On-Demand Manufacturing, CNC Machining and Sheet Metal

Custom mass production and small quantity prototyping service from China. Get your quality parts in days.

All uploads are secure and confidential.

Prolean’s Manufacturing Processes

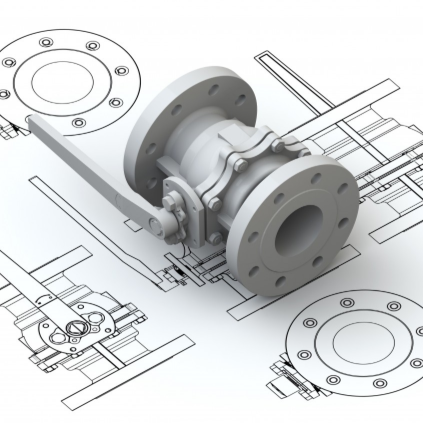

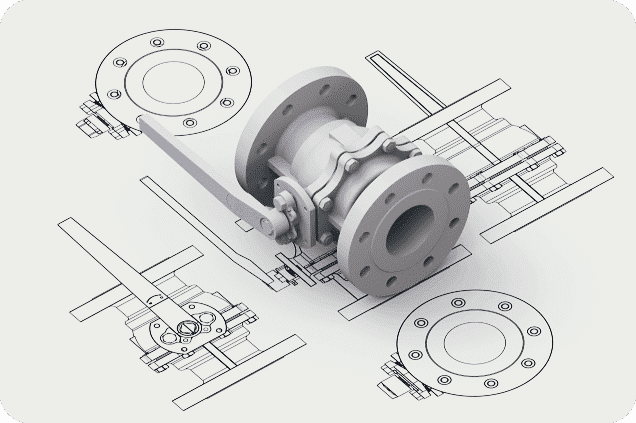

CNC Machining

Prolean provides CNC machining services of any complexity for rapid prototypes and production parts. Start a one-hour CNC quote from a real engineer, and get your parts made as fast as one day.

CNC Milling

Our 3-axis & 5-axis CNC milling center is dedicated to creating complex geometries and features

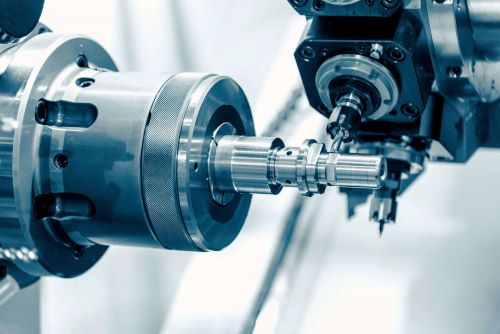

CNC Turning

With our latest CNC lathes and turning centers, even the most complex turned parts are possible

Turning-Milling

Allow multiple operations on a single machine, perfect for high precision parts with complex geometries

Electrical Discharge

Highly accurate machining service of cutting metal to precise shapes using electricity

Wire Cut

Our wire cut services can provide high precision tolerances, as tight as ±0.0002″ for an array of industries and applications.

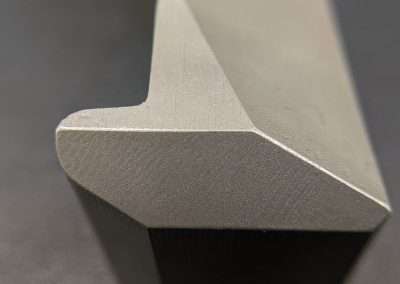

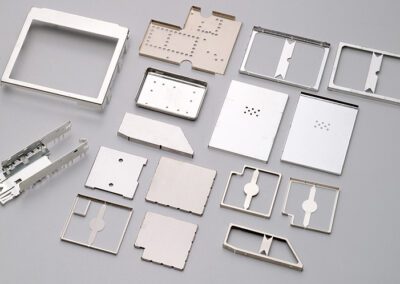

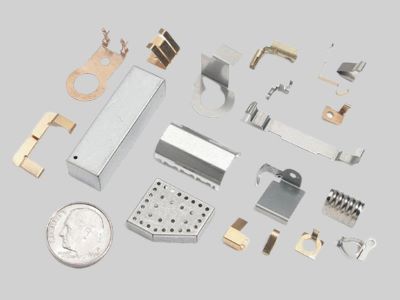

Sheet Metal Fabrication

Sheet metal cutting and forming services from prototypes to on-demand production of sheet metal parts. This service is widely used in a variety of industries including construction, automotive, aerospace, and electrical.

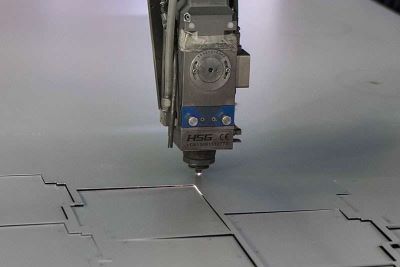

Laser Cutting Service

Our laser cutting service are able to deliver high-precision cutting and engraving on materials such as aluminum steel, coppe and more

Sheet Metal Bending

Deliver accurate angles with our bending services, achieving a final product that fits within tight tolerances

Stamping Service

Stamping service is a rapid process that generates parts with complex geometries at relatively lower costs.

Waterjet Cutting

High precision CNC waterjet cutting service cut through sheet metals without leaving burn marks

Welding Service

If you need to create a joint on the Metal & alloy pieces for your project, the Welding process is the right choice!

Try Prolean Now!

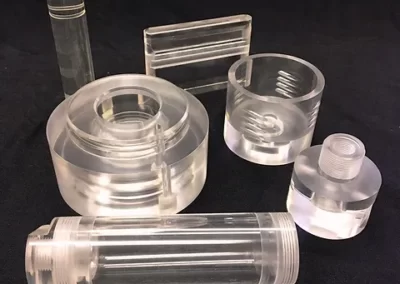

On-Demand Manufacturing Solutions

Whether you’re looking to validate a design with rapid prototyping or seeking mass production capabilities, Proleantech offers comprehensive On-Demand Manufacturing Solutions.

Our array of services encompasses Rapid Prototyping, Low Volume Production, Mass Production, and Sub-contract offerings, ensuring tailored solutions for every project need.

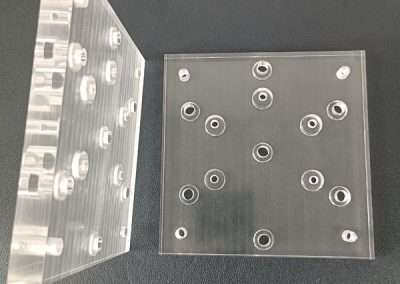

Production Tooling Service

Production tooling is the plastic injection molding process used for the mass production of precision plastic parts.

Overmolding Service

Overmolding services offer all the different combinations for over-moulded parts with a wide range of materials

Sub-contract

Sub-contract services seamlessly integrate with your business, our skilled team will handle them with precision, ensuring timely delivery and quality.

Try Prolean Now!

How to Order Parts?

Get a free quote from a real engineer; once we receive your design, our engineer will review it and send you a quote as fast as one hour.

Get A Quote Within 12 Hours

Upload your design or email our engineer directly and get your quotes as fast as one hour.

Start Production

Your parts will be made once your orders are confirmed. Besides, you will get real-time order updates of the production status from our order tracking system.

Receive Your Part

After all parts pass QC inspection, they will be well packed from transportation accidents. Then, your custom parts are delivered straight to your doorstep.

Why Choose Our Machining Service

Professional Service

- An hour response

With our management system, Prolean is able to allocate a real engineer in a few mins, and you can get your quotation and professional design advice as fast as 1 hour.

- Directly talk to a real engineer

Prolean has around 20 engineers by your side, providing professional advice and DFM feedback that helps optimize your design and save cost.

Quality Assurances

- ISO 9001 Accredited

Prolean passed the ISO9001 quality system certification, we follow strict manufacturing of DIN-2768-fine and DIN-2768-medium to produce parts with high tolerance and impeccable quality. Learn more

- Visual inspection and Protection

With consistent visual inspection conditions, we are able to provide high-quality cosmetic surface finishes, all parts are cleaned and well protected

- Quality Report

Material Certification Hardness,

Dimension Inspection Report,

Salt Spray Inspection Report,

First Article Inspection Report,

CMM Inspection Report

Lead Time Assurance

- Rapid production scheduling

The intelligent order matching system can quickly and optimally match the order with the power supply network and capacity, and minimize the waiting time.

- Real-time progress tracking

The Real-time Progress Tracking System gives real-time feedback on the machining progress so that you can truly control the production progress, timely handling of exceptions, and ensure that orders are completed on time.

40 Experienced Engineers

2000+ Companies Served

10,000,000 Parts Machined

30+ countries Shipped

10+ Years Industry Experience

Ways to Ensure Perfection

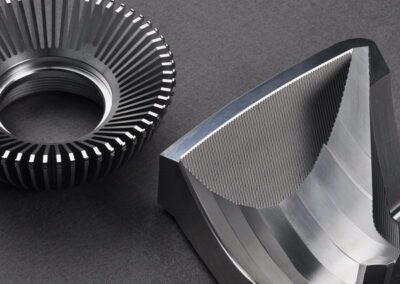

Precision and Accuracy

Our precision machines and state-of-the-art software ensure accuracy and consistency in every product we create. Strict quality control processes guarantee that every product meets our high standards and is exactly to specification.

Skilled Technicians

Our technicians are highly trained and experienced in all aspects of machine processing. Their expertise and attention to detail ensure that every product we produce is of the highest quality.

Advanced Technology

We invest in the latest technology and equipment to provide our customers with the highest quality machine processing services. Our cutting-edge technology guarantees efficiency and effectiveness in all our production processes.

Testimonials

It's challenging to describe the Prolean in a few words, but the three stand out: Fantastic, Amazing, and Perfect.

The best addition to our firm has been Prolean. With their cutting-edge 5-axis CNC machine, they are providing the service of replacing and installing new components in our pharmaceutical development industry with accuracy and cleanliness as their top concerns.

-Jose Gaonkar, Mechanical Engineer at Cadila Pharmaceuticals

The heat sink was marvelous, within the critical tolerance, and the surface finish was excellent. The fan position, seal, and fin structure all performed as intended. I'll tell my friends and other electronics companies about your service.

I appreciate your exceptional communication and CNC-Machining service.

-Blake Henderson, Product Designer at MechaTronix,

I needed a quick prototype for my research, but I had no idea that their CNC machines were so sophisticated and could produce it in just three days. The prototype was quite precise and fell within the tolerances of the CAD I provided.

Thumbs up! Not just selling, nothing else count for them; Service ServiceService, first!

-Jason Barrett, Individual Mechanical Engineer

Prolean has been manufacturing numerous customized components for my metal-workshop machines for the past two years, and I have found that they are excellent with their CNC machining services.

I am delighted with the level of quality they offer and the precision of the customized machine parts.

-Mason Lucas, Purchasing manager at Alpha Manufacturing

I am delighted with the Service from Prolean regarding the prototype development for my research. I have never expected this type of regular communication and quality of service from any manufacturers.

I will be associated further with my upcoming projects! Thanks to the Prolean.

-Gresham Green, Individual Engineer

Last year I looked for custom manufacturers for laser cutting services on the internet and found Prolean.

I get help with great patience and understanding, which may be why I am still working with Prolean on various laser-cutting and bending tasks for my current sheet-metal fabrication project.

-RupakDhital, Owner at Awai Auto Trading

Prolean has met all the expectations regarding all the complex sheet metal fabrication work presented by our service department.

The quick response from prolean has allowed us to meet our client's needs. In addition, I have often found that their engineers are always ready to think out-of-the-box to provide excellent service.

-Christina Smith, Mechanical Engineer at Marlin steel wire

Latest Blog

Check out our latest blogs, we share industry trends, design tips, and experience earned from manufacturing.

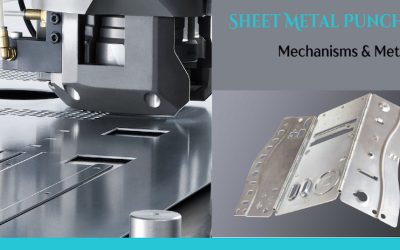

Sheet Metal Punching: Mechanisms & Methods

Sheet Metal punching in-depth, including mechanism, design tips, punching methods, etc.

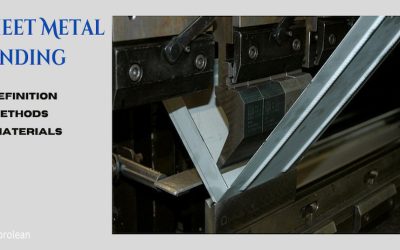

Sheet Metal Bending: Definition, Methods, and Materials

Different aspects of sheet metal bending, working mechanism, methods, and more.

Benefits of Wire EDM Cut-Process, Advantages & Applications

Wire EDM machine defines its use for exceptional ability to create thin-detailed parts.

Get Your Parts Made Today

All uploads are secure and confidential.