SURFACE FINISHING

Bead Blasting Services

Bead blasting refines the surface of your custom parts, boosting their functionality and appearance. We use high-pressure glass beads to create a consistent matte or satin finish. If you’re only after the look, we offer a cosmetic-only option. Simple, effective, and reliable—that’s our approach to perfection.

Bead blasted Service Key Properties

| Features | Info |

|---|---|

| Materials for bead blasting | ABS, Titanium, Aluminum, Brass, Copper, Stainless Steel, Tool Steel |

| Color | White glossy |

| Cosmetic availability | Cosmetic upon request |

| Texture | Matte |

| Thickness | n/a |

Try Prolean Now!

Prolean’s Bead blasted Service

-

ABS

asfafwaff

-

Aluminum

asfafwaff

-

ABS

asfafwaff

-

ABS

asfafwaff

-

ABS

asfafwaff

-

ABS

asfafwaff

-

ABS

asfafwaff

ABS Plastic Bead Blasting Service

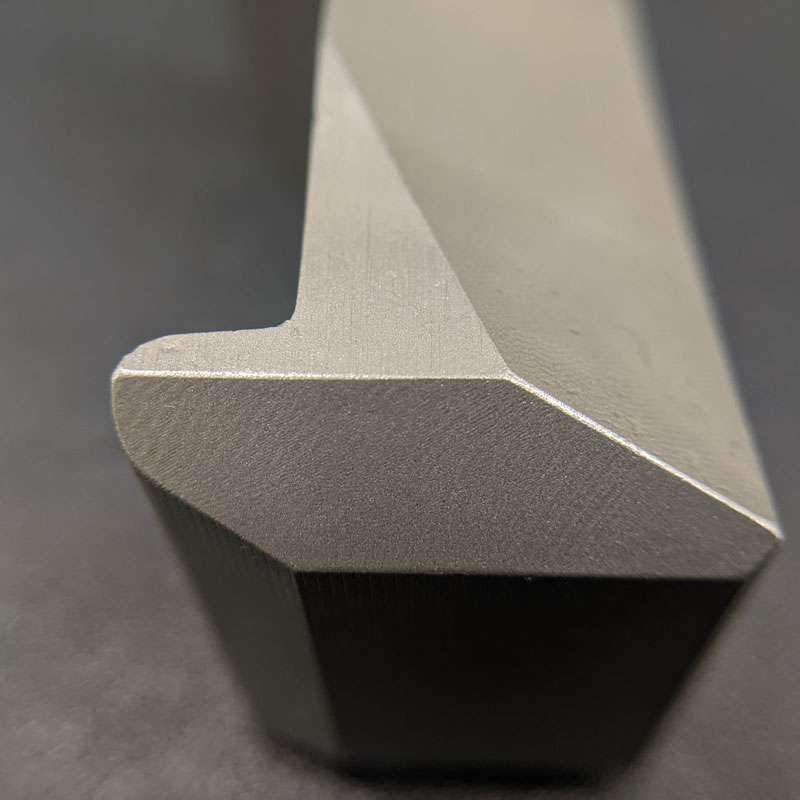

Bead Blasted

Bead blasting produces a smooth, shiny surface. This process combines abrasive materials, including aluminum oxide, glass pieces, and steel beads, with high-speed compressed air. Bead blasting removes all tool marks from surfaces, making them equally matte.

The attached burr gets washed away by the high-pressure air jet angled and directed at the part’s surface. It applies to claims made. It applies to ABS, Aluminum, Brass, Stainless Steel, and Steel parts.

Example of Bead Blasted Parts

Uses and Benefits

Here are the Uses and Benefits of bead blasting services:

- Finishing: It gives a uniform matte finish to various materials, like medical tools, making them look good and easy to clean.

- Deburring: The method removes sharp edges from machined parts.

- Peening: With bead blasting, materials can gain increased fatigue resistance, especially when using steel shots (shot peening).

- Texturing: It can add specific textures to surfaces for better grip or looks.

FAQs of Bead Blasting Services

What is bead blasting?

Bead blasting is a process that uses delicate glass beads propelled at a high velocity to clean or smooth the surface of materials. This process is non-abrasive, ensuring the material’s dimensional integrity remains intact.

How can I get a bead blasting quote?

To get a bead-blasting quote, contact our customer service team with details about your project. We’ll provide a comprehensive quote for your parts.

I've heard of bead blasted aluminum. What benefits does this process offer for aluminum surfaces?

Can you explain what is bead blasted stainless steel?

Certainly! Bead-blasted stainless steel refers to applying the bead-blasting process on stainless steel surfaces. This gives the stainless steel a matte, uniform appearance, enhancing its visual appeal and resistance to fingerprint marks.

Is glass bead blasting aluminum different from regular bead blasting?

Glass bead blasting uses explicitly glass beads to treat the surface of materials like aluminum. Glass bead blasting aluminum results in a cleaner and brighter finish than other blasting materials.

What kind of finish can I expect with bead blasted stainless steel texture?

The bead-blasted stainless steel texture is recognized for its uniform, matte finish. This enhances the material’s aesthetics and provides a surface that’s less susceptible to smudges and fingerprints.

Are there any materials you would recommend against bead blasting?

While bead blasting is versatile, certain delicate materials or finishes may not be suitable. It’s always recommended to consult with our team before proceeding to ensure the best results for your specific needs.

Get Your Parts Made Today

All uploads are secure and confidential.