tau tab sis tuaj yeem raug extruded rau hauv cov duab nyuaj nrog lub ntsej muag zoo nkauj.Cov hlau no tuaj yeem siv rau cov khoom zoo li thiab cov khoom siv hluav taws xob sib txuas. |

| 3003— 3000 Nws | cov hlau no feem ntau yog extruded rau cov cua kub exchanger raj nkaus xwb. |

| ib 6063 | Qhov zoo tshaj plaws rau kev kho kom zoo nkauj, muaj qhov zoo nkauj tiav thiab tuaj yeem extruded nrog cov yam ntxwv zoo xws li cov phab ntsa nyias lossis cov ntsiab lus zoo.Nws yog corrosion resistant, tab sis muaj tsawg weld zog, txawm hais tias nws yog yooj yim welded. |

| ib 6061 | Cov hlau no muaj zog dua 6063 thiab yog cov khoom siv tseem ceeb rau kev thauj mus los thiab kev lag luam machined.Lub alloy yog yooj yim rau extrude thiab weld.Cov khoom no ua ke nrog cov pob txha tawg zoo thiab lub zog qaug zog zoo ua rau nws yog khau rau cov tswv cuab ntawm cov khoom siv, xws li tsheb, tsheb thauj khoom thiab trailer thav duab, tsheb ciav hlau thiab cov kav dej. |

| ib 7004 | Ib qho ntawm cov "qis kawg" 7000 series (Al-Zn) alloys uas yog xovxwm kub kho tau, tsim nyog extrudable thiab nqi me ntsis ntau tshaj 6061. Lub 7000 series muaj keeb kwm tau siv dav hauv cov khoom ua si, tsheb kauj vab thiab maus taus kev lag luam.7004 alloys muaj qhov kawg tawm los thiab lub zog tensile siab tshaj 40,000 thiab 50,000 psi, feem. |

Cov txiaj ntsig ntawm Aluminium Extrusion

1. Cov khoom zoo tag nrho.Extrusion molding tuaj yeem txhim kho cov qauv thiab cov khoom siv ntawm txhuas.Tom qab quenching, lub longitudinal (extrusion direction) mechanical zog ntawm cov khoom extruded yog ntau dua li cov khoom zoo sib xws uas tsim los ntawm lwm txoj kev ua.Piv nrog rau dov, forging thiab lwm txoj kev ua, cov khoom extruded muaj ntau dua qhov tseeb thiab qhov zoo ntawm qhov chaw.

2. Muaj ntau yam khoom.Extruded profiles tuaj yeem tsim tsis tau tsuas yog cov kav dej yooj yooj yim, tuav thiab cov xov hlau, tab sis kuj tseem muaj cov duab sib txawv heev, cov khoom siv thiab hollow profile.Extruded khoom kuj tseem muaj nyob rau hauv ntau qhov ntau thiab tsawg, los ntawm cov hlab loj heev thiab cov kab uas hla ntawm 500-1000 hli mus rau ultra-me me precision profiles qhov loj ntawm matchsticks.

3. Kev ua haujlwm siab ntau lawm.Extrusion molding muaj ntau qhov kev hloov pauv.Cov khoom ntawm cov duab sib txawv, qhov ntau thiab tsawg, qhov tshwj xeeb thiab ntau yam tuaj yeem ua rau tib lub tshuab los ntawm kev hloov cov tuag.Tsis tas li ntawd, kev hloov pauv tuag yog qhov yooj yim, yooj yim, txuag lub sijhawm thiab ua haujlwm tau zoo.

4. Cov txheej txheem yooj yim thiab kev nqis peev hauv cov cuab yeej siv tsawg.Piv nrog cov yeeb nkab thiab cov txheej txheem ntau lawm xws li perforation dov thiab zawj dov, extrusion molding muaj qhov zoo ntawm cov txheej txheem luv luv, cov khoom siv tsawg thiab kev nqis peev tsawg.

Kev txwv ntawm Aluminium Extrusion

1. Cov khoom tsis sib xws ntawm cov ntaub so ntswg.Tsis sib xws nto, qhov chaw, lub taub hau thiab tus Tsov tus tw ntawm cov khoom extruded vim tsis sib npaug ntawm cov hlau thaum lub sij hawm extrusion.

2. Cov kev ua haujlwm ntawm extrusion tuag yog hnyav thiab nquag hnav.Thaum lub sij hawm extrusion txheej txheem, lub billet nyob rau hauv ib tug ze-kaw lub xeev nrog ib tug siab tee siab.Nyob rau tib lub sijhawm, cov neeg tuag feem ntau raug kub siab thiab kev sib txhuam loj thaum lub sijhawm kub extrusion txheej txheem, uas cuam tshuam rau lub zog thiab kev pab cuam lub neej ntawm cov tuag.

3. Tsawg ntau lawm efficiency.Tsuas yog txoj kev nruam extrusion tsim nyob rau hauv xyoo tas los no, cov qauv extrusion tsis tuaj yeem ua tiav kev tsim khoom tas mus li.Qhov dav dav extrusion ceev yog qis dua li dov ceev, thiab cov khoom seem geometric poob thiab tawm los ntawm extrusion ntau lawm yog tsawg.

Prolean muaj ntau yam khoom siv rau txhuas extrusion, xws li hlau thiab yas.Thov saib covdaim ntawv teev cov khoom sivpeb siv.Yog tias koj xav tau cov ntaub ntawv uas tsis tau teev tseg ntawm no, thov hu rau peb vim peb yuav muaj peev xwm muab tau rau koj.

Post lub sij hawm: May-04-2022